Cathode leakage detection method and device for fuel cell system

A fuel cell system and leak detection technology, which is applied in the computer field, can solve the problems of system efficiency impact, car flameout, and inability to detect leaks, and achieve the effect of improving the efficiency of cathode leak detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

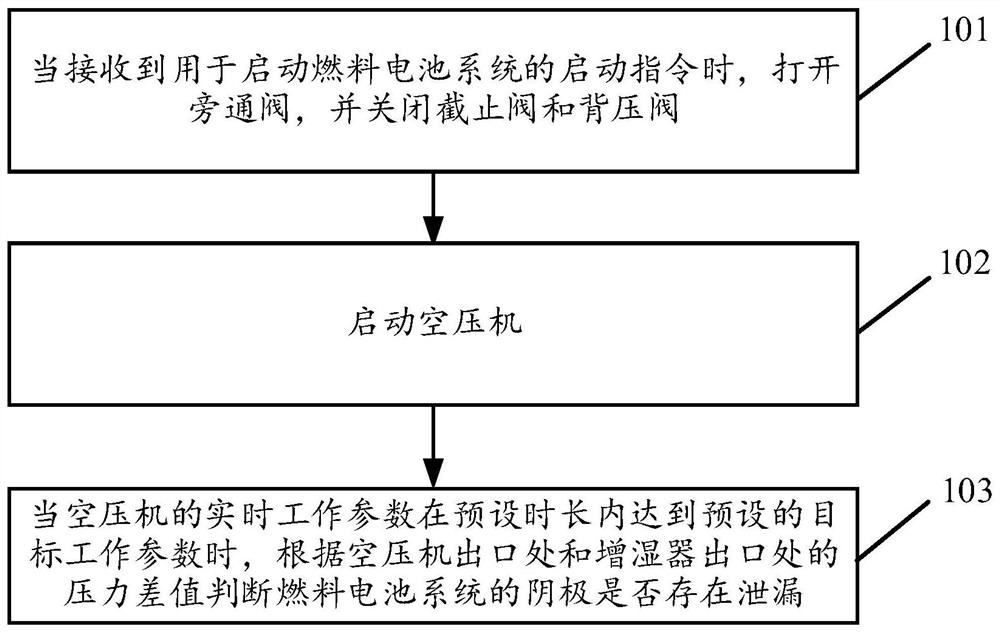

[0029] see figure 1 , figure 1 It is a schematic flowchart of a cathode leakage detection method for a fuel cell system disclosed in an embodiment of the present invention. in, figure 1 The described cathode leakage detection method for a fuel cell system can be applied to a controller of the fuel cell system. Such as figure 1 As shown, the cathode leakage detection method of the fuel cell system may include the following operations:

[0030] 101. Open the bypass valve, and close the shut-off valve and the back pressure valve when receiving a starting instruction for starting the fuel cell system.

[0031] In the above step 101, the starting command of the fuel cell system may be issued by the vehicle controller of the fuel cell vehicle, wherein the vehicle controller is used for overall control of the fuel cell vehicle. After the controller of the fuel cell system receives the startup command issued by the vehicle controller, the controller of the fuel cell system will c...

Embodiment 2

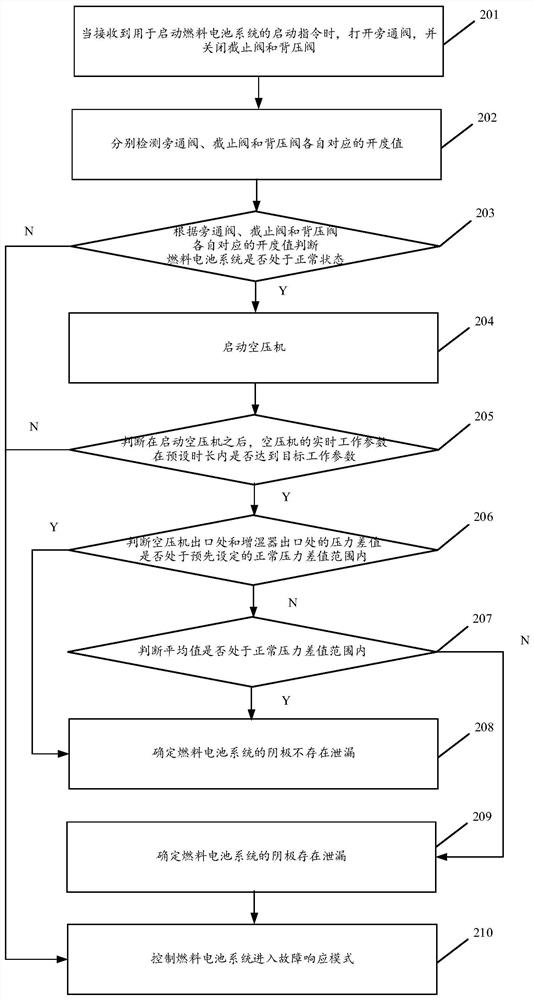

[0038] see figure 2 , figure 2 It is a schematic flowchart of another cathode leakage detection method for a fuel cell system disclosed in an embodiment of the present invention. in, figure 2 The described cathode leakage detection method for a fuel cell system can be applied to a controller of the fuel cell system. Such as figure 2As shown, the cathode leakage detection method of the fuel cell system may include the following operations:

