Three-protection-function water-base drilling fluid system

A liquid and drilling technology, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve problems such as narrow application range, inability to meet environmental protection requirements at the same time, environmental protection and performance index impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

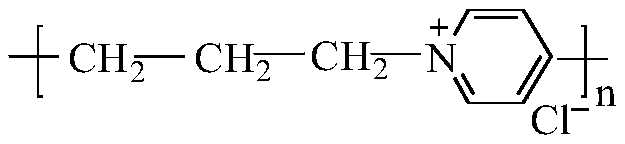

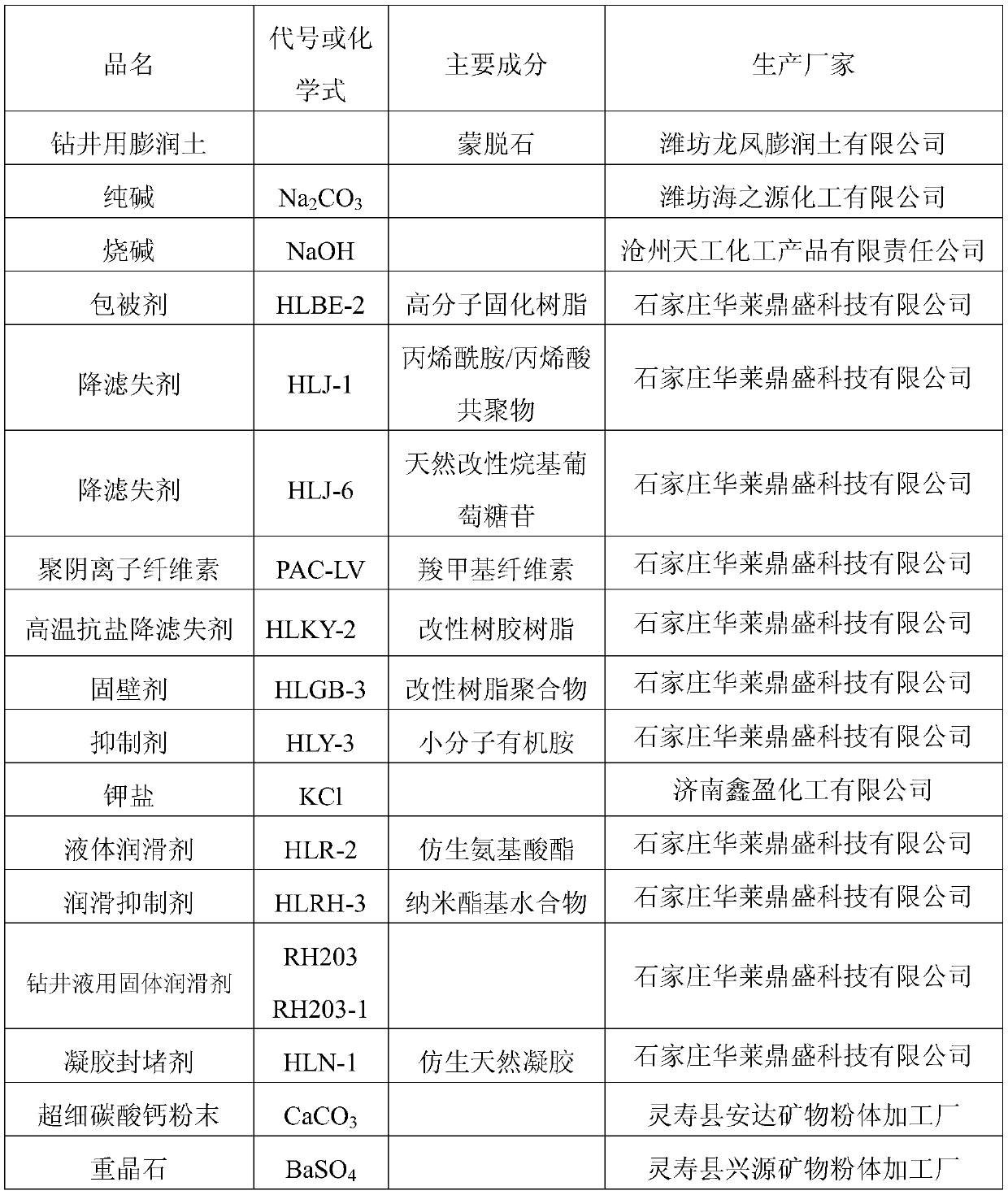

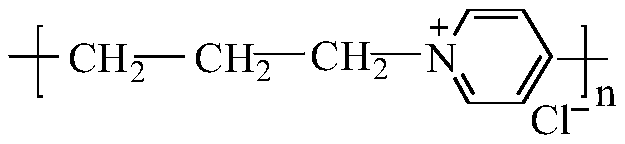

[0038] Embodiment 1: the three water-based drilling fluid system of the present invention is characterized in that it is made of the following mass ratio raw materials: 1000 parts of tap water, 40 parts of bentonite, 2 parts of sodium carbonate, 0.6 parts of sodium hydroxide 5 parts, coating agent HLBE-2 5 parts, fluid loss additive HLJ-1 8 parts, fluid loss additive HLJ-6 20 parts, polyanionic cellulose PAC-LV 6 parts, high temperature salt-resistant fluid loss additive HLKY- 26 parts, 25 parts of wall-solidifying agent HLGB-3 (no component poly-1,3-propylene chloride pyridinium chloride during preparation), 20 parts of liquid lubricant HLR-2, 20 parts of lubrication inhibitor HLRH-3, drilling 20 parts of solid lubricant (RH203-1) for liquid, 70 parts of inhibitor HLY-37, 70 parts of KCl, 2.5 parts of gel plugging agent HLN-1, 13 parts of ultrafine calcium carbonate powder, weighting agent, the amount of weighting agent should be The mud density after adjustment can reach 1.2...

Embodiment 2

[0039] Embodiment 2: The Sanbao water-based drilling fluid system of the present invention is made from the raw materials of the following mass ratio: 1000 parts of tap water, 45 parts of bentonite, 2.5 parts of sodium carbonate, 0.7 part of sodium hydroxide, coating agent