Sealed cavity leak detection method based on spontaneously expanding gas

A sealed cavity, leak detection technology, applied in the field of leak detection, can solve the problems of difficulty in implementation, leak detection sensors and instruments cannot be deeply tested inside, and detection methods cannot be effectively carried out, etc., and achieves low corrosiveness and low environmental toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and examples.

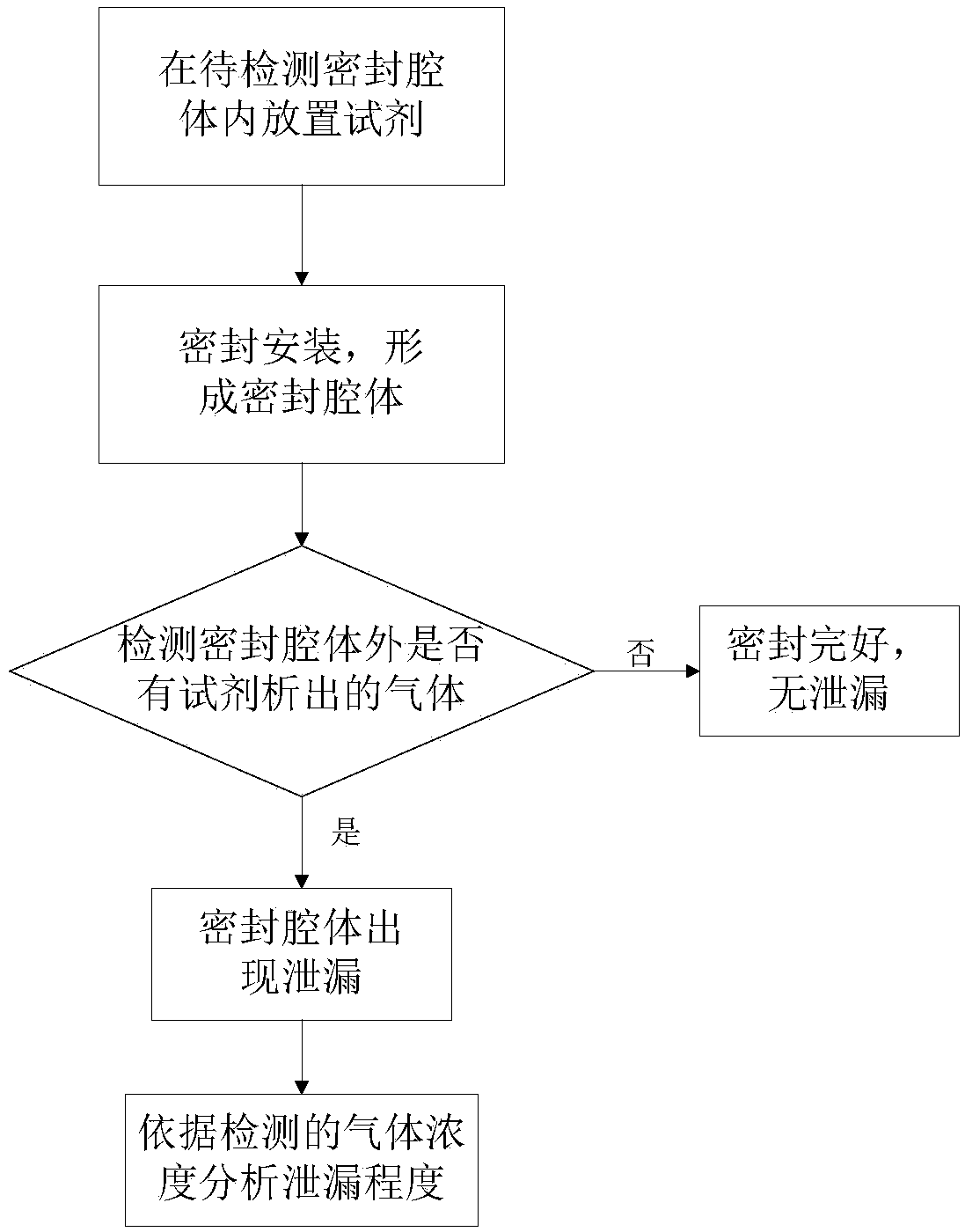

[0015] The key to this method is to select a solid substance that can generate expansion gas when heated or is volatile at normal temperature as a reagent, and place it in a sealed cavity that needs to be detected. The detection principle is as follows: when leak detection, heat the sealed chamber to an appropriate temperature, and gas will be precipitated in the reagent. Due to the micro pressure difference generated by the gas, there will be a tendency to overflow; when there is a leakage problem in the sealed chamber, it will be in the sealed The presence of this gas component was detected outside the cavity. Quantitative analysis of leakage can also be realized by detecting the concentration of leakage gas.

[0016] Alcohol and ammonium bicarbonate both have the above characteristics, but ammonia gas is corrosive, alcohol is less irritating, and is ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com