Patents

Literature

40results about How to "Enable leak detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

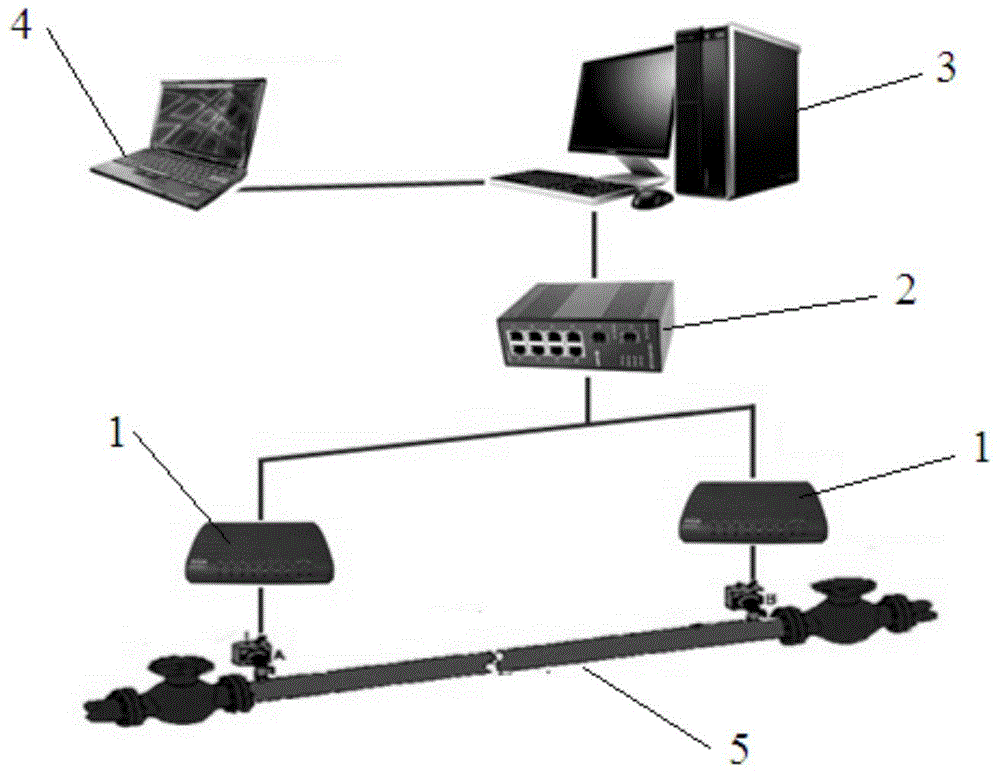

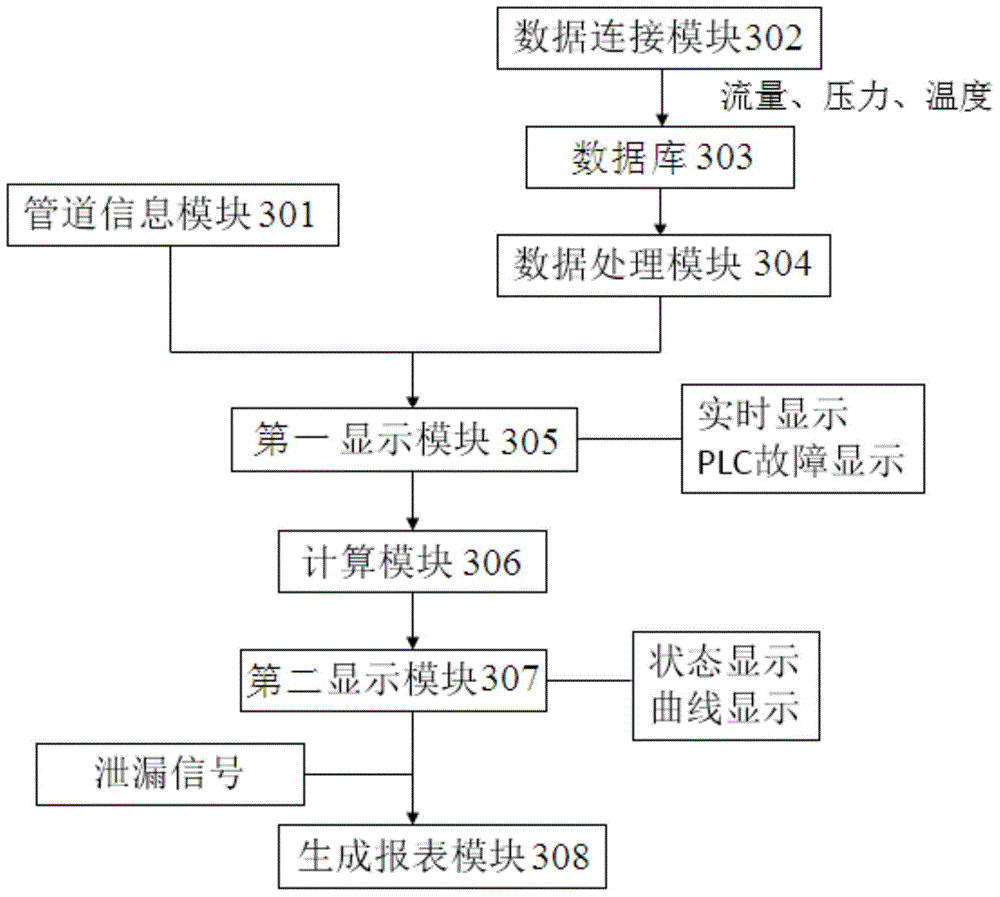

Subsea pipeline leakage monitoring system

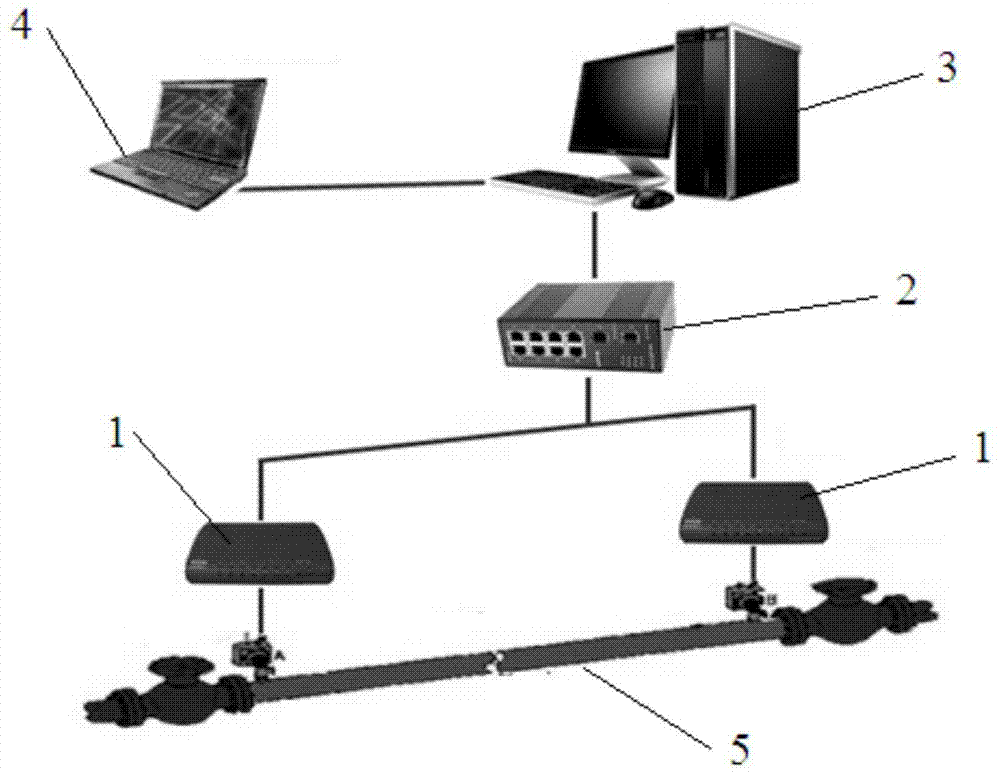

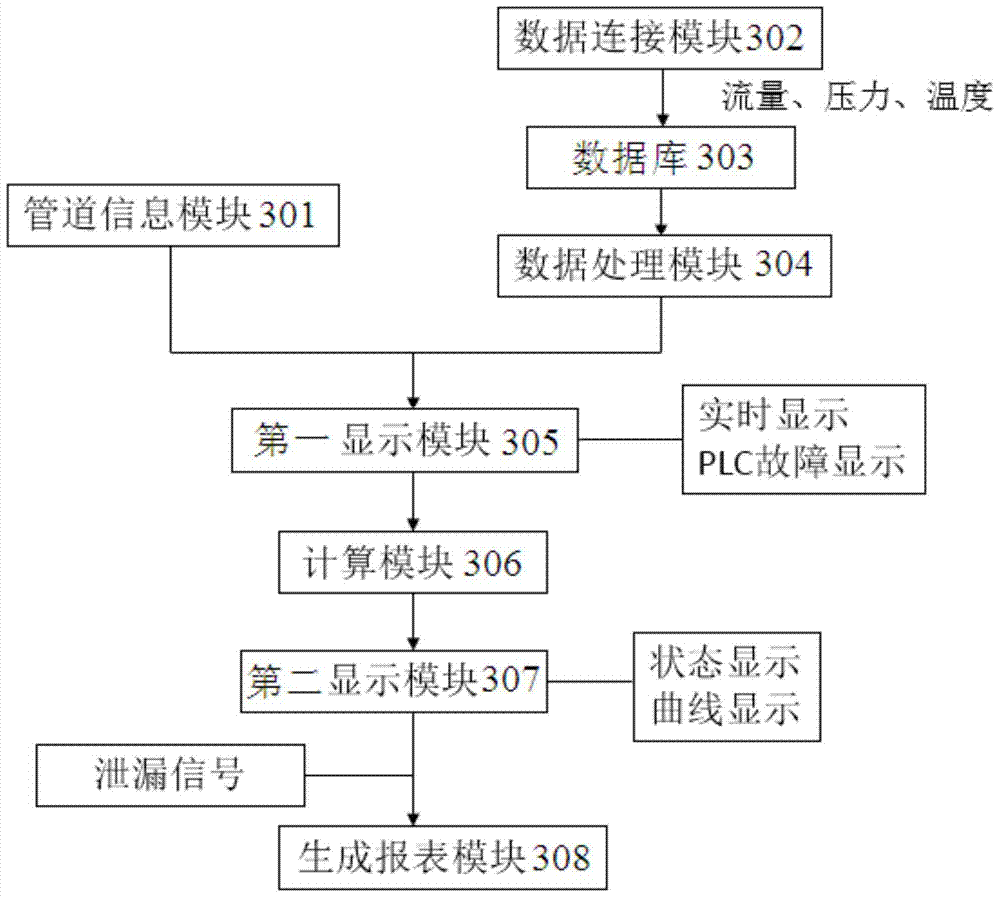

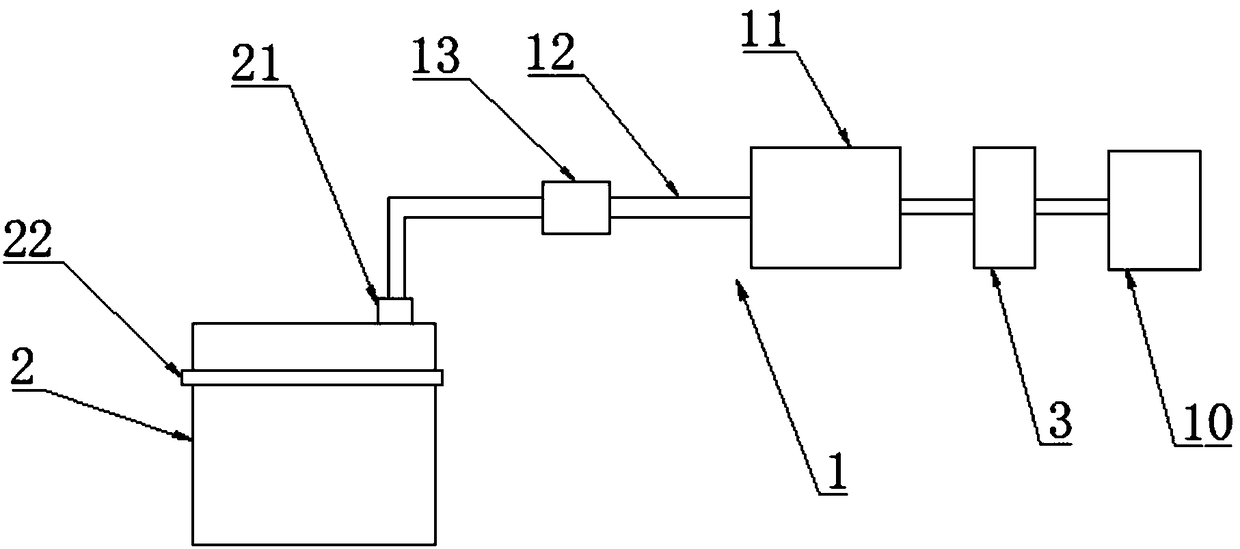

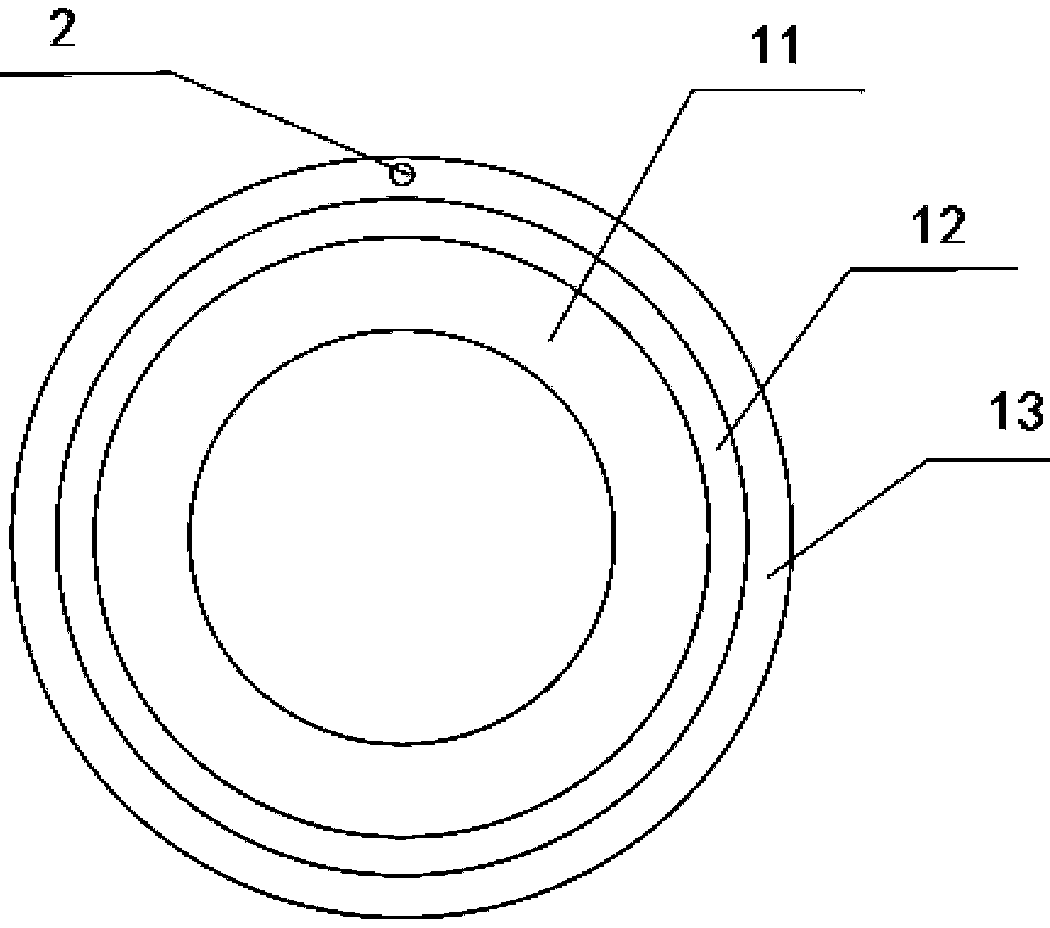

The invention relates to a subsea pipeline leakage monitoring system. The subsea pipeline leakage monitoring system comprises controllers, flow sensors, pressure sensors, temperature sensors and a center host computer. The inlet end and the outlet end of a pipeline to be monitored are each provided with one flow sensor, one pressure sensor and one temperature sensor. The flow sensor, the pressure sensor and the temperature sensor at the inlet end collect the flow, pressure and temperature signals of the inlet end in real time and send the flow, pressure and temperature signals to the first controller. The flow sensor, the pressure sensor and the temperature sensor at the outlet end collect the flow, pressure and temperature signals of the outlet end in real time and send the flow, pressure and temperature signals to the second controller. The controllers send the signals to the center host computer through an Ethernet switch, the leakage monitoring system inside the center host computer displays the information in real time and judges where the pipeline to be monitored is leaked or not, a leakage alarm is given out when leakage happens, and the leakage amount and leakage position are worked out and displayed. The center host computer sends the received signals and the judgment result to remote monitoring devices.

