Clean air foam cracking liquid

An air foam and clean technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high cost, high surfactant concentration, unspecified clay stabilizer compatibility, etc., and achieve gel breaking speed Fast, low cost, and excellent sand-carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific steps for preparing 250g of clean foam fracturing fluid: First, add 5g of clay stabilizer potassium chloride to 240g of water, stir in a beaker until completely dissolved, and prepare a salt solution; then add 1.4g of anionic surfactant AOS to the brine , continue to stir until the anionic surfactant is evenly dissolved, and add the obtained mixed solution to the high-speed stirrer; turn on the high-speed stirrer, and add the zwitterionic surfactant oleic acid amidopropyl betaine 1.5 prepared in advance while stirring. g and 2.3 g of low-molecular-weight alcohol, continue to shear at a high speed to make a clean foam fracturing fluid.

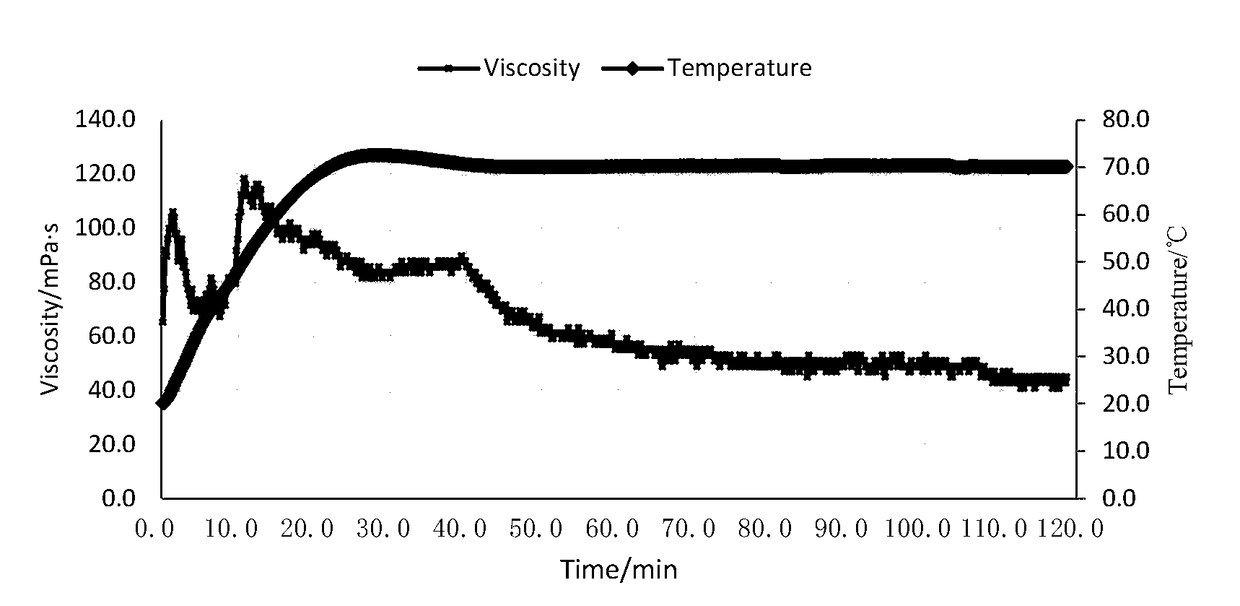

[0030] according to figure 1 As shown, at 70°C, use a rheometer to test its viscosity-temperature curve. pass figure 1 It can be seen that the foam fracturing fluid of the present invention can be prepared by adding 0.55% anionic surfactant AOS and 0.6% zwitterionic surfactant oleic acid amidopropyl betaine at a lower dosa...

Embodiment 2

[0032]The specific steps for preparing 250g of clean foam fracturing fluid containing temperature stabilizers: first, add 5g of clay stabilizer potassium chloride to 239g of water, stir in a beaker until completely dissolved, and prepare a salt solution; then add 1.4 g anionic surfactant AOS, 0.5g foam stabilizer APG810, continue to stir until the anionic surfactant and foam stabilizer are uniformly dissolved, and add the resulting mixture to the high-speed stirrer; turn on the high-speed stirrer and add while stirring A mixture of 1.5 g of the zwitterionic surfactant oleic acid amidopropyl betaine and 2.3 g of low molecular weight alcohol prepared in advance was continuously sheared at a high speed to obtain a clean foam fracturing fluid containing a temperature stabilizer.

