Cabin door latching mechanism

A technology for door latches and hatches, which is applied in building locks, building structures, construction, etc., can solve the problems of different forms, weights, costs, and reliability, difficult to meet actual needs, and complex structures, and achieve light weight, The effect of ingenious structure and simple latch mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Provided following embodiment in conjunction with accompanying drawing:

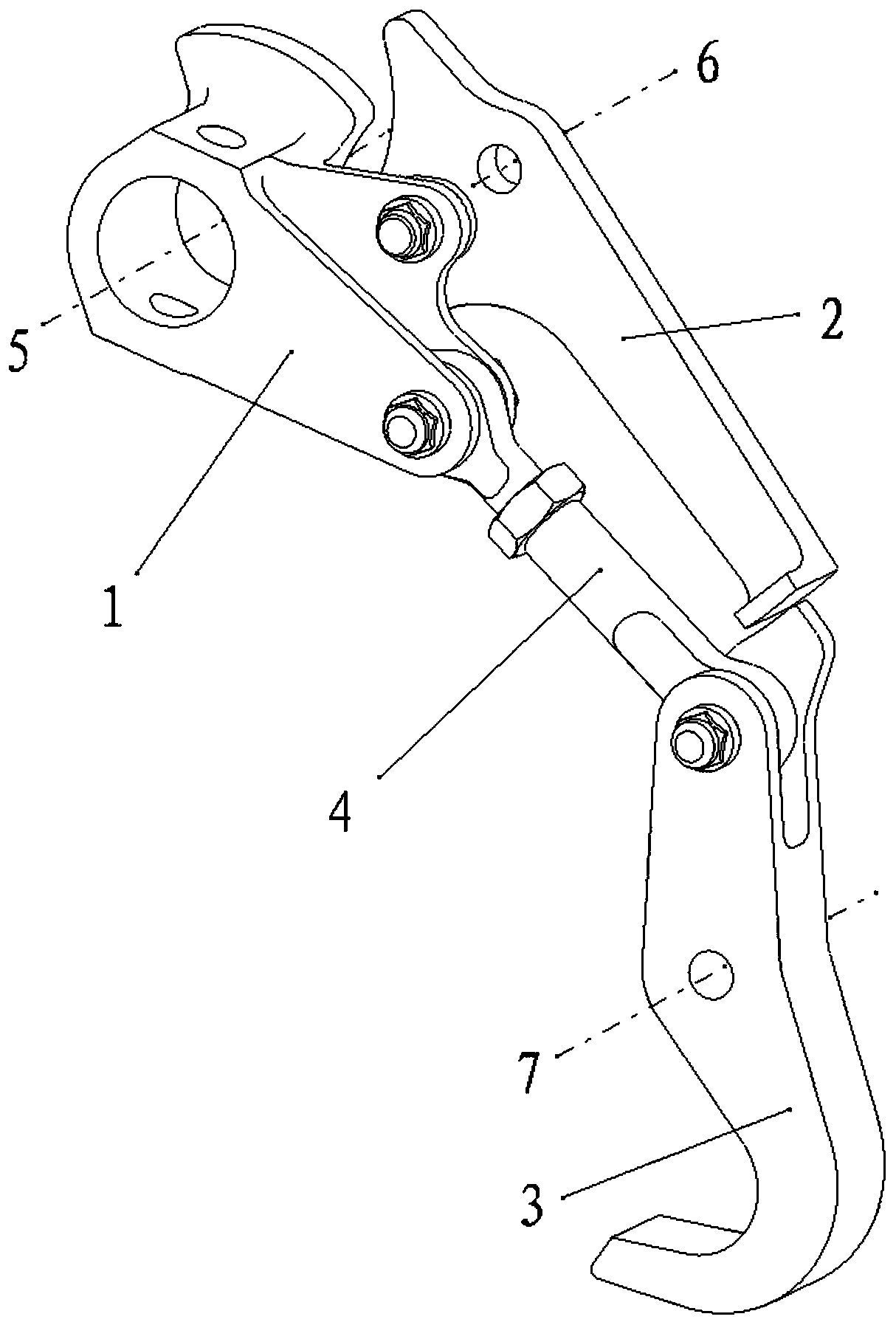

