Organic aluminum-zirconium crosslinking agent and preparation method thereof, and low-molecular polymer fracturing fluid

A technology of organoaluminum and cross-linking agent, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of unsatisfactory cross-linking effect of synthetic polymers, limited application range, gel instability, etc., and achieve excellent Sand-carrying ability, low cost, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

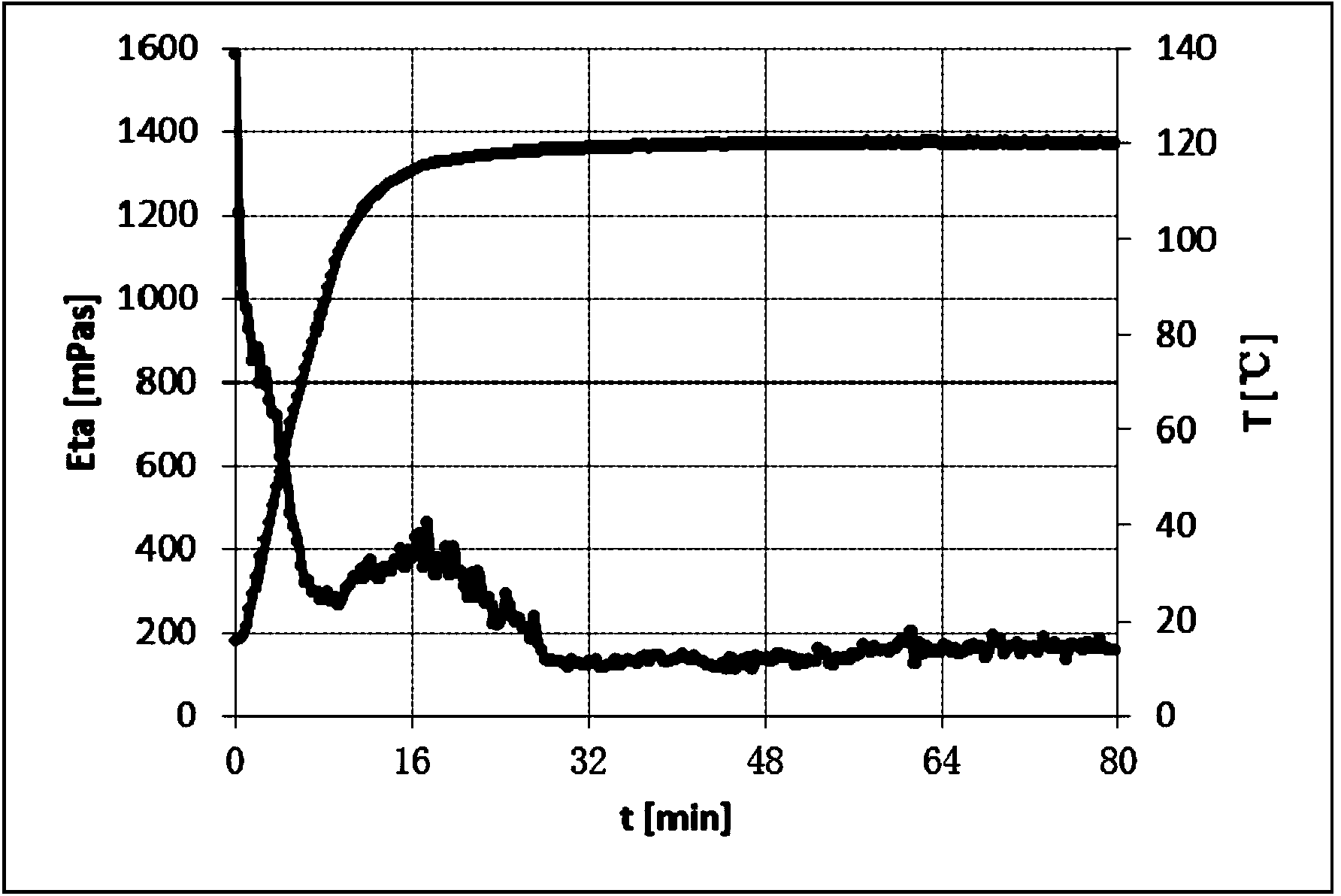

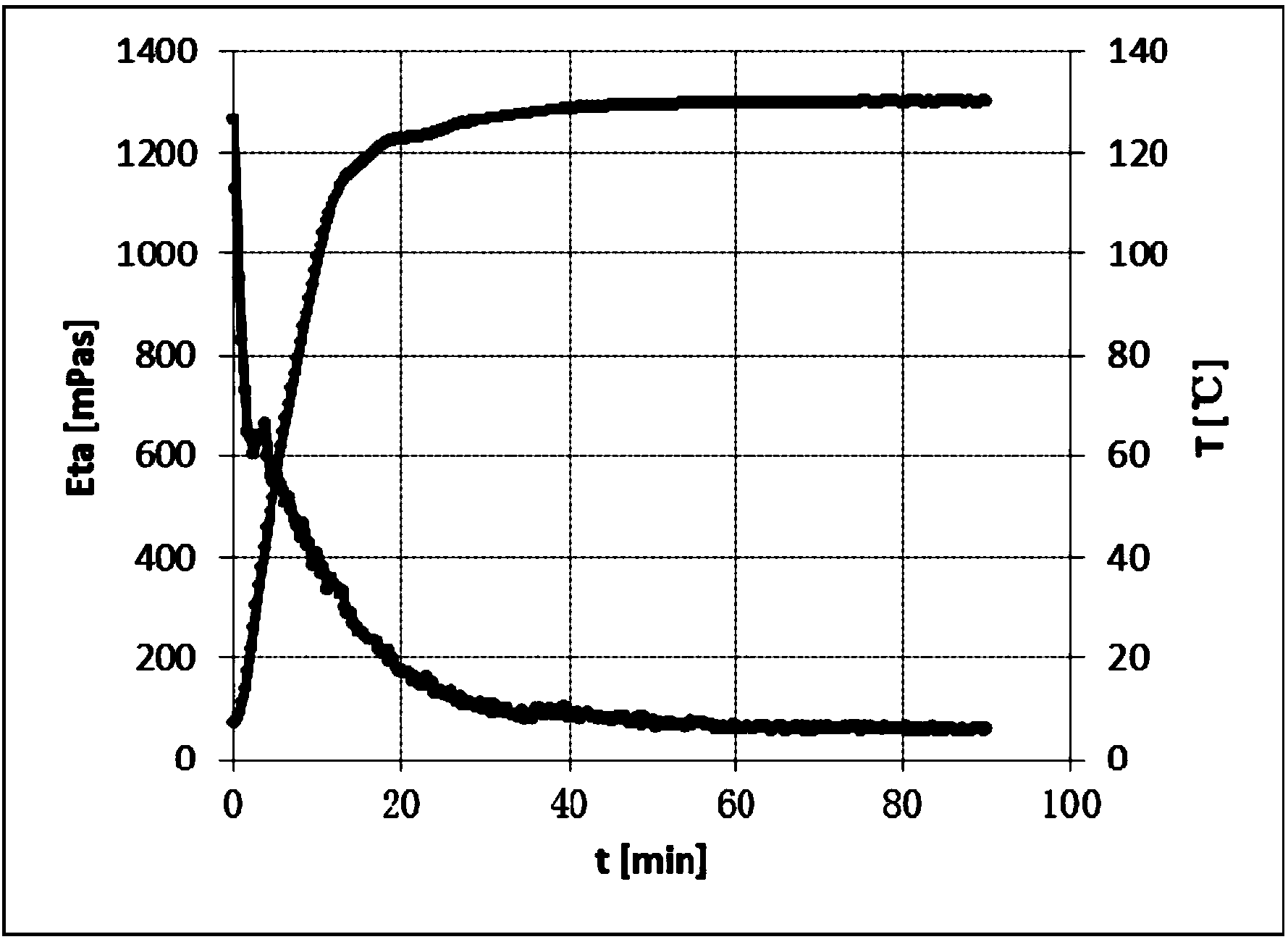

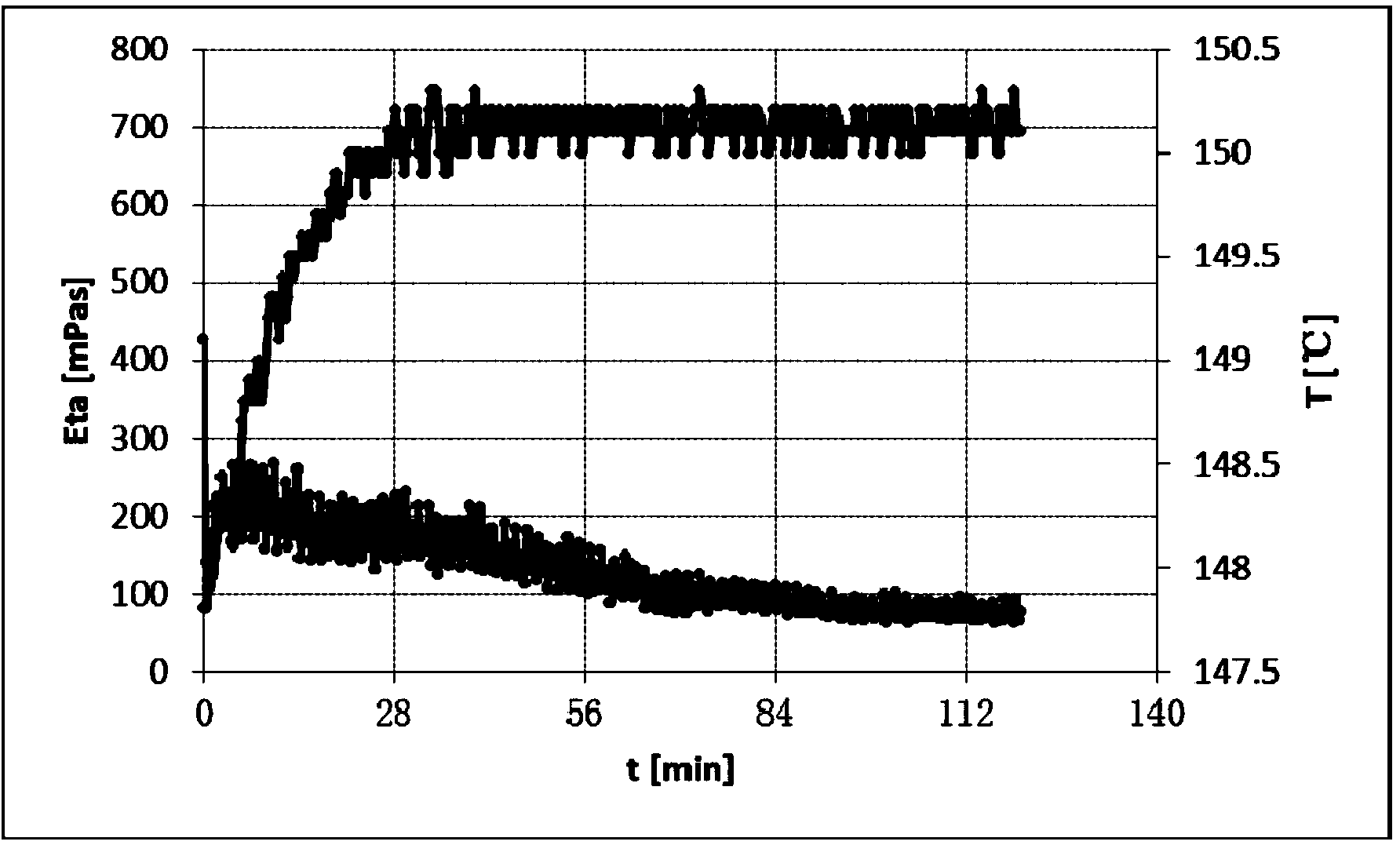

Image

Examples

Embodiment 1

[0033] The organoaluminum-zirconium crosslinking agent of this embodiment is prepared by reacting the following raw materials in parts by weight:

[0034]

[0035] The preparation method of the organoaluminum-zirconium crosslinking agent of the present embodiment comprises the following steps:

[0036] 1) Take 180g of diethylene glycol and add it to 55g of water, mix well and heat up to 45°C to obtain a mixture;

[0037] 2) under stirring condition, add 18g aluminum trichloride, 18g zirconium trichloride in step 1) gained mixture, stirring and dissolving, after mixing uniformly, add 15g potassium gluconate