A rotary hydraulic jet cutting casing tool and its construction method

A technology of hydrojet and construction method, which is applied in the direction of earthwork drilling and production, wellbore/well parts, etc., and can solve the problems of forging and milling displacement blade speed, unreasonable application of drilling pressure, large changes in the performance of forging and milling mud, and forging and milling cutters. In order to reduce the risk of stuck pipe, enrich the series of permanent well sealing technology and improve the efficiency of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

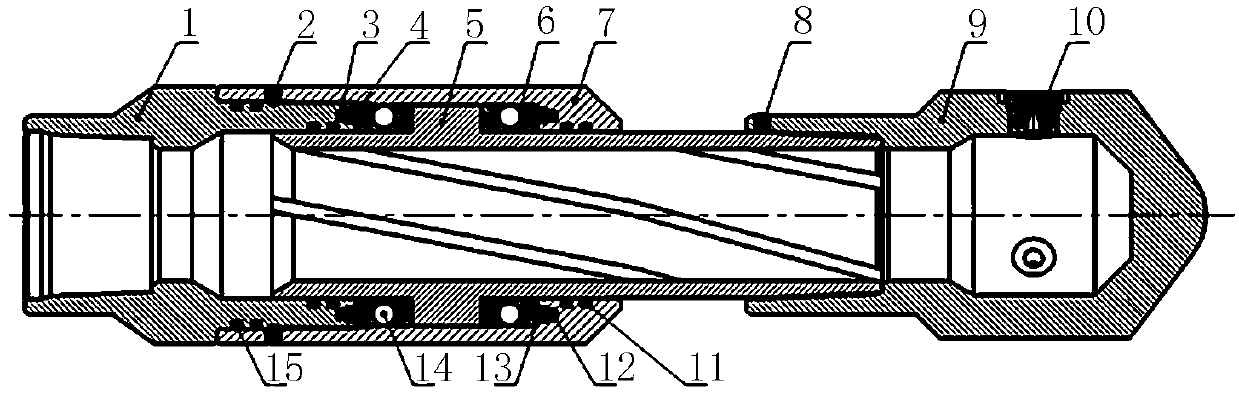

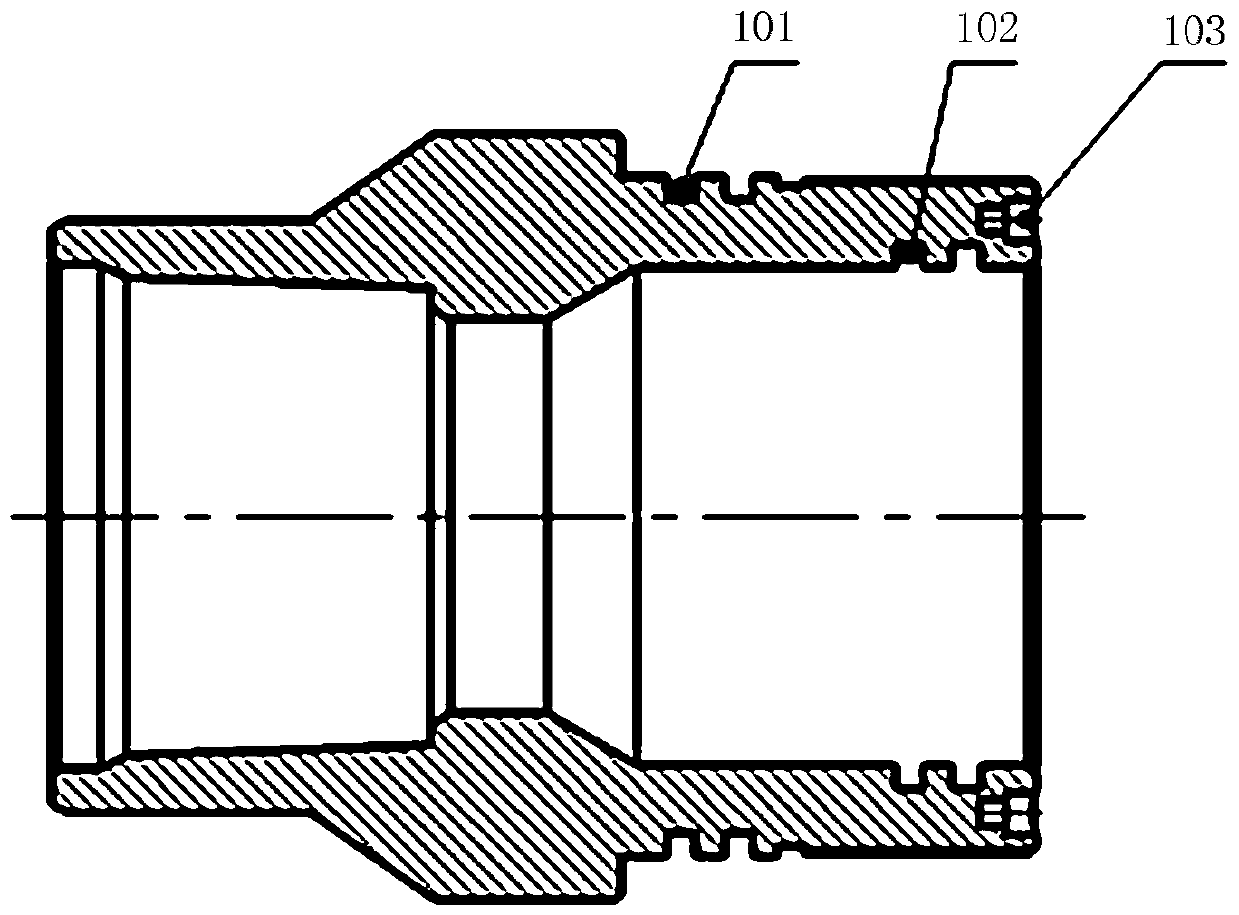

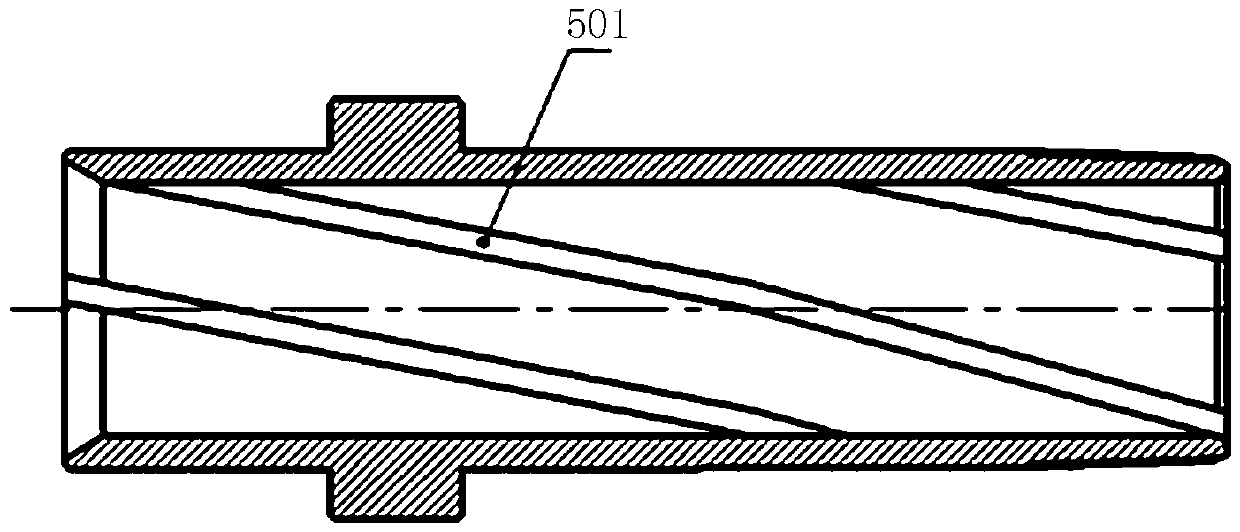

[0037] Such as figure 1 As shown, a rotary hydraulic jet cutting casing tool includes an upper joint 1, a rotating sleeve 5, an outer sleeve 7 and a rotating head 9; one end of the upper joint 1 is connected to an oil pipe 18, and the other end of the upper joint 1 One end is sleeved on the rotating sleeve 5 and inserted into the outer sleeve 7. The rotating sleeve 5 passes through the outer sleeve 7 and is inserted into the rotating head 9. The rotating sleeve 5 and the outer sleeve 7 are connected by bearings. The rotating sleeve 5 and the rotating head 9 are fixedly connected by screws, and the rotating head 9 is processed with a plurality of nozzle seats 901 along the circumferential direction, and the nozzle seats 901 deflect along the circumferential direction of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com