Fuel double-wall pipe leakage detection device and detection method

A leak detection device, double-walled pipe technology, which is used in measuring devices, fluid tightness testing, and machine/structural component testing, etc. Large and other problems, to achieve the effect of convenient operation, simplified structure, and reduced space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

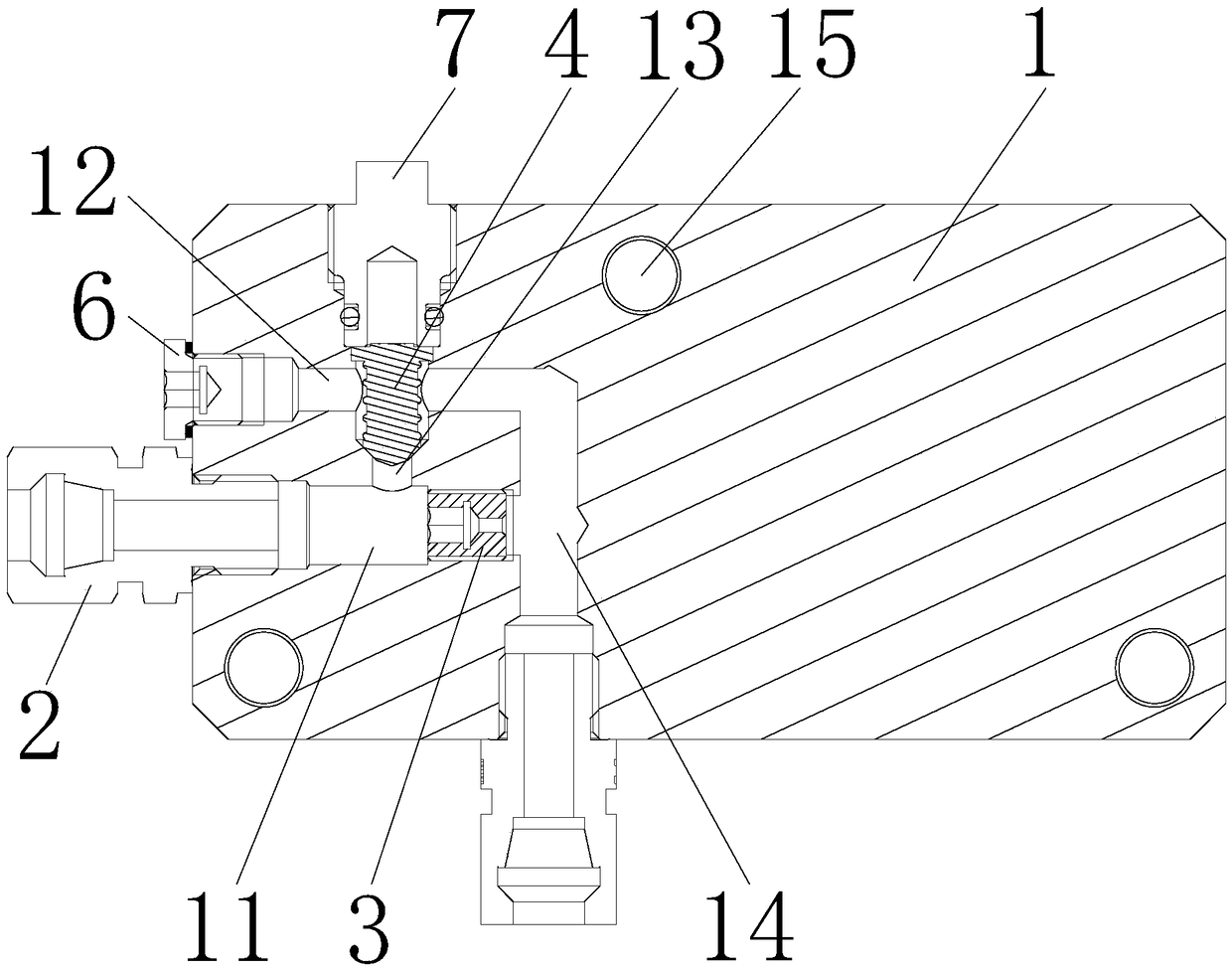

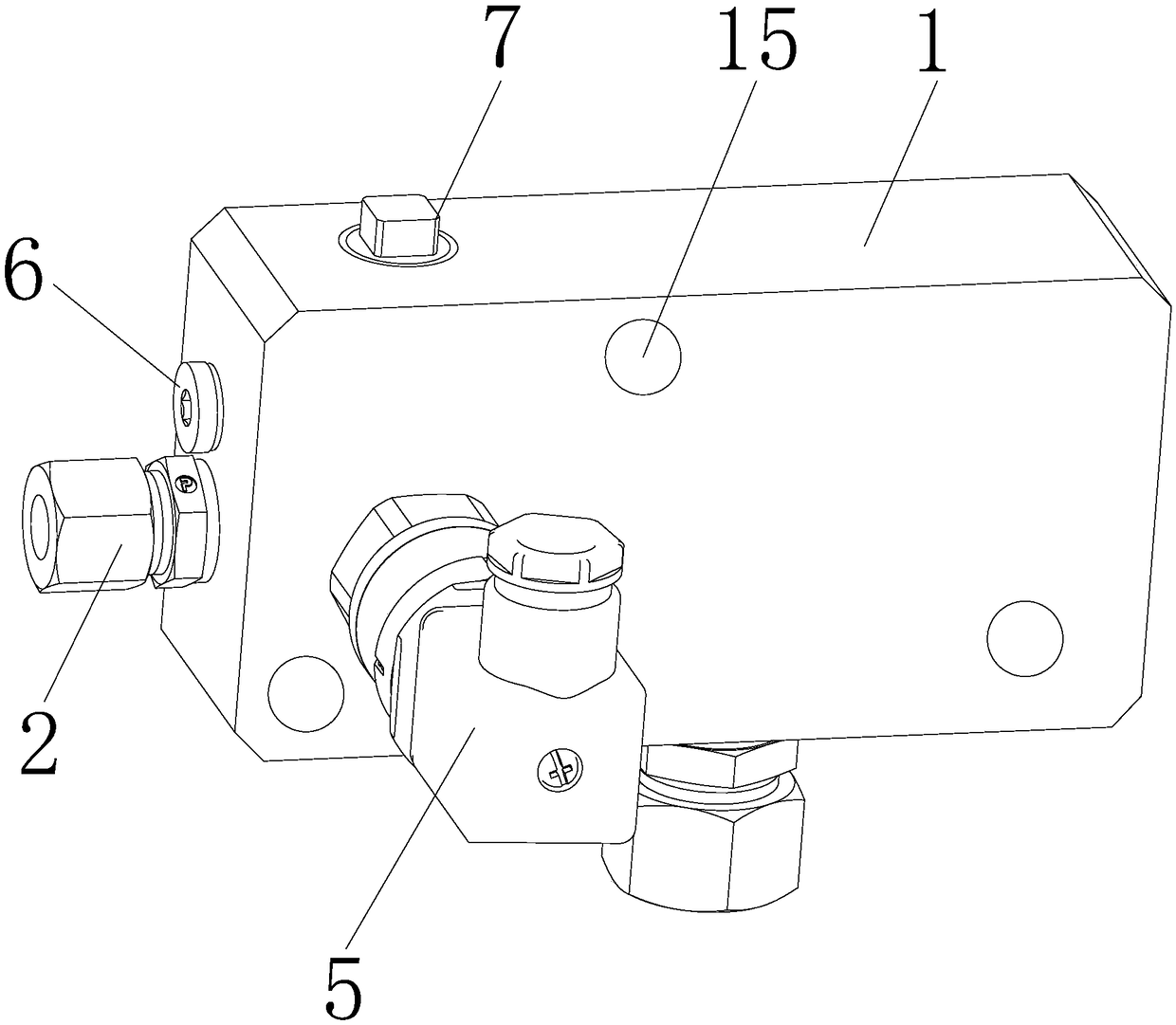

[0024] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0025] refer to Figure 1 to Figure 2 , this embodiment discloses a fuel oil double-wall pipe leakage detection device, which includes an integrated block 1, the integrated block 1 is in the shape of a cuboid, and the left end surface of the integrated block 1 is horizontally provided with an oil inlet hole 11, and the oil inlet The upper end of the hole 11 is provided with a first process hole 12 in parallel, the upper end surface of the integrated block 1 is vertically provided with a second process hole 13, and the lower end surface is vertically provided with an oil outlet hole 14, and the oil outlet hole 14 and the second Process 13 holes communicate with the first process hole 12 and the oil inlet hole 11 respectively, the oil inlet h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com