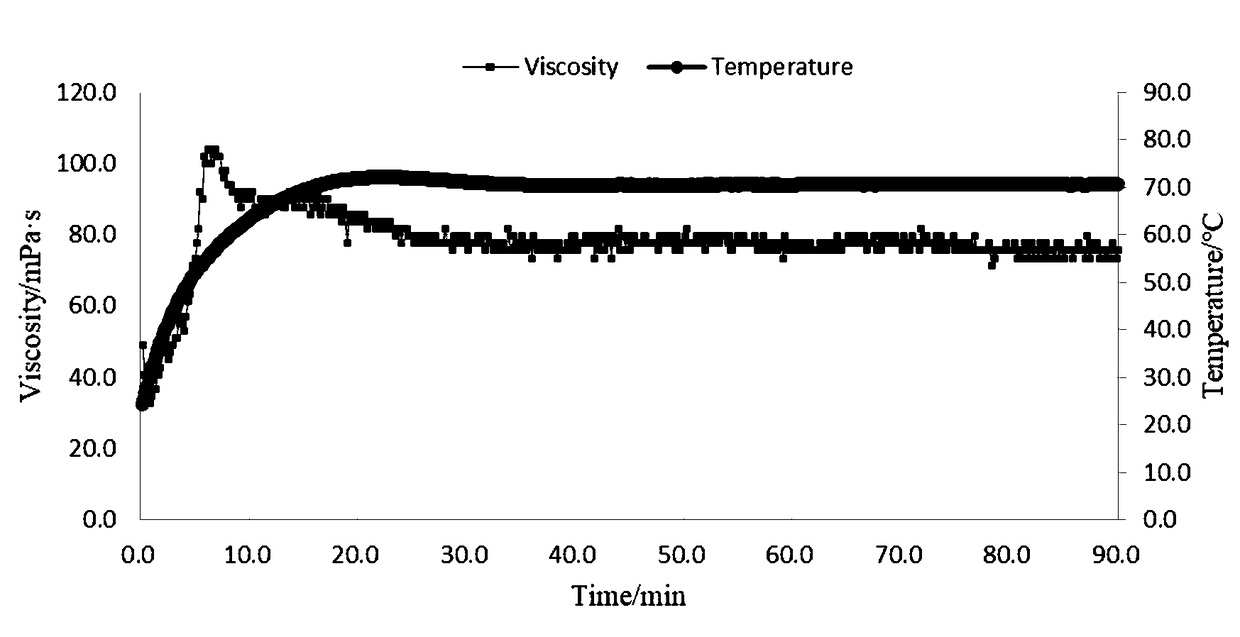

[0033] according to figure 2 As shown, at 70°C, use a rheometer to test its viscosity-temperature curve, through the figure 1 In contrast, after adding foam stabilizer APG810, the viscosity can be stab...

Embodiment 3

[0035] The specific steps for preparing 250g of clean foam fracturing fluid containing temperature stabilizers: first, add 5g of clay stabilizer potassium chloride to 238g of water, stir in a beaker until completely dissolved, and prepare a salt solution; then add 1.4 g anionic surfactant AOS, 0.5g foam stabilizer APG810, continue to stir until the anionic surfactant and foam stabilizer are uniformly dissolved, and add the resulting mixture to the high-speed stirrer; turn on the high-speed stirrer and add while stirring The mixed solution of 2.0 g of zwitterionic surfactant oleic acid amidopropyl betaine and 3.0 g of low molecular weight alcohol prepared in advance was sufficiently sheared at high speed to obtain a clean foam fracturing fluid containing a temperature stabilizer.

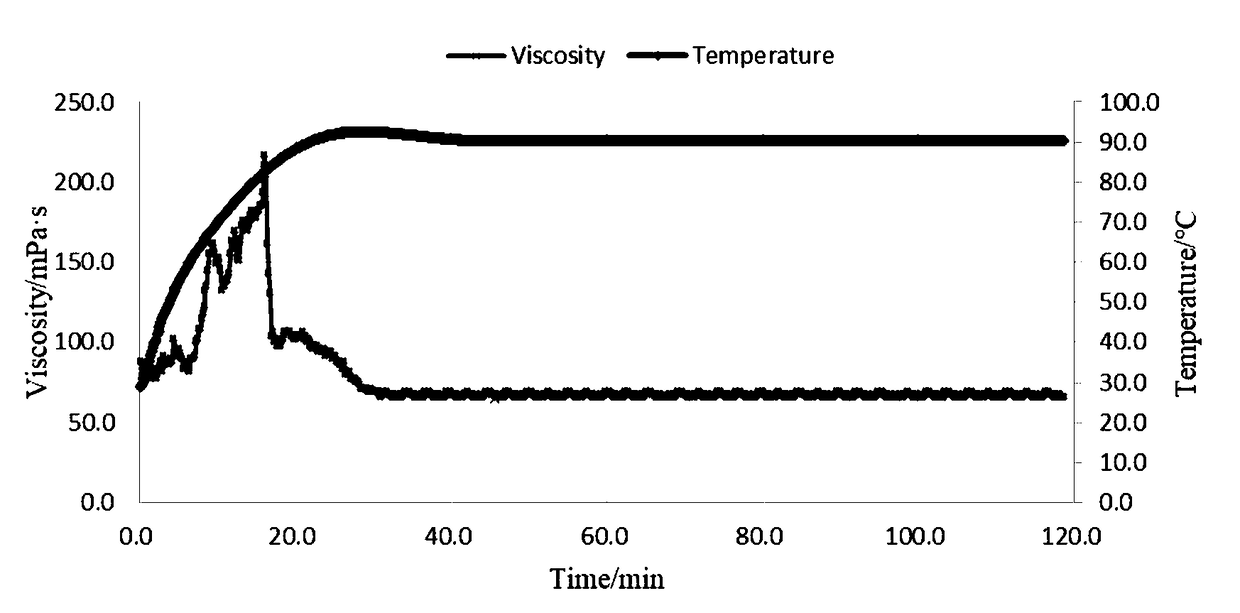

[0036] according to image 3 As shown, at 90°C, use a rheometer to test its viscosity-temperature curve, and compare figure 2 It can be seen that increasing the zwitterionic surfactant oleic acid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com