Novel online scanning ultrasonic gas leak detection system

An ultrasonic and scanning technology, applied in the field of new online scanning ultrasonic gas leak detection system, can solve the problems of inability to locate the leak source, unguaranteed measurement accuracy, and leakage calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For ease of understanding, the following explanations are given to some nouns that appear in the specific embodiments of the present invention:

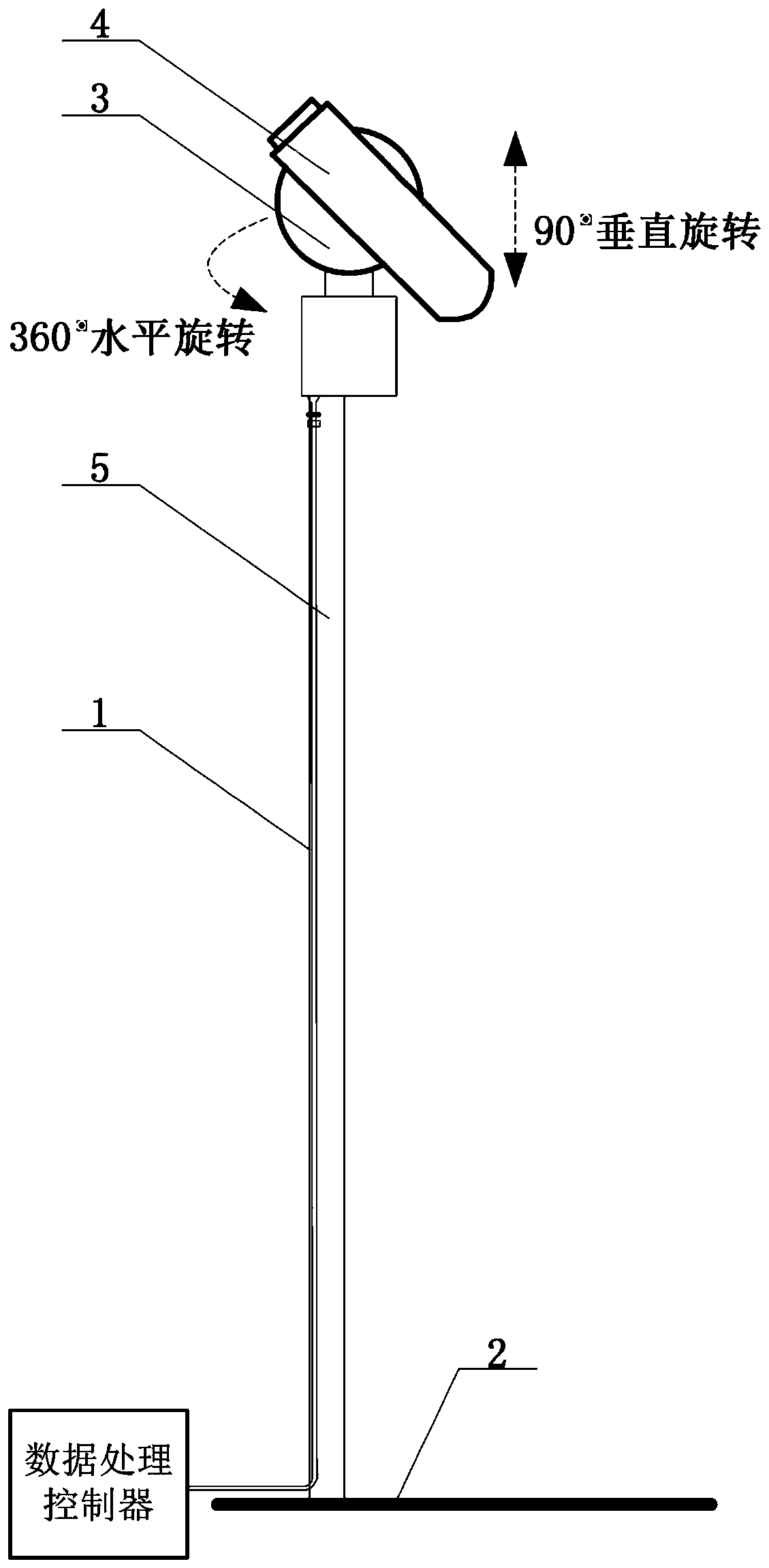

[0030] Horizontal scanning: After setting the vertical ordinate and left and right limits, it can scan left and right, and the rotation angle is 360°;

[0031] Vertical scanning: set the horizontal abscissa, the upper and lower limits, and scan up and down, and the rotation angle is from downward 90° to upward 90°;

[0032] Mixed scan: First scan horizontally and then scan vertically.

