A test method for unpacking ability of k344 packer under repeated stimulation conditions of horizontal wells

A technology of repeated transformation and test methods, applied in the testing of machines/structural components, instruments, mechanical components, etc., can solve the problems of high cost, no unsealing ability, complex structure, etc., achieve low cost, reduce card Drill risk, simple effect of test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

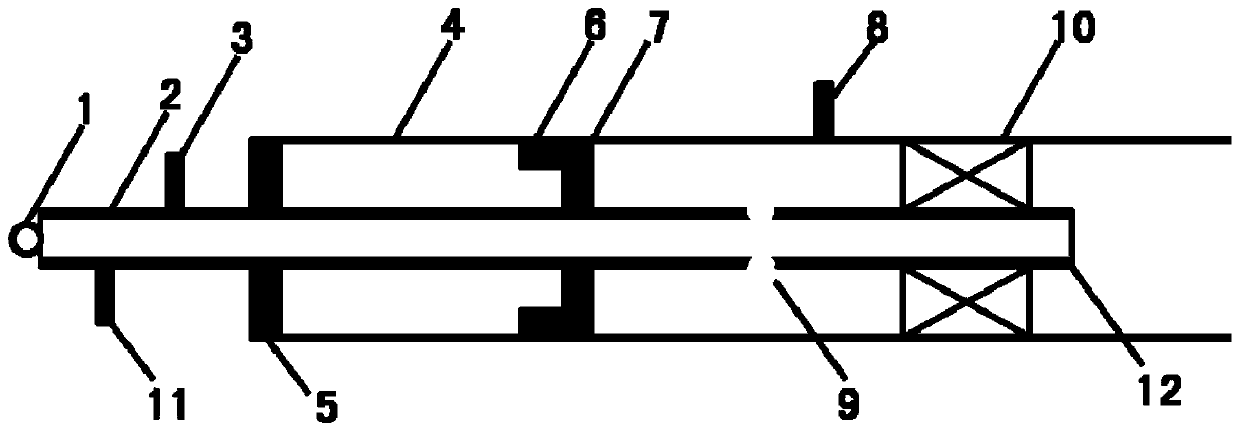

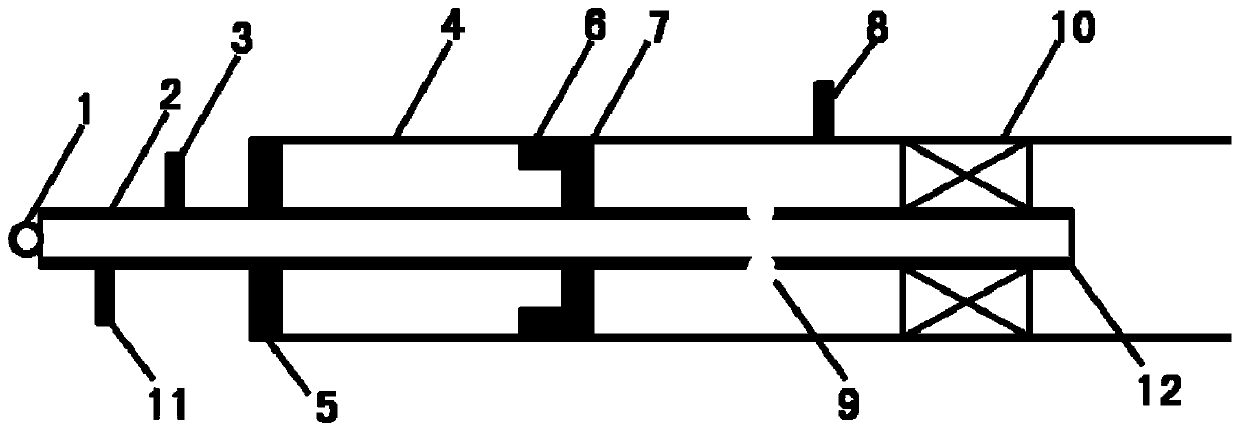

[0026] Such as figure 1 As shown, the present invention provides a K344 packer unsealing ability test device under the repeated reconstruction conditions of horizontal wells. Plug 12, test oil pipe 2 is provided with oil pipe pressure hole 3, blasting liquid outlet channel 11 and throttle hole 9, and test oil pipe 2 with throttle hole 9 is equipped with simulated casing 4, simulated casing 4 and A first plug 5, a piston 7 and a K344 packer 10 are arranged in sequence between the test tubing 2, and a limit ring 6 is arranged inside the simulated casing 4, and the piston 7 can move upward along the axial direction of the test tubing 2 during operation.

[0027] Among them, the right end of the simulated casing 4 is vented to simulate the low pressure end, thereby forming the high pressure difference between the upper end and the lower end of the K344 packer rubber.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com