Concentric double-layer sprayer

A nozzle and double-layer technology, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of large number of nozzles, heavy maintenance workload, insufficient water curtain coverage, etc., and achieve compact structure of nozzles, good spray formation, and good spray effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

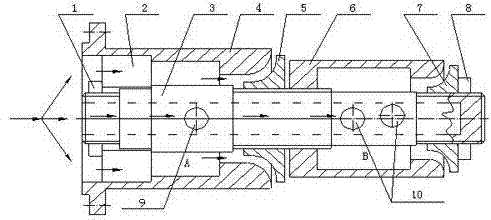

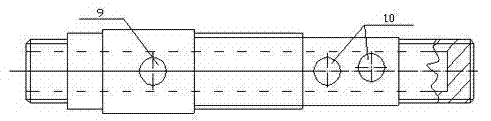

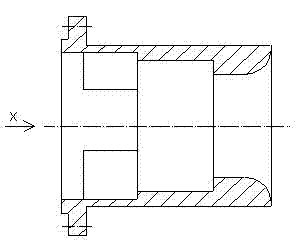

[0023] Such as Figure 1~4 As shown in the figure, a concentric double-layer nozzle adopts a series structure of double nozzles, double nozzles, and a single core rod, and is in the shape of a hollow sleeve. One end of the nozzle is a medium inlet, and the other end is sealed. The nozzles are ring-shaped slits arranged along the circumference of the nozzle; two stages of nozzles (that is, Class A nozzles and Class B nozzles) are arranged on the side wall of the nozzle along the length direction. The nozzle is in the shape of a two-stage stepped sleeve, and its outer diameter decreases along the direction of medium inflow. The two-stage nozzles are respectively arranged at the ends of the two-stage stepped sleeves, that is, the A-stage nozzle is arranged on the first stage with a larger outer diameter. At the end of the sleeve, the B-level nozzle is arranged at the end of the second-stage stepped sleeve with a smaller outer diameter. A-level nozzles and B-level nozzles are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com