Fluid conveying pipeline, preparation method thereof and leakage detection system

A technology for fluid transmission and pipeline leakage, applied in pipeline systems, pipeline protection, pipeline anti-corrosion/rust protection, etc., can solve problems such as inability to cover long distances, easy corrosion of pipelines, poor detection accuracy, etc., and reduce the time for laying costs , high precision, not easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

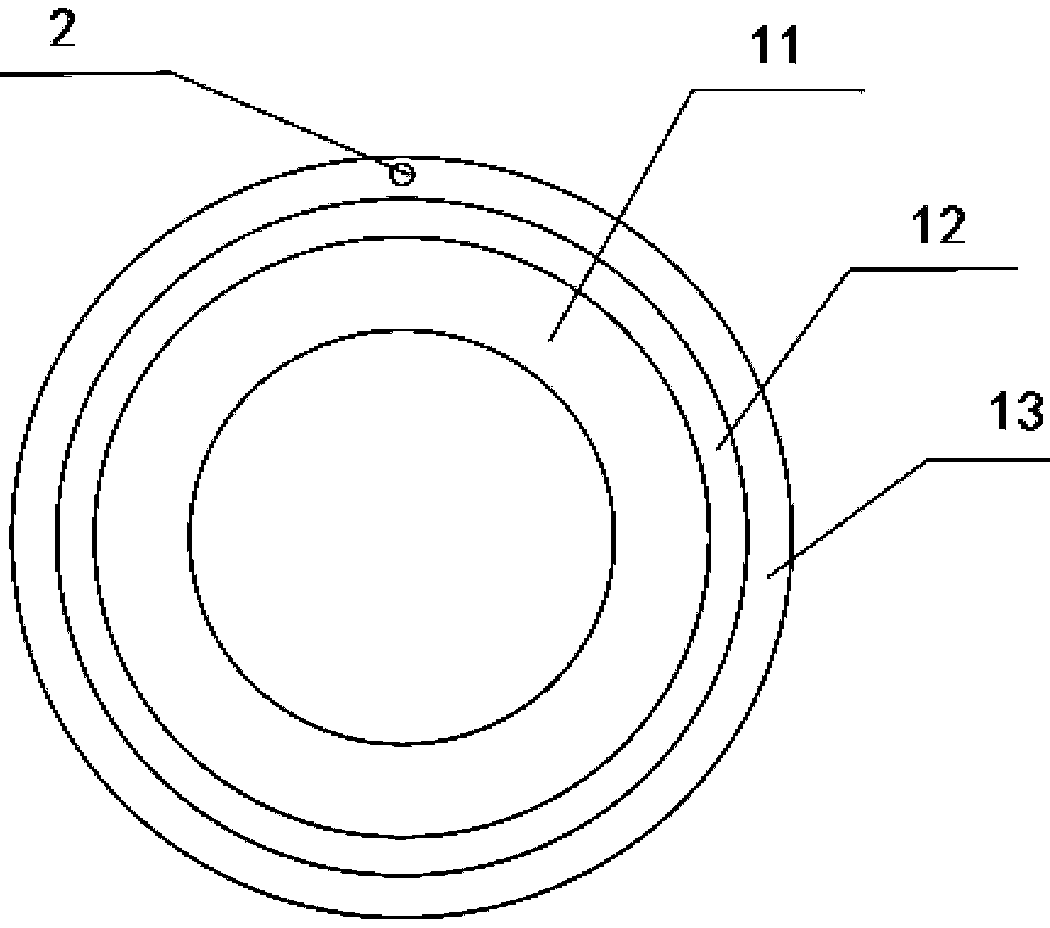

[0025] Such as figure 1 As shown, Embodiment 1 of the present invention provides a fluid transmission pipeline, which includes a non-metallic pipe body and an optical fiber sensor 2. The non-metallic pipe body includes an anti-corrosion inner pipe 11 and a protective outer pipe arranged in sequence from the inside to the outside. 13. The optical fiber sensor 2 includes an optical fiber 21 and a Faraday rotating mirror 22, the optical fiber 21 is connected to the Faraday rotating mirror 22, and the optical fiber 21 and the Faraday rotating mirror 22 are both embedded in the protective outer tube 13 .

[0026] In the embodiment of the present invention, the transmission pipeline is set as a non-metallic pipe body, which is not easy to corrode.