Owner:CHINA NAT OFFSHORE OIL CORP +1

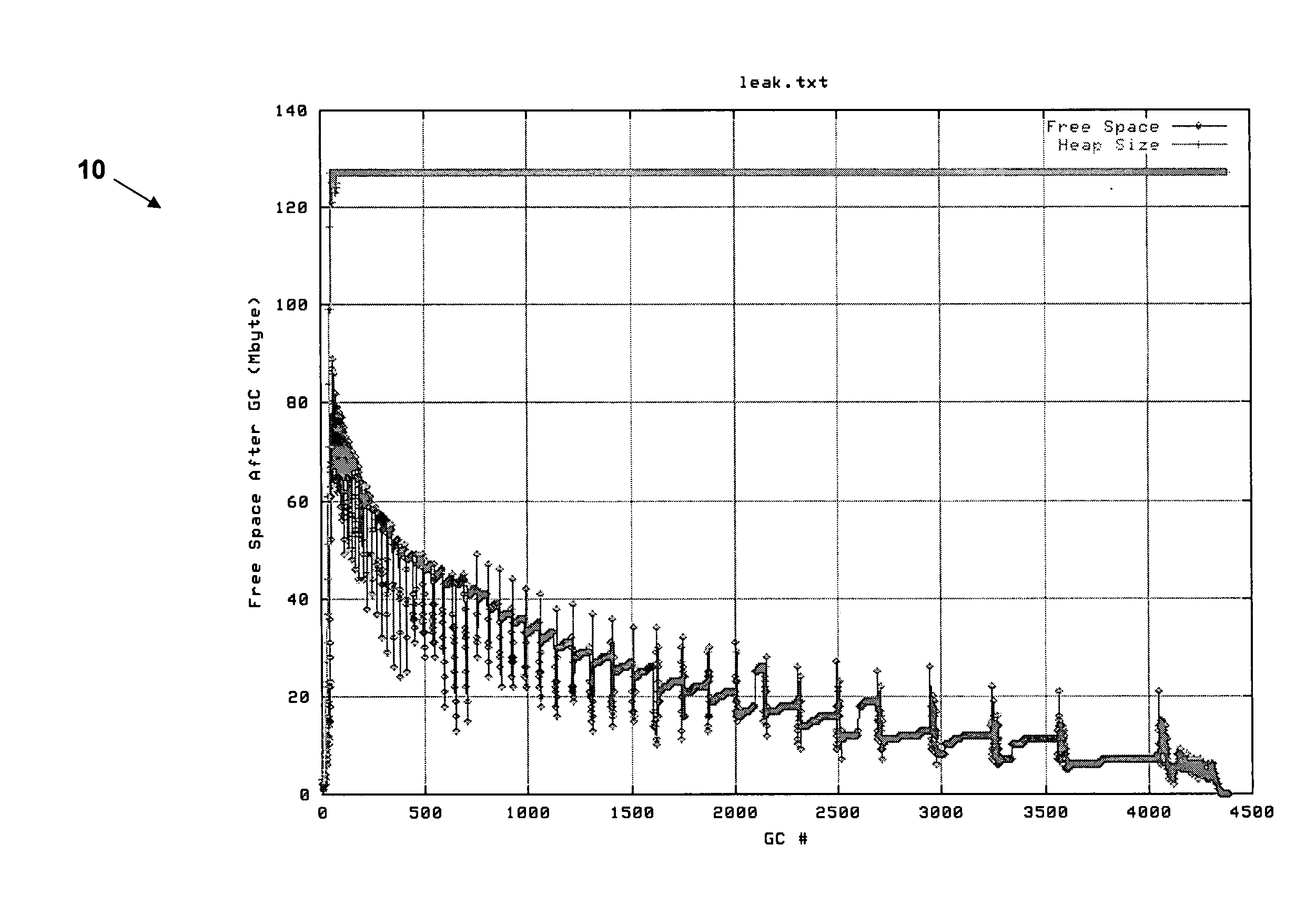

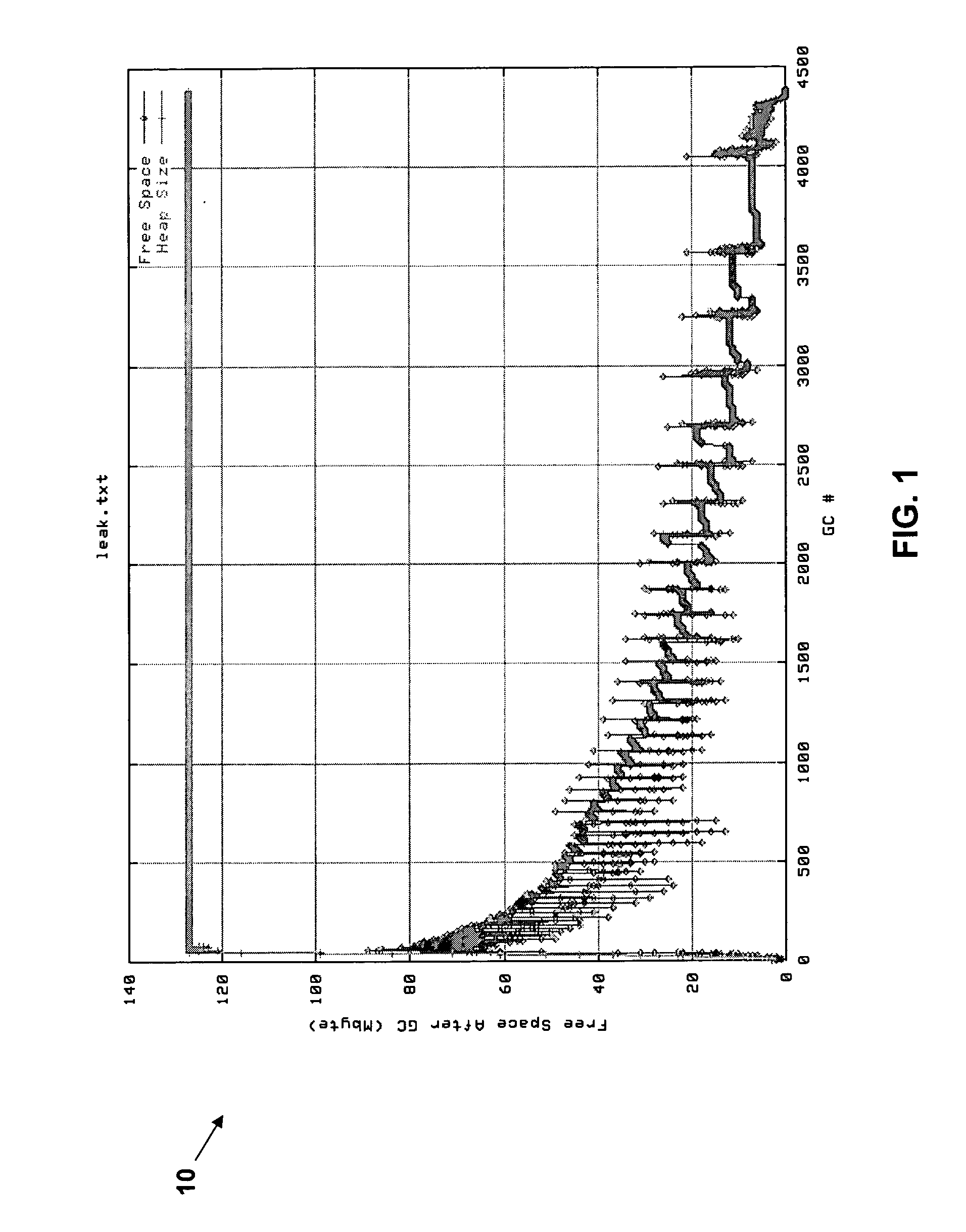

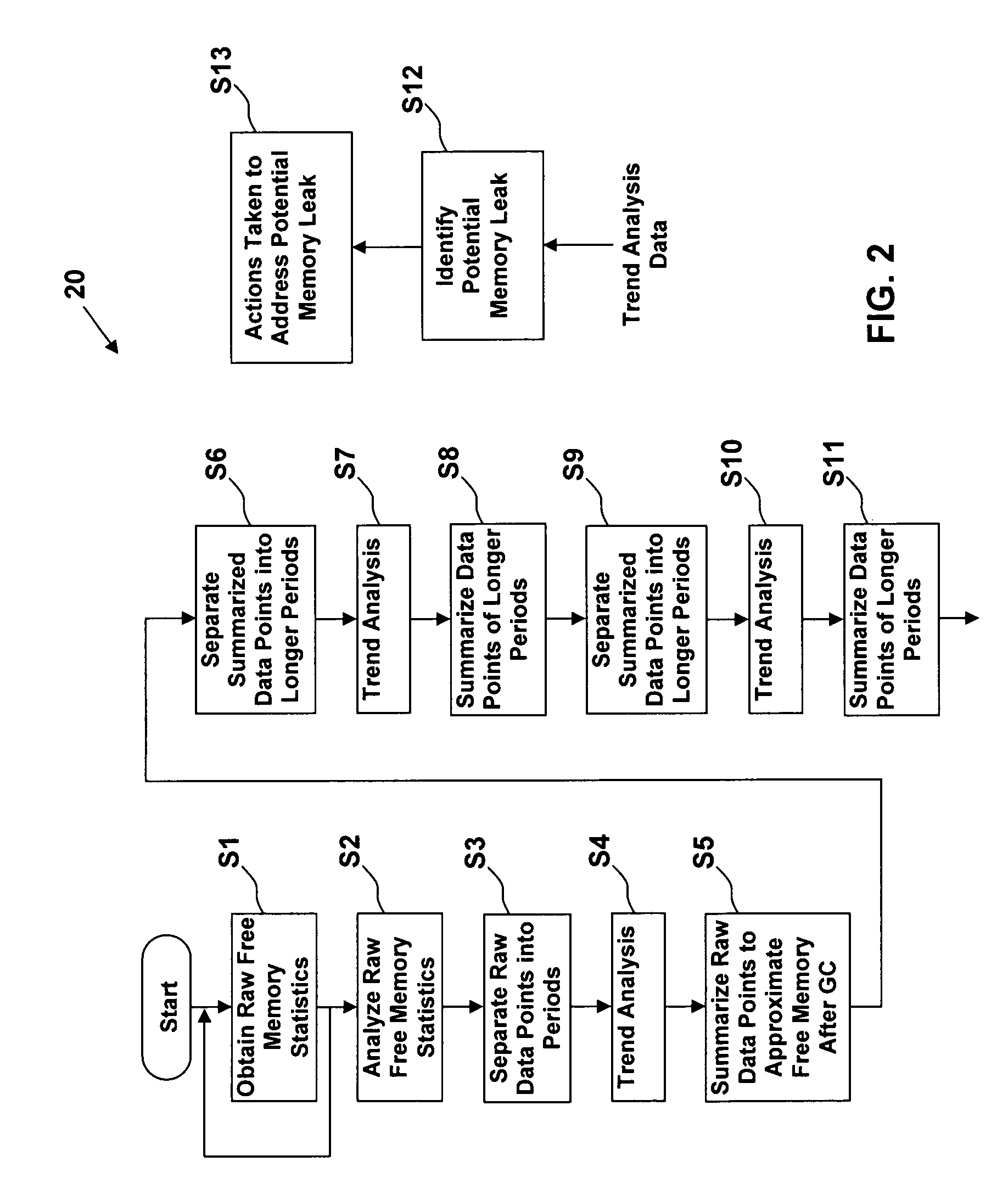

Method, system, and computer program product for light weight memory leak detection

InactiveUS20060277440A1Enable leak detectionData processing applicationsError detection/correctionParallel computingWaste collection

The present invention provides a method, system, and computer program product for light weight memory leak detection. A method in accordance with an embodiment of the present invention comprises: obtaining raw free memory statistics; approximating free memory after garbage collection from the raw free memory statistics; and analyzing the approximated free memory after garbage collection to identify a potential memory leak. A method in accordance with another embodiment of the present invention comprises the steps of: obtaining raw free memory statistics; generating a vector of memory leak indicators from the raw free memory statistics; comparing the vector of memory leak indicators against a plurality of vectors of the same memory leak indicators for known memory leak scenarios; and identifying a potential memory leak based on the comparison.