[0033] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

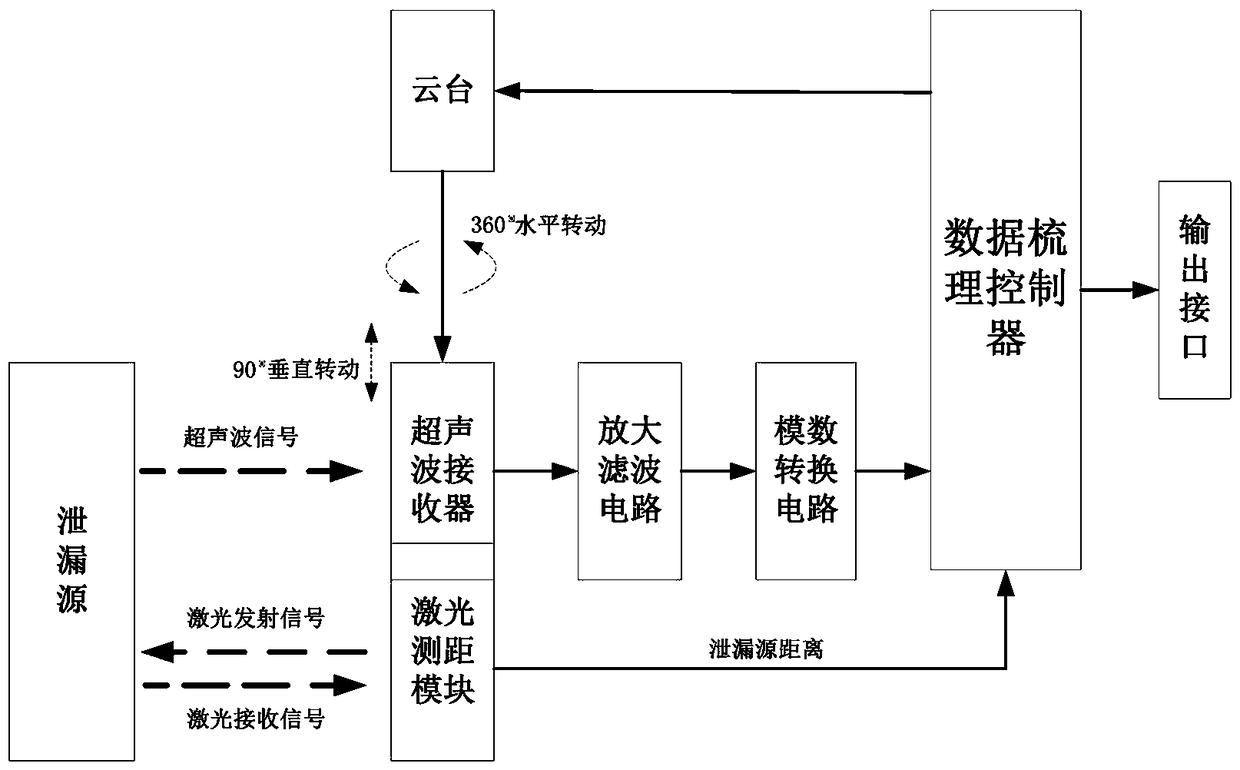

[0034] Such as figure 1 As shown, a new online scanning ultrasonic gas leak detection system includes a data processing controller, a cloud platform, an ultrasonic receiver and a laser ranging module installed on the cloud platform, the cloud platform, the ultrasonic receiver Both the device and the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com