Patents

Literature

34results about How to "Improve mud performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

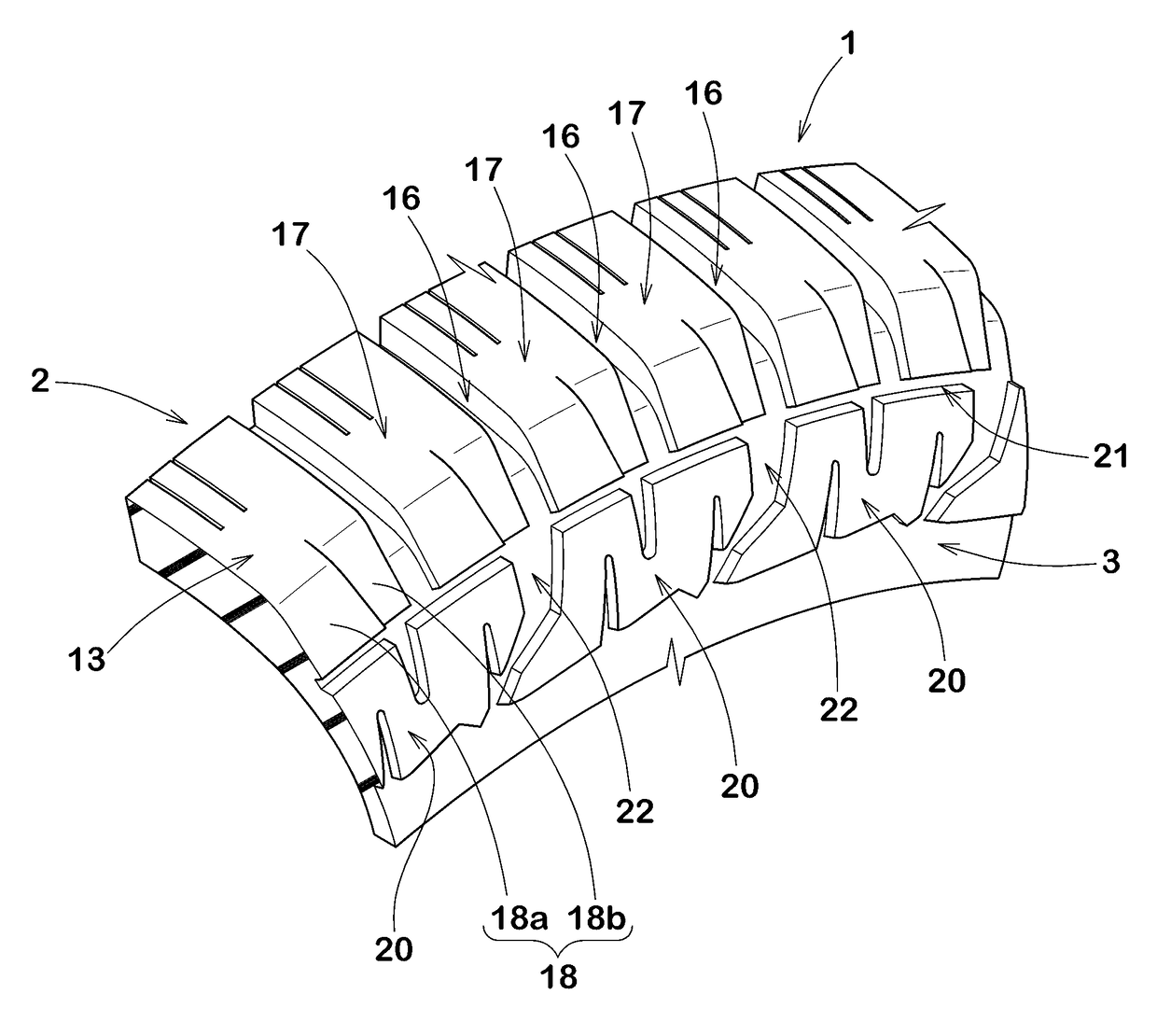

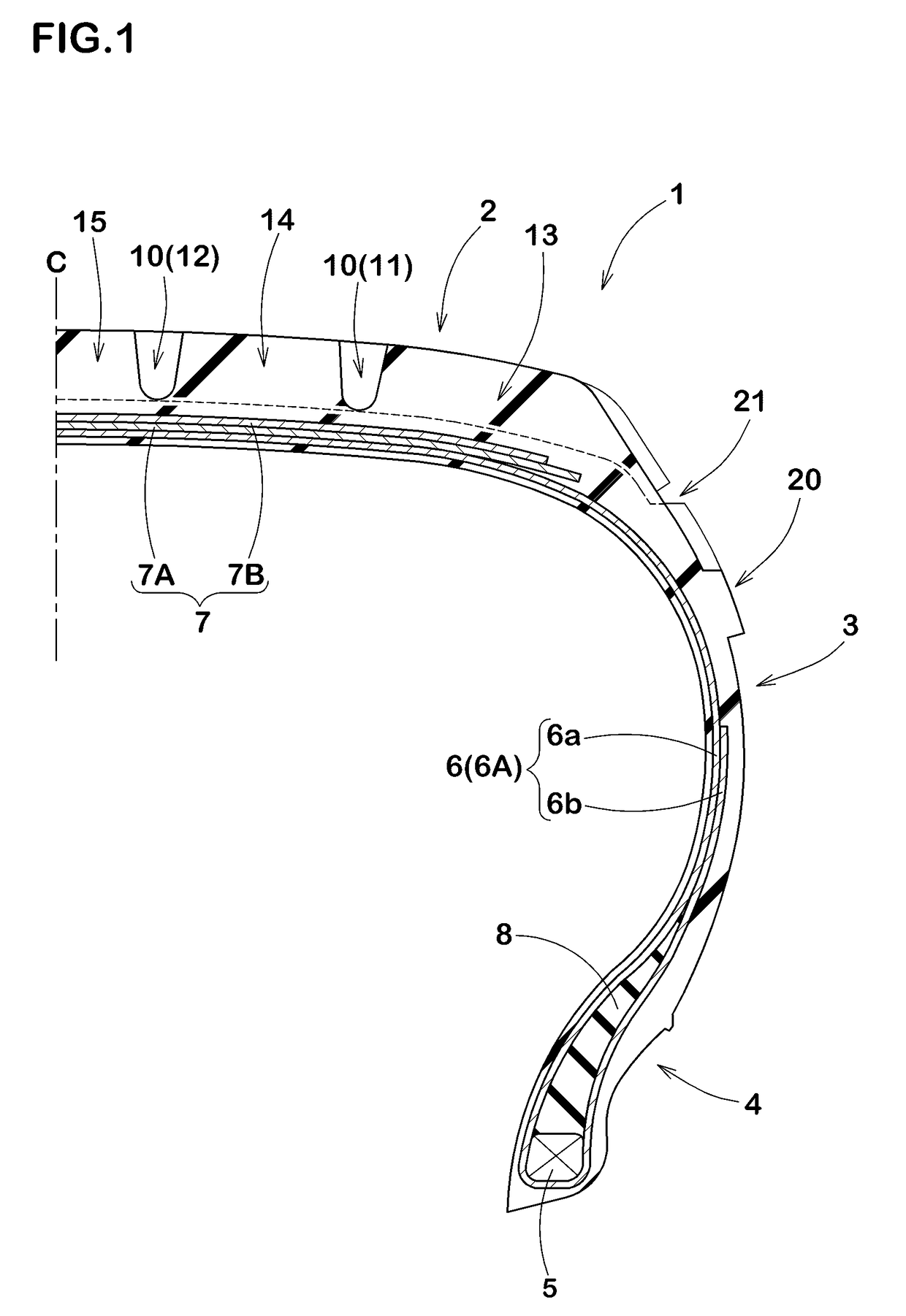

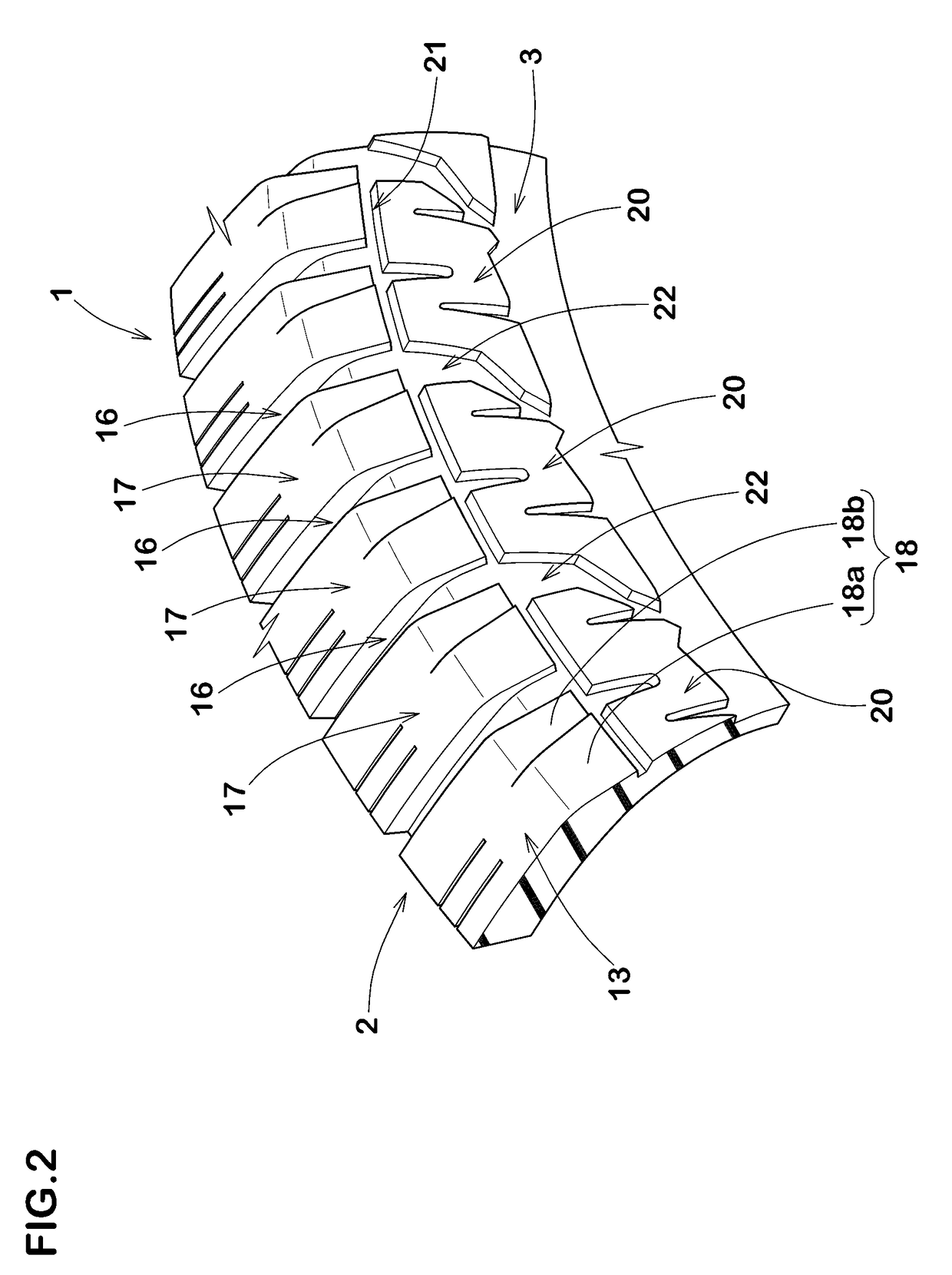

Pneumatic tire

ActiveUS20180029424A1Improve mud performanceIncreased durabilityTyre tread bands/patternsTyre sidewallsEngineeringMechanical engineering

