A separation process for ethylene-rich cracking dry gas classification used in ethylbenzene production equipment

An ethylene-rich, gas-liquid separation tank technology, applied in the field of separation technology, can solve the problems of difficult to accurately control the temperature and temperature rise of an alkylation reactor, unfavorable to obtain high-quality ethylbenzene products, complicated reactor process flow, etc. Achieve the effect of reducing the demand for cooling capacity, increasing the partial pressure, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

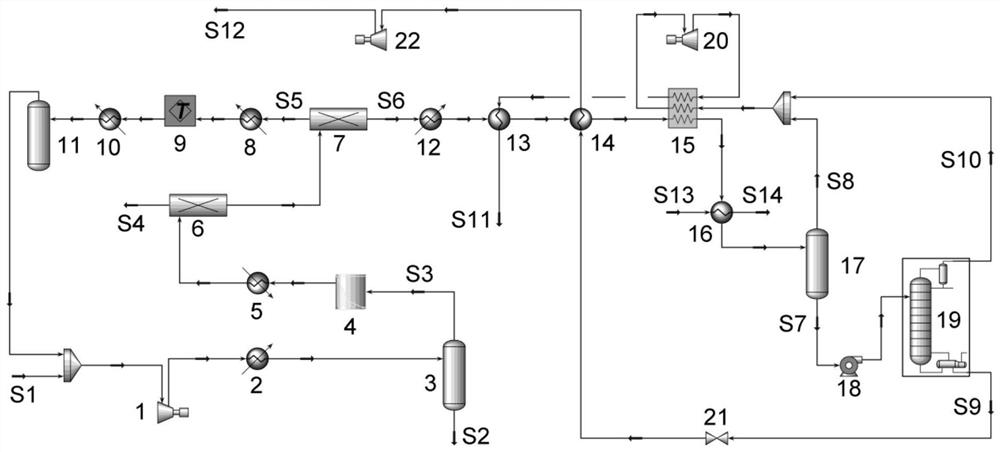

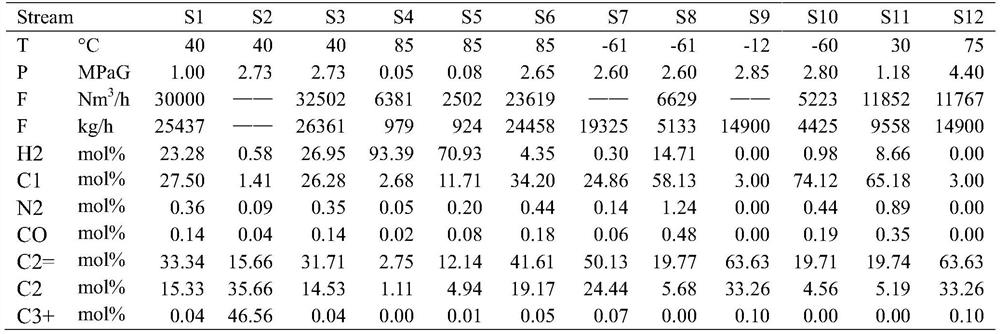

[0018] Example 1 Aiming at the by-product of a 2.2 million tons catalytic cracking unit of a refining and chemical enterprise, the ethylene-rich cracking dry gas with deep removal of propylene and above hydrocarbons, the flow rate is about 30000Nm 3 / h, using the ethylene-rich cracking dry gas classification in the present invention to be used in the separation process of the ethylbenzene production device to produce low-concentration ethylene (60mol%) raw materials.

[0019] Table 1 Example 1 key material (dry basis) composition and a list of operating parameters.

[0020]

[0021] The ethylene-rich cracking dry gas S1 with deep removal of propylene and above hydrocarbons is pressurized by the first compressor 1 to 2.75MPaG, then enters the first cooler 2, lowers the temperature to 40°C, and then enters the first gas-liquid separation tank 3 , the first condensate S2 is produced at the bottom of the tank, and the first non-condensable gas S3 is produced at the top of the t...

Embodiment 2

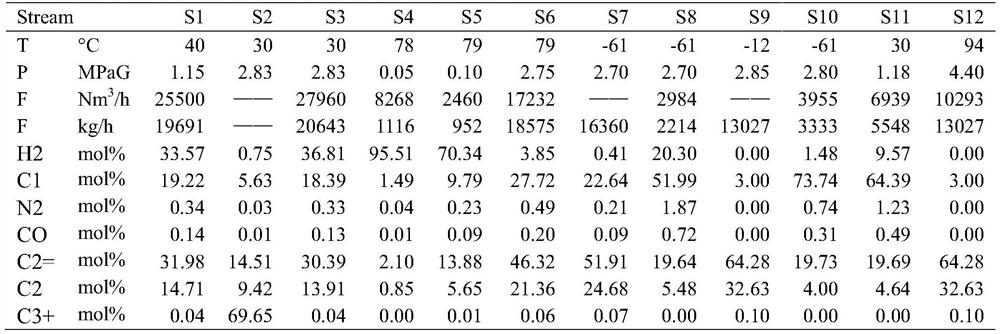

[0026] Example 2 Aiming at the ethylene-rich cracking dry gas with deep removal of propylene and above hydrocarbons produced by a 3.5 million tons catalytic cracking unit in a refining and chemical enterprise, the flow rate is about 25500Nm 3 / h, using the ethylene-rich cracking dry gas classification in the present invention to be used in the separation process of the ethylbenzene production device to produce low-concentration ethylene (60mol%) raw materials.

[0027] The ethylene-rich cracked dry gas S1 with deep removal of propylene and above hydrocarbons is pressurized to 2.85MPaG by the first compressor 1, then enters the first cooler 2, lowers the temperature to 40°C, and then enters the first gas-liquid separation tank 3 , the first condensate S2 is produced at the bottom of the tank, and the first non-condensable gas S3 is produced at the top of the tank; the first non-condensable gas S3 enters the precision filter 4 to remove solid particles and residual liquid mist, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com