Owner:IBM CORP

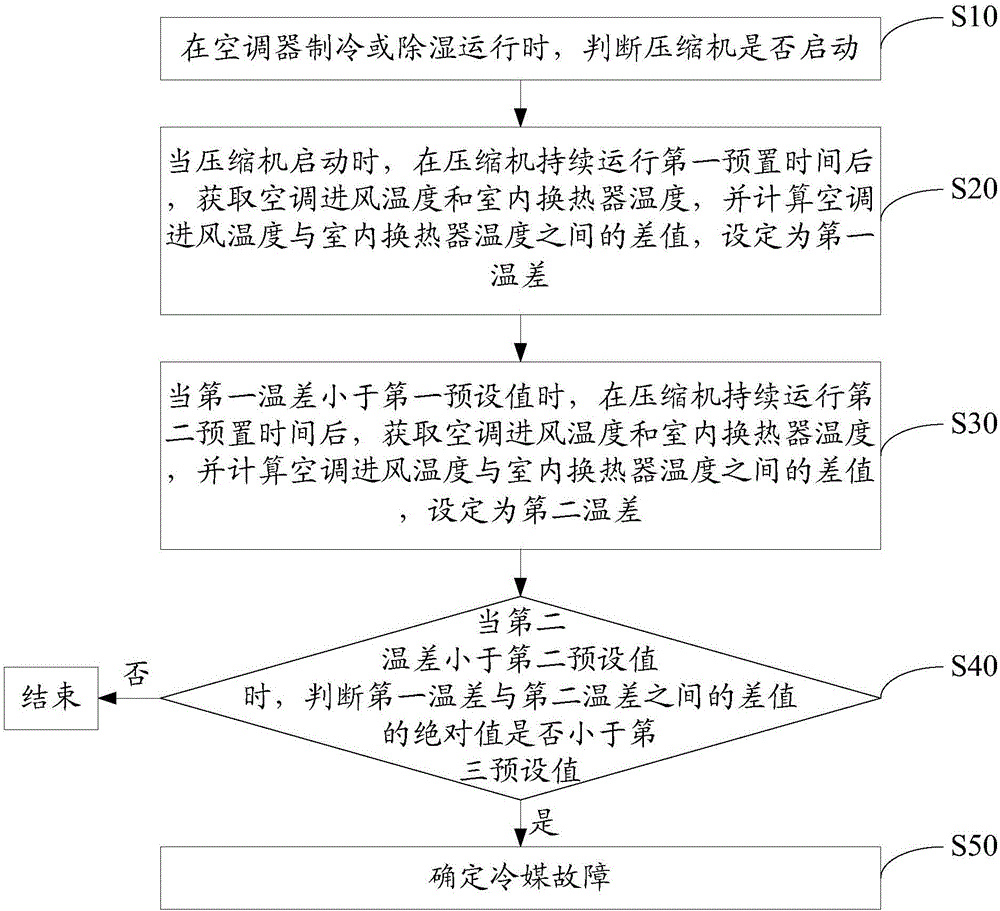

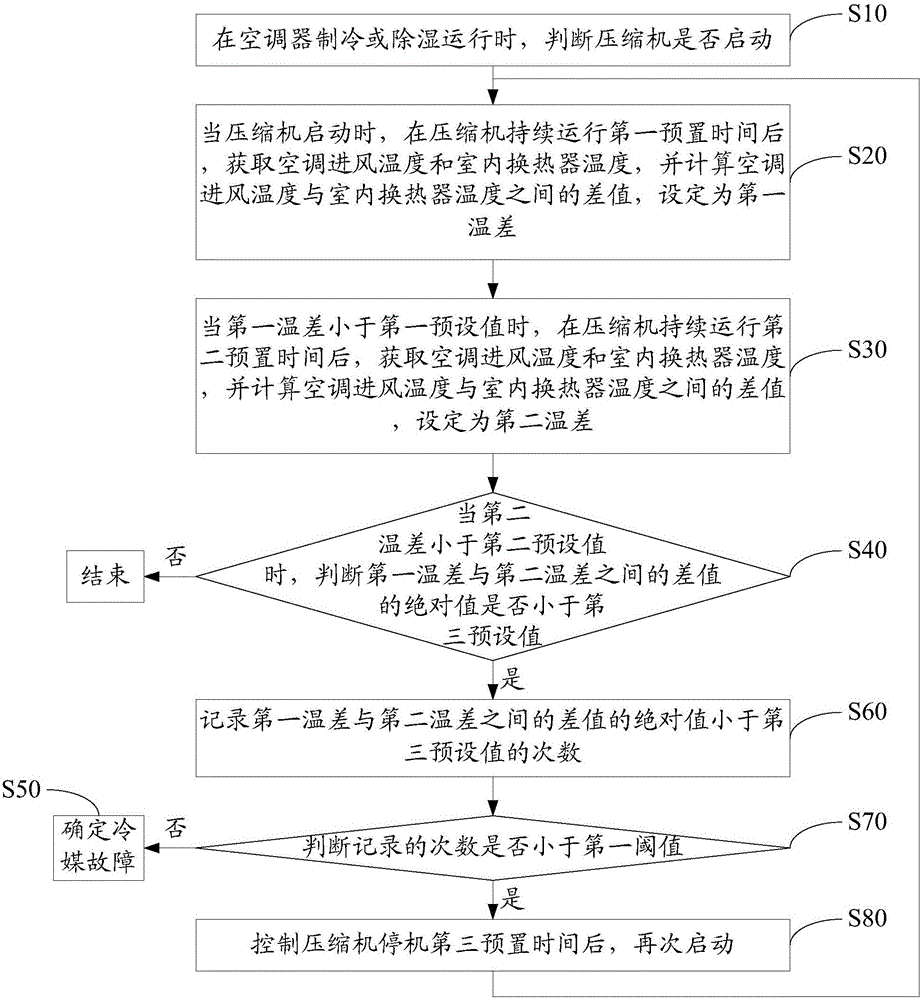

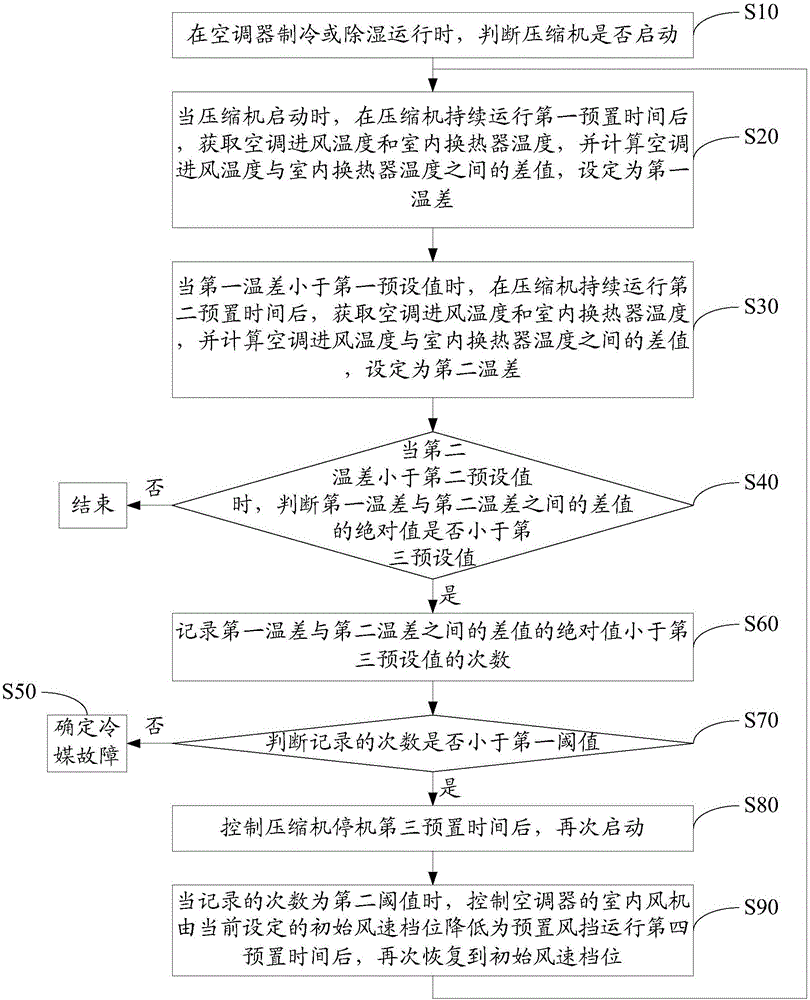

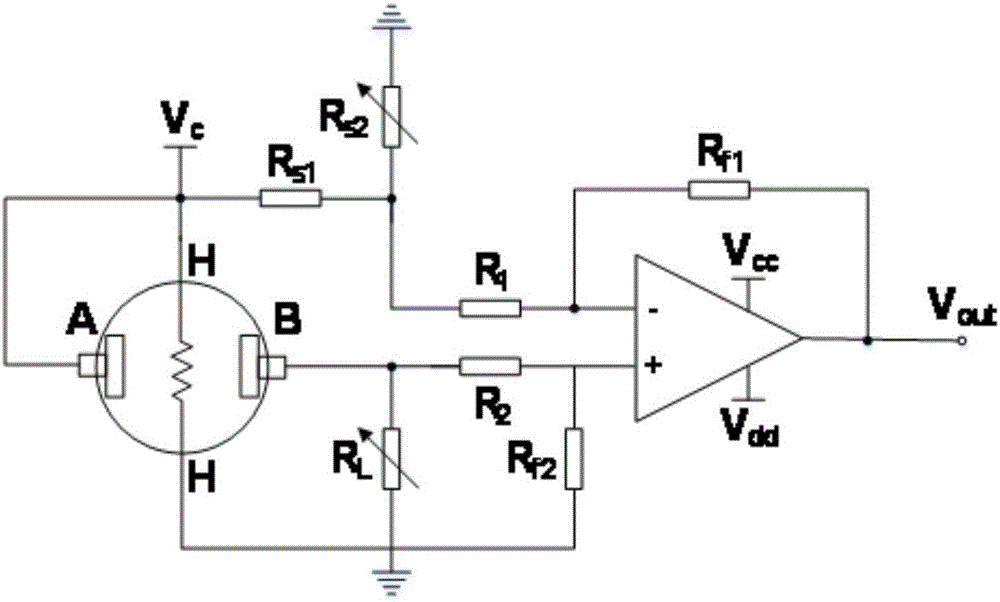

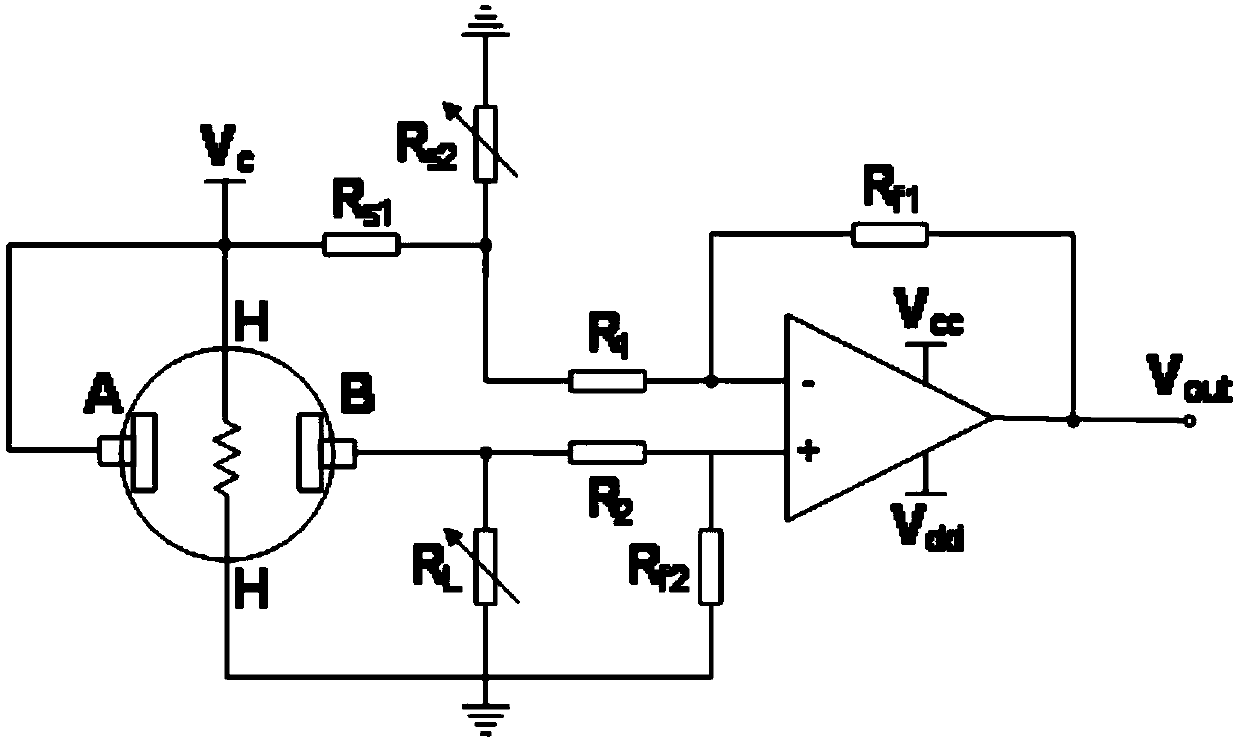

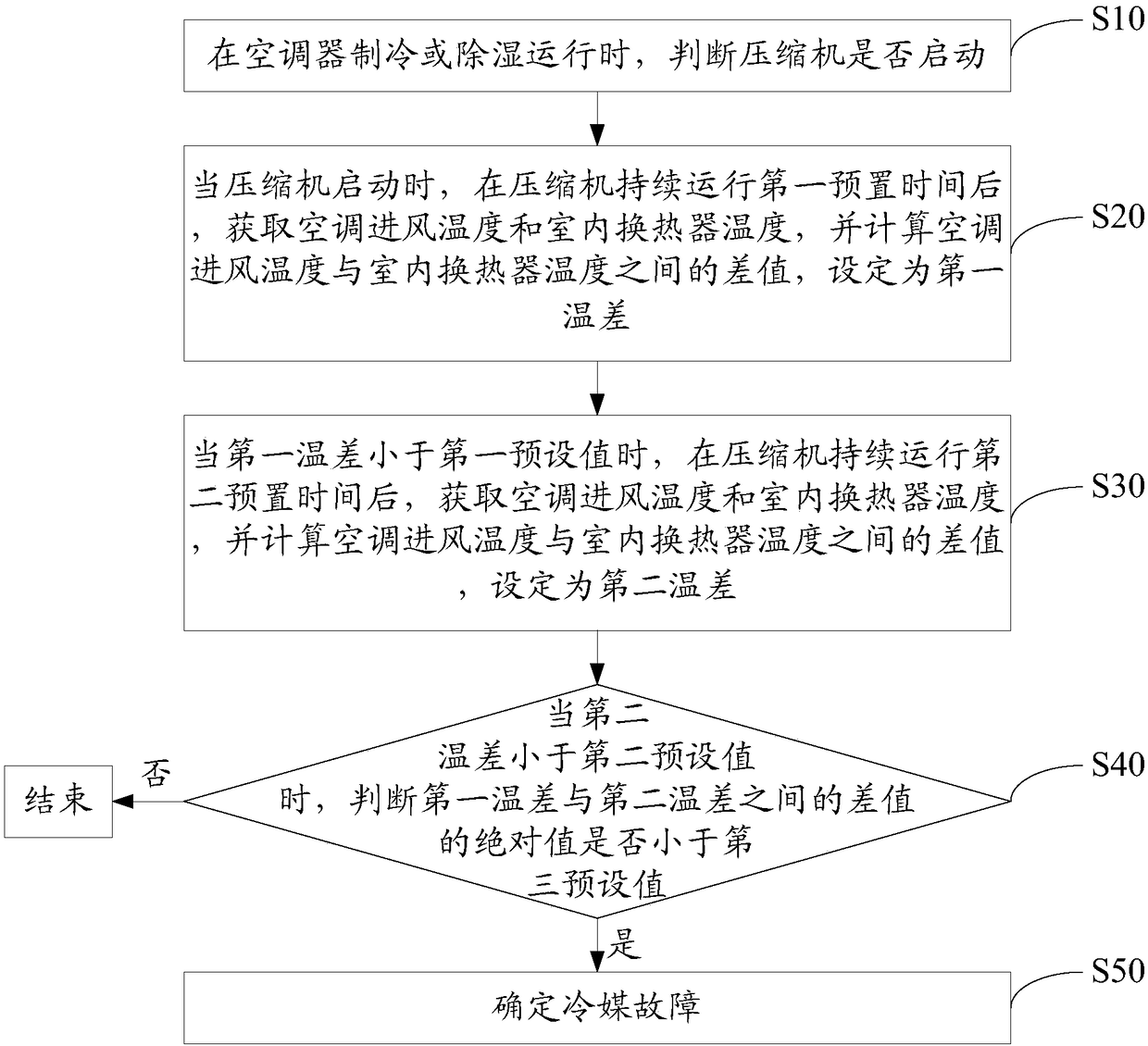

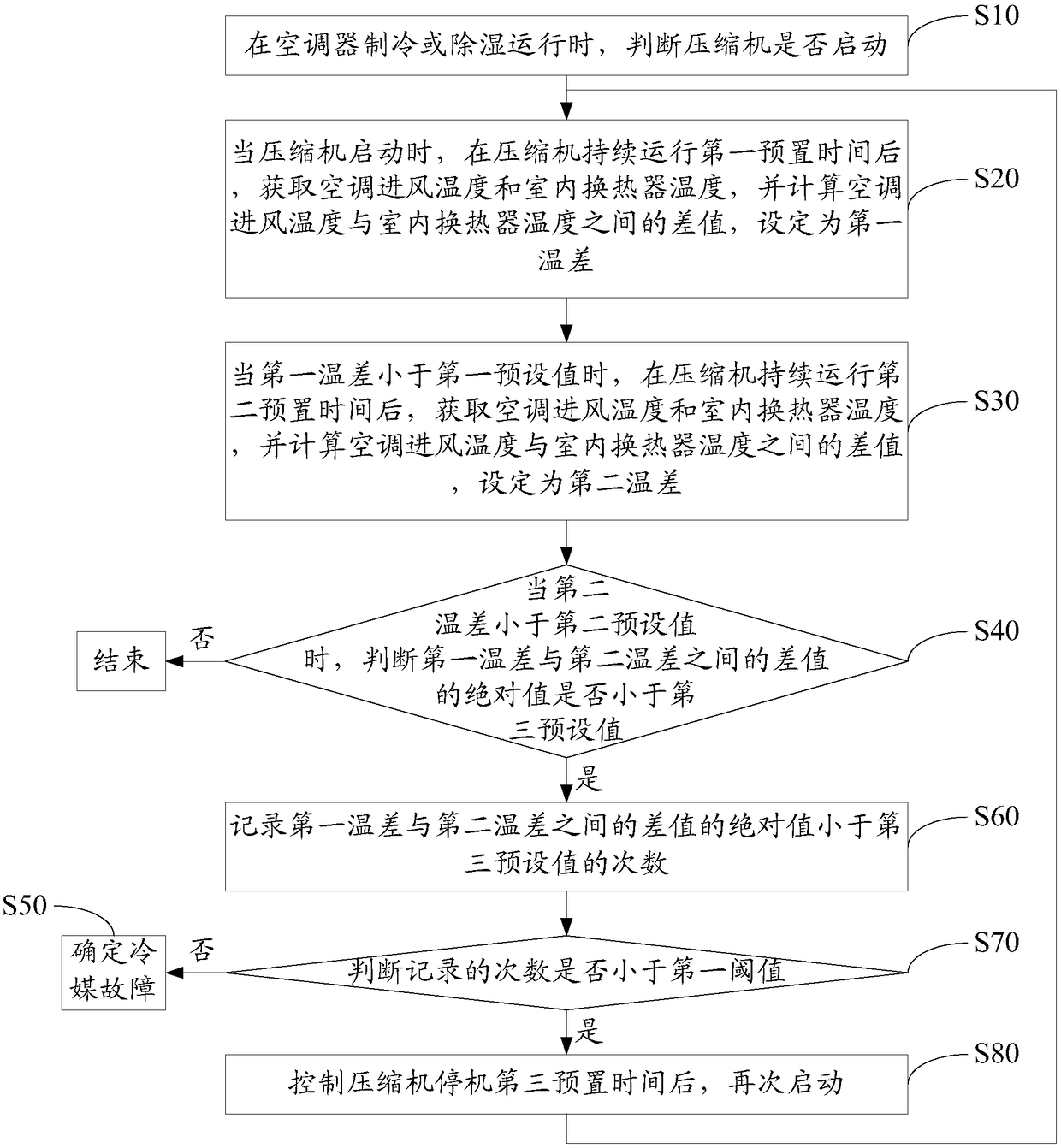

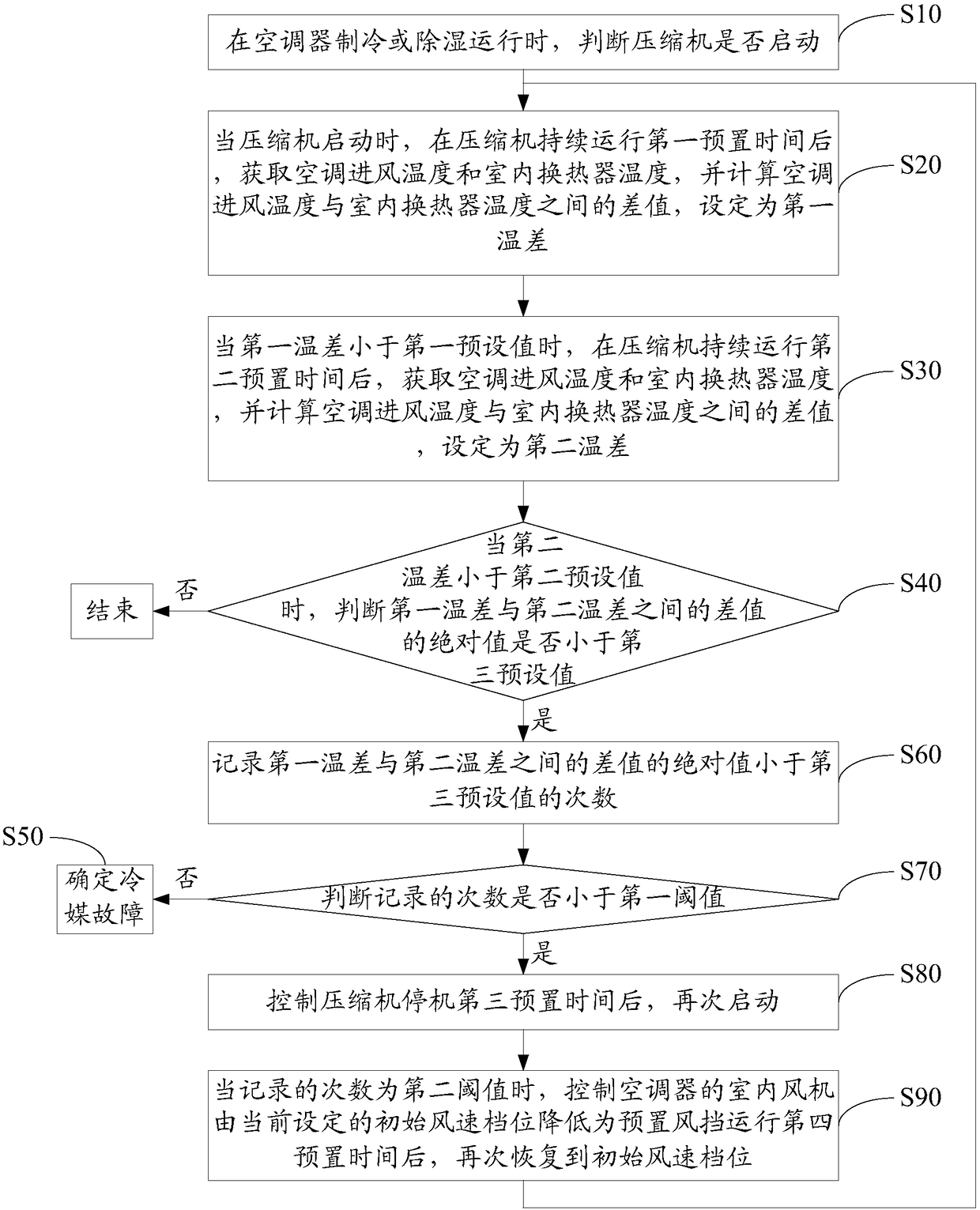

Method and device for detecting refrigerants of air conditioner

ActiveCN105674507AImprove reliabilityEnable leak detectionMechanical apparatusSpace heating and ventilation safety systemsTemperature differenceEngineering

The invention discloses a method for detecting refrigerants of an air conditioner. The method comprises the steps of judging whether a compressor is started when the air conditioner carries out refrigeration or dehumidification; when the compressor is started, after the compressor is continuously operated for the first preset time, obtaining the air inlet temperature of the air conditioner and the temperature of an indoor heat exchanger, calculating the difference value between the air inlet temperature of the air conditioner and the temperature of the indoor heat exchanger and setting the difference value as the first temperature difference; when the first temperature difference is smaller than the first preset value, after the compressor is continuously operated for the second preset time, obtaining the air inlet temperature of the air conditioner and the temperature of the indoor heat exchanger, calculating the difference value between the air inlet temperature of the air conditioner and the temperature of the indoor heat exchanger and setting the difference value as the second temperature difference; when the second temperature difference is smaller than the second preset value, judging whether the absolute value of the difference value between the first temperature difference and the second temperature difference is smaller than the third preset value; if the absolute value of the difference value between the first temperature difference and the second temperature difference is smaller than the third preset value, judging that the refrigerant malfunction exists. The invention further discloses a device for detecting the refrigerants of the air conditioner. According to the method and device, leakage detection of the refrigerants is realized, and the operation reliability of the air conditioner is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

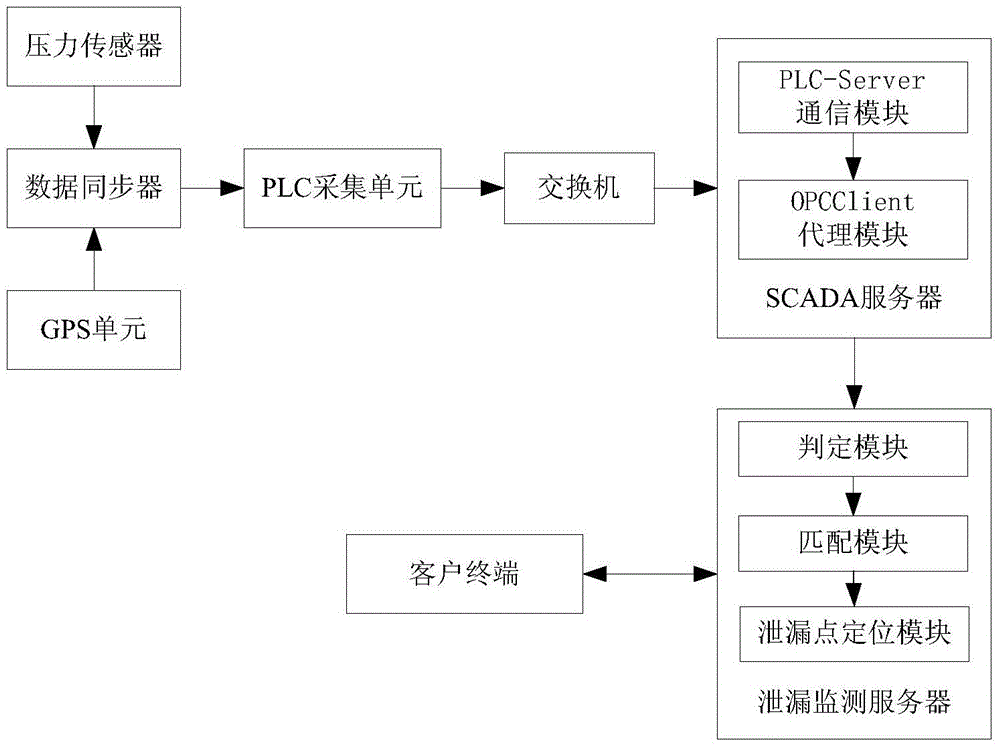

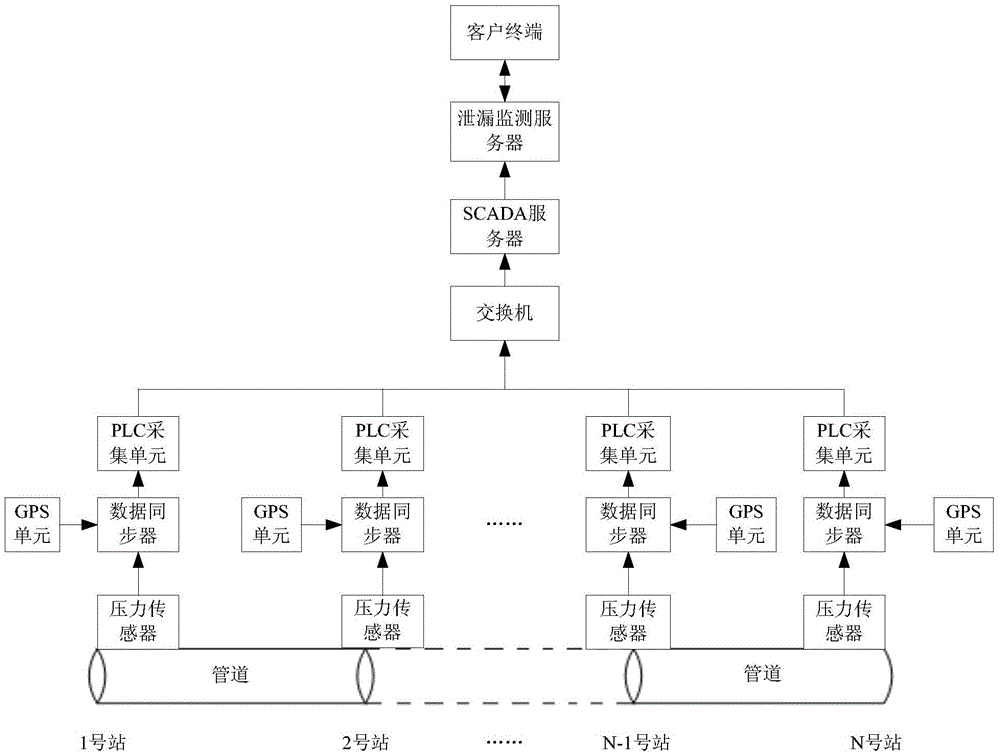

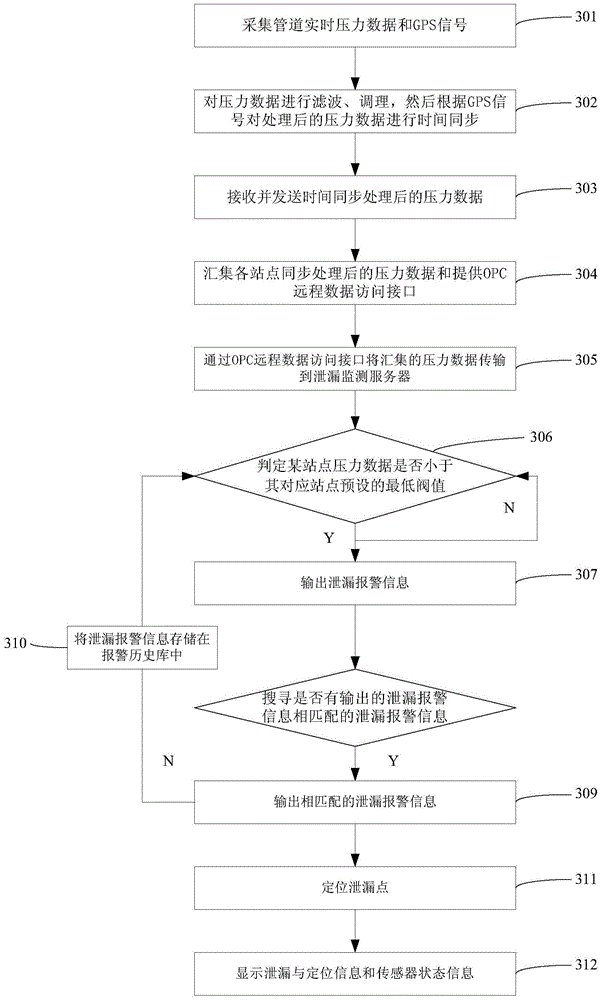

Pipeline leakage detection system and method using negative pressure waves

ActiveCN105485524AGuaranteed stabilityEnable leak detectionPipeline systemsData synchronizationSCADA

The invention provides a pipeline leakage detection system and method using negative pressure waves, and relates to the field of oil pipeline leakage detection. According to the system and method, time synchronization of pressure data is achieved accurately through pressure sensors, GPS units and data synchronizers which are arranged at all stations of pipelines; a PLC collecting unit transmits pressure data subjected to time synchronization to an SCADA server; the SCADA server assembles the pressure data of all the stations and provides a remote access interface; the data is uploaded to a leakage detection server through the access interface, so that the stability of data transmission is guaranteed, sending of a pressure data read failure is avoided, and the reliability and the accuracy of the pressure data are guaranteed; and finally the leakage detection server finishes judging and matching of the pressure data as well as the detection positioning, leakage detection among multi-station pipelines is achieved, and the accuracy of the final computed result is improved.

Owner:江苏中海达海洋信息技术有限公司

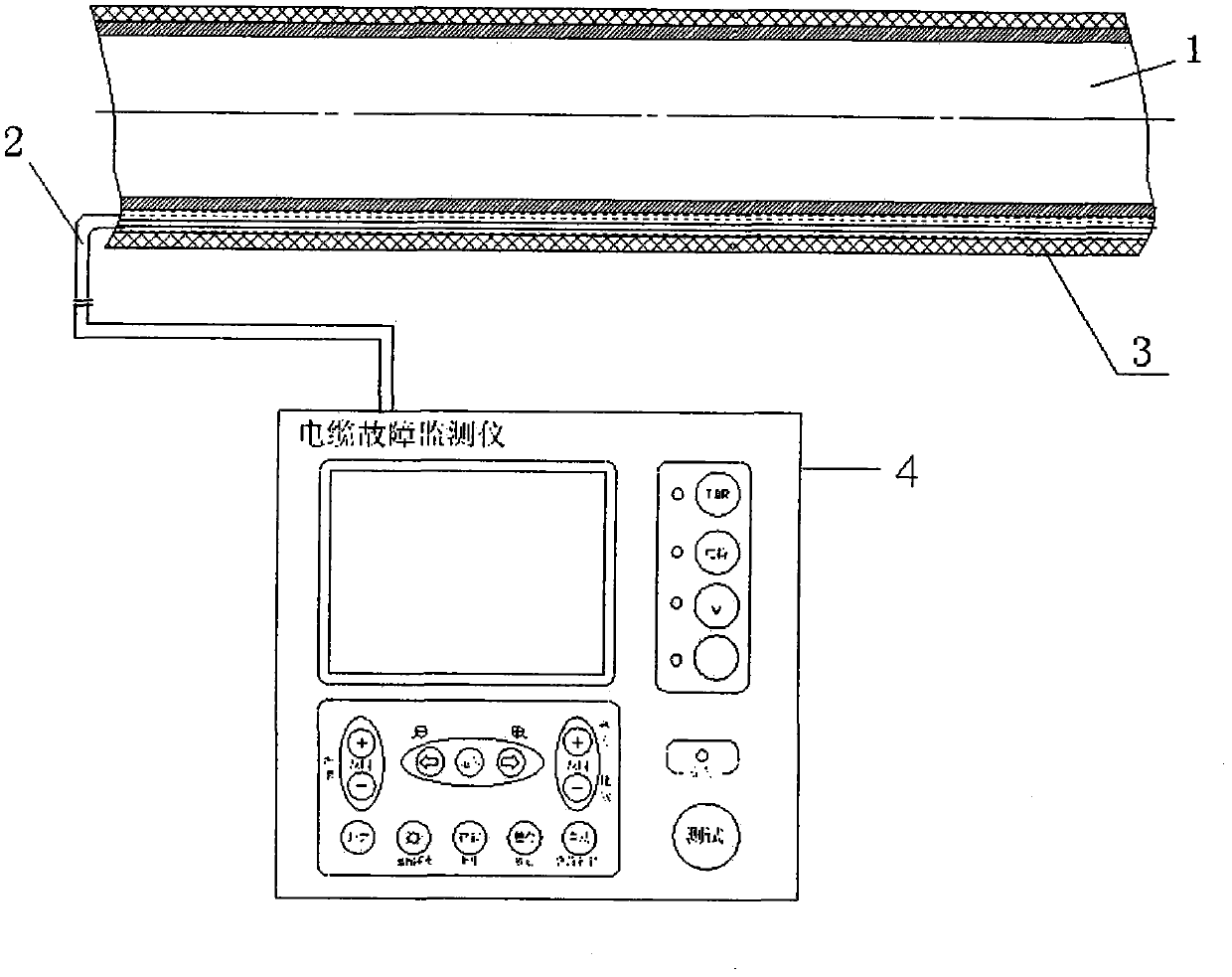

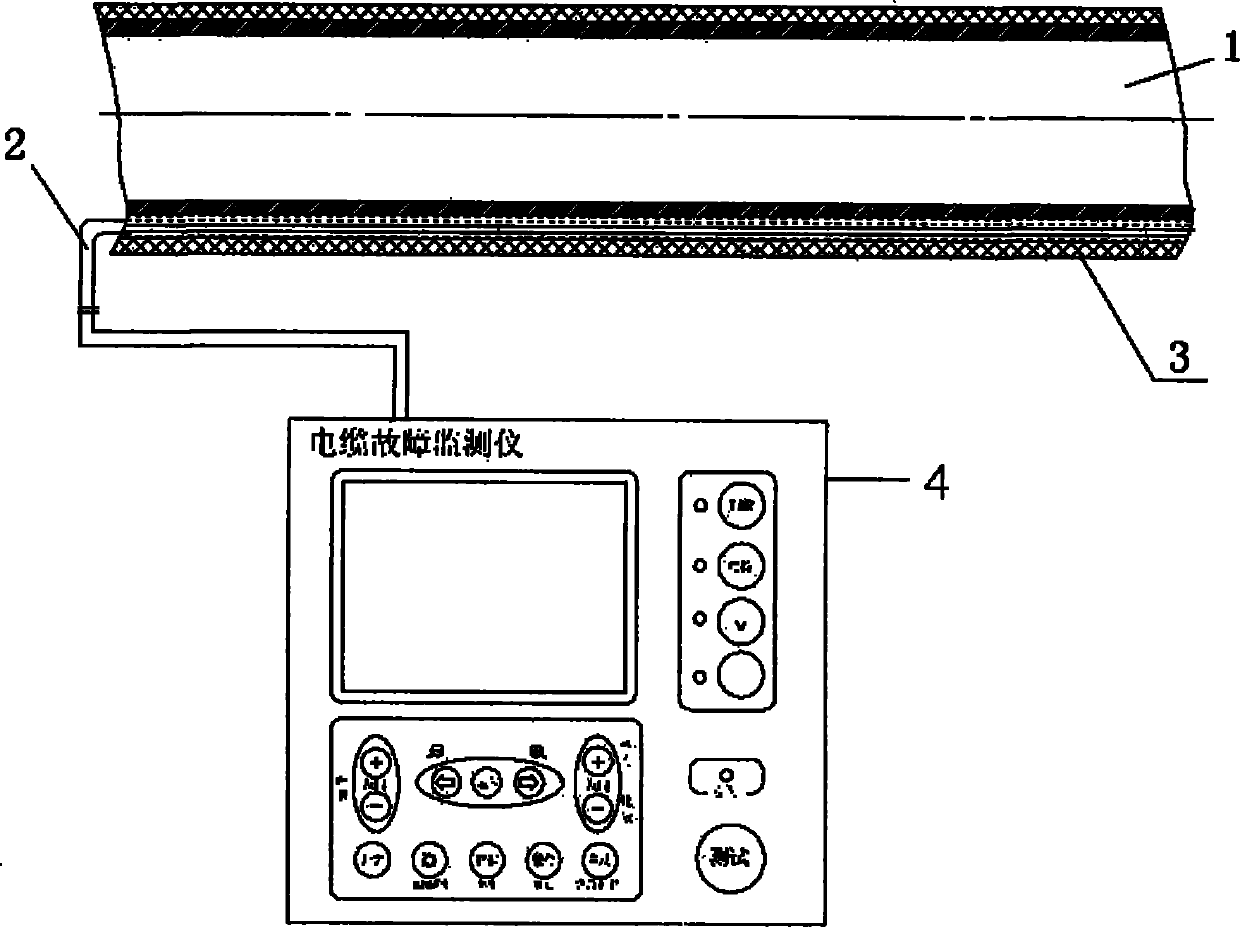

Long distance concentrated sulphuric acid pipe leakage monitoring method

InactiveCN102003624ALong monitoring distanceRealize online monitoringPipeline systemsPolyether ether ketoneMonitoring methods

