Synchronous excitation system used for thin shell high-order modal shape test and test method

A synchronous excitation, high-order mode technology, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve problems such as difference in output power of driving power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

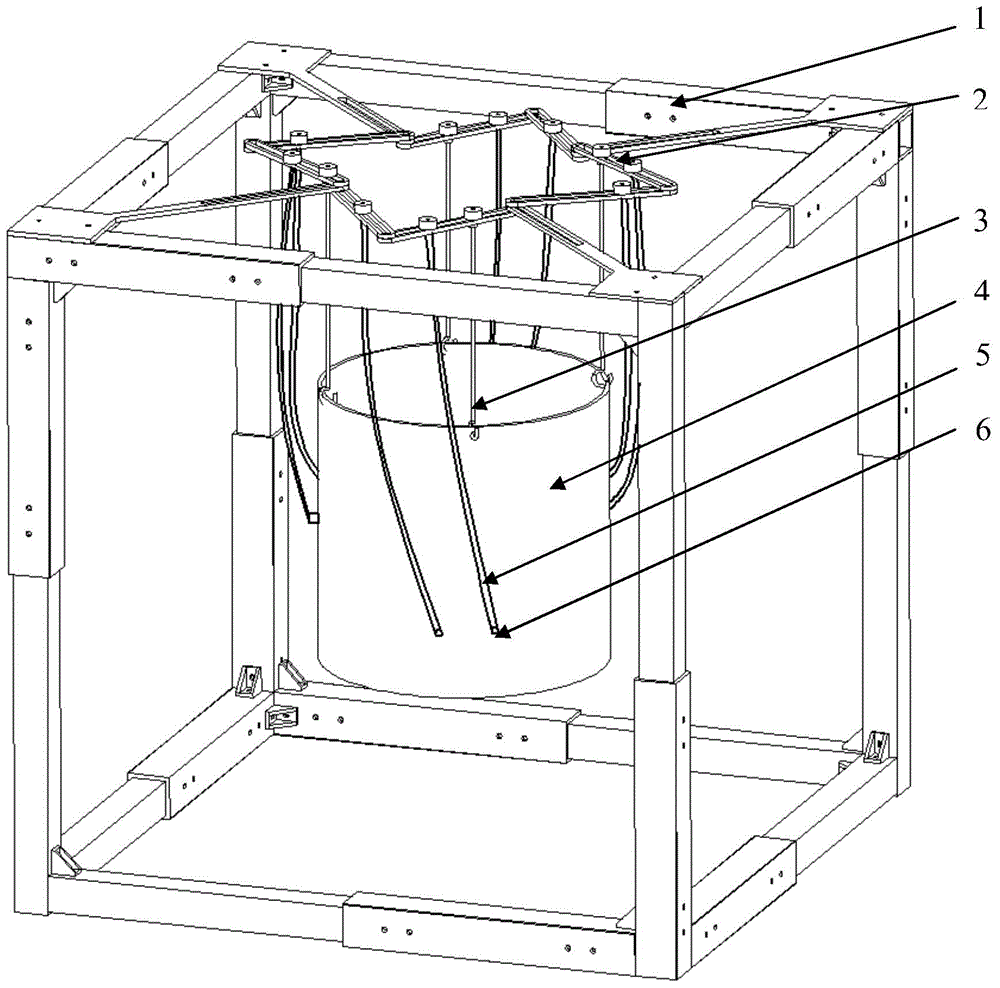

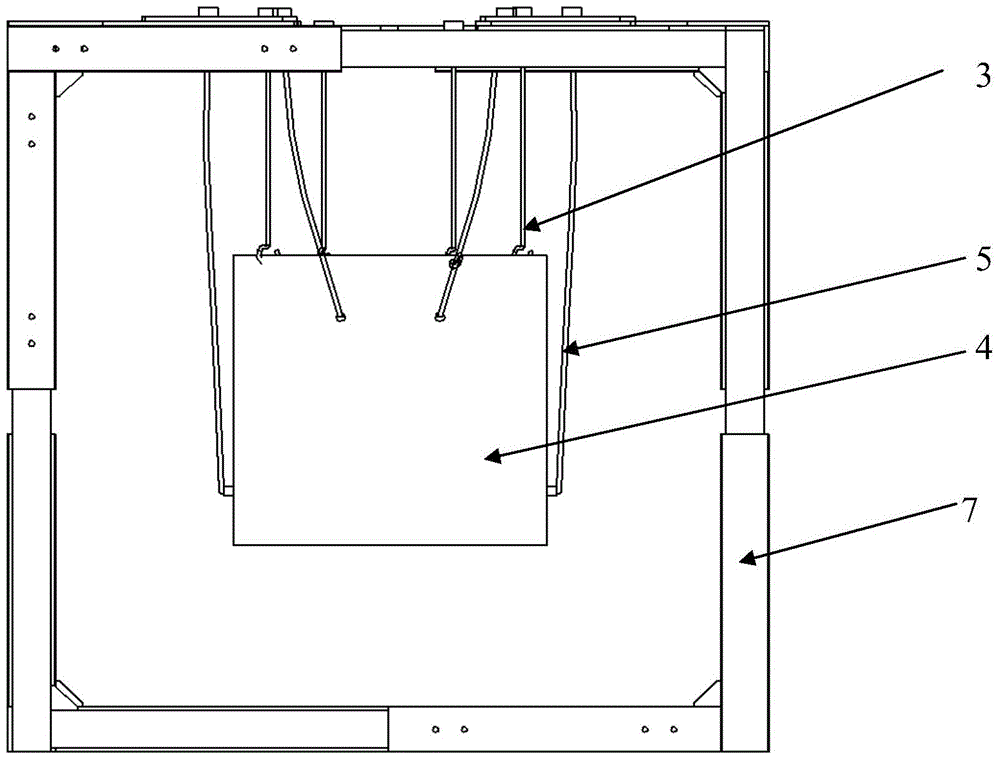

[0084] Specific embodiments of the present invention will be described in detail below.

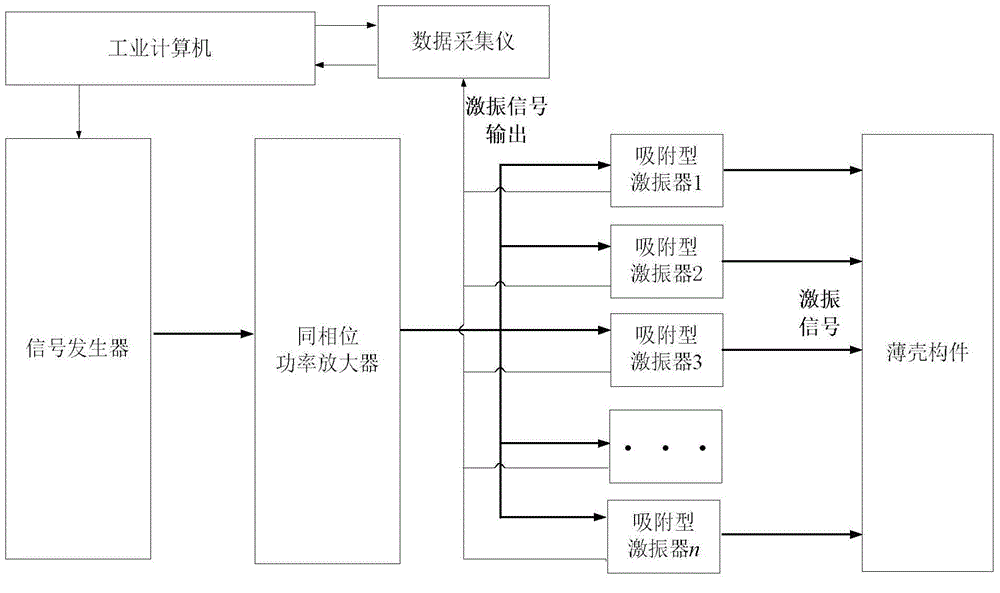

[0085] A synchronous excitation system for testing high-order mode shapes of thin shells, such as figure 1 shown, including:

[0086] An industrial computer that sends commands to generate vibration sources and obtains excitation signals in real time;

[0087] A signal generator that generates the corresponding vibration source signal according to the vibration source instruction of the industrial computer;

[0088] An in-phase power amplifier that converts the vibration source signal into an excitation signal with constant output frequency and phase and amplitude amplification;

[0089] Adsorption-type vibrators that use excitation signals to vibrate thin-shell components by means of adsorption;

[0090] A data acquisition instrument for collecting the excitation signal of the adsorption type vibrator;

[0091] The output end of the industrial computer is connected to the input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com