Oil conveying pipeline leakage monitoring method based on negative pressure wave method and flow trend method

An oil pipeline and negative pressure wave technology, which is applied in the field of oil pipeline leakage monitoring based on negative pressure wave method and flow trend method, can solve the problems of reducing system reliability, increasing workload, and low accuracy, and achieve good economic benefits and social benefits, high A/D conversion accuracy, and high sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

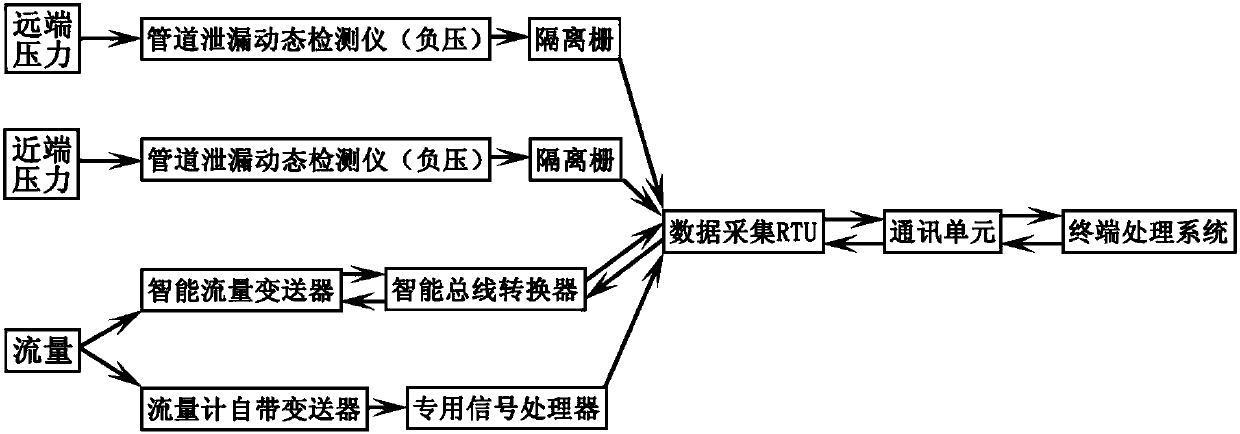

Method used

Image

Examples

Embodiment 1

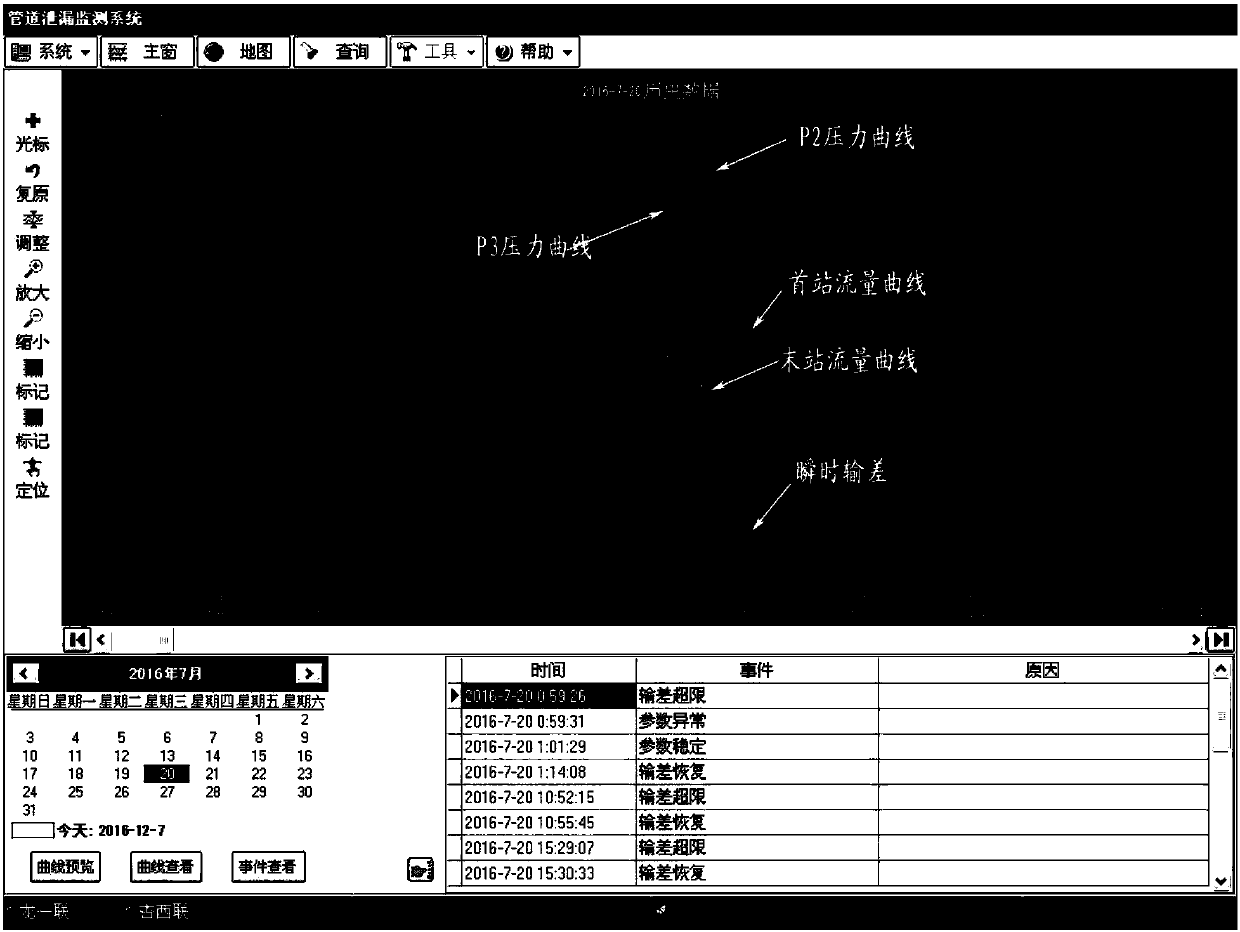

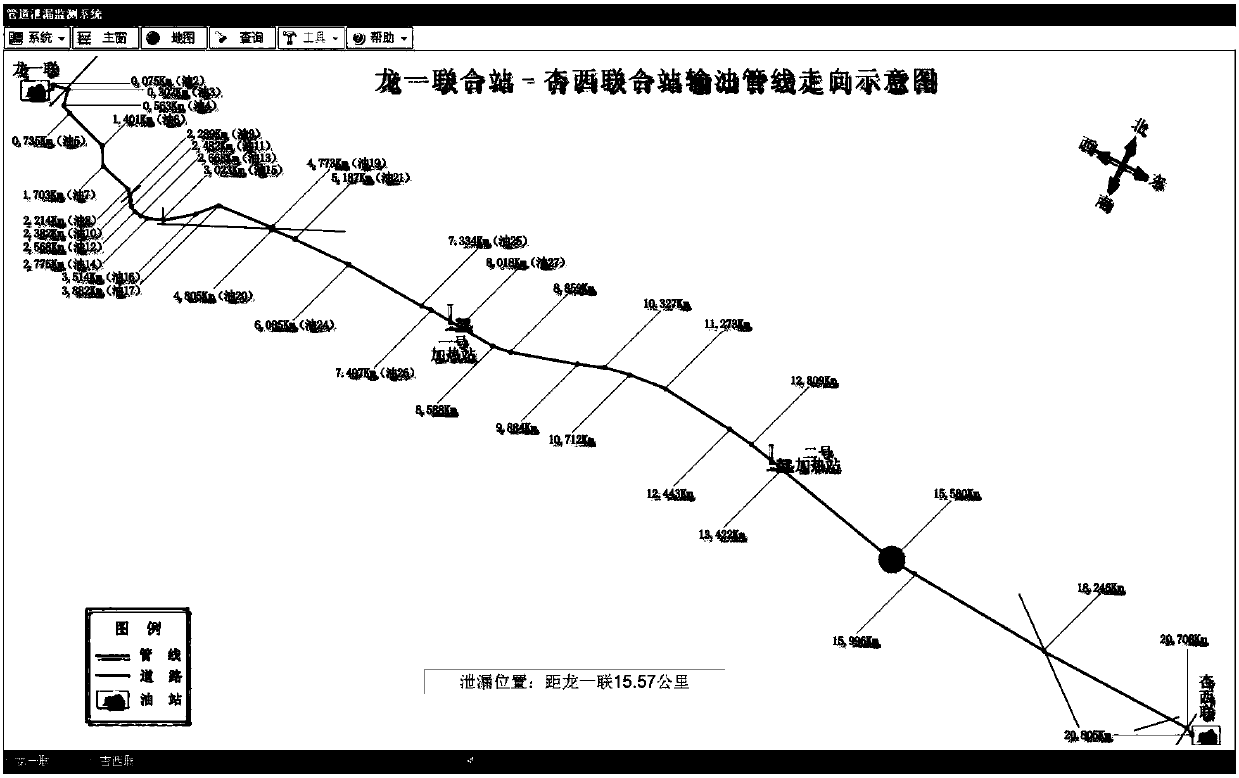

[0040] When applied to the No. 9 Oil Production Plant of Daqing Oilfield, among them, the pipeline profile, such as Figure 2-3 As shown, the oil pipeline from Longyilian (first station) to Xingxilian (last station) has a pipe diameter of ф219mm and a total length of 23Km, with a daily crude oil output of 1000m3, using continuous oil transportation. 1. The first station (Longyilian): One pressure transmitter (P1) installed at the outlet of the output flow, one pressure transmitter (P2) installed 20 meters away from the last station, and the signal cable leads to the first station Data acquisition unit; 2. The last station (Xingxilian): install one pressure transmitter (P4) at the inlet of the manifold of the five oil pipelines, and install one pressure transmitter (P3) at 20 meters in the direction of the first station. The cable is led to the data acquisition unit of the last station; 3. The first and last stations: respectively install a set of data acquisition devices and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com