The invention relates to a long distance concentrated sulphuric acid pipe leakage monitoring method, including that a cable and a cable fault monitor are utilized to monitor leakage state and leakage position of concentrated sulphuric acid pipe. The method is characterized in that the cable is an acid sensitive one with dressing made by polyether-ether-ketone PEEK material, adapts to water, alkali or mixture thereof and multiple mediums and is sensitive to concentrated sulphuric acid only, the acid sensitive cable is parallelly paved at the bottom of pipe along the whole course of concentrated sulphuric acid pipe, one end of the acid sensitive cable is connected on to the cable fault monitor, concentrated sulphuric acid leakage is monitored in real time, and the cable fault monitor automatically alarms once pipe leakage happens and provides the position of leakage point. The invention has the advantages that monitoring distance is long, single section longest monitoring distance can reach 30km, the method is heat resistant and can be resistant to high temperature of 250 DEG C for a long time, insulating property is good, structure is simple, use convenience is achieved, cost is low, no danger is produced, and online monitoring, leakage alarming and leakage positioning can be realized, and the invention is widely applied in long distance concentrated sulphuric acid pipe leakage monitoring.

Owner:常贵宁

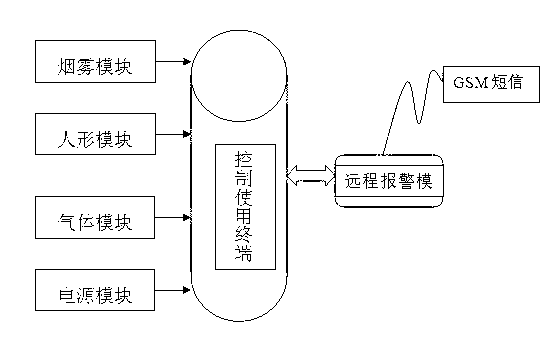

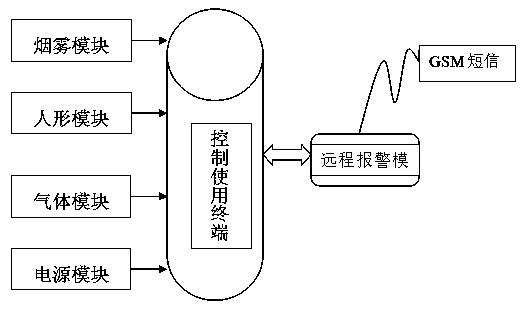

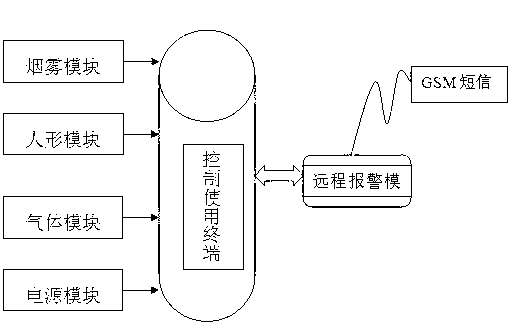

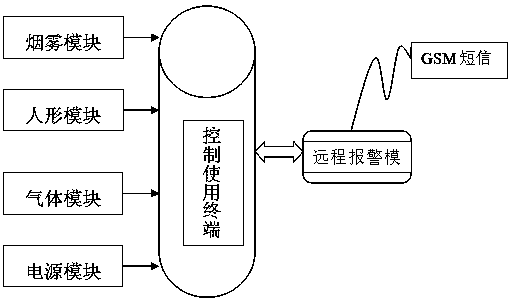

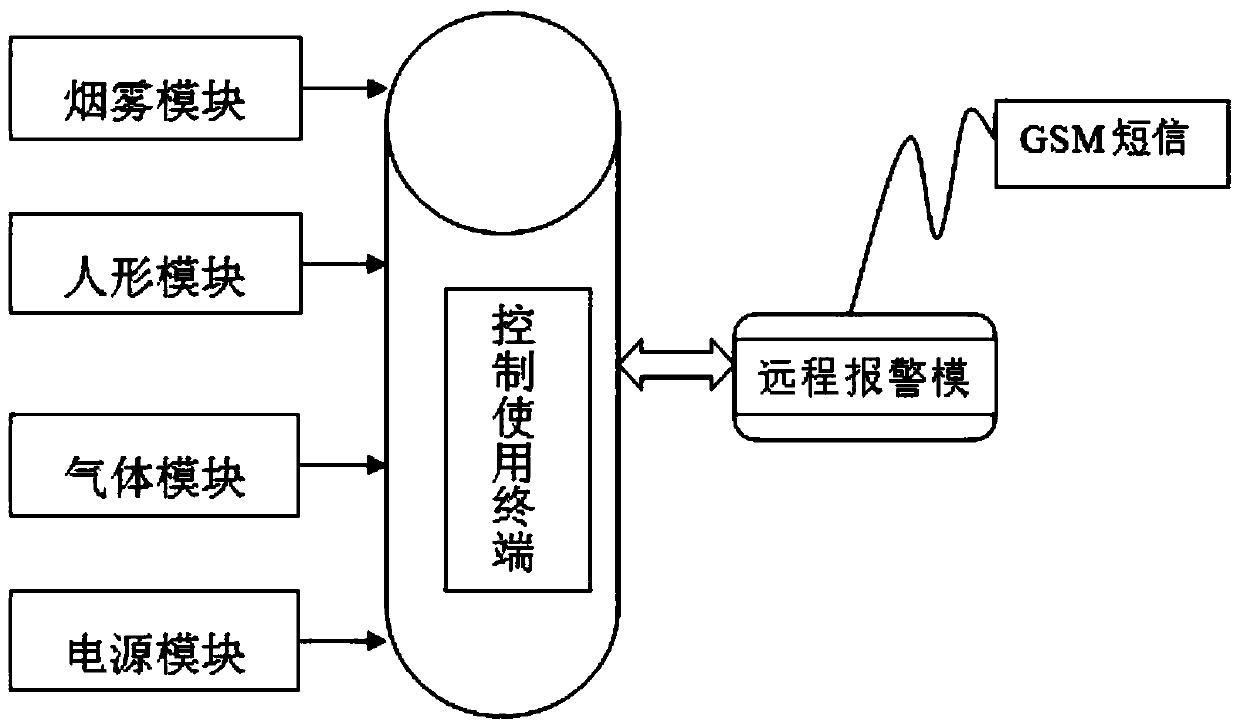

Pre-warning system based on Internet of Things technology

The invention discloses a pre-warning system based on an Internet of Things technology. The system comprises a control using terminal, a smoke module, a human shape module, a gas module, a remote alarming module and a power supply module, and the smoke module, the human shape module, the gas module, the remote alarming module and the power supply module are connected with the control using terminal. The pre-warning system based on the Internet of Things technology is capable of achieving remote anti-theft and fireproof pre-warning.

Owner:SUZHOU YAAN INTELLIGENT TECH

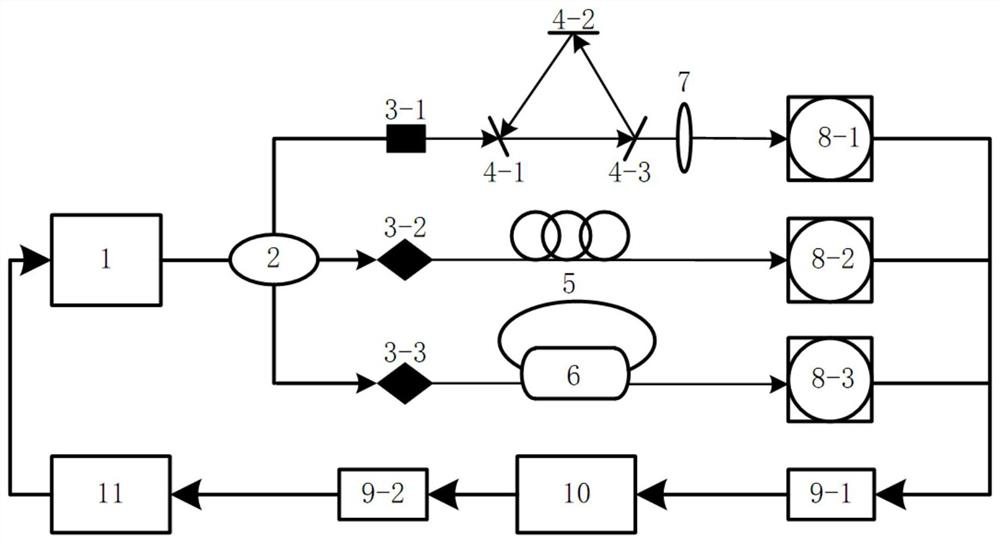

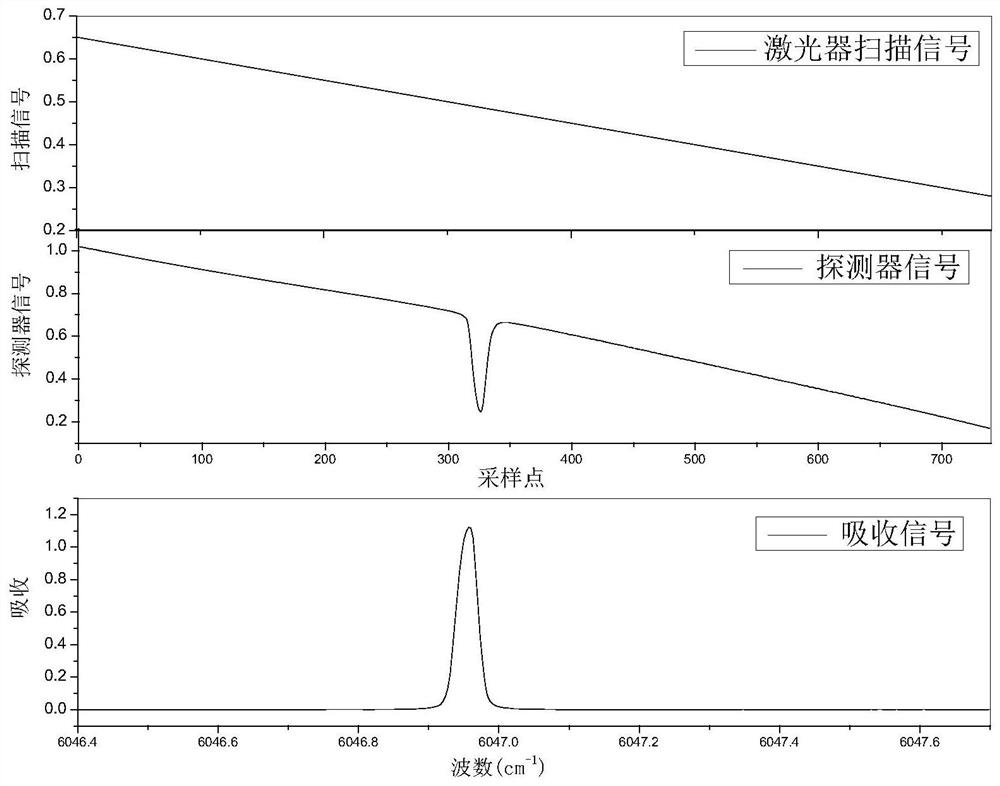

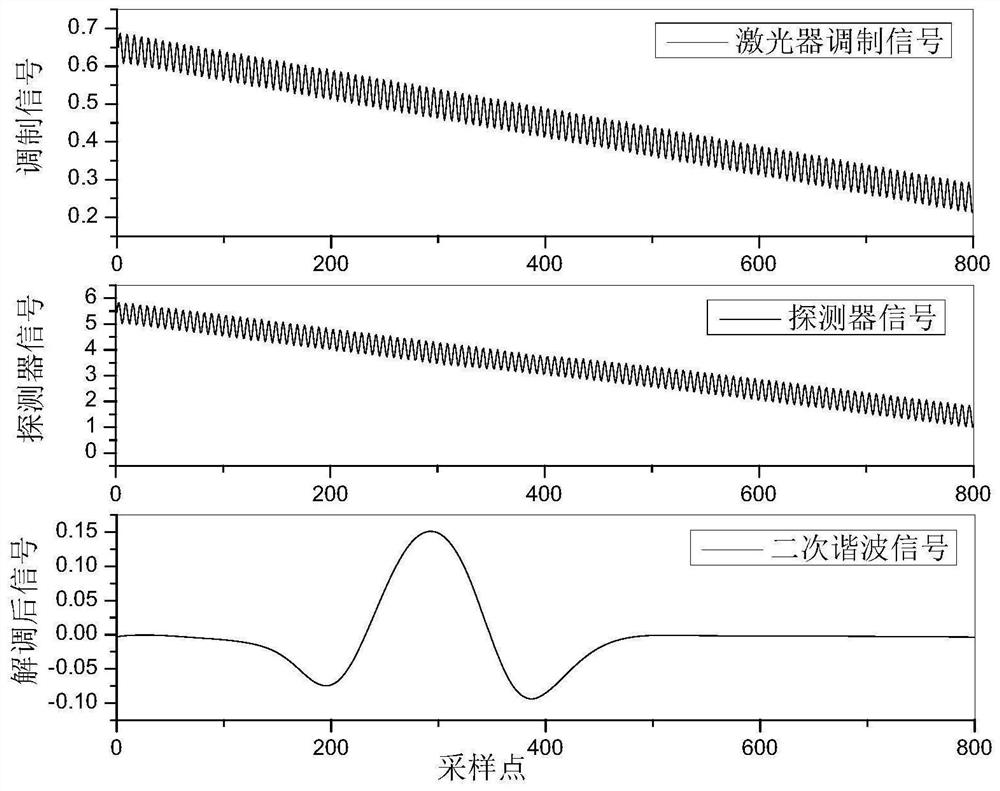

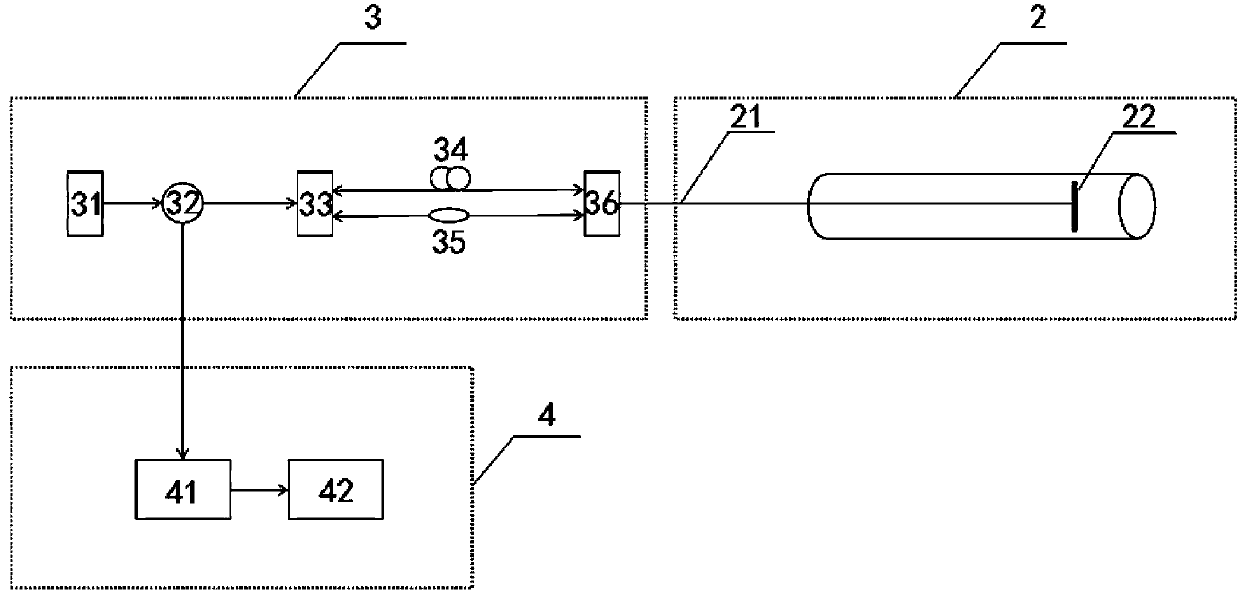

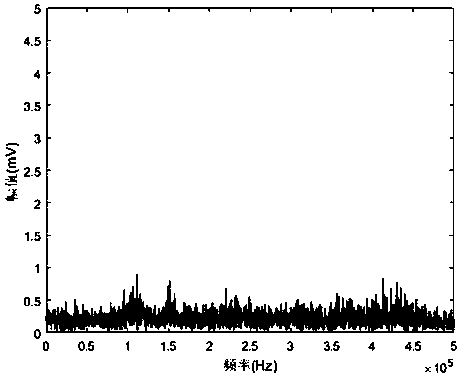

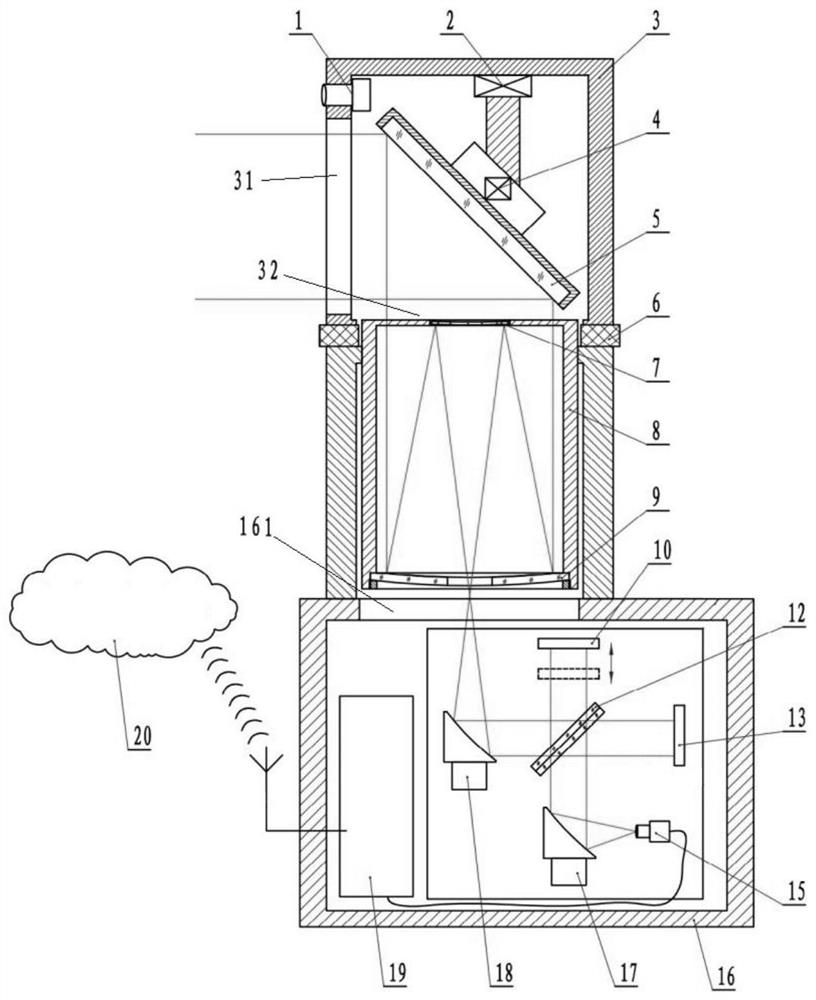

All-fiber open type gas monitoring system and detection method

ActiveCN111982813ARealize measurementEnable leak detectionColor/spectral properties measurementsAir quality improvementBeam splitterEngineering

The invention discloses an all-fiber open type gas monitoring system and a detection method. The system comprises a wavelength tunable laser, an optical fiber coupler, an optical fiber beam splitter,an optical fiber collimator, a reference pool based on a hollow-core optical fiber, an optical fiber ring cavity interferometer, a three-mirror cavity system, a focusing lens, a photoelectric detector, a laser control module, an analog-to-digital conversion module, a digital-to-analog conversion module and a computer control unit. According to the invention, the hollow-core optical fiber and the optical fiber ring cavity interferometer which are small in size and high in flexibility are used for replacing a traditional fragile glass type absorption cell and an F-P type etalon sensitive to an optical path respectively to realize laser center frequency locking, spectral system correction and tuning frequency range correction; the three-mirror cavity system is used for replacing a traditionaltwo-mirror linear reflection mode to achieve large-range area open type gas monitoring.

Owner:ANHUI UNIVERSITY

Safety warning platform applying wireless sensing technology

The invention discloses a safety warning platform applying a wireless sensing technology. The platform includes a control use terminal, a smog module connected with the control use module, a humanoid module, a gas module, a remote alarm module and a power module so that antitheft and fireproof remote early warning is realized and thus the safety warning platform applying the wireless sensing technology is realized.