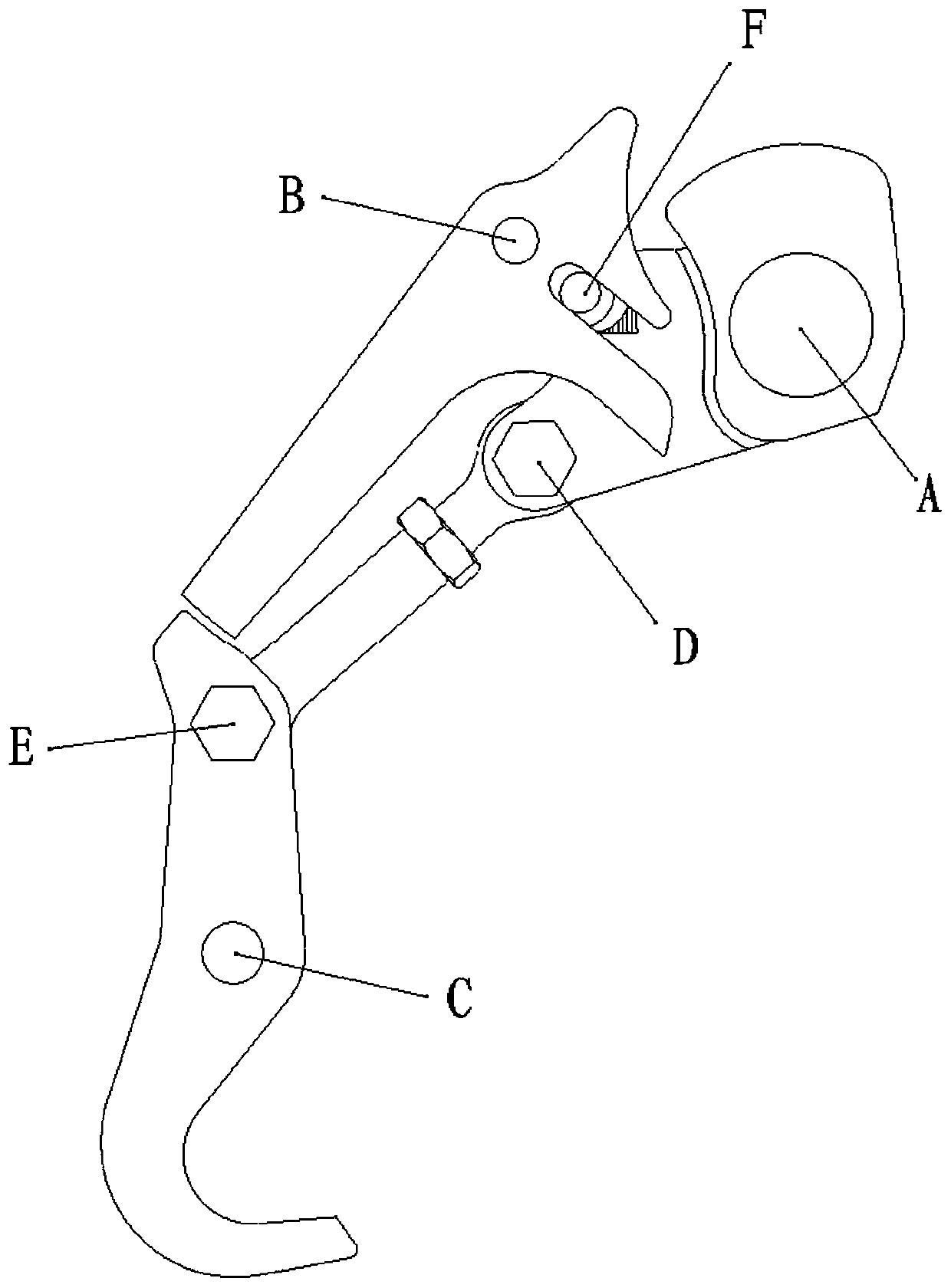

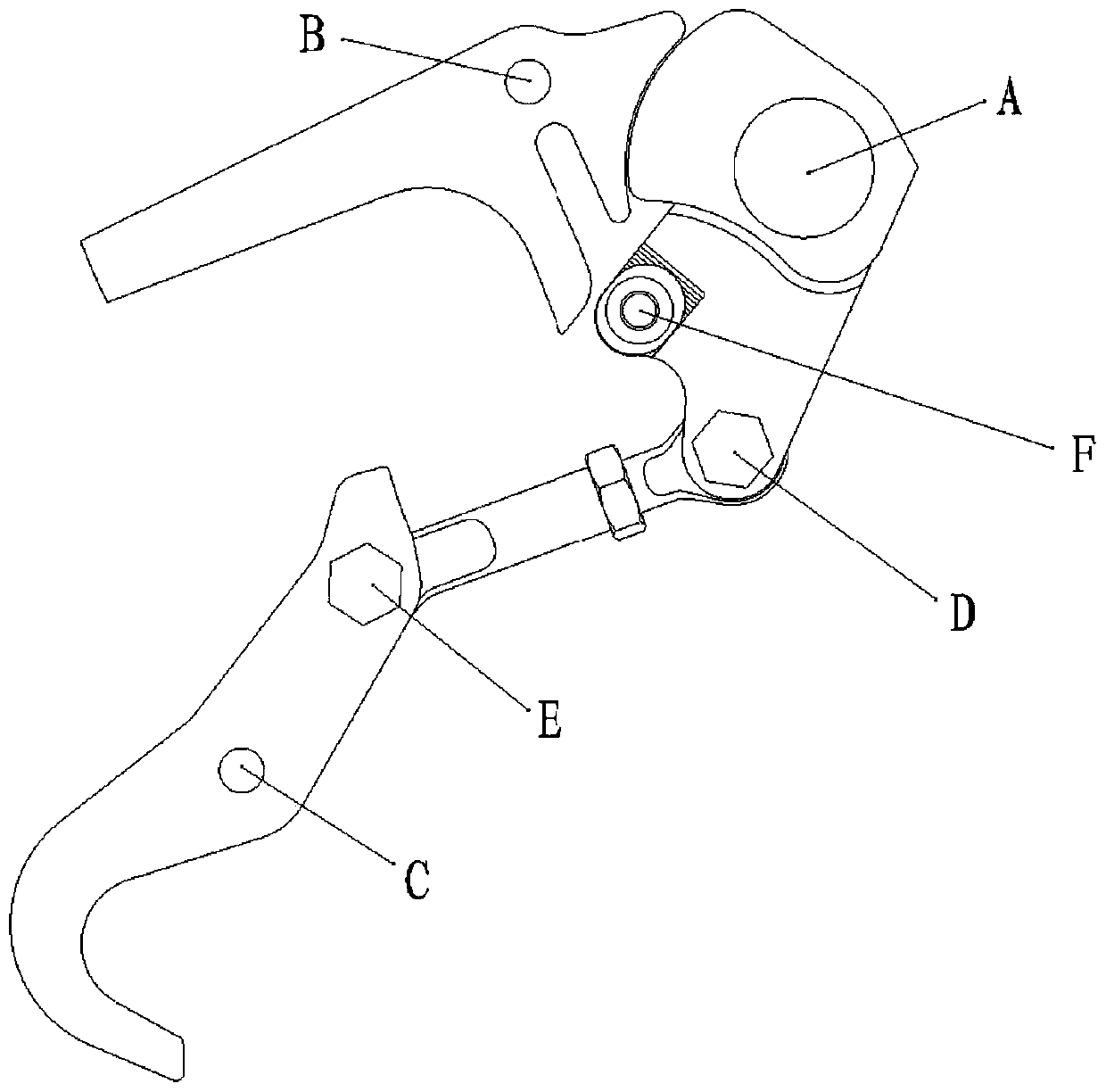

[0032] Please also see figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , the door latch mechanism of the present invention is located on the door frame and includes a rocker arm assembly 1 , a lock 2 , a bolt 3 and a connecting rod 4 . Among them, the rocker arm assembly 1 is connected with the driving source of the mechanism, the rocker arm assembly 1 rotates around the axis a5, the latch 3 can rotate around the axis b7, and the lock 2 can rotate around the axis c6, and the three axes are parallel to each other and distributed in a triangle.

[0033] see figure 1 , figure 2 , image 3 As shown, the rocker arm assembly 1 and the latch 3 are connected by a connecting rod 4, and the intersection point D of the rocker arm assembly 1 and the connecting rod 4 adopts an over-center design, that is, the intersection point D passes through the connecting line AE during the movement to reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com