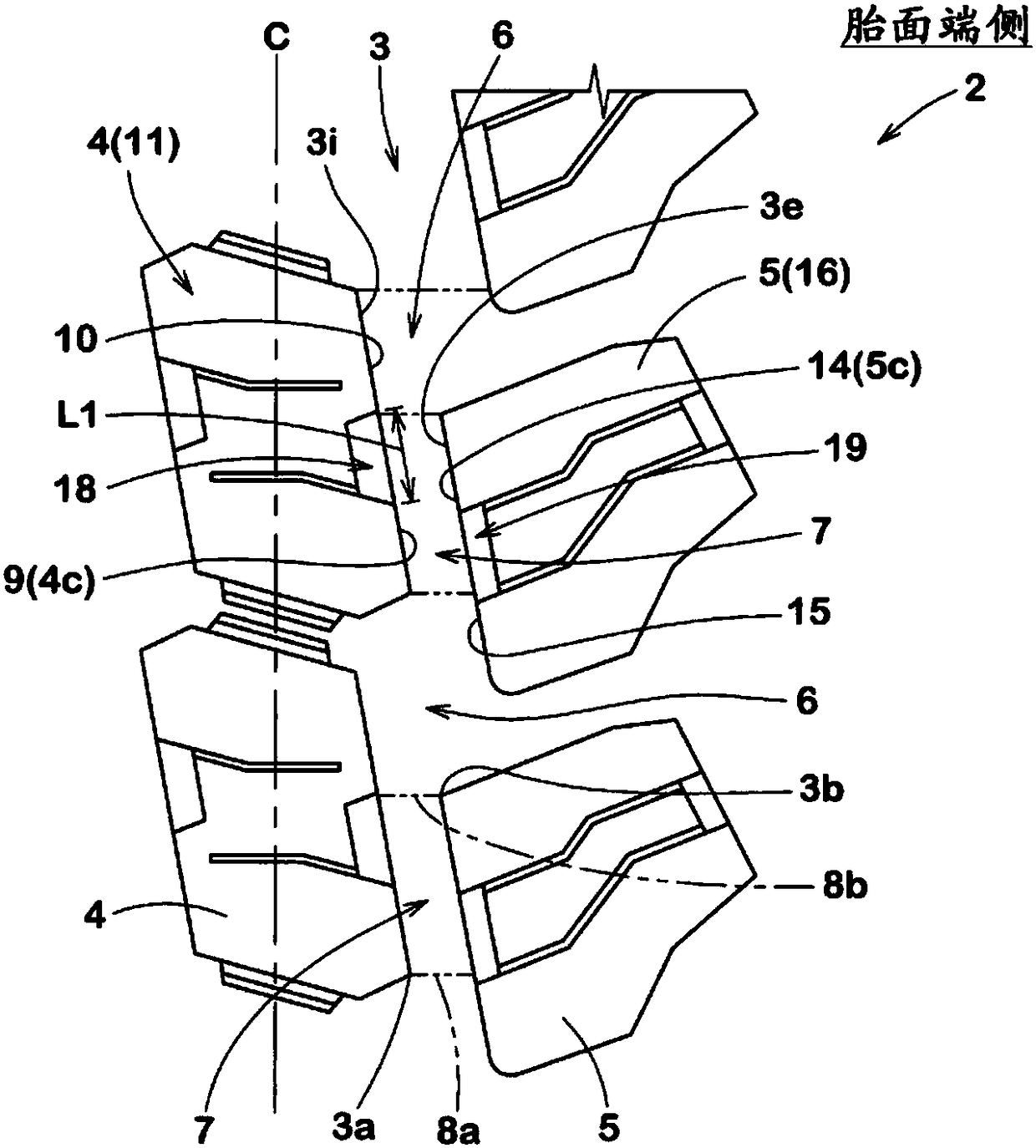

A pneumatic tire comprises a tread portion, a pair of sidewall portions, bead portions formed radially inside the sidewall portions, shoulder blocks arranged in the tire circumferential direction with first pitches on at least one of end portions of the tread portion, side protectors protruding axially outwardly on at least one of the sidewall portions which is located on a side of the shoulder blocks, a recessed portion between a pair of side protectors adjacent in the tire circumferential direction. The side protectors are arranged in the tire circumferential direction with second pitches larger than the first pitches. Each of the side protectors is provided with at least one first groove extending radially inwardly from a side of the tread portion and terminating within the side protector and at least one second groove extending radially outwardly from a side of the bead portion and terminating within the side protector.