Owner:SUZHOU YAAN INTELLIGENT TECH

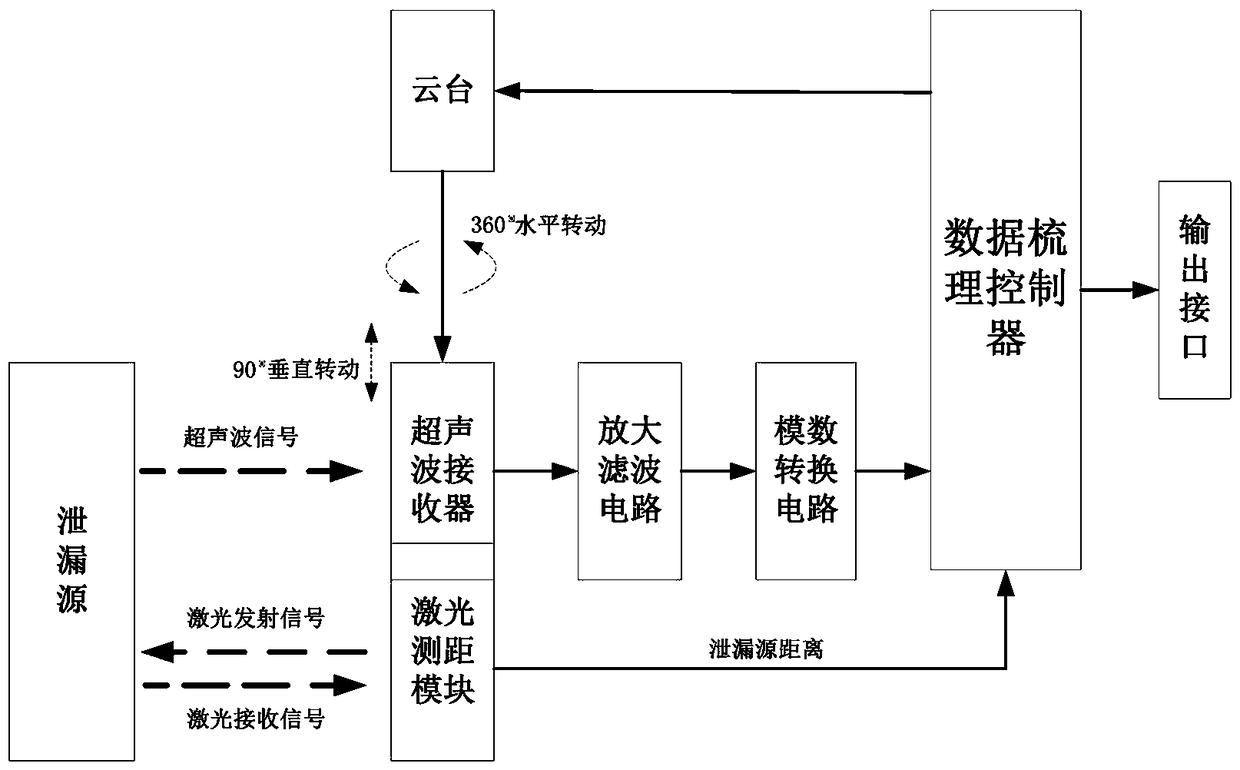

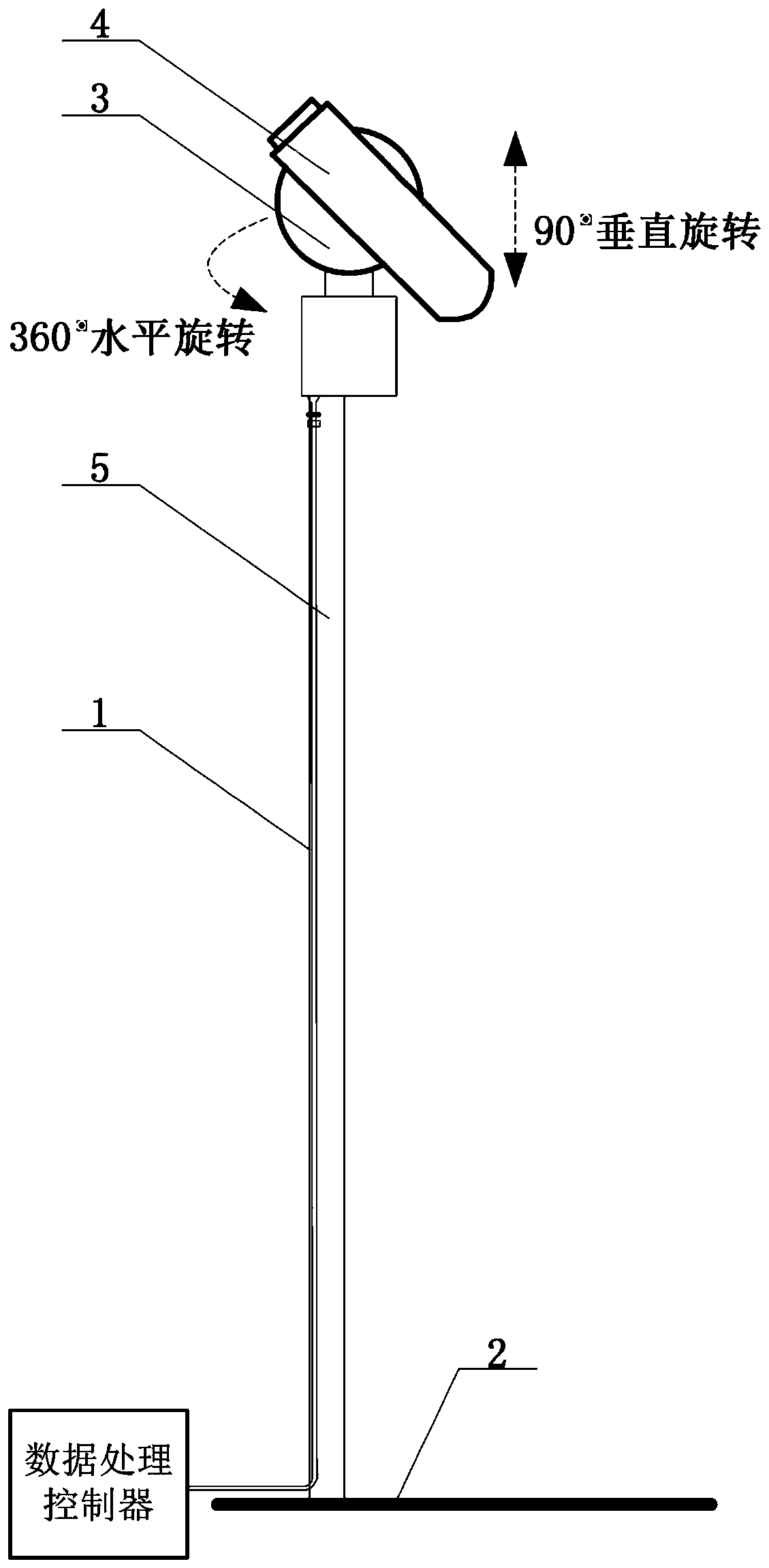

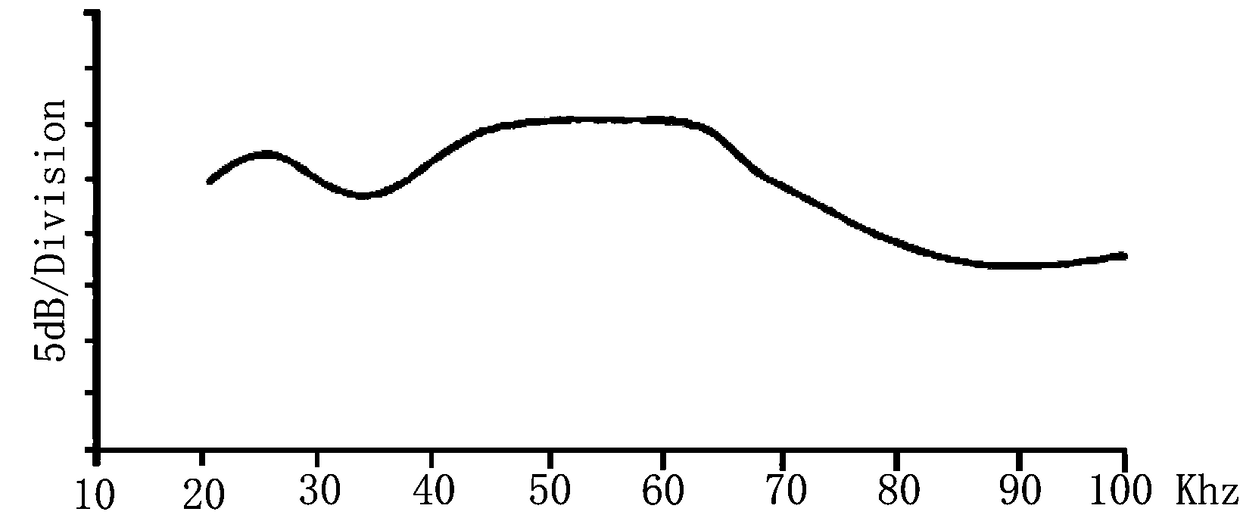

Novel online scanning ultrasonic gas leak detection system

PendingCN109506848AAchieve positioningHighlight substantive featuresDetection of fluid at leakage pointDirection finders using ultrasonic/sonic/infrasonic wavesLaser rangingComputer science

The invention provides a novel online scanning ultrasonic gas leak detection system. The system comprises a data processing controller, a cloud platform and an ultrasonic receiver and a laser rangingmodule mounted on the cloud platform; the data processing controller controls the cloud platform to achieve rotation scanning, and the ultrasonic receiver receives an ultrasonic signal in real time during the rotation of the cloud platform to upload to the data processing controller; the data processing controller determines a leakage source direction according to a maximum ultrasonic signal obtained during the rotation scanning process of the cloud platform, controls the cloud platform to rotate to a leakage source direction, and controls the laser ranging module to perform laser ranging to obtain a leakage source distance; the data processing controller adopts a neural network algorithm to calculate a leakage source pressure value and a leakage source leak diameter according to the frequency data and the amplitude data of the maximum ultrasonic signal and the leakage source distance, and estimates the leakage amount based on the leakage source pressure value and the leakage source leak diameter.

Owner:HENAN HANWEI ELECTRONICS

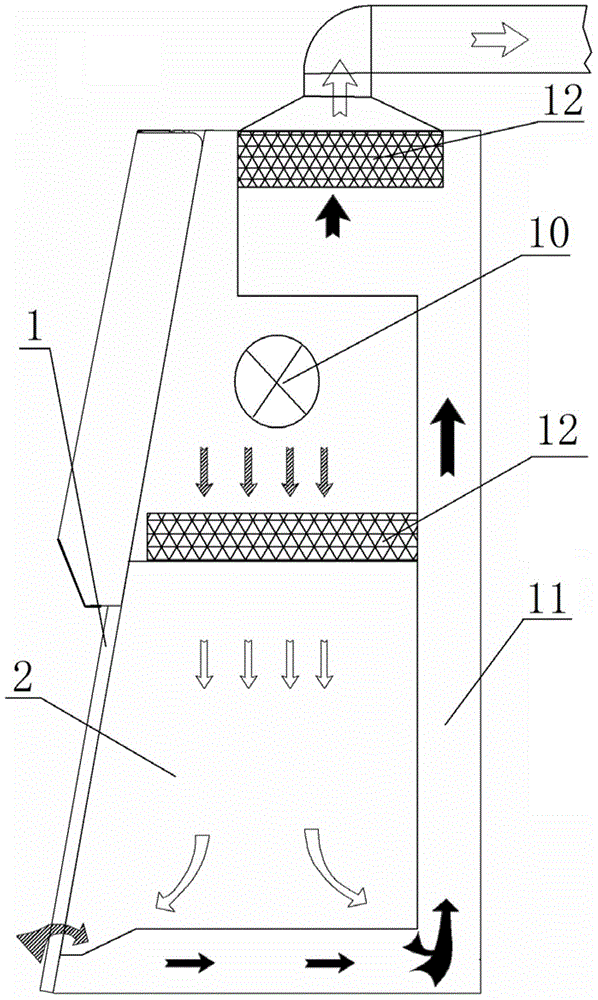

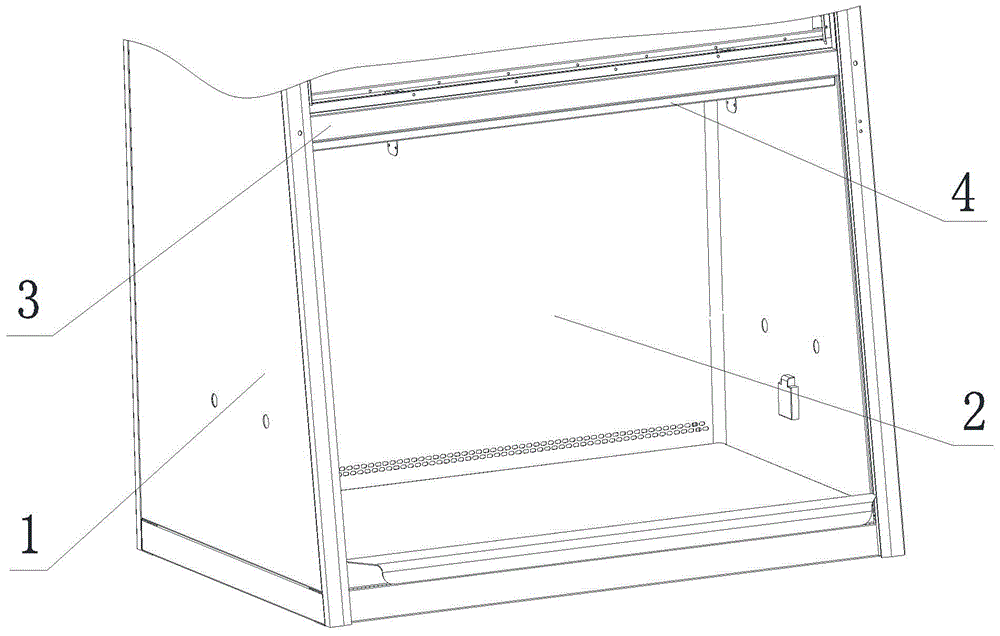

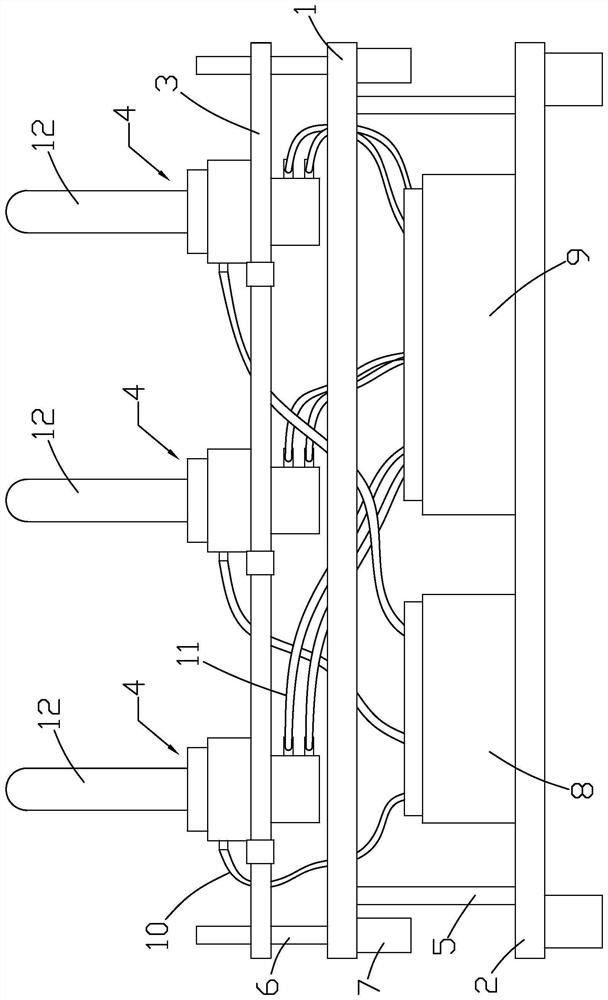

Biological safety cabinet for monitoring filter leakage in real time

InactiveCN104437684AReal-time inspection and maintenanceTimely inspection and maintenanceEnclosures/chambersMonitor filterAir blower

The invention discloses a biological safety cabinet for monitoring filter leakage in real time. The biological safety cabinet comprises a cabinet body, an air blower, a negative pressure channel and a detecting structure, wherein an air outlet is formed in the top of the cabinet body; the air blower is arranged on the inner upper part of the cabinet body; the negative pressure channel is arranged at the outer side of the rear part of the cabinet body; one end of the negative pressure channel is arranged below the cabinet body, and the other end of the negative pressure channel extends to the top end of the cabinet body along the rear part of the cabinet body; the detecting structure is arranged on a position, positioned on the upper part of a cabinet body working region, in the cabinet body. According to the biological safety cabinet for monitoring filter leakage in real time disclosed by the invention, the detecting structure is arranged in the working region, and a probe for detecting cleanness is fixed on a movable track in the detecting structure and can move in the track, so that in the practical use of a workbench, the cleanness detecting probe scans along the track row by row to realize leakage detection; when leakage exists, a signal is output in real time, so that the equipment can timely emit a sound-light alarm signal to prompt an operator to timely check and maintain a filter.

Owner:上海力申科学仪器有限公司

A Submarine Pipeline Leakage Monitoring System

ActiveCN104976518BEasy accessLow priceDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringSubmarine pipeline

The invention relates to a submarine pipeline leakage monitoring system, comprising a controller, a flow sensor, a pressure sensor, a temperature sensor and a central main computer; the inlet end and the outlet end of the pipeline to be monitored are provided with a flow sensor, a pressure sensor and a The temperature sensor, inlet flow sensor, pressure sensor and temperature sensor collect the flow, pressure and temperature signals at the inlet in real time, and send them to the first controller; the flow sensor, pressure sensor and temperature sensor at the outlet collect the flow, pressure and temperature at the outlet in real time. The temperature signal is sent to the second controller; each controller sends the signal to the central host computer through the Ethernet switch, and the leakage monitoring system in it displays the information in real time and judges whether the pipeline to be monitored leaks. Then the leakage alarm will be carried out, and the leakage amount and leakage position will be calculated and displayed; the central host computer will send the received signal and judgment result to each remote monitoring equipment.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for achieving pre-warning system based on internet of things technology

The invention discloses a method for achieving a pre-warning system based on the internet of things technology. The pre-warning system comprises a control use terminal and a smoke module, a figure module, a gas module, a remote alarm module and a power supply module which are connected with the control use terminal. The pre-warning system achieves remote pre-warning of burglary prevention and fire prevention, and accordingly the method for achieving the pre-warning system based on internet of things technology is achieved.

Owner:SUZHOU YAAN INTELLIGENT TECH

Method for realizing wireless-sensing-technology safety early-warning platform

The invention discloses a method for realizing a method for realizing a wireless-sensing-technology safety early-warning platform which includes a control use terminal, a smog module connected with the control use module, a humanoid module, a gas module, a remote alarm module and a power module so that antitheft and fireproof remote early warning is realized and thus the method for realizing the wireless-sensing-technology safety early-warning platform is realized.

