One-button circuit breaker just close point precise positioning debugging device and using method

A technology of precise positioning and circuit breaker, applied in the direction of calibrating/finding protection devices, etc., can solve the problems of lowering production maintenance quality, lowering production efficiency, and measuring deviation of rigid point positioning, improving production quality and efficiency, and simple and convenient operation and use , the effect of avoiding data bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

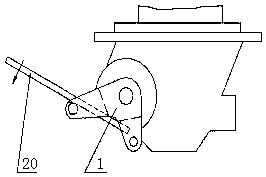

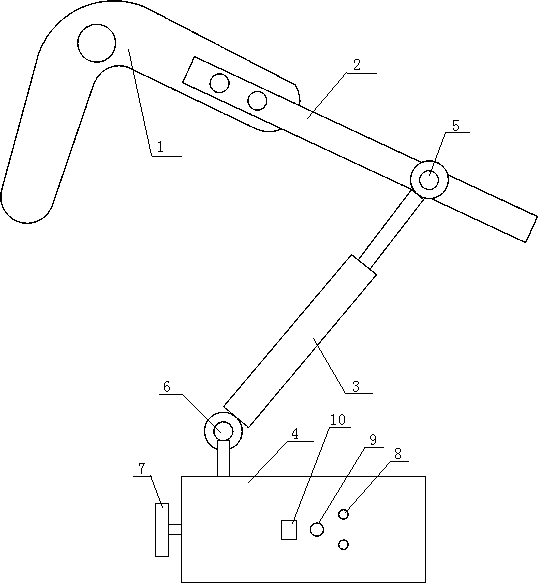

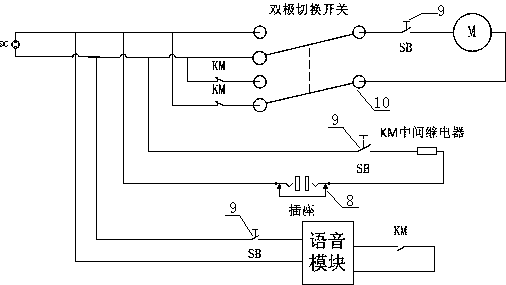

[0031] Such as figure 2 , image 3 As shown, the device of this embodiment includes: including: a fixed rod 2, a push rod 3, a motor and an intermediate relay; the fixed rod 2 is fixed to the transmission arm 1 of the circuit breaker through two pin shafts; It is connected by a universal joint bearing to more flexibly promote the rotation of the transmission crank arm 1; the push rod 3 and the fixed rod 2 are connected through the first universal joint bearing 5; the push rod 3 is connected to the The magnetic base 4, the circuit formed by the motor and the intermediate relay are arranged in the magnetic base 4.

[0032] In this embodiment, the length of the fixed rod 2 is designed to be 50 cm, and two holes are drilled at its front end. At the same time, the transmission crank arm 1 drills another hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com