[0039] 201. Open the bypass valve, and close the cut-off valve and the back pressure valve when receiving a starting instruction for starting the fuel cell system.

[0040] For the specific definition of step 201, reference may be made to the specific definition of step 101, which will not be repeated here.

[0041] 202. After opening the bypass valve and closing the cut-off valve and the back pressure valve, respectively detect the corresponding opening values of the bypass valve, the stop valve and the back pressure valve.

[...

Embodiment 3

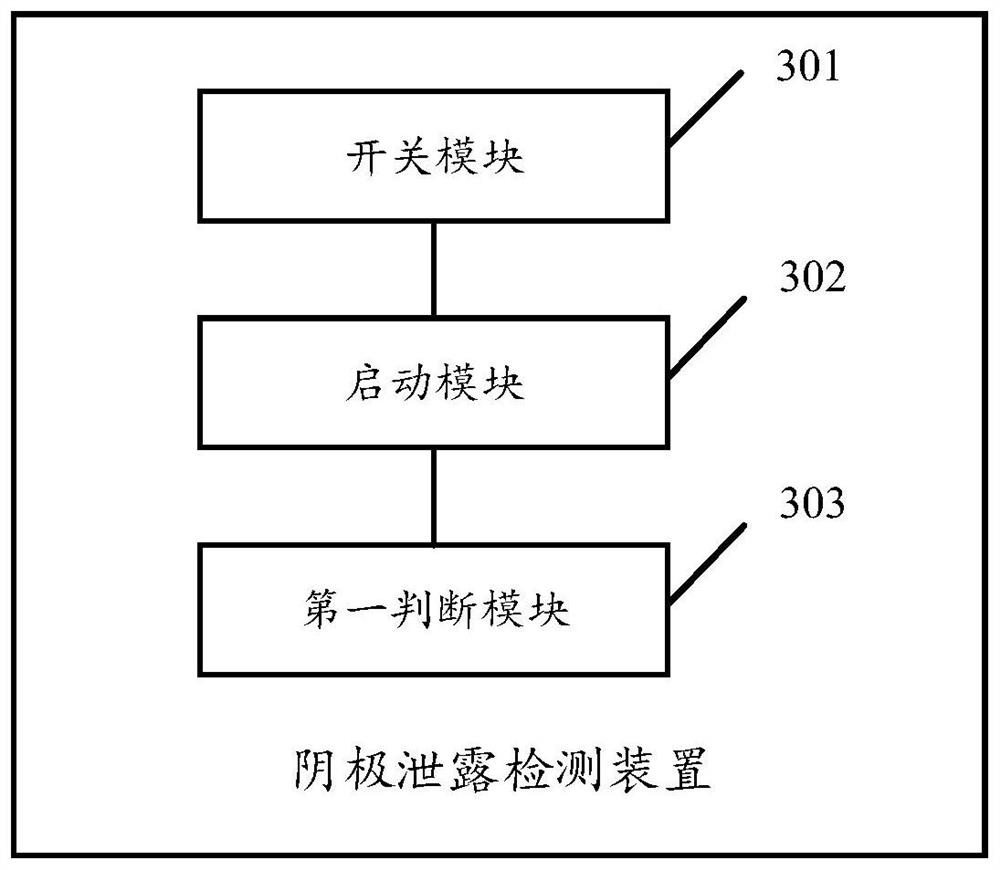

[0078] see image 3 , image 3 It is a schematic structural diagram of a cathode leakage detection device for a fuel cell system disclosed in an embodiment of the present invention. in, image 3 The described arrangement can be applied in a controller of a fuel cell system. Such as image 3 As shown, the cathode leakage detection device of the fuel cell system may include:

[0079] The switch module 301 is configured to open the bypass valve, and close the cut-off valve and the back pressure valve when receiving a starting instruction for starting the fuel cell system.

[0080] Further, after the switch module 301 opens the bypass valve and closes the stop valve and the back pressure valve, the start module 302 can be triggered to start.

[0081] The starting module 302 is used to start the air compressor.

[0082] Further, after the starting module 302 starts the air compressor, the first judging module 303 may be triggered to start.

[0083] The first judging module 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com