Oil well pipe cleaning and sand flushing integrated device and pipe cleaning and sand flushing method

A technology for sand washing and oil wells, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of increasing the completion cycle, low efficiency of reverse circulation sand washing, increasing the cost of completion fluid, etc., to reduce the risk of pipe sticking , Strong sand-carrying ability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

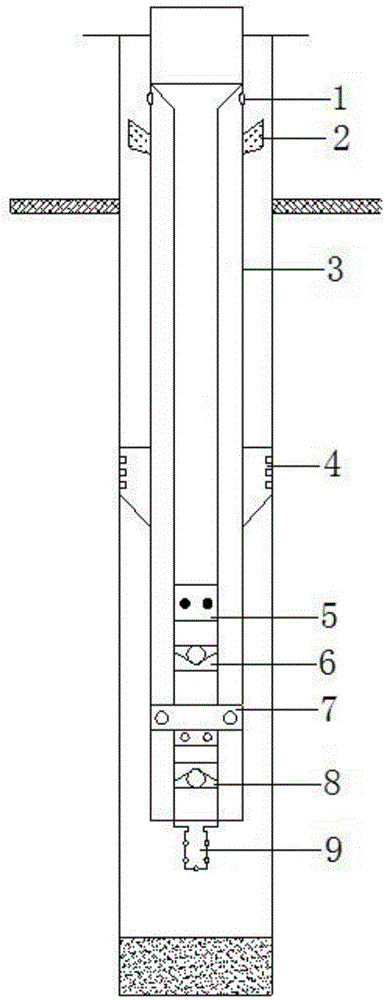

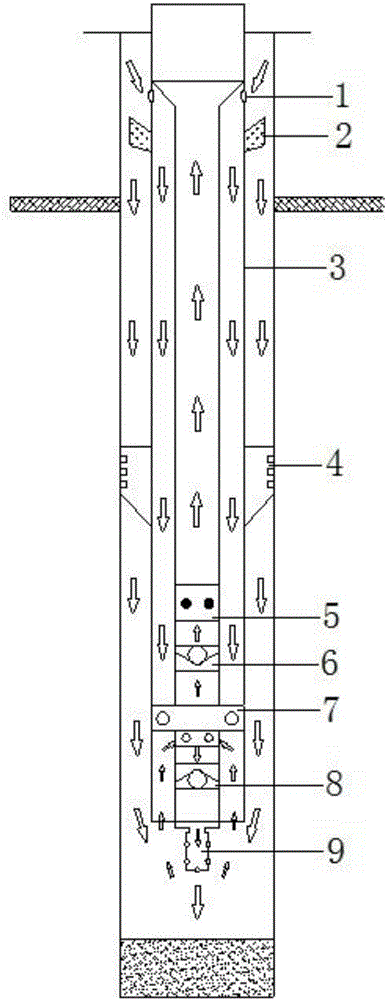

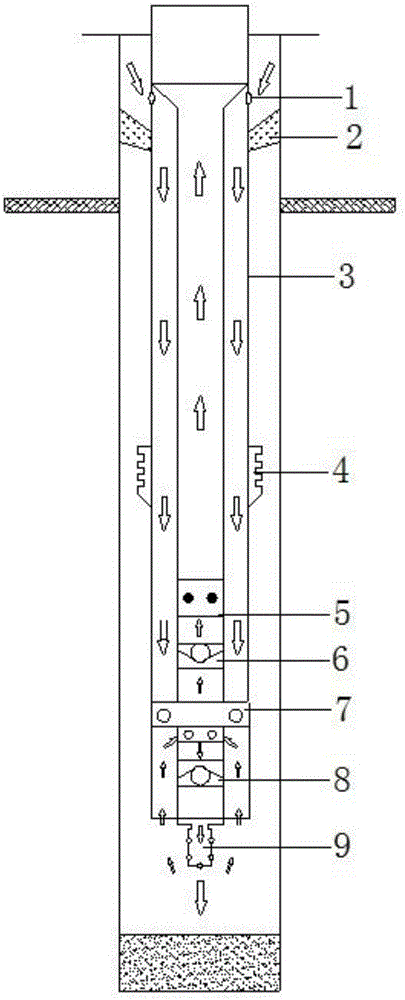

[0041] as attached figure 1 As shown in the figure, an oil well scraper sand washing integrated device includes a sub-section 1, a sub-packer 2, a double-layer pipe body 3, a scraper 4, and a sub-section for sand washing, which are sequentially connected and communicated with each other. The diverting sub-section 1, the diverting packer 2, the scraper 4 and the sand washing section are all double-layer pipe structures; the sand washing sub includes an upper double-layer pipe body connected in sequence, The bridge nipple 7 and the lower double-layer pipe body, the inner pipe of the upper double-layer pipe body is provided with a sliding sleeve 5 and a first check valve 6 from top to bottom, and the sliding sleeve 5 can be opened by wire operation and closed, its interior is matched with the jet pump 10; the inner tube of the lower double-layer pipe body is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com