Polymer-type acidic slickwater and preparation method thereof

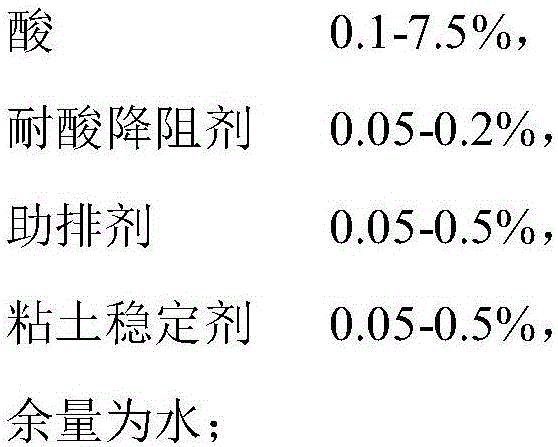

A technology of polymer and slick water, which is applied in drilling compositions, chemical instruments and methods, earthwork drilling and production, etc., can solve the problems of increasing the comprehensive cost of fracturing, poor compatibility, poor fracturing adaptability, etc., and achieve improvement The effect of fracturing reconstruction, simple preparation method, and the effect of enhancing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A polymer-type acidic slick water and its preparation method. Weigh 94.65% of water, add 5% hydrochloric acid, then evenly and slowly add 0.15% anionic polyacrylamide, stir for 5 minutes, and then add 0.1% fluorocarbon and iso A mixture of propanol in any proportion, a mixture of 0.1% choline chloride and ammonium chloride in any proportion.

[0022] Performance evaluation:

[0023] Table 1 Performance evaluation of acidic slick water fracturing fluid

[0024] comment content HCl concentration Viscosity mPa.s Resistance reduction rate Surface tension mN / m contact angle° Evaluation results 5% 3.3 71.20% 24.1 81

Embodiment 2

[0026] A polymer-type acidic slippery water and its preparation method. Weigh 96% of water, add 7% hydrochloric acid, then evenly and slowly add 0.2% anionic polyacrylamide, stir for 10 minutes, and then add 0.5% OP-10 and A mixture of isopropanol in any proportion, a mixture of 0.3% cetyltrimethylammonium chloride and ammonium chloride in any proportion.

[0027] Performance evaluation:

[0028] Table 2 Performance evaluation of acidic slick water fracturing fluid

[0029] comment content HCl concentration Viscosity mPa.s Resistance reduction rate Surface tension mN / m contact angle° Evaluation results 7% 3.1 73.50% 23.4 79

Embodiment 3

[0031] A polymer-type acidic slick water and its preparation method. Weigh 96.05% of water, add 3% hydrochloric acid, then evenly and slowly add 0.1% anionic polyacrylamide, stir for 10 minutes, and then add 0.5% dodecyl A mixture of sodium benzenesulfonate and propanol in any proportion, 0.35% potassium chloride

[0032] Performance evaluation:

[0033] Table 3 Performance evaluation of acidic slick water fracturing fluid

[0034] comment content HCl concentration Viscosity mPa.s Resistance reduction rate Surface tension mN / m contact angle° Evaluation results 3% 4.0 70.80% 25.6 83

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com