Owner:SUMITOMO RUBBER IND LTD

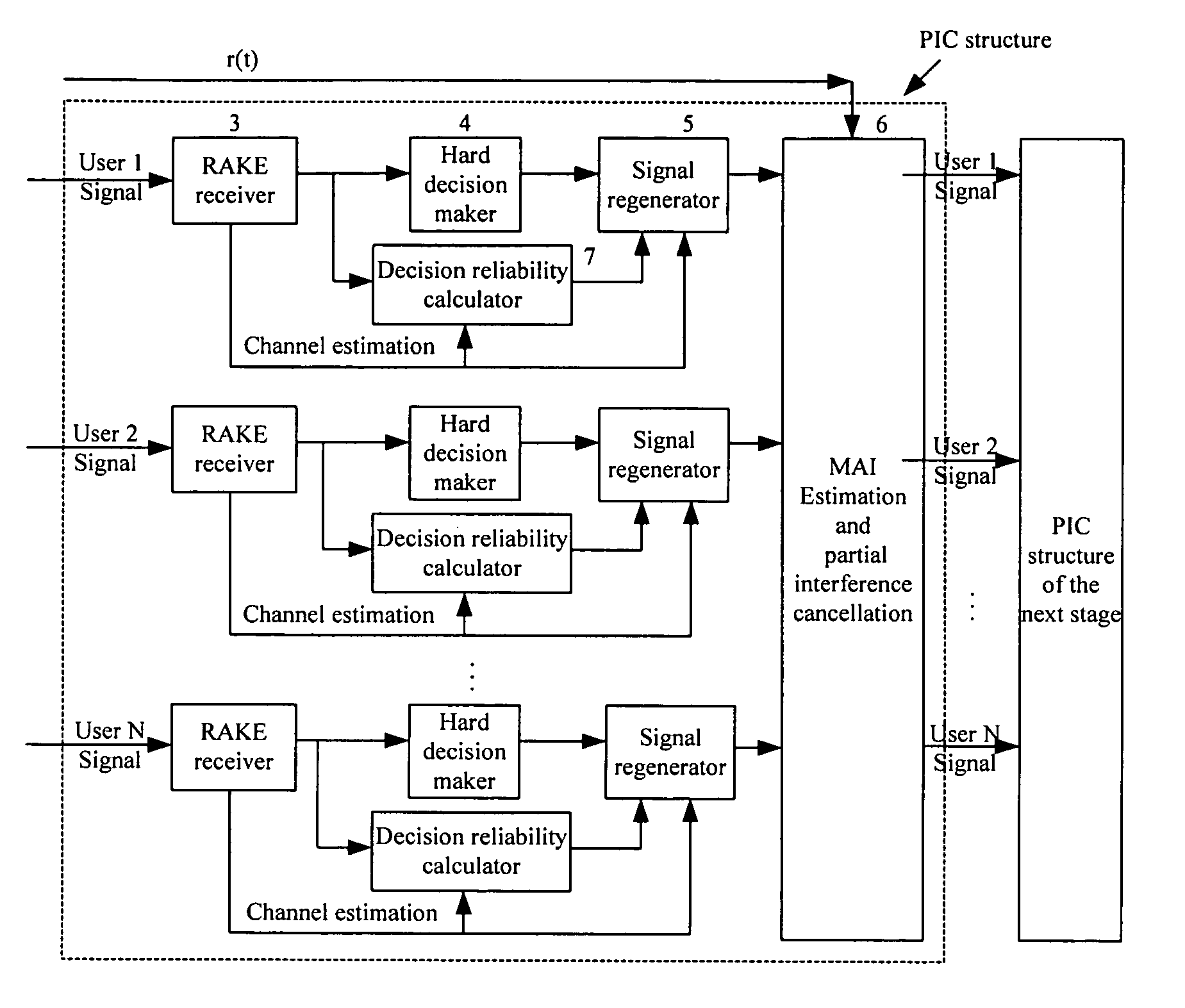

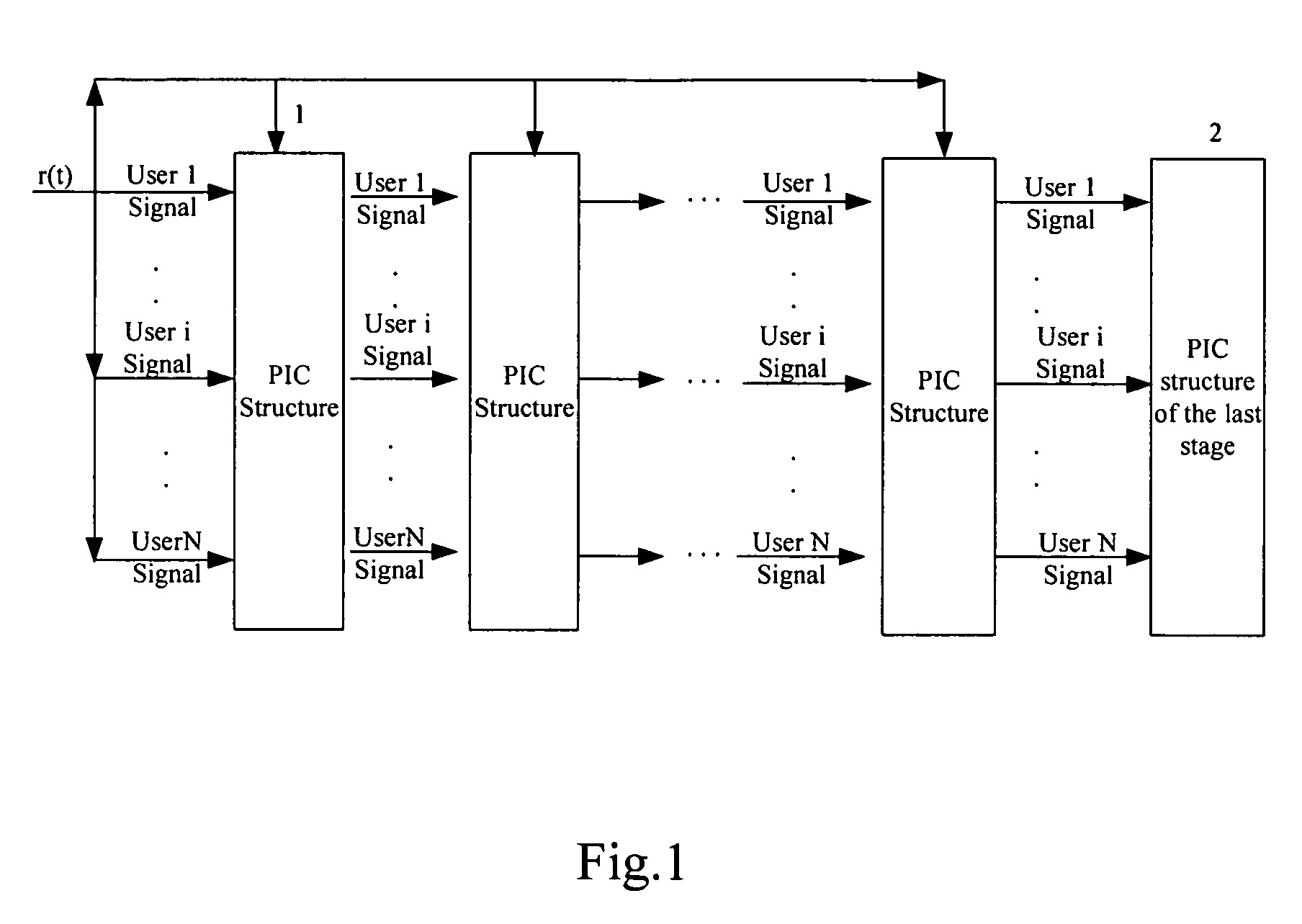

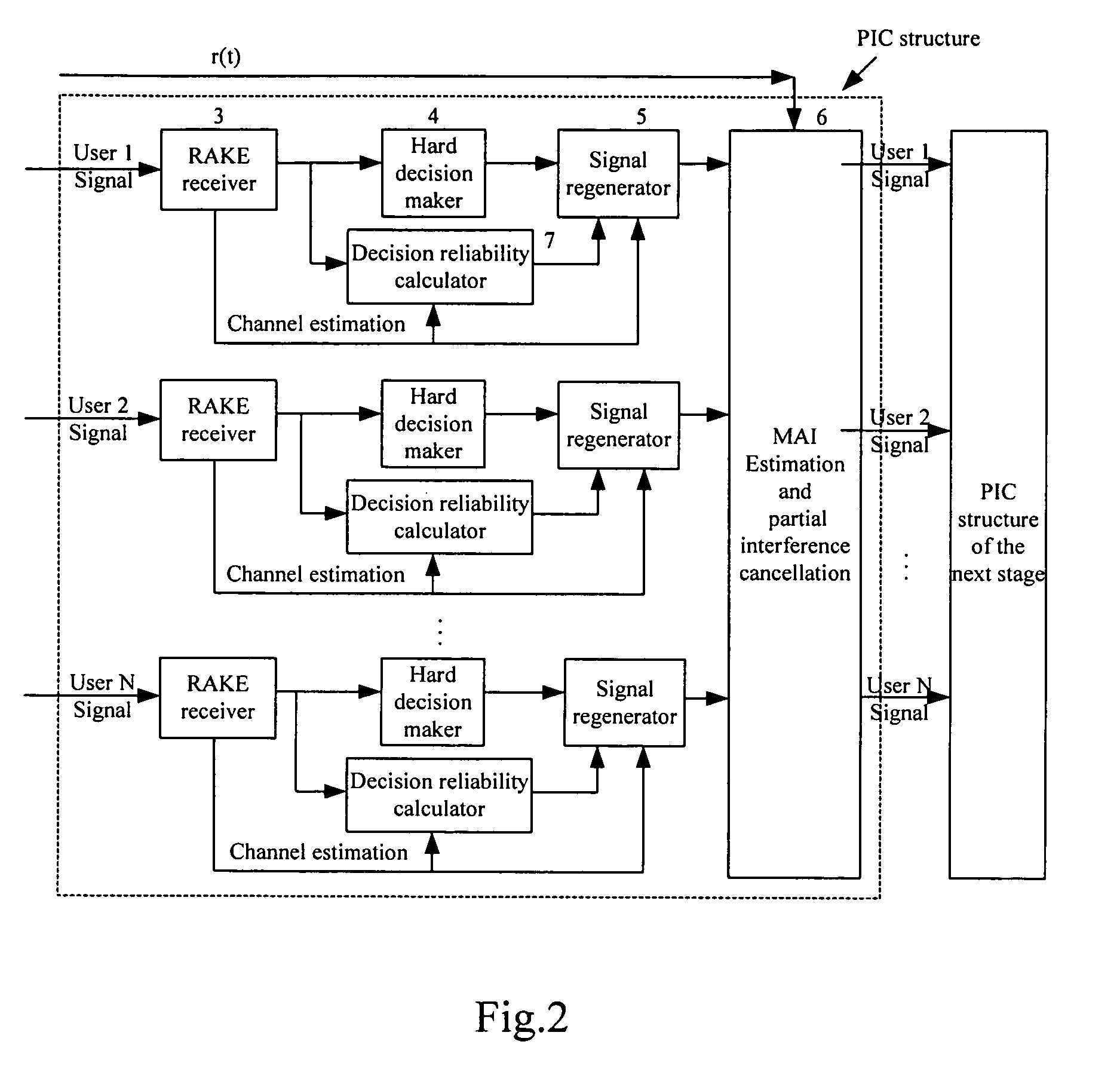

Method of double weighting parallel interference cancellation

ActiveUS7321581B2Reduce Algorithmic ComplexityPerformance unchangedRadio transmissionCommunications systemInterference cancelation

A method for double weighting parallel interference cancellation in CDMA mobile communication system, integrates ideas of both partial weighting method and weighting method based on Bayes rule. When making a decision on each symbol of the user, calculating reliability coefficient of a decision result on the symbol of the user according to the weighting algorithm based on Bayes rule; weighting regenerated signal of the symbol of the user with the reliability coefficient. During process of MAI estimating and removing, obtaining the MAI on the expected user from weighted regenerated signal of other users in chip level; and then setting a weight value, weighting the MAI with the weight value. Finally, removing weighted MAI from received signal, which means partially removing MAI produced by other users on the expected user. At the same time, the present invention also discloses a double weighting PIC method with simplified algorithm, which transfers weighting in chip level to weighting in symbol level, replacing a Hyperbolic tangent decision with a piecewise linear decision method or a look-up table method.

