Force amplifier capable of generating axial displacement and axial thrust through rotation

A technology of axial thrust and booster mechanism, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve problems such as complex structures, and achieve the effects of simple structure, stable output force and displacement, and convenient use

Pending Publication Date: 2022-05-31

山东力得汽车科技股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing wet brakes have a complex structure that converts small rotational torque shaft displacement into large axial thrust and axial position.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

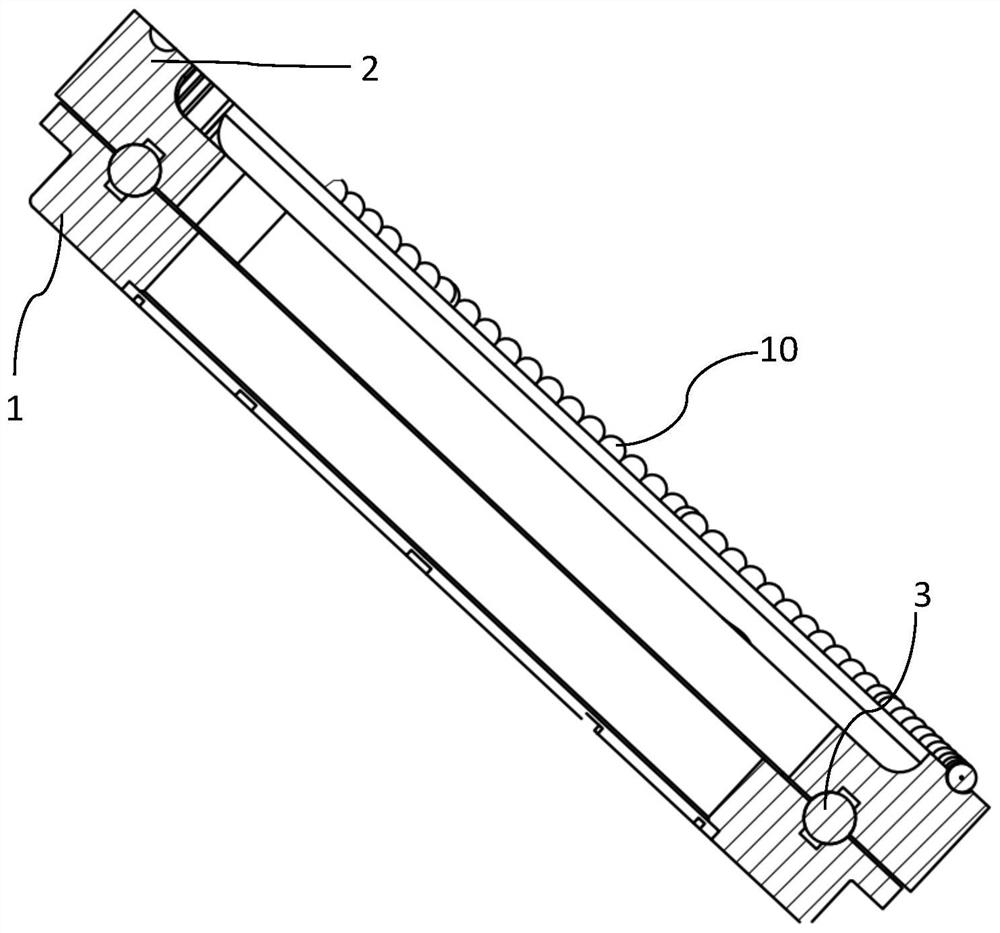

[0028] In the present embodiment, the outer edge of the piston 1 is provided with an outer circular table 7 for connecting the return spring.

