High-precision full-angle multi-station steel tube drilling machine

A multi-station, all-angle technology, used in boring/drilling, drilling/drilling equipment, workpieces, etc., can solve the problem of unsatisfactory machining accuracy, inconvenient adjustment and positioning of drilling rigs, and no setting to avoid welding. Seams and other problems, to achieve the effect of high pressure, avoid overall quality damage, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

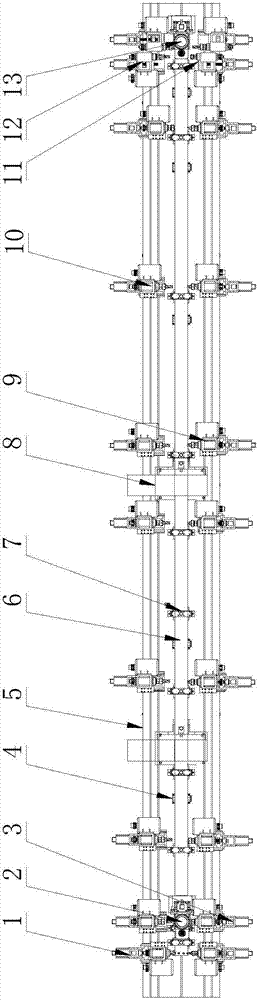

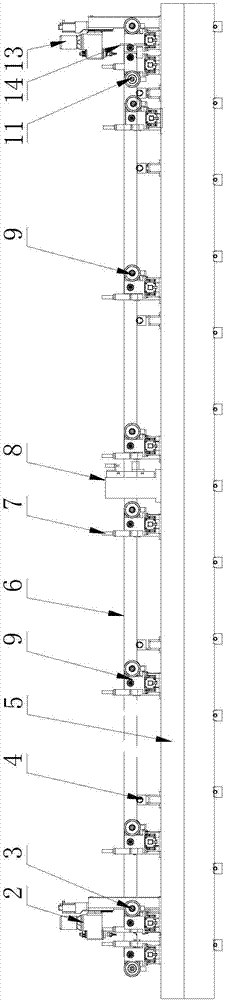

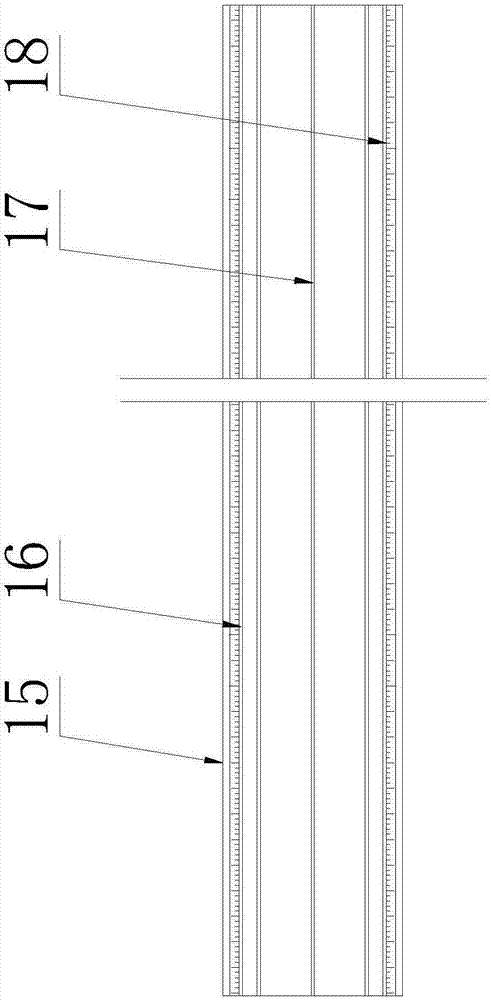

[0031] A high-precision full-angle multi-station steel pipe drilling machine is composed of a base 5, a transmission device 4, an indexing plate 8, a clamping device 7, a positioning baffle 14, a drilling tool, a control system, a lubrication system, and a cooling system. The indexing plate is set in the middle of the top surface of the base, the transmission device, the clamping device, and the drilling tool are set at intervals on the top surface of the base, the positioning baffle is set at the upper rear end of the base, and the control system is respectively connected with the indexing plate, the transmission device, and the clamp. The tightening device, positioning baffle, drilling tool control connection, lubrication system and cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com