HLBE-2 4 parts, fluid loss additive HLJ-1 7 parts, fluid loss additive HLJ-6 18 parts, polyanionic cellulose PAC-LV 7 parts, high temperature salt-resistant fluid loss Wall agent HLGB-325 parts (no component poly-1,3-propylene chloride pyridinium chloride during preparation), liquid lubricant HLR-2 22 parts, lubrication inhibitor HLRH-3 22 parts, solid lubricant for drilling fluid ( RH203-1) 22 parts, inhibitor HLY-3 8 parts, KCl 75 parts, gel plugging agent HLN-1 2.2 parts, superfine calcium carbonate powder 12 parts, weighting agent, the amount of weighting agent should meet the mud density after adjustment up to 1.30g / cm 3 requirements; the main component of the inhibitor HLY-3 is tetraethylenepentamine;...

Embodiment 3

[0040] Embodiment 3: The Sanbao water-based drilling fluid system of the present invention is made from the following mass ratio raw materials: 1000 parts of tap water, 50 parts of bentonite, 3 parts of sodium carbonate, 0.9 part of sodium hydroxide, coating agent 5 parts of HLBE-2, 16 parts of fluid loss additive HLJ-16, 16 parts of fluid loss additive HLJ-6, 7 parts of polyanionic cellulose PAC-LV, 10 parts of high temperature salt-resistant fluid loss additive HLKY-2, solid wall 25 parts of agent HLGB-3 (no component poly-1,3-propylene chloride pyridinium chloride during preparation), 25 parts of liquid lubricant HLR-2, 25 parts of lubrication inhibitor HLRH-3, solid lubricant for drilling fluid (RH203 -1) 25 parts, 10 parts of inhibitor HLY-3, 75 parts of KCl, 2.5 parts of gel plugging agent HLN-1, 13 parts of superfine calcium carbonate powder, weighting agent, the amount of weighting agent should meet the mud density after adjustment 1.40g / cm 3 requirements. The main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com