Leakage detecting device for non-excavation construction arc pipes

A leak detection device and leak detection technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of arc pipeline leakage and low efficiency, improve the clamping accuracy, avoid safety hazards, Improved stability and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

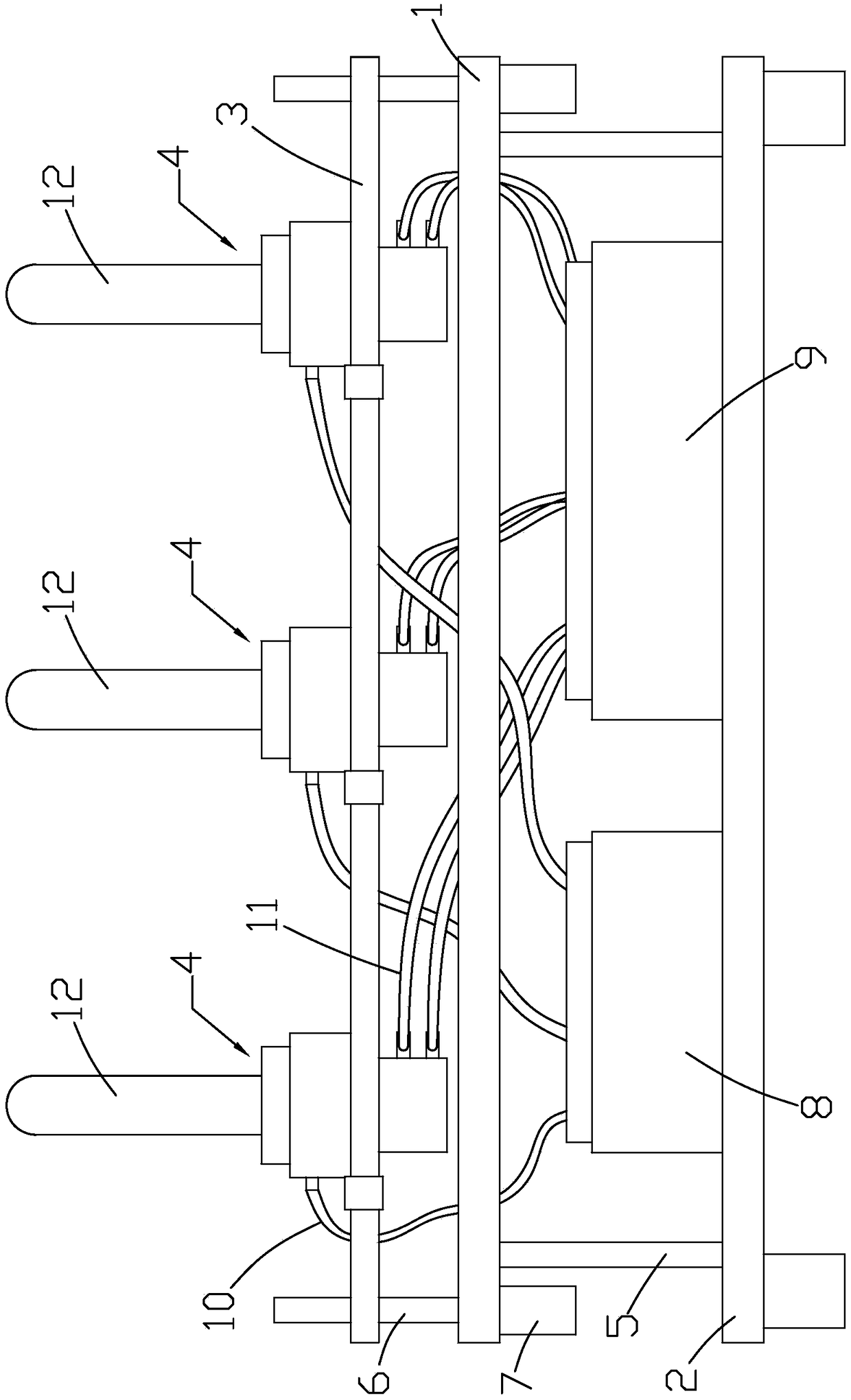

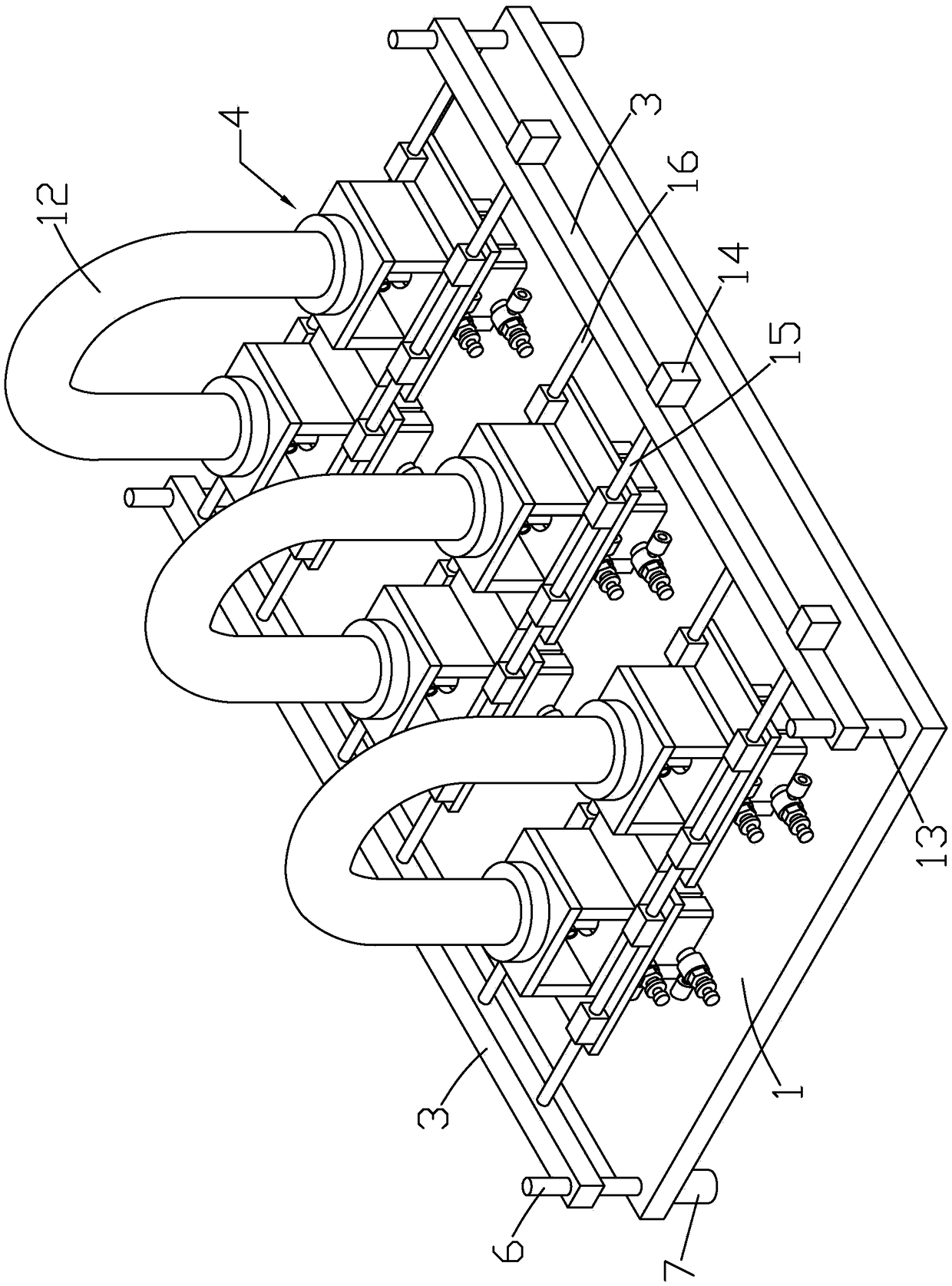

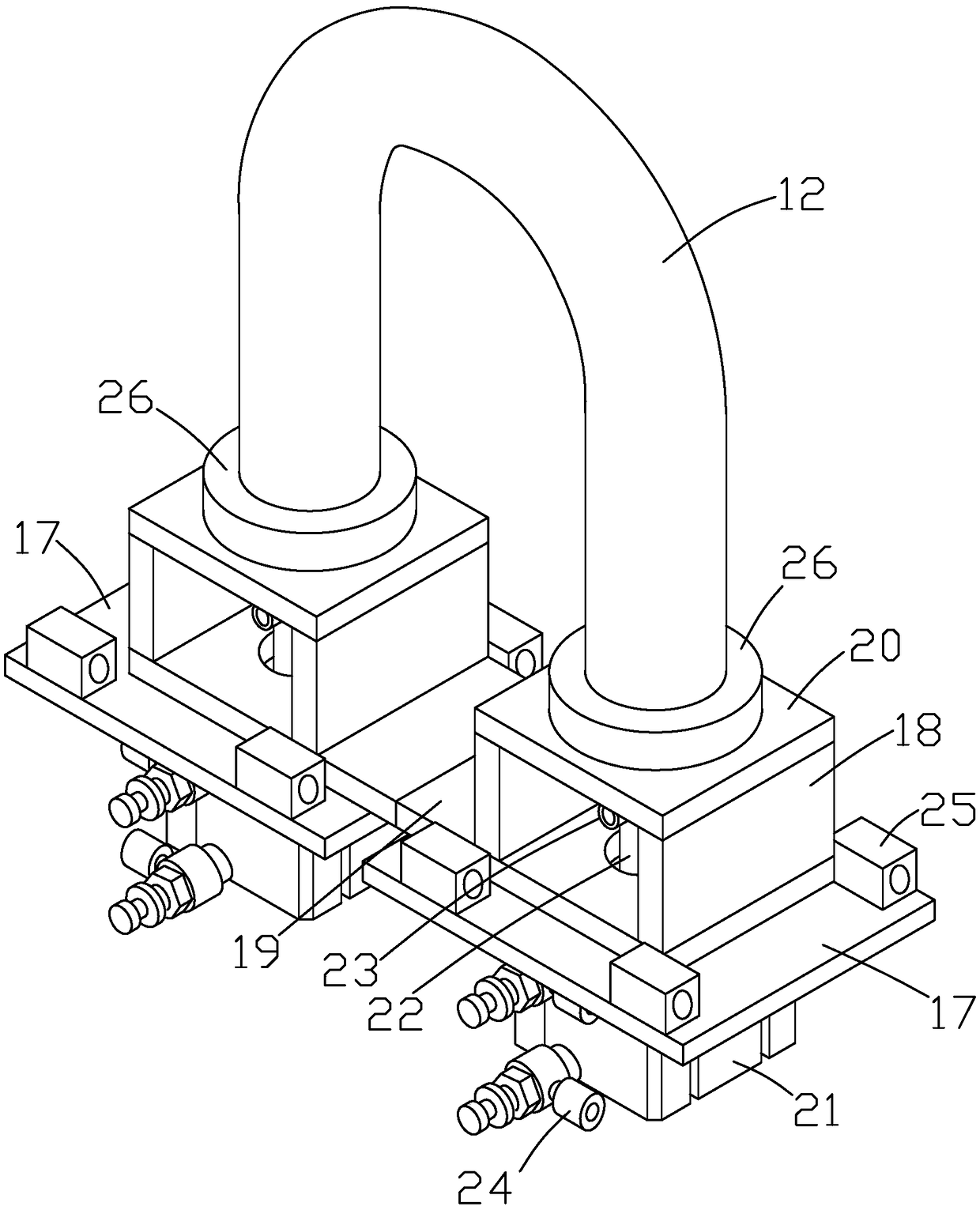

[0033] Such as Figure 1 to Figure 7 As shown, it is a leak detection device for a trenchless construction arc pipeline of the present invention, including a base plate 1, a base plate 2, a leak detection mechanism 4, a water storage tank 8 and a hydraulic oil tank 9, the base plate 1 is located above the base plate 2, and the base plate 2 The base plate 1 is fixedly connected to the base plate 1 through the first column 5. At least three leak detection mechanisms 4 are arranged at equal intervals above the base plate 1. The leak detection mechanism 4 includes two symmetrically arranged leak detection components. Above the detection assembly, the leakage detection assembly includes a horizontal moving plate 17, a hydraulic cylinder 21 and a clamping ring 26, the hydraulic cylinder 21 is fixedly connected to the bottom surface of the horizontal moving plate 17, and two oil delivery ports are arranged on the side of the hydraulic cylinder 21 24. A positioning plate 19 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com