[0027] At the same time, the traditional form of laying the optical fiber 21 outside the pipeline is changed to implanting the optical fiber 21 into the protective outer layer inside the pipeline, which not only integrates the laying of non-m...

Embodiment 2

[0032] The optical fiber 21 of the patent and the Faraday rotating mirror 22 are both buried in the protective outer tube 13, which is achieved through the following steps:

[0033] Heat and shear and compress the thermoplastic raw materials to obtain viscous fluid raw materials;

[0034] Coating the viscous flow material on the anti-corrosion inner tube 11, and pull the optical fiber 21 and the Faraday rotating mirror 22 into the viscous flow material along the length direction of the anti-corrosion inner tube 11;

[0035] After the viscous fluid raw material is cooled, the non-metallic tube body in which the optical fiber 21 and the Faraday rotating mirror 22 are embedded is formed.

[0036] The process of embedding the optical fiber 21 in the protective outer tube 13 is: putting the thermoplastic raw material into a plastic extruder, heating and shearing and compressing the raw material to obtain the viscous fluid state raw material, the viscous fluid state is obtained through the p...

Embodiment 3

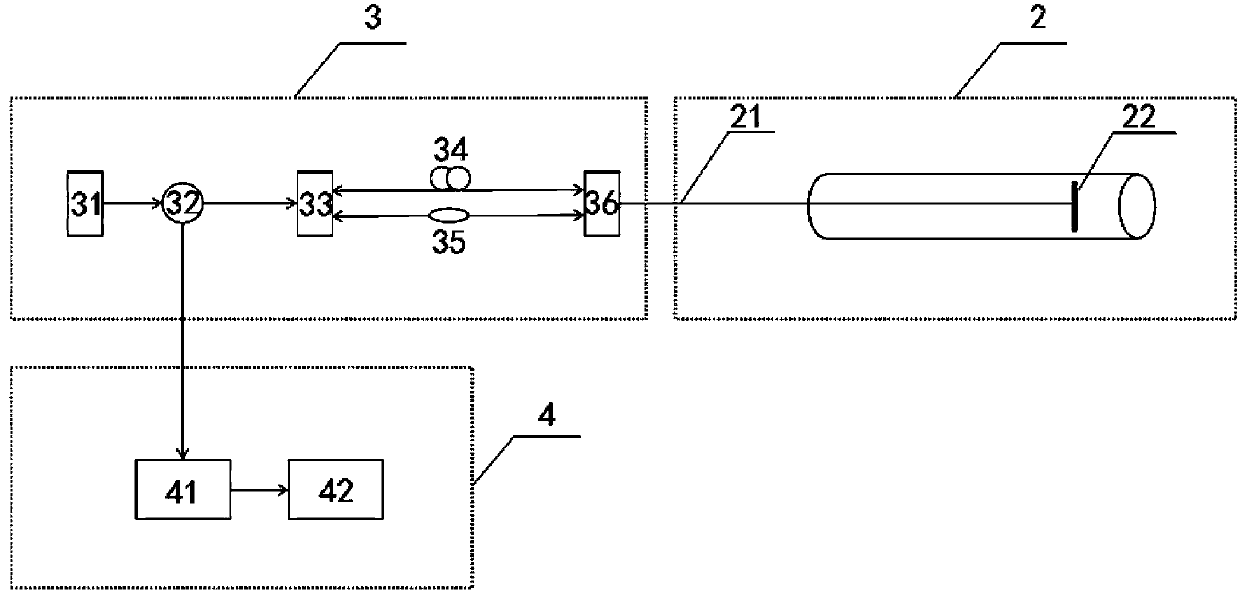

[0038] Such as figure 2 As shown, Embodiment 2 of the present invention provides a fluid transmission pipeline leakage detection system, which includes the fluid transmission pipeline provided in the above embodiments, and further includes a demodulator 3 and a signal processing terminal 4.

[0039] The demodulator 3 is connected to the optical fiber 21 and used to transmit optical signals to the optical fiber 21 and the Faraday rotator mirror 22. The optical fiber 21 and the Faraday rotator mirror 22 form an interferometer, and the demodulator 3 It is also used to receive the reflected light signal returned through the optical fiber 21 and the Faraday rotating mirror 22, the signal processing terminal 4 is connected to the demodulator 3, and the signal processing terminal 4 is used to receive the reflected light signal, And according to the reflected light signal, it is judged whether the fluid transmission pipeline leaks.

[0040] The leak detection system provided in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com