and 78g glacial acetic acid successively under stirring condition, then in Reflux at 45°C for 4.5 hours under stirring conditions to obtain the organoaluminum-zirconium crosslinking agent.

[0038] The low-molecular polymer fracturing fluid using the above-mentioned organoaluminum-zirconium crosslinking agent in this embodiment includes the following components in parts ...

Embodiment 2

[0045] The organoaluminum-zirconium crosslinking agent of this embodiment is prepared by reacting the following raw materials in parts by weight:

[0046]

[0047] The preparation method of the organoaluminum-zirconium crosslinking agent of the present embodiment comprises the following steps:

[0048] 1) Take 200g of polyalcohol and add it into 60g of water, mix well and heat up to 50°C to get the mixture;

[0049]2) Under stirring conditions, add 20g of aluminum trichloride and 20g of zirconium oxychloride to the mixture obtained in step 1), stir and dissolve, after mixing evenly, add 20g of sodium gluconate and 80g of lactic acid successively under stirring conditions, and then , and reflux reaction for 5 hours under stirring conditions to obtain the organoaluminum-zirconium crosslinking agent.

[0050] The low-molecular polymer fracturing fluid using the above-mentioned organoaluminum-zirconium crosslinking agent in this embodiment includes the following components in ...

Embodiment 3

[0056] The organoaluminum-zirconium crosslinking agent of this embodiment is prepared by reacting the following raw materials in parts by weight:

[0057]

[0058] The preparation method of the organoaluminum-zirconium crosslinking agent of the present embodiment comprises the following steps:

[0059] 1) Add 220g of polyalcohol to 65g of water, mix well and then heat up to 55°C to obtain the mixture;

[0060] 2) under stirring condition, add 22g aluminum sulfate, 22g zirconium oxychloride in step 1) gained mixture, stir and dissolve, after mixing uniformly, add 22g potassium gluconate and 50g lactic acid, 30g glacial acetic acid successively under stirring condition, then in Reflux reaction at 55°C and stirring for 5.5 hours to obtain the organoaluminum-zirconium crosslinking agent.

[0061] The low-molecular polymer fracturing fluid using the above-mentioned organoaluminum-zirconium crosslinking agent in this embodiment includes the following components in parts by volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com