Owner:SUZHOU YAAN INTELLIGENT TECH

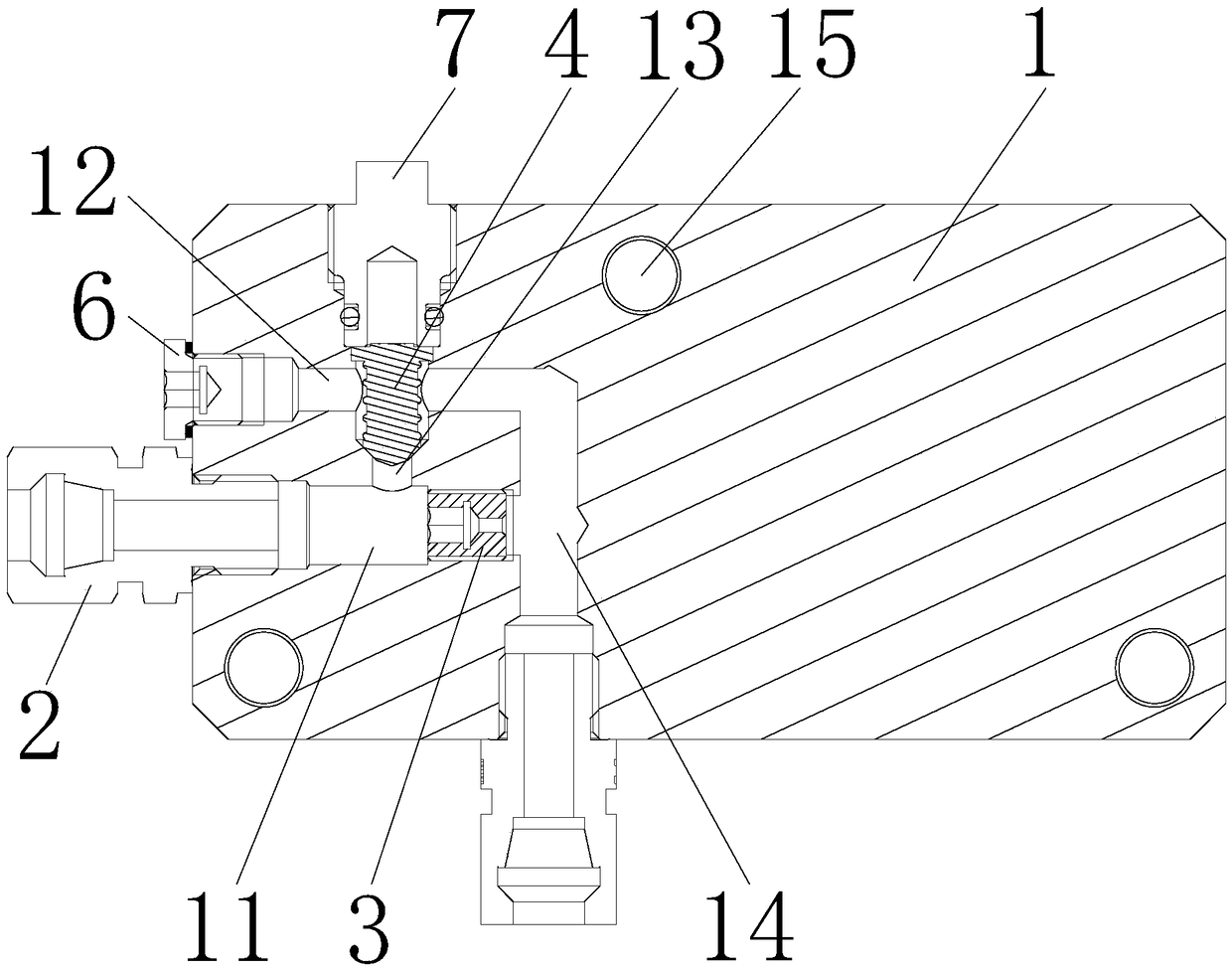

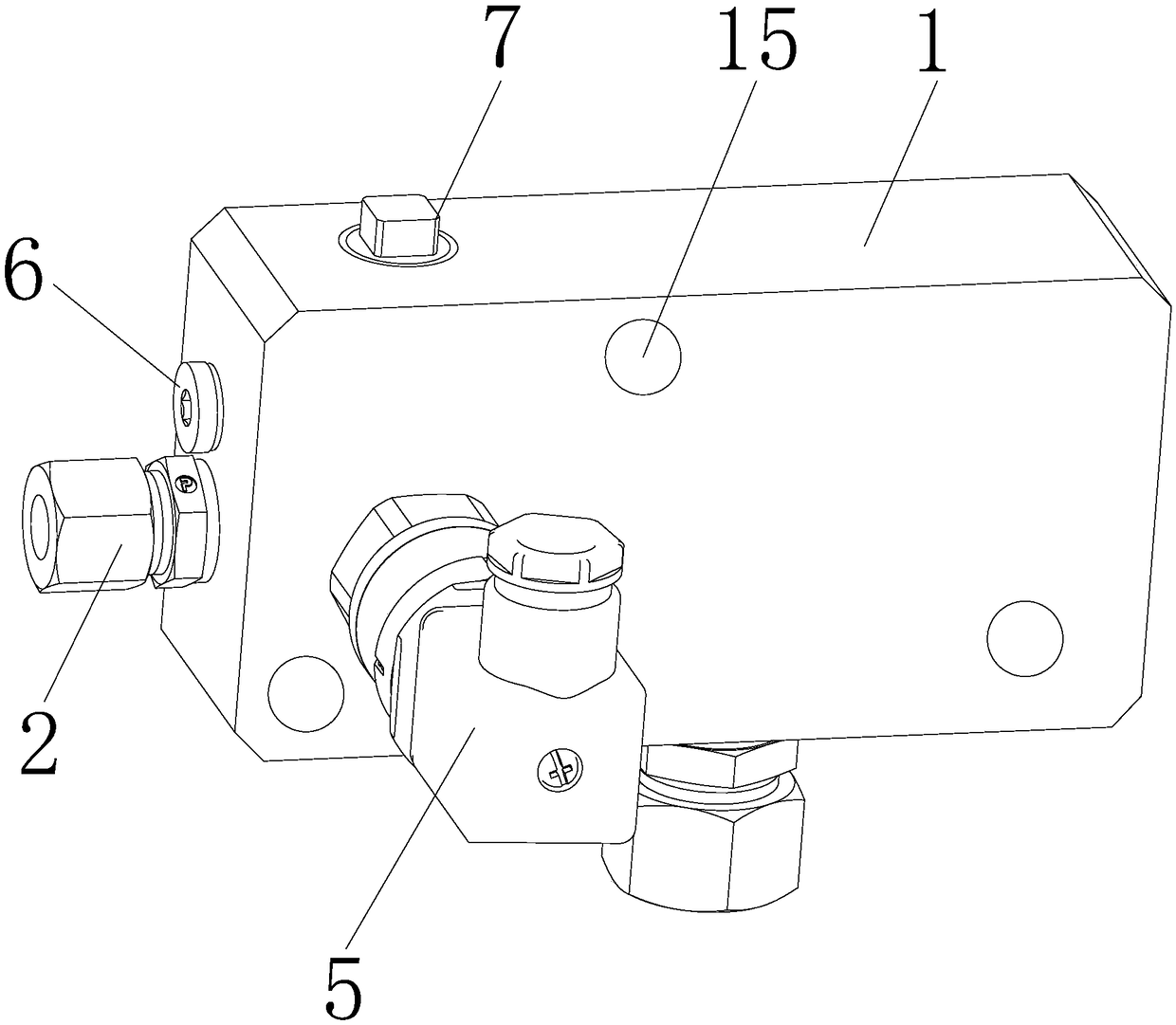

Fuel double-wall pipe leakage detection device and detection method

PendingCN109186893ASimple structureSave spaceMeasurement of fluid loss/gain rateDouble-walled pipeThrottle

The invention discloses a fuel double-wall pipe leakage detection device and a detection method. The detection device comprises an integrated block, an oil inlet hole is horizontally arranged at a left end surface of the integrated block, a first process hole is arranged at an upper end of the oil inlet hole in a parallel way, a second process hole is vertically arranged at an upper end surface ofthe integrated block, an oil outlet hole is vertically arranged at a lower end surface, and the oil outlet hole and the second process hole respectively communicate with the first process hole and the oil inlet hole; each of the oil inlet hole and the oil outlet hole is connected with a pipe joint, and a throttle valve is arranged at a right end of a junction of the oil inlet hole and the oil outlet hole, and an overflow valve is arranged at the junction of the first process hole and the second process hole; a pressure sensor is arranged at a front end surface of the integrated block and is connected into the first process hole. The detection device disclosed by the invention has the advantages that the device is simplified in structure, reduced in space, and convenient for operation; thedetection on the fuel double-wall pipe leakage is realized through the cooperative use of the throttle valve and the overflow valve, and meanwhile, the pressure-reduced discharging is performed on the leaked oil, thereby preventing large pressure from damaging the detection device.

Owner:ANQING CSSC DIESEL ENGINE

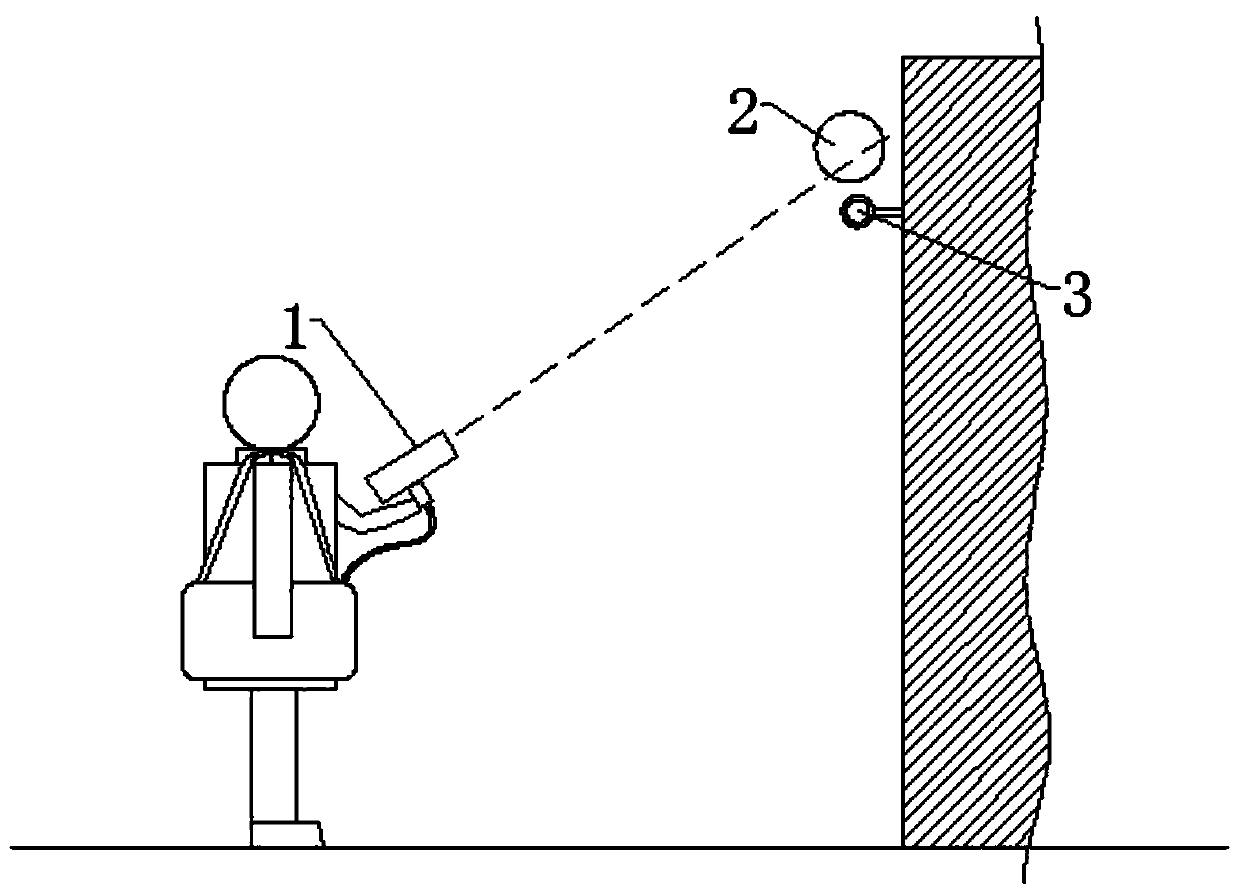

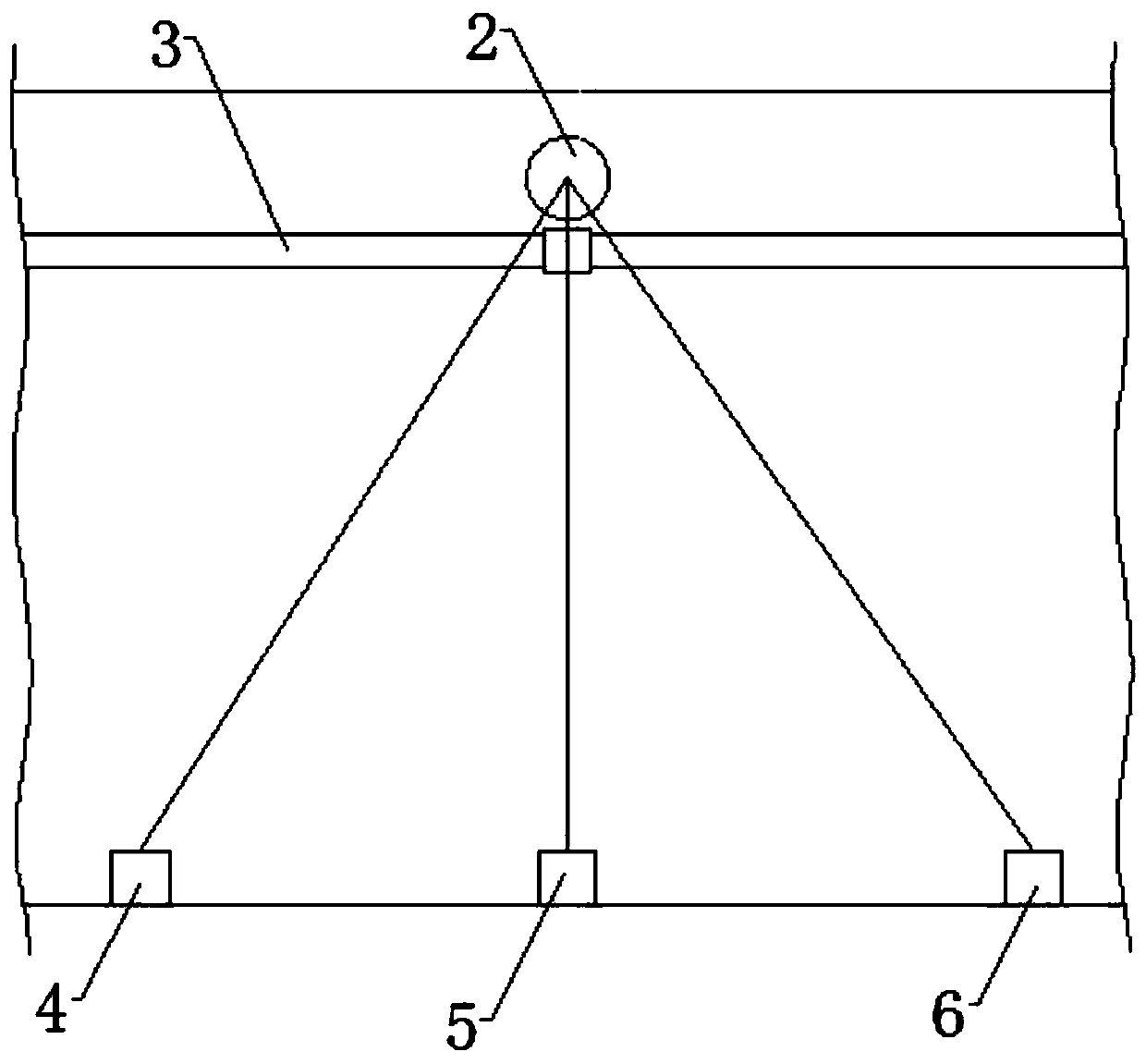

Outdoor aerial gas pipeline non-contact long-distance leakage detecting method

InactiveCN109827075AEnable leak detectionImprove securityDetection of fluid at leakage pointMaterial analysis by optical meansInfraredAbnormal positions

The invention discloses an outdoor aerial gas pipeline non-contact long-distance leakage detecting method. The method comprises the following steps that a, a leakage detecting point is determined, specifically, the position of the to-be-detected leakage point is observed, and a pipeline joint position or a pipeline structure abnormal position is selected as the leakage detecting point; b, standingpoints are determined, specifically, after the leakage detecting point is determined, three standing points are arranged in a position right facing the leakage detecting point, a position 2-3 m deviating leftwards from the leakage detecting point and a position 2-3 m deviating rightwards from the leakage detecting point correspondingly; c, leakage detection is performed; d, data analyzing is performed; and e, data recording is performed. The method has the beneficial effects that by adopting an infrared detecting technology, by means of the characteristic that wavebands reflected by methane in light waves are inconsistent after natural gas is leaked, aerial long-distance outdoor aerial gas pipeline leakage detection is achieved, operation is easy, and the safety is high; and by measuringthe leakage detecting point from the multiple points in multiple directions, the gas leakage status can be evaluated comprehensively, and the detecting precision is improved.

Owner:湖南九申燃气集团股份有限公司

Method for detecting leakage of air compressor and detection device thereof

InactiveCN108956037AEnable leak detectionSimple structureDetection of fluid at leakage pointGas compressorEngineering

The invention discloses a method for detecting leakage of an air compressor. The method comprises the following steps: firstly, a pressurizing device is arranged to be connected with the air source equipment, then the pressurizing device is connected with the air outlet connector of the air compressor to input the high pressure air source to the air outlet cavity of the air compressor, and an airsource triple piece is arranged between the pressurizing device and the air source equipment for air source treatment; and finally, the soap bubbling method is applied to detect air leakage of the aircompressor. The invention provides a detection device for detecting leakage of the air compressor. The detection method is that the soapy water is smeared on the leakage-prone part, bubbling is visually detected and leakage detection is realized so that the structure is simple and checking is convenient, and the soapy liquid can be washed away by the air gun after the detection is completed. Thecover is arranged so that the detection can be performed quickly and conveniently, the detection speed can be greatly accelerated and the cleaning is convenient.

Owner:GUANGXI YUCHAI MASCH CO LTD

Method for realizing home security monitoring platform

The invention discloses a method for realizing a home security monitoring platform. According to the method for realizing the home security monitoring platform, a control and usage terminal as well as a smoke module, a figure module, a gas module, a remote warning module and a power module which are connected with the control and usage terminal are adopted, and anti-theft and fireproof remote early-warning is realized.

Owner:SUZHOU YAAN INTELLIGENT TECH

Fluid conveying pipeline, preparation method thereof and leakage detection system

InactiveCN111006075ANot easy to corrodeAvoid influenceCorrosion preventionPipeline systemsEngineeringMechanical engineering

The invention discloses a fluid conveying pipeline. The pipeline comprises a non-metal pipe body and an optical fiber sensor; the non-metal pipe body comprises an anti-corrosion inner pipe and a protective outer pipe which are sequentially arranged from inside to outside; the optical fiber sensor comprises an optical fiber and a Faraday rotator mirror; the optical fiber is connected with the Faraday rotator mirror; and the optical fiber and the Faraday rotator mirror are both buried in the protective outer pipe. The invention further discloses a preparation method of the fluid conveying pipeline and a fluid conveying pipeline leakage detection system. The fluid conveying pipeline leakage detection device comprises the fluid conveying pipeline, a demodulator connected with the optical fiber, and a signal processing terminal connected with the demodulator. According to the fluid conveying pipeline of the invention, the conveying pipeline is set to be the non-metal pipe body and is not prone to corrosion, meanwhile, the optical fiber is buried in the non-metal pipe body; the laying of the non-metal pipe body and the laying of the optical fiber are integrated; the optical fiber is laidin the whole length direction of the non-metal pipe body; and therefore, long-distance non-metal pipe body leakage detection can be achieved, a detection coverage rate is higher, and detection precision is higher.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST +1

