Drill rod centralizer

A technology for centralizers and drill pipes, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of induced downhole accidents, etc., and achieve the effect of increasing the overall length and large stroke space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

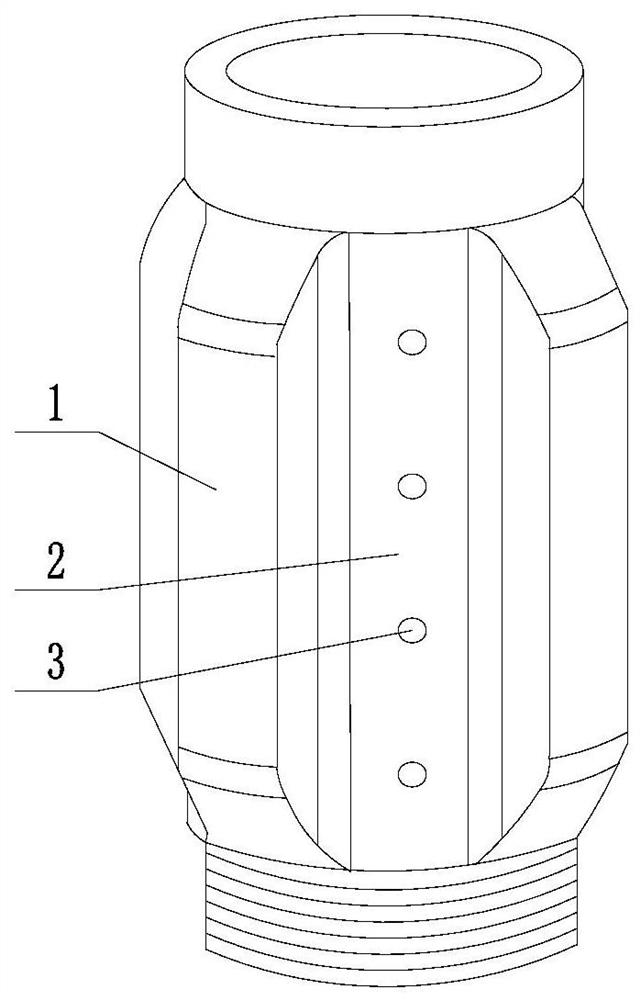

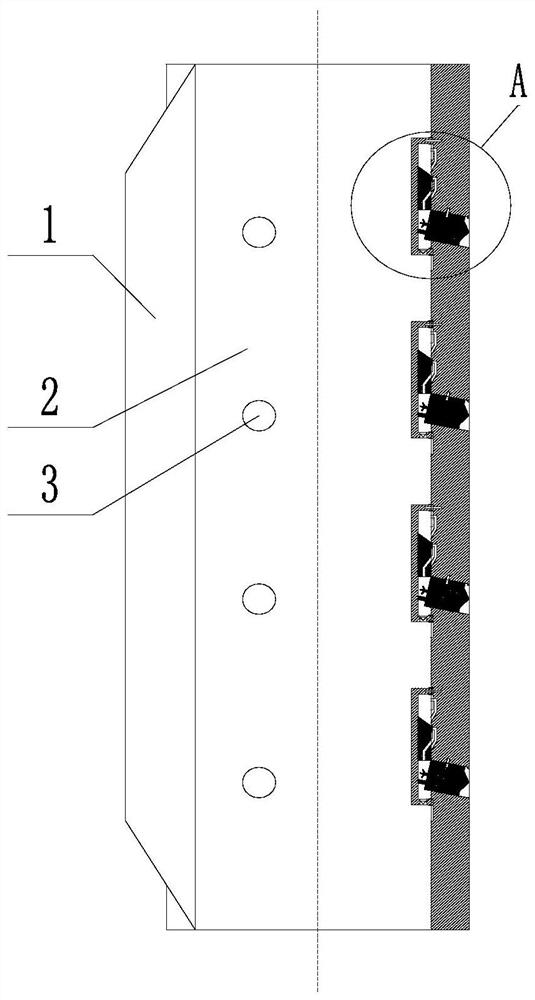

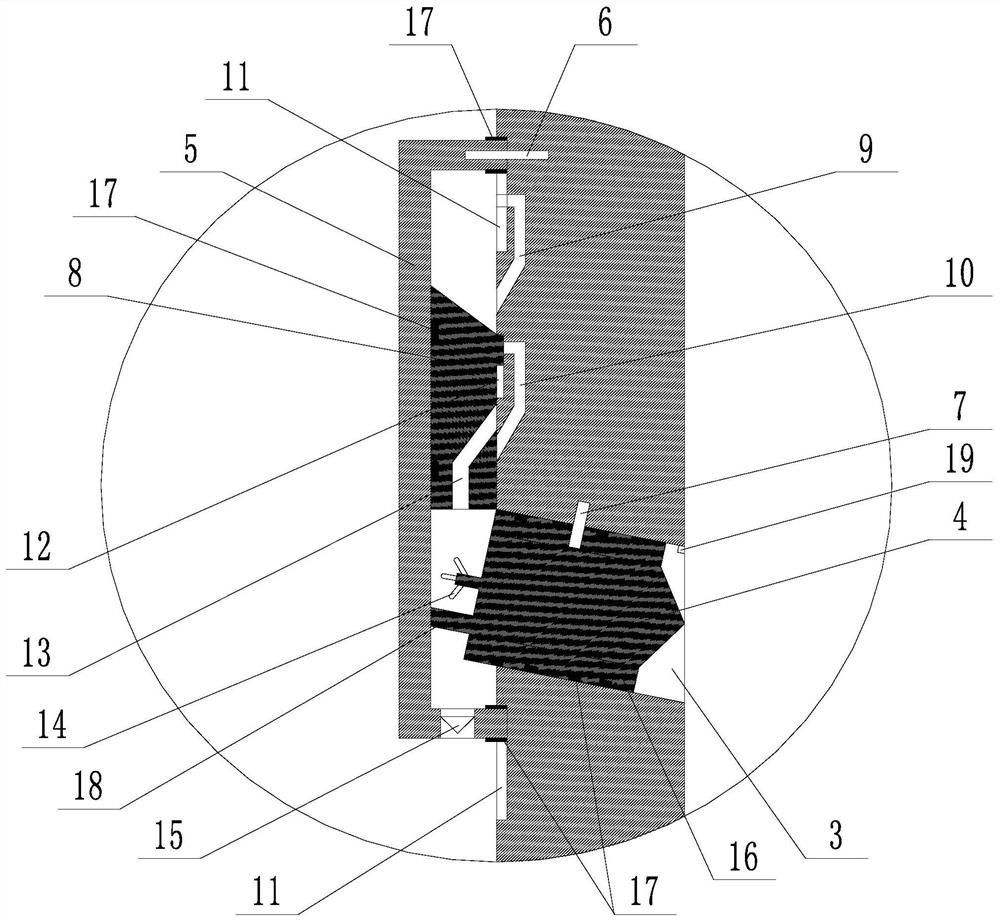

[0044] Such as Figure 1 to Figure 5 A drill pipe centralizer shown includes several centralizing wings 1, an upper backflow channel 2 located between two adjacent centralizing wings 1, and several through-holes 3 are provided on the upper backflow channel 2, and the through-holes 3 The hole 3 is sealed with a tapered piece 4, the tapered end of the tapered piece 4 faces the outside of the through hole 3, and the tapered piece 4 is connected to the wall of the through hole 3 through the first shear pin 7; The through holes 3 correspond to the sliding sleeves 5 one by one. The sliding sleeves 5 are sealed and connected to the inner wall of the centralizer. The bottom of the sliding sleeves 5 is provided with a one-way valve 15. The direction of the one-way valve 15 is from the inside of the sliding sleeve to the outside of the sliding sleeve. Conduction, that is, conduction from top to bottom in the figure, and the connection between the sliding sleeve 5 and the centralizer is ...

Embodiment 2

[0057] Such as Figure 1 to Figure 5 In the shown drill pipe centralizer, on the basis of Embodiment 1, the through hole 3 is inclined downward from the inside to the outside, and the axis of the tapered part 4 is collinear with the axis of the through hole 3 . Cooperate by bearing 16 between described conical part 4 and through hole 3, the outer ring of described bearing 16 is connected with through hole 3 hole wall by first shear pin 7, the inner ring of described bearing 16 and conical part 4 Rotational connection; several sealing rings 17 are sheathed on the outer ring of the bearing 16 . A protruding portion 18 is provided on the side of the conical member 4 away from the pointed conical end, and when the first shear pin 7 is kept connected, the protruding portion 18 is in contact with the inner wall of the sliding sleeve 5 . The sliding push block 8 is in dynamic sealing cooperation with the inner wall of the sliding sleeve 5, and the sliding pushing block 8 divides the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com