Three freedom precision control apparatus based on eccentric structure

A technology of precision adjustment and eccentric structure, which is applied in the direction of manipulators, program-controlled manipulators, and manufacturing tools. It can solve problems such as gaps in kinematic pairs, mechanism crawling, and large space occupation. It achieves small motion resistance, easy assembly and adjustment, The effect of reducing motion pair clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

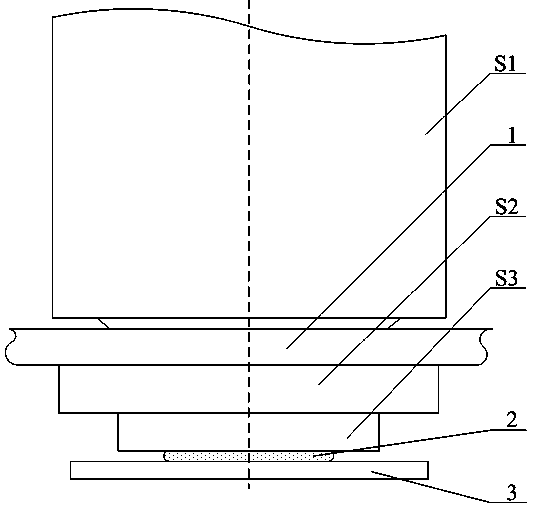

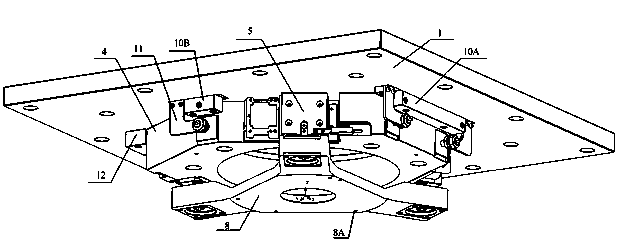

[0031] Such as figure 1 , figure 2 As shown, the present invention S2 is installed between the main board 1 and the immersion unit S3, the optical system S1 runs through the main board 1, the present invention S2 and the immersion unit S3, and exposes the lowermost silicon wafer 3 through the immersion flow field 2 . S2 of the present invention is installed on the main board 1 through the mounting hole 4A of the mounting base plate using mounting bolts 4C to adjust, locate and monitor the position of the mounting base plate 4, and the immersion unit S3 is installed on the lower end surface of the motion platform 8 through the immersion unit mounting hole 8A.

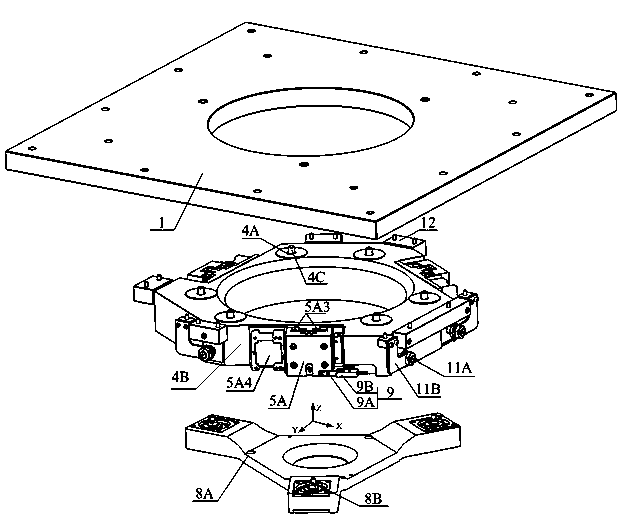

[0032] Such as figure 2 , image 3 As shown, the present invention S2 includes three preloading components 12, a positioning component 10, three horizontal displacement measurement component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com