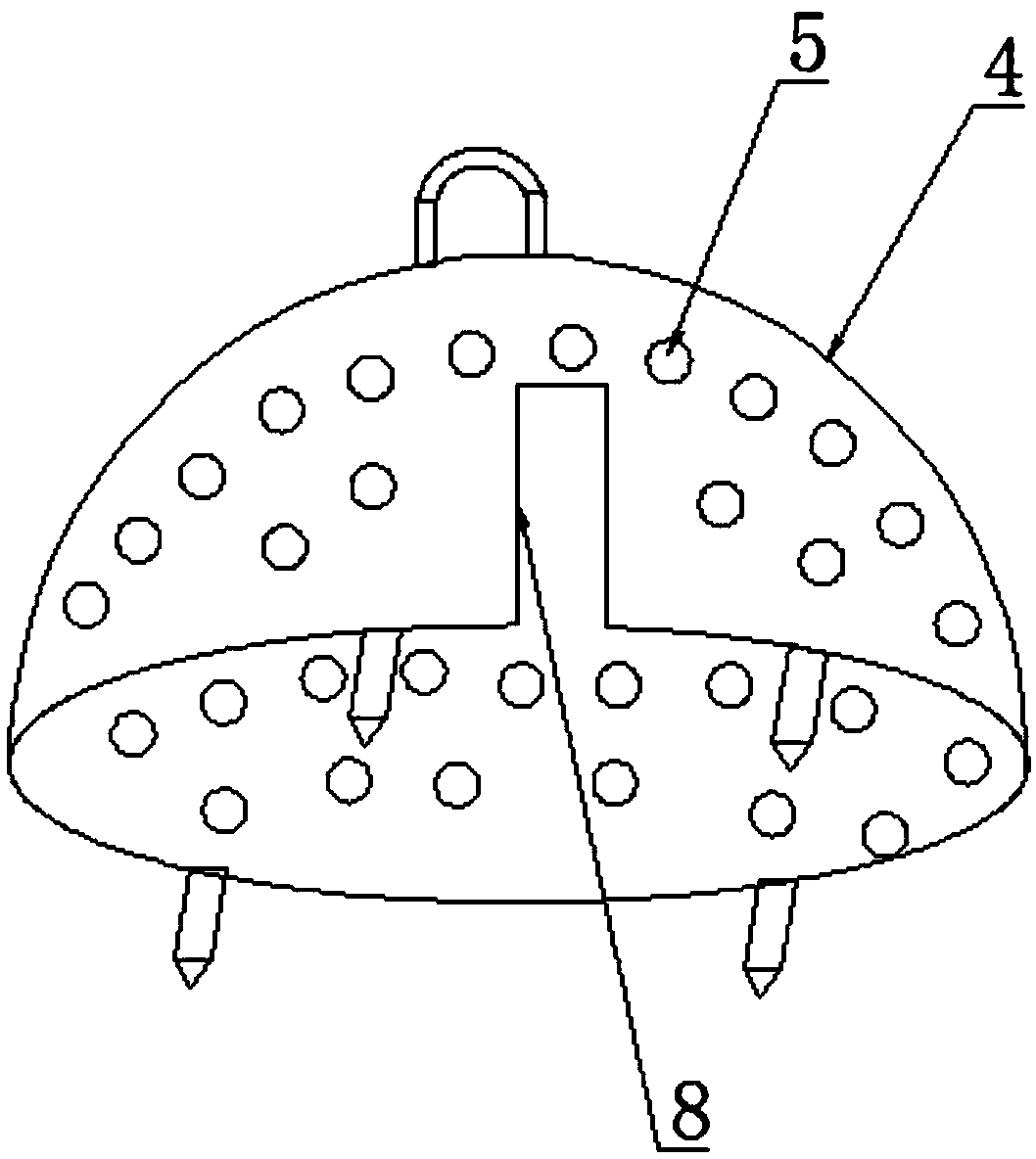

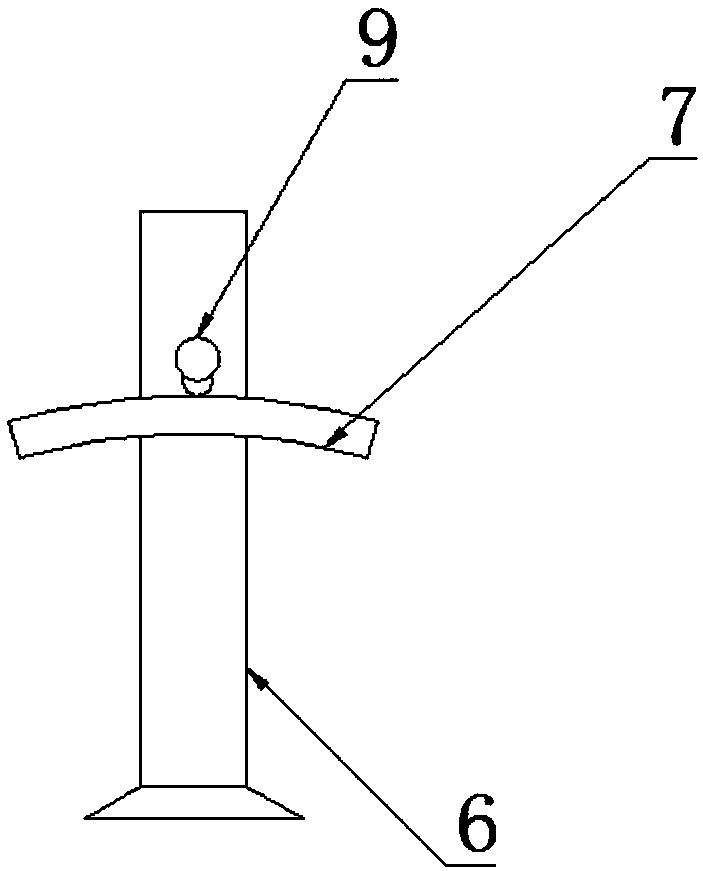

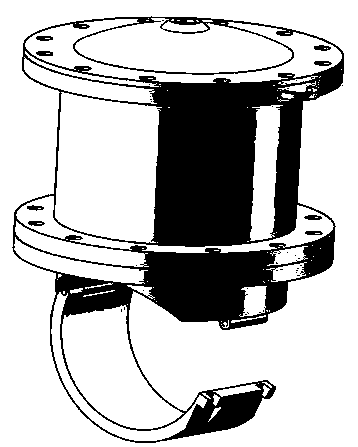

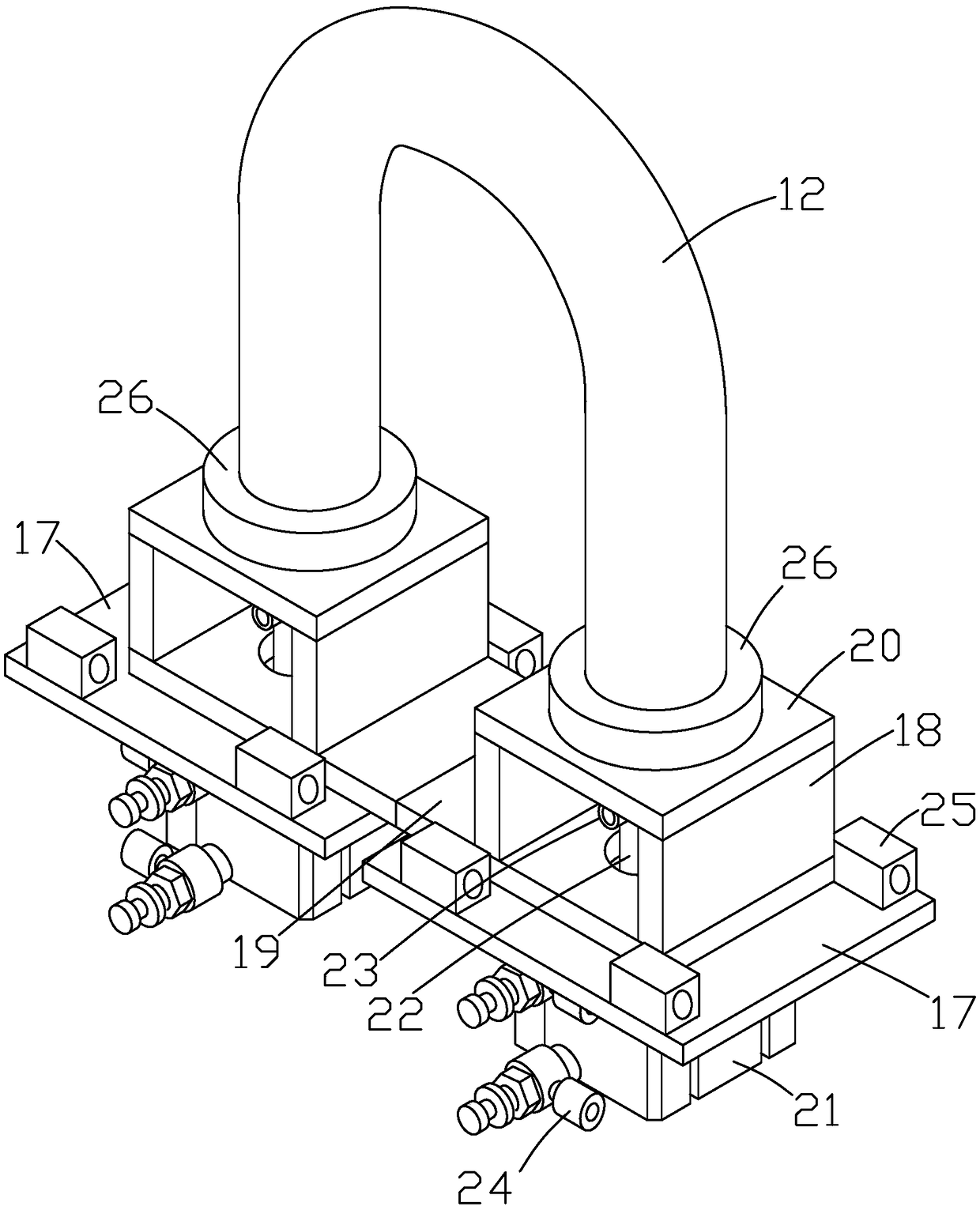

Deepwater process facility acoustic emission detection device

InactiveCN109696282AHigh specific strengthEasy to installDetection of fluid at leakage pointAcoustic emissionEngineering

The invention belongs to the field of deepwater leakage detection, and particularly relates to a deepwater process facility acoustic emission detection device which comprises an external compression resistance device and an internal acoustic emission detection system. The compression resistance device comprises a cylinder body, a spherical-crown-shaped end socket, a flat-cover end socket and a fixing device, wherein the cylinder body is a streamline cylindrical pressure-resistant shell; the spherical-crown-shaped end socket is provided with a watertight plug connector to achieve power supply and signal transmission, and hanging rings are welded to facilitate fixing and carrying; the flat-cover end socket realizes compression resistance and good signal transmission; O-shaped sealing rings are designed between the end sockets and the cylinder body to realize sealing; an adjustable hoop structure is designed to be fixed to technological facilities of different shapes and sizes; the acoustic emission detection system comprises an acoustic emission sensor, a signal transmission cable and a signal processor, wherein the acoustic emission sensor collects and amplifies signals, and the signal processor displays, processes and analyzes data. The device has the advantages of pressure resistance, water resistance, good signal transmission, reasonable design, high applicability and capability of realizing leakage detection of deepwater process facilities.

Owner:CHINA NAT OFFSHORE OIL CORP +2

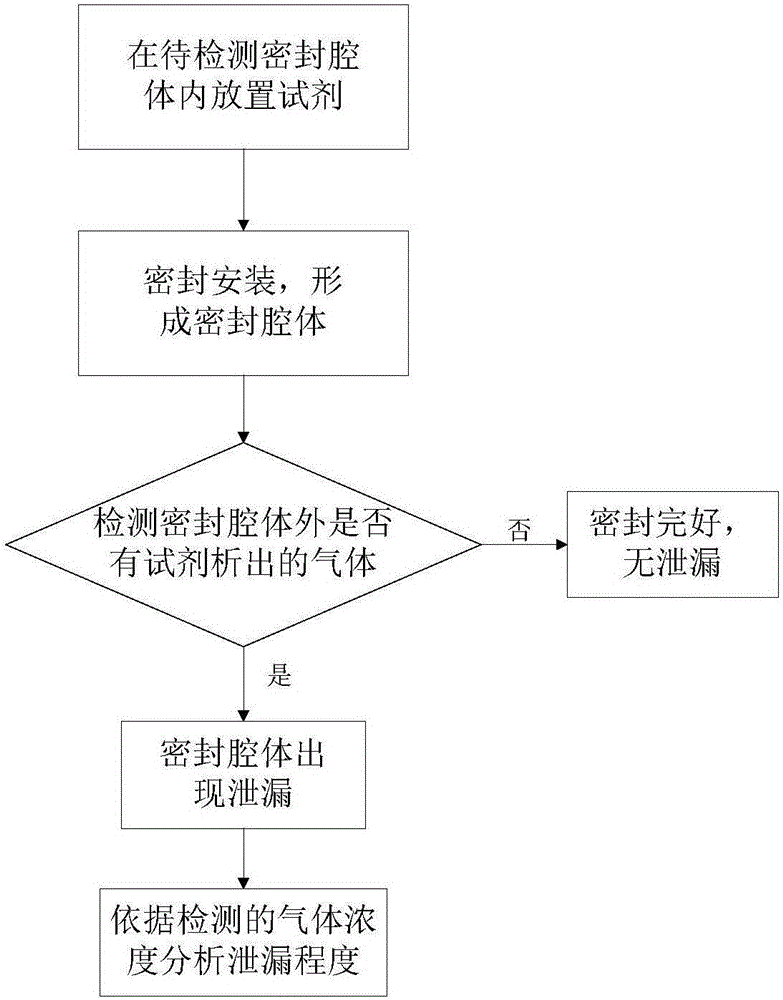

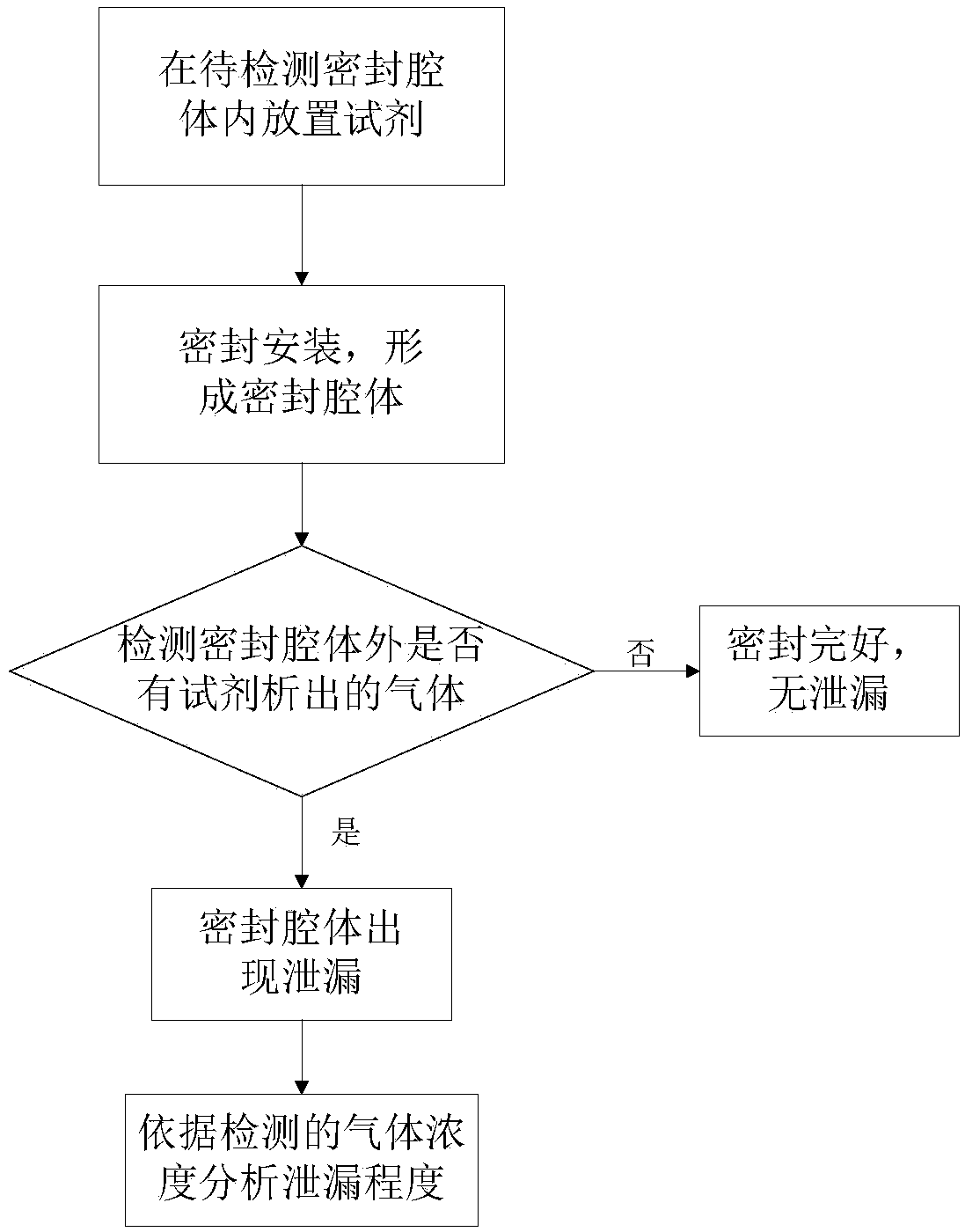

Method for detecting leakage of seal chamber based on spontaneous expanding gas

ActiveCN106768688ALow environmental toxicityLess corrosiveDetection of fluid at leakage pointEngineeringPressure difference

The invention provides a method for detecting the leakage of a seal chamber based on spontaneous expanding gas, and belongs to the technical field of leakage detection. The method specifically comprises the steps: placing a solid material, which can generate expanded gas when meeting heat or is volatile under the normal temperature, in the seal chamber as a reagent before the assembly of the seal chamber; carrying out the assembly to form the seal chamber, heating the seal chamber to proper temperature during leakage detection (there is no need of heating when a reagent is volatile under the normal temperature), and separating out the gas in the solid reagent, wherein the gas tends to overflow because of the miniature pressure difference generated by the gas. When the seal chamber has a leakage problem, the method can detect the gas outside the seal chamber. When the method is used for the detection of the leakage of the seal chamber, the method can effectively achieves the leakage detection of a seal chamber which is compact in structure or has any complex structure.

Owner:BEIJING POWER MACHINERY INST

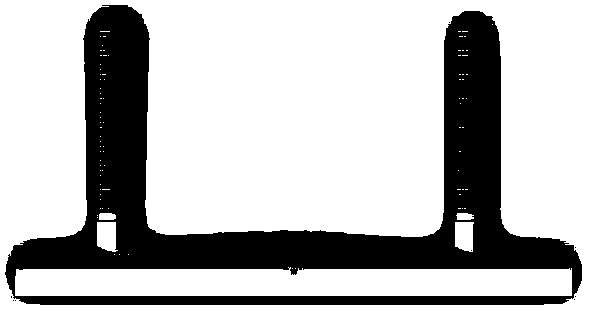

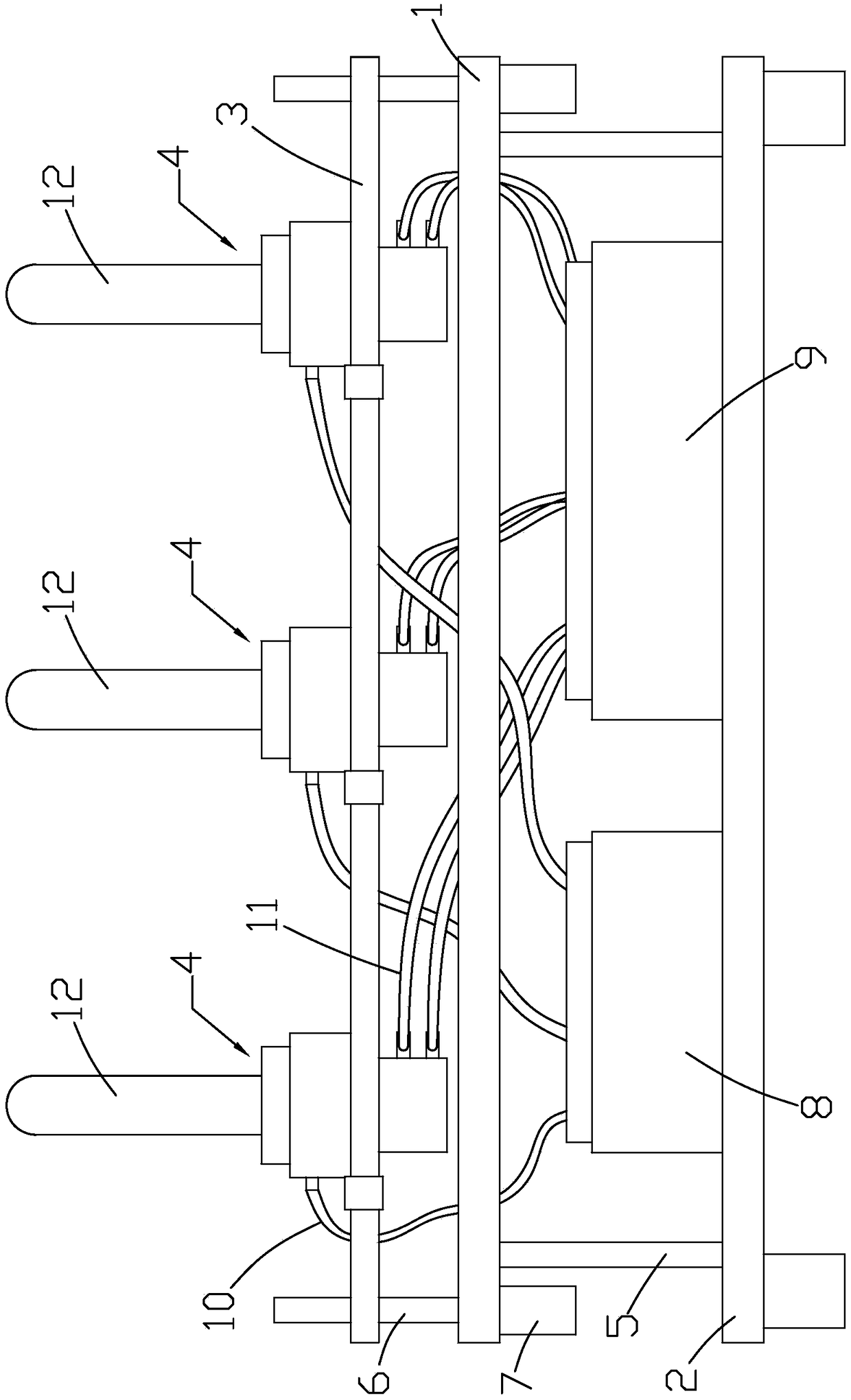

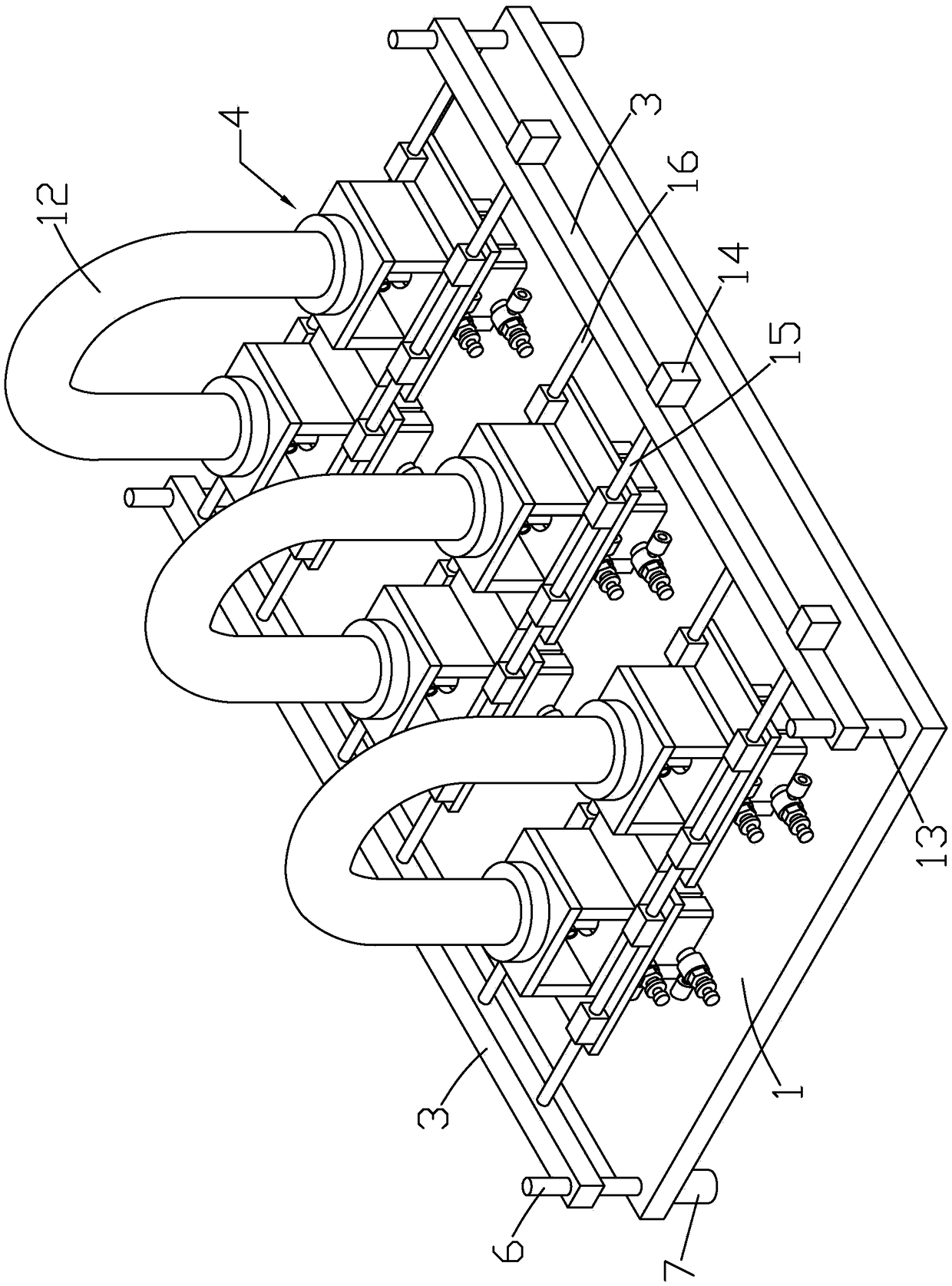

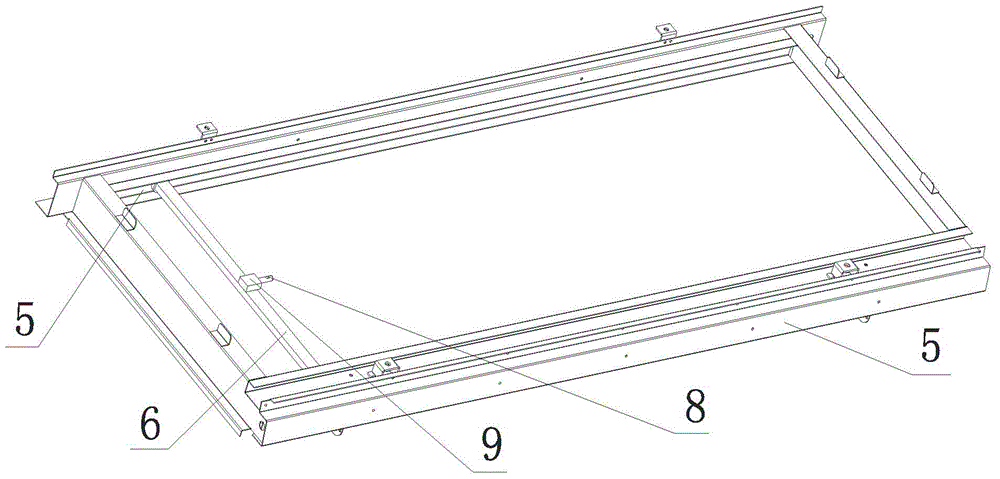

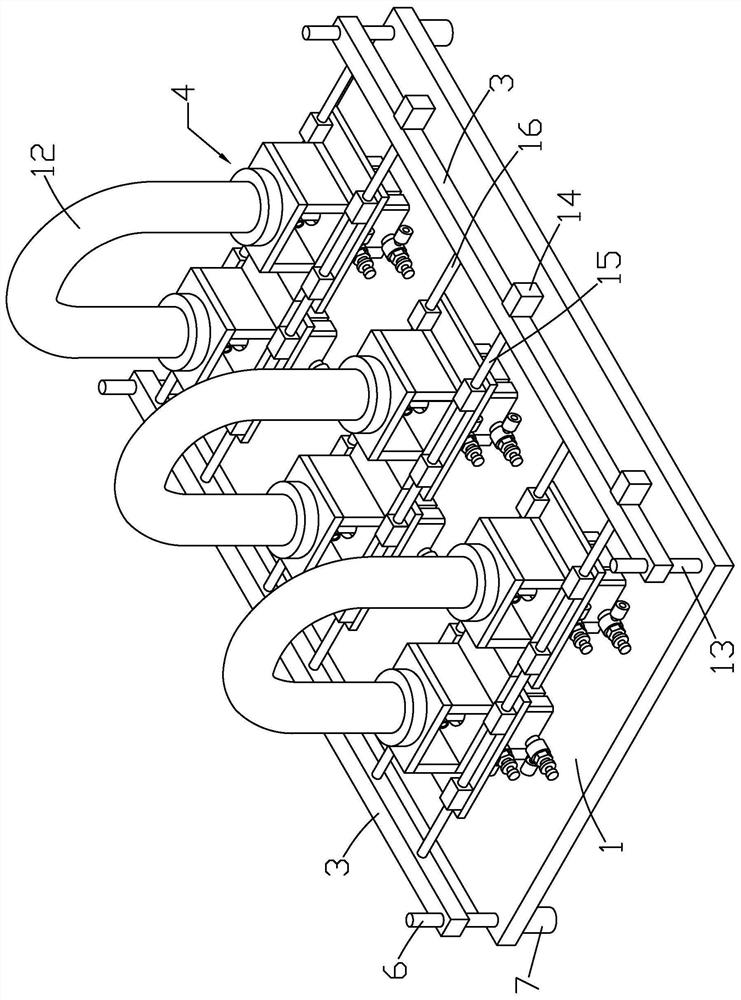

Leakage detecting device for non-excavation construction arc pipes

ActiveCN109469835ARealize spacing adjustmentImprove stabilityPipeline systemsWater storage tankFuel tank

