Spring compensator assembling and testing device and using method thereof

A technology of spring compensation and testing equipment, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve the problems of inconvenient operation, labor and time-consuming, etc., achieve convenient assembly and adjustment operation, improve stability and Accuracy, the effect of reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

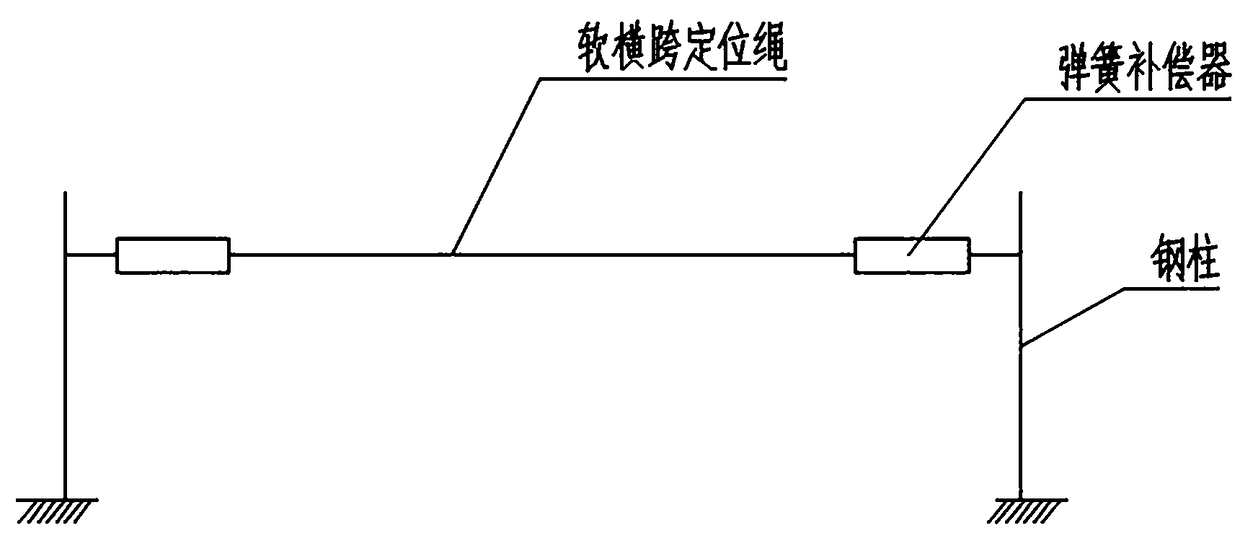

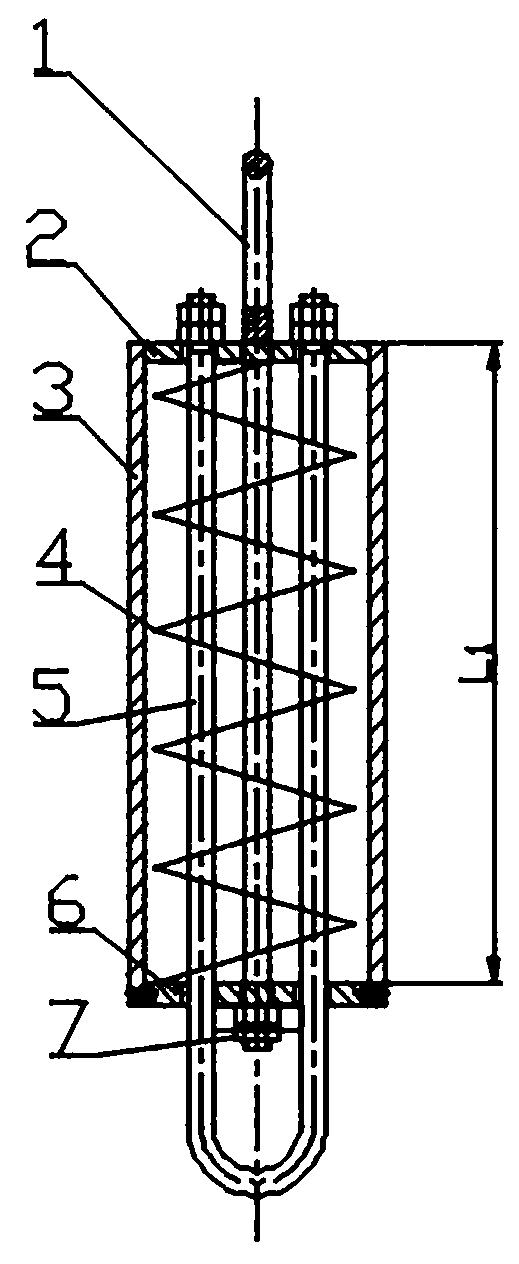

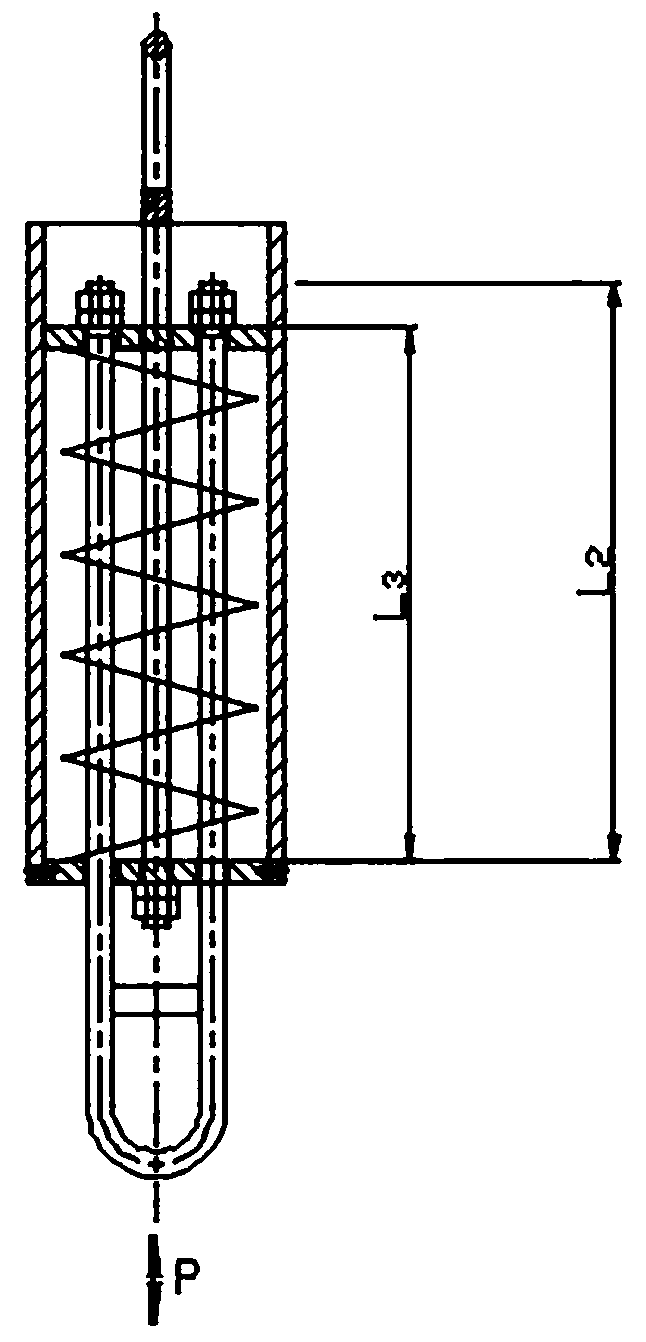

[0029] A spring compensator assembly test equipment, including a frame, a workbench 11, a guide rod 12, a compression rod 9, a pull rod connecting lever 10, a tension sensor and a spring compensator, the spring compensator includes an outer cylinder 3, a movable end cover 2. Fixed end cover 6, fixed pull rod 1, transfer pull rod 5, spring 4 and adjustment nut 7, the fixed end cover 6 is fixedly connected to the lower end of the outer cylinder 3, and the movable end cover 2 is movably connected to the upper end of the outer cylinder 3 to move A spring 4 is placed between the end cap 2 and the fixed end cap 6. The movable end cap 2 can slide up and down along the inner wall of the outer cylinder 3. The spring 4 is compressed or released by sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com