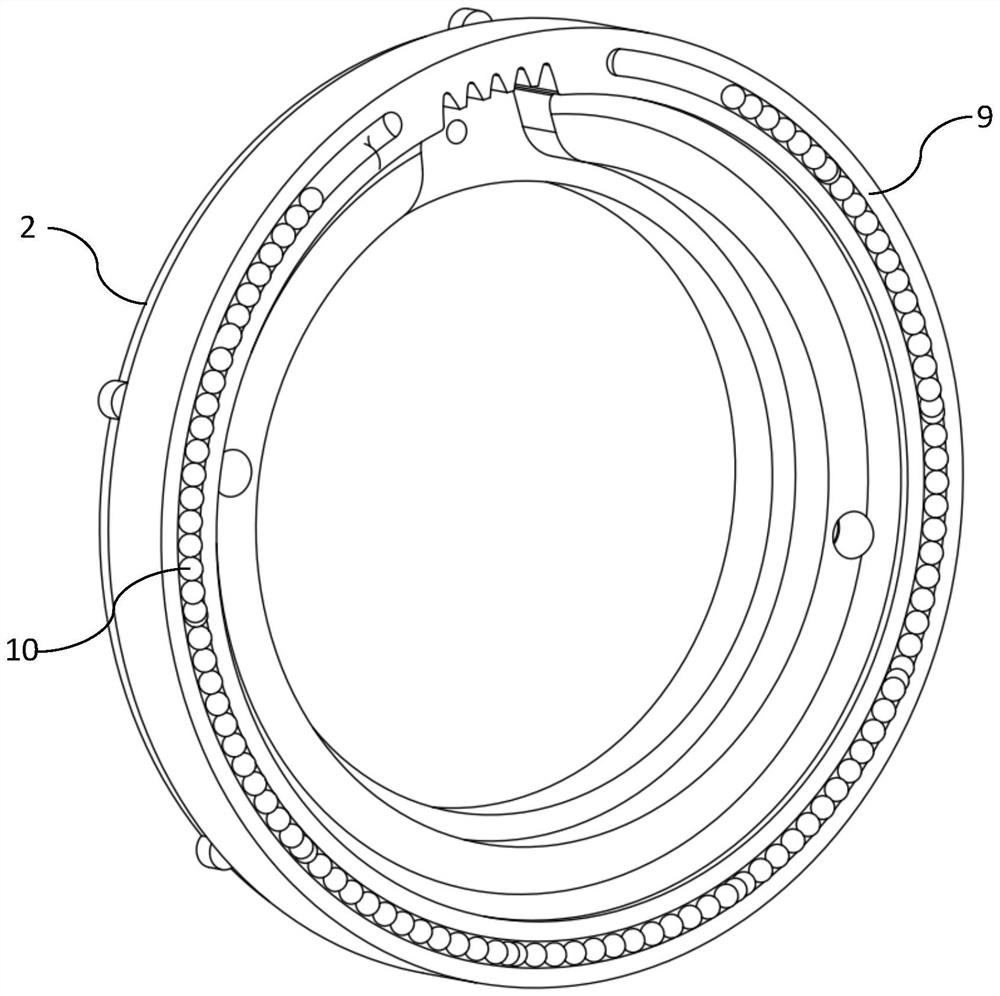

[0034] When the brake plate is stepped on, the air chamber device is triggered, and the adjusting arm gear is pushed by the air chamber push rod to make the gear shaft rotate,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

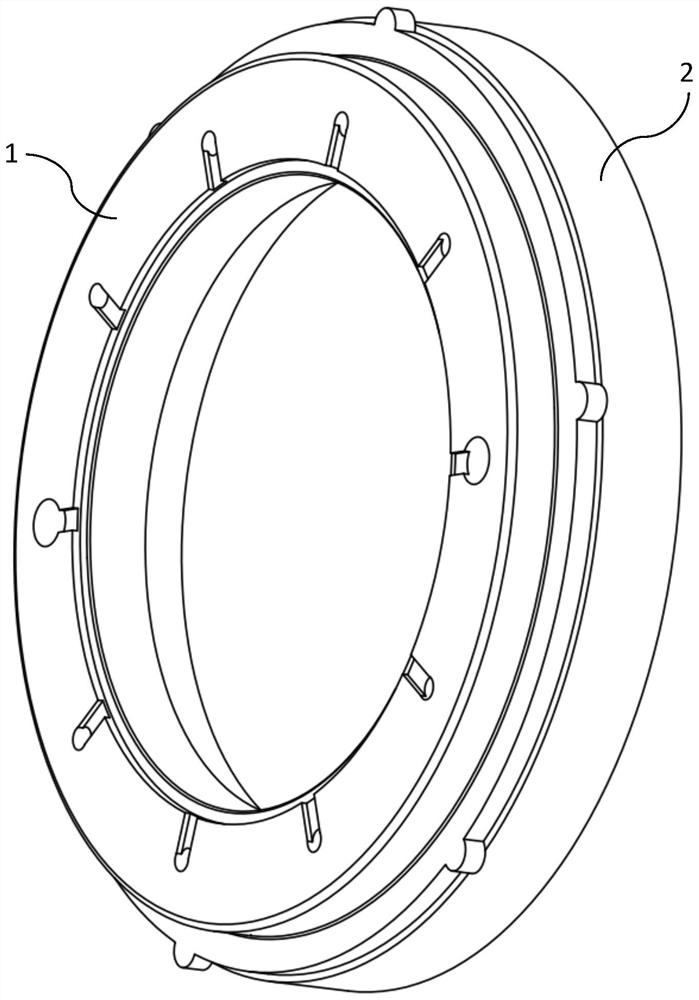

The invention discloses a force amplifying mechanism capable of generating axial displacement and axial thrust through rotation. The force amplifying mechanism comprises a piston and a gear ring, the piston and the gear ring are oppositely arranged, the top of the gear ring is close to the bottom of the piston, a plurality of spiral rising ball channels are annularly distributed between the piston and the gear ring, and steel balls are arranged in the spiral rising ball channels. According to the invention, small rotation torque can be converted into large axial thrust and axial displacement through the gear and the spiral ball groove structure, and the generated axial displacement and thrust can be adjusted.

Description

A booster mechanism that rotates to generate axial displacement and axial thrust technical field The invention belongs to the technical field of automobile braking, more specifically relate to a kind of rotation to produce axial displacement and axial displacement thrust booster. Background technique Most of the brakes on the market are traditional pneumatic drum brakes, and it is easy to enter foreign objects in a muddy environment and cause the braking effect. Poor or malfunctioning, it is also easy to damage the braking device, long-term braking will cause wear and tear, and the failure rate is high. Wet brake tightness It has strong anti-pollution ability and large structural rigidity, and is widely used. But existing wet brakes will have less turning force The moment shaft shift is transformed into a large thrust force and a complex structure in the axial position. Therefore, how to provide a booster mechanism that rotates to generate axial displacement and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16D65/14F16D121/04F16D125/06

CPCF16D2121/04F16D65/14F16D2125/06

Inventor 李路峰

Owner 山东力得汽车科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com