The invention discloses a leakage detecting device for non-excavation construction arc pipes. The leakage detecting device comprises a substrate, a bottom plate, leakage detecting mechanisms, a waterstorage tank and a hydraulic oil tank; the at least three leakage detecting mechanisms are arranged above the substrate at equal intervals, two transverse beams are arranged on the two sides of the leakage detecting mechanisms in parallel, the leakage detecting mechanisms are movably connected between the two transverse beams through second screws and guiding rods, the ends of the second screws are provided with second motors, the two ends of the transverse beams are connected with the substrate through first screws and second stand columns, first motors are arranged at the bottom ends of thefirst screws, and the leakage detecting mechanisms are connected with the water storage tank and the hydraulic oil tank through water conveying pipes and oil conveying pipes. The leakage detecting device is simple in structure and high in practicability, leakage detection processing of the arc pipes with different pipe diameter modes and sizes can be achieved, rapid clamping positioning of the arcpipes can be achieved, the leakage detection efficiency on the arc pipes is greatly improved, and the working range of the leakage detecting device is enlarged.

Owner:江西圣杰市政工程有限公司

Sealed cavity leak detection method based on spontaneously expanding gas

ActiveCN106768688BEnable leak detectionSimple methodDetection of fluid at leakage pointProduct gasEngineering

The invention provides a method for detecting the leakage of a seal chamber based on spontaneous expanding gas, and belongs to the technical field of leakage detection. The method specifically comprises the steps: placing a solid material, which can generate expanded gas when meeting heat or is volatile under the normal temperature, in the seal chamber as a reagent before the assembly of the seal chamber; carrying out the assembly to form the seal chamber, heating the seal chamber to proper temperature during leakage detection (there is no need of heating when a reagent is volatile under the normal temperature), and separating out the gas in the solid reagent, wherein the gas tends to overflow because of the miniature pressure difference generated by the gas. When the seal chamber has a leakage problem, the method can detect the gas outside the seal chamber. When the method is used for the detection of the leakage of the seal chamber, the method can effectively achieves the leakage detection of a seal chamber which is compact in structure or has any complex structure.

Owner:BEIJING POWER MACHINERY INST

Hazardous chemical substance gas telemetering detection equipment and method

PendingCN113176224AAvoid safety hazardsEnable leak detectionMaterial analysis by optical meansMiddle infraredFt ir spectra

The invention provides hazardous chemical substance gas telemetering detection equipment and method. The hazardous chemical substance gas telemetering detection equipment comprises a server, a lens group used for collecting images, a sweeping device used for collecting infrared spectrums, an infrared telescopic system used for amplifying the collected infrared spectrums, and a measuring device used for measuring the amplified infrared spectrums. And the lens group and the measuring device are in signal connection with the server. Compared with the prior art, the hazardous chemical substance gas telemetering detection equipment provided by the invention is based on a Fourier transform infrared spectroscopic analysis principle, adopts a passive telemetering mode, can acquire characteristic radiation or absorption spectrum of hazardous chemical substance gas at a middle infrared band of 2.5-15 microns in situ at a leakage place, and through an intelligent identification algorithm running at a cloud end, the analysis on the leaked gas is realized.

Owner:湖南航天远望科技有限公司

Air conditioning refrigerant detection method and device

ActiveCN105674507BImprove reliabilityEnable leak detectionMechanical apparatusSpace heating and ventilation safety systemsEngineeringTemperature difference

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Monitoring platform for family safety

The invention discloses a monitoring platform for family safety. The monitoring platform comprises a control use terminal, a smoke module connected with the control use terminal, a human shape module, a gas module, a remote alarm module and a power module. Remote early warning for preventing burglary and fire is realized, so that the monitoring platform for the family safety is realized.

Owner:苏州博康生物医疗科技有限公司

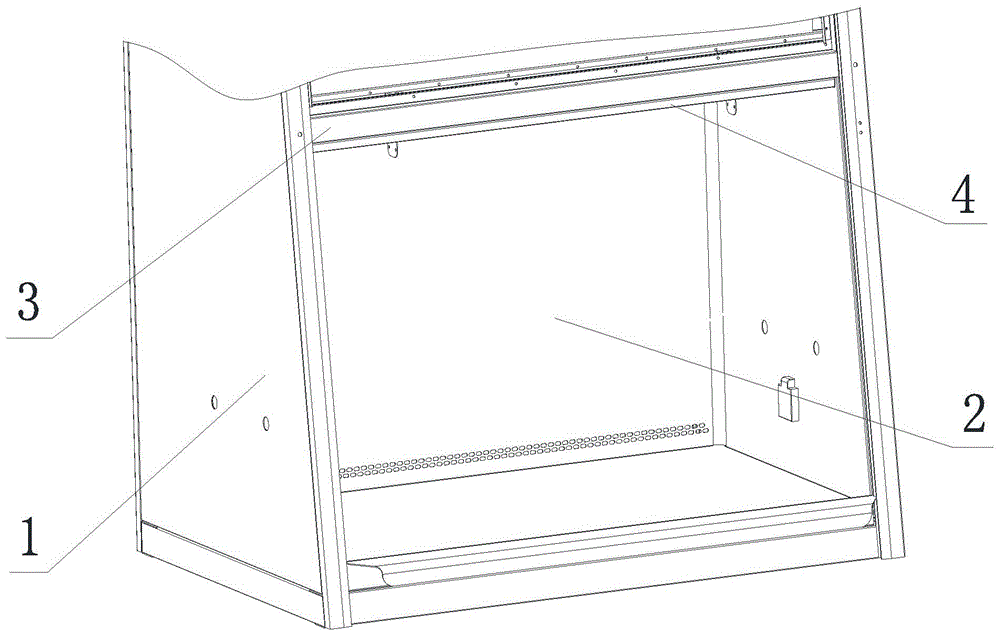

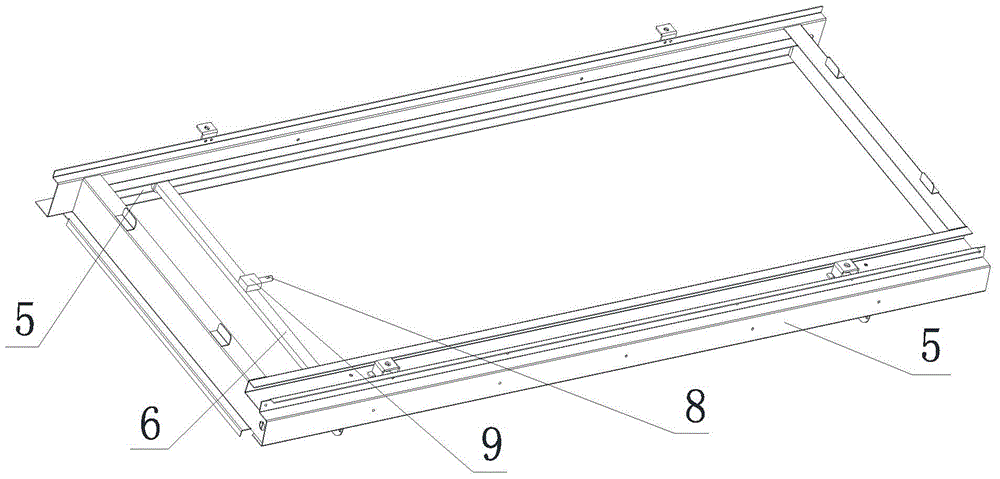

Clean bench capable of monitoring leakage in real time

InactiveCN104437705AReal-time inspection and maintenanceTimely inspection and maintenanceWork benchesLaboratory benches/tablesEngineeringActual use

The invention relates to a clean bench capable of monitoring leakage in real time. The clean bench comprises a box body, a detection structure, a movement unit and a scanning probe, wherein the box body is of a structure with an opening in one side, and a working area is formed inside the box body; the detection structure is arranged in the box body and is positioned at the upper part of the working area; the detection structure comprises a scanning movement platform which is arranged in the box body and is positioned at the upper part of the working area; the movement unit is arranged in the scanning movement platform; and the scanning probe is arranged on the movement unit. According to the clean bench capable of monitoring the leakage in real time, the detection structure is arranged in the working area, the probe for detecting the cleanliness is fixed on one movement track in the detection structure and can move in the track, the probe for detecting the cleanliness can gradually scan along the track when the clean bench is in actual use and the leakage detection is realized; when the leakage occurs, a signal can be output in real time, and equipment can give a sound-light alarm signal timely to prompt operating personnel to check and maintain timely.

Owner:上海力申科学仪器有限公司

Method for realizing and using Internet of things technology early warning system

The invention discloses a method for realizing and using an Internet of things technology early warning system. The Internet of things technology early warning system comprises a control use terminal,and a group connected with the control use terminal and including a smoke module, a human shape module, a gas module, a remote alarm module and a power supply module, so as to realize the remote alarm of antitheft and fire prevention. Thus, the method for realizing and using an Internet of things technology early warning system is achieved.

Owner:西安博士创新科技有限公司

Leak detection device for non-excavation construction arc pipeline

ActiveCN109469835BImprove stabilityImprove reliabilityPipeline systemsWater storage tankElectric machinery

The invention discloses a leakage detecting device for non-excavation construction arc pipes. The leakage detecting device comprises a substrate, a bottom plate, leakage detecting mechanisms, a waterstorage tank and a hydraulic oil tank; the at least three leakage detecting mechanisms are arranged above the substrate at equal intervals, two transverse beams are arranged on the two sides of the leakage detecting mechanisms in parallel, the leakage detecting mechanisms are movably connected between the two transverse beams through second screws and guiding rods, the ends of the second screws are provided with second motors, the two ends of the transverse beams are connected with the substrate through first screws and second stand columns, first motors are arranged at the bottom ends of thefirst screws, and the leakage detecting mechanisms are connected with the water storage tank and the hydraulic oil tank through water conveying pipes and oil conveying pipes. The leakage detecting device is simple in structure and high in practicability, leakage detection processing of the arc pipes with different pipe diameter modes and sizes can be achieved, rapid clamping positioning of the arcpipes can be achieved, the leakage detection efficiency on the arc pipes is greatly improved, and the working range of the leakage detecting device is enlarged.

Owner:江西圣杰市政工程有限公司

Method for achieving home security monitoring platform

The invention discloses a method for achieving a home security monitoring platform. The method is that a use terminal, a smoke module, a human module, a gas module, a remote alarming module and a power module which are connected with the use terminal are controlled to achieve remote early warning for preventing theft and fire.

Owner:苏州博康生物医疗科技有限公司

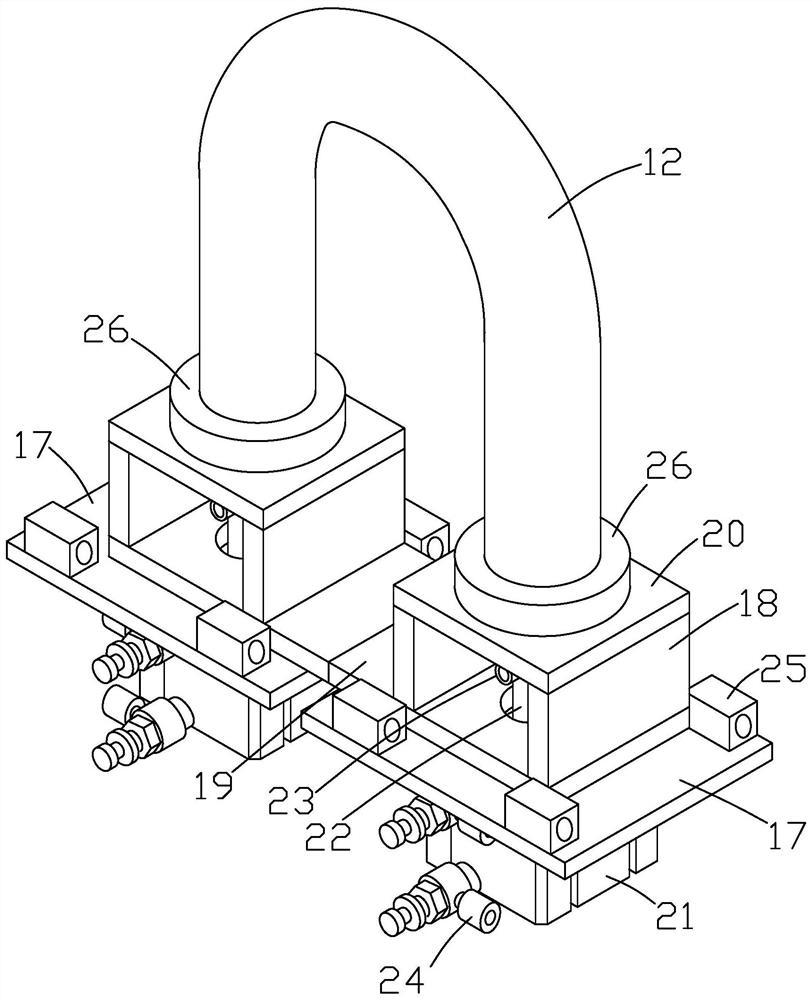

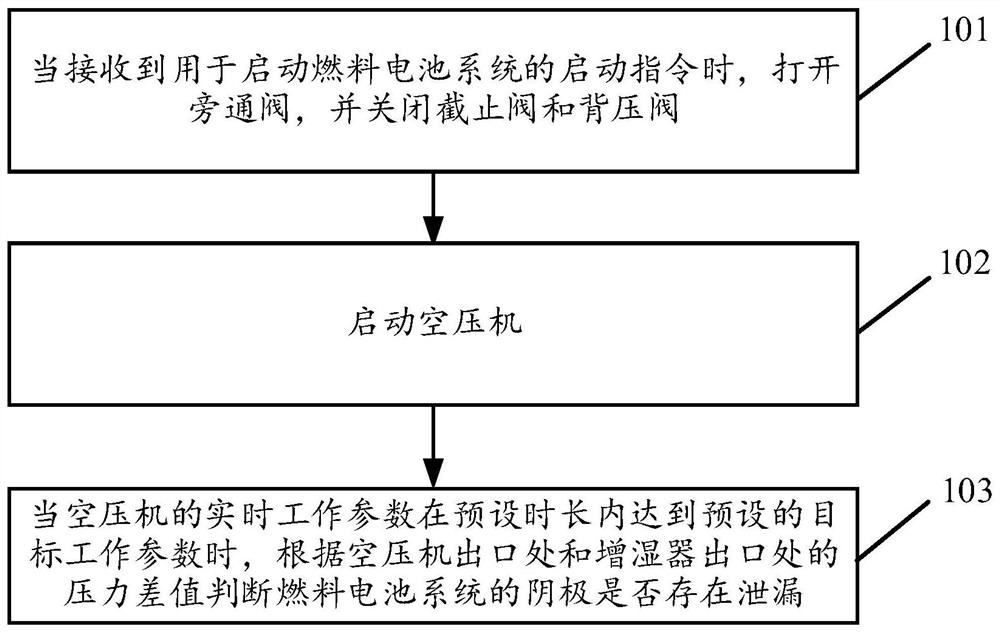

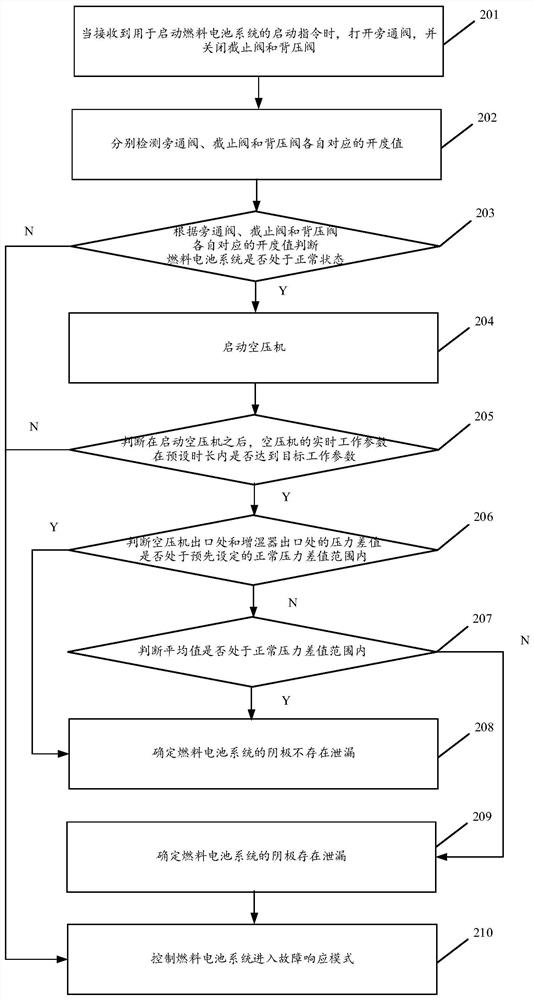

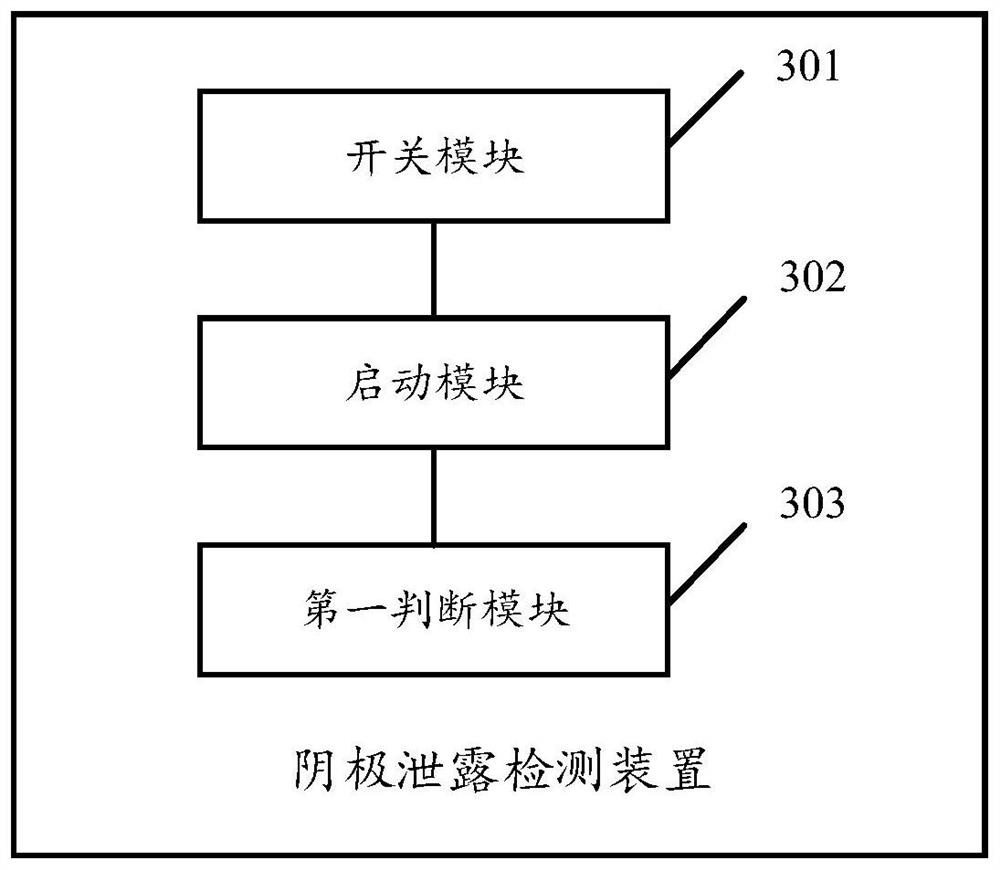

Cathode leakage detection method and device for fuel cell system

ActiveCN113690470AImproving Cathode Leak Detection EfficiencyEnable leak detectionFuel cellsFuel cellsAir compressor

The invention discloses a cathode leakage detection method and device for a fuel cell system. The method comprises the steps of opening a bypass valve when a starting instruction for starting the fuel cell system is received, and closing a stop valve and a back pressure valve; starting an air compressor; and when the real-time working parameters of the air compressor reach the preset target working parameters within the preset duration, judging whether leakage exists in the cathode of the fuel cell system or not according to the pressure difference value between an outlet of the air compressor and an outlet of a humidifier. By implementing the cathode leakage detection method of the fuel cell system provided by the invention, online leakage detection on the cathode of the fuel cell system can be realized, so that the cathode leakage detection efficiency of the fuel cell system can be improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com