Positioning and alarming system and method for ore pulp pipeline leakage

A pipeline leakage and alarm system technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of inaccuracy, wrong judgment of the location of the leakage point, and the location of the leakage of the slurry pipeline, so as to reduce the transmission line , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

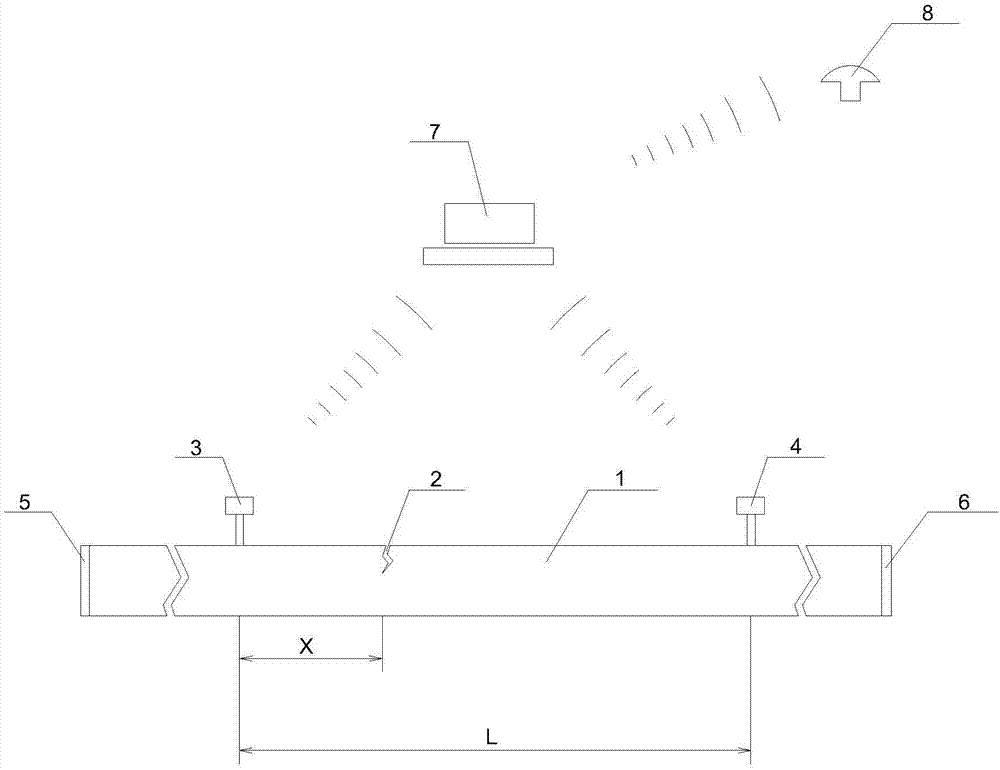

[0045] Such as figure 1 As shown, the slurry pipeline leakage location alarm system and the schematic diagram of the slurry pipeline structure, the slurry pipeline leakage location alarm system includes more than two pressure sensors, No. 1 flow sensor 5, No. 2 flow sensor 6, data processor 7 and alarm 8, two More than one pressure sensor is connected to the outer wall of the slurry pipeline 1 along the flow direction of the slurry pipeline 1, and the distance between adjacent pressure sensors is equal. The No. 1 flow sensor 5 is set at the beginning of the slurry pipeline 1, and the No. 2 flow sensor 6 is set at the end of the slurry pipeline 1. The processor 7 is respectively connected with the pressure sensor, the No. 1 flow sensor 5 , the No. 2 flow sensor 6 and the alarm 8 .

[0046] When in use, the No. 1 flow sensor, No. 2 flow sensor and pressure sensor collect statistics on the pipe pressure and pulp flow rate of the pulp pipeline during normal transportation, and obt...

Embodiment 2

[0049] Based on Embodiment 1, more than two pressure sensors, the No. 1 flow sensor 5 , the No. 2 flow sensor 6 and the alarm 8 are connected to the data processor 7 in a wireless manner.

Embodiment 3

[0051] The method for locating and alarming the leakage of the slurry pipeline comprises the following steps:

[0052] The pressure reading of the pressure sensor, the flow rate of the first flow sensor 5 and the flow rate of the second flow sensor 6 are counted by the No. 1 flow sensor 5, the No. 2 flow sensor 6 and the pressure sensor when the slurry pipeline 1 is normally transported.

[0053] The pressure wave propagation velocity a in the slurry pipeline 1 is calculated by the following formula:

[0054]

[0055] Among them, a is the pressure wave propagation velocity in the slurry pipeline 1, and the unit is m / s; K is the volume elastic coefficient of the slurry, and the unit is Pa; ρ is the average density of the slurry, and the unit is Kg / m 3 ; E is the elasticity of the slurry pipeline 1, the unit is Pa; D is the diameter of the pipeline, the unit is m; e is the thickness of the pipe wall, the unit is m; C 1 Correction factor for piping constraints.

[0056] Coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Bulk modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com