Three-dimensional universal full-angle optical measurement platform for space optical remote sensor

A space optical remote sensing and optical measurement technology, which is applied in the testing of optical instruments, measuring devices, and testing of machinery/structural components, etc., can solve the lack of special ground simulation devices for on-board optical instruments, the complex and difficult test processes and tooling structures, etc. problems, to achieve the effect of easy expansion of functions, high degree of freedom of installation, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

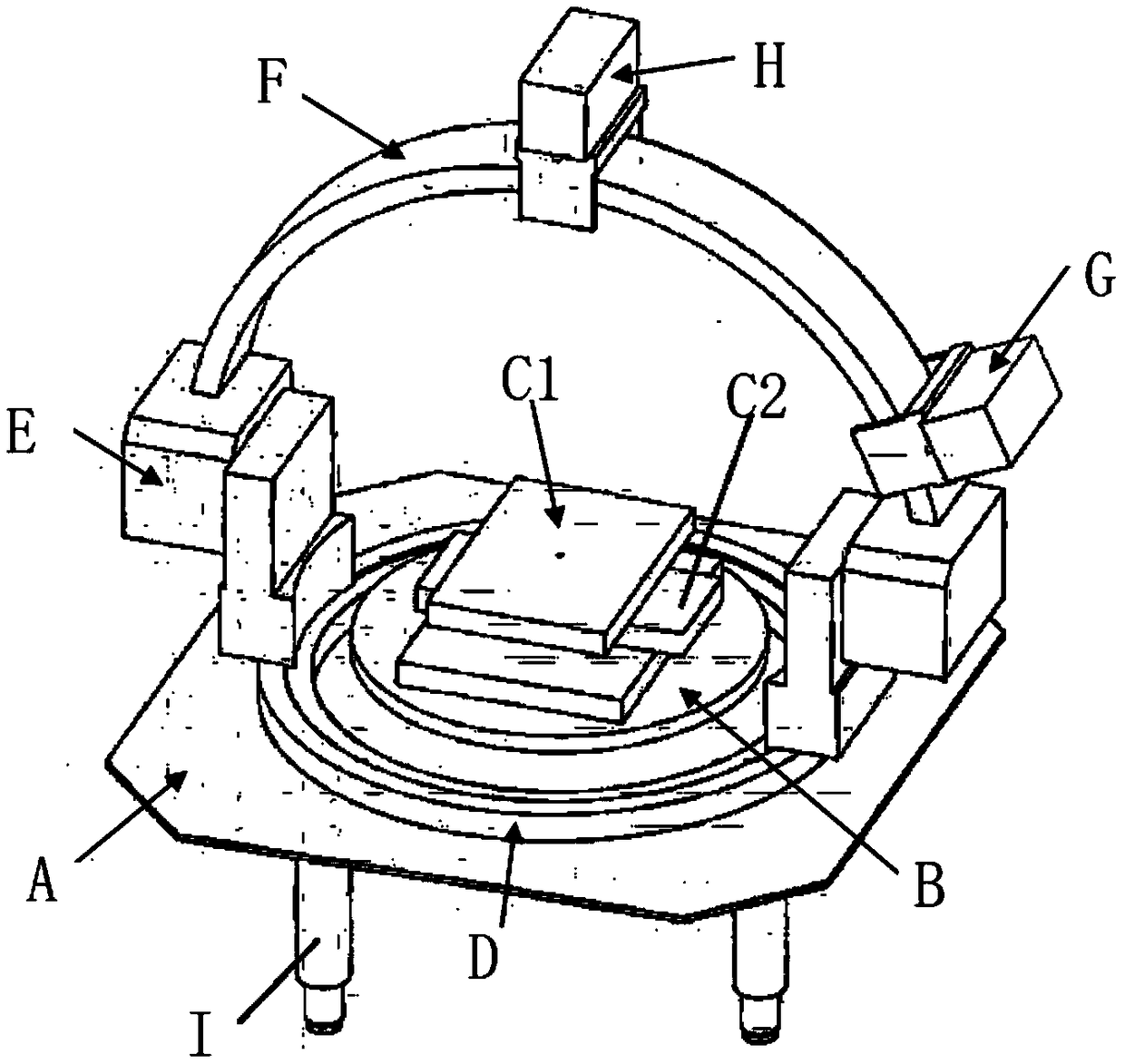

[0020] Such as figure 1 As shown, the three-dimensional universal all-angle optical measurement platform for space optical remote sensors includes a stable platform A, a lifting platform B, a translation platform, an azimuth circular guide rail D, a pitch arm E, a rolling guide rail F, a light source mobile platform G and a detector Mobile platform H; the stable platform A is equipped with a lifting platform B and an azimuth circular guide rail D surrounding the lifting platform B, and a translation platform is installed on the lifting platform B, and the translation platform includes an X-direction translation platform C1 and a Y-direction stacked up and down. On the translation platform C2, a pair of pitching arms E are symmetrically slidably installed on the azimuth circular guide rail D, and a rolling guide rail F is mounted on the two pitching arms E, and the rolling guide rail F is a semicircular structure. Light source mobile platform G and detector mobile platform H; i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com