Deepwater process facility acoustic emission detection device

A technology of acoustic emission detection and acoustic emission sensor, which is applied in the measurement device, detects the appearance of fluid at the leakage point, tests the fluid tightness, etc., can solve the problems of difficult installation and fixation of the acoustic emission detection device, and achieves simple structure, Easy installation and maintenance, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

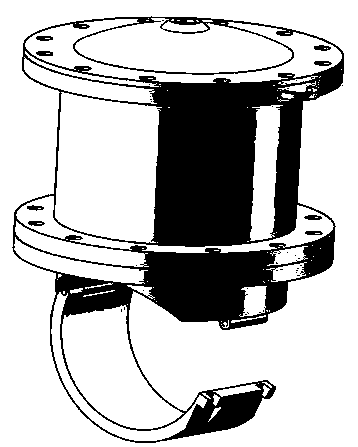

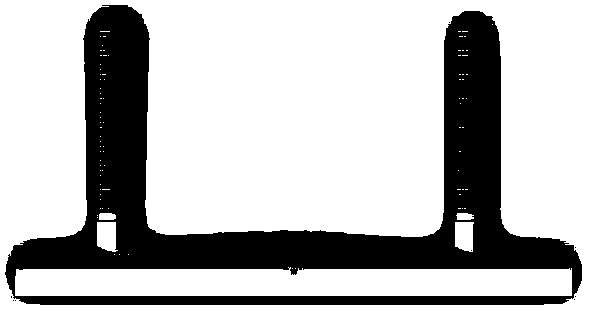

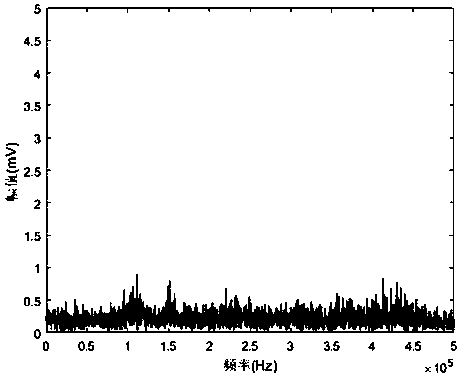

[0021] Such as figure 1 As shown, the device is composed of a spherical crown-shaped head 1, a lifting ring 2, a cylinder 3, an O-ring 4, a flat cover head 5, a clamp structure 6, an acoustic emission sensor 7, a signal processor 8 and a power source 9.

[0022] The external spherical crown-shaped head 1 and the cylinder body 3 of the device and the flat-cap head 5 and the cylinder body 3 are tightly connected by flanges. Double sealing rings are used between the spherical crown-shaped head 1 and the cylinder body 3 Radial seal, double seal ring is used between flat cover head 5 and cylinder 3, radial seal and axial seal are combined, this sealing method is simple and reliable; spherical cap head 1 and cylinder 3 adopt stronger High, lighter and cost-effective aluminum alloy 7050 material reduces its volume, weight and cost; flat cover head 5 uses 45# steel with good guided wave performance and higher strength, thereby reducing stress wave transmission loss , In order to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com