Owner:HUAWEI TECH CO LTD

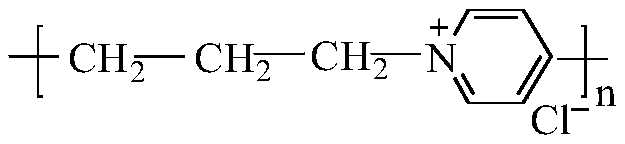

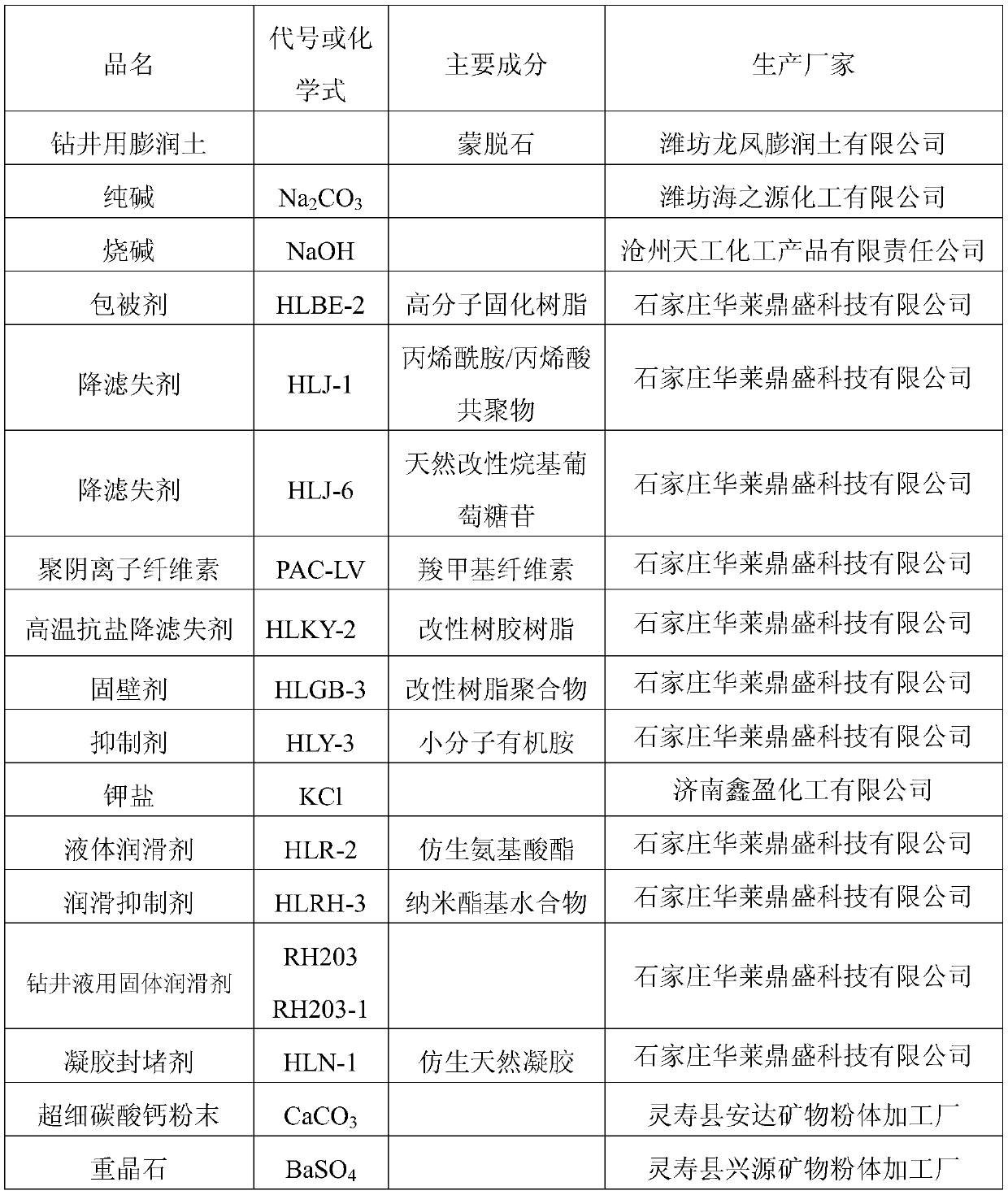

Three-protection-function water-base drilling fluid system

InactiveCN111574973AImprove performanceEasy to dehydrateDrilling compositionCellulosePhysical chemistry

The invention discloses a three-protection-function water-base drilling fluid system. Raw materials comprise 1000 parts of tap water, 40-50 parts of bentonite, 2-3 parts of sodium carbonate, 0.5-1 part of sodium hydroxide, 3-5 parts of coating agents HLBE-2, 6-8 parts of filtrate reducers HLJ-1, 15-20 parts of filtrate reducers HLJ-6, 5-7 parts of polyanionic cellulose PAC-LV, 5-10 parts of high-temperature salt-resistant filtrate reducer HLKY-2, 20-25 parts of wall-fixing agents HLGB-3, 20-25 parts of liquid lubricants HLR-2, 20-25 parts of lubrication inhibitors HLRH-3, 20-25 parts of drilling fluid solid lubricants, 5-10 parts of inhibitors HLY-3, 70-80 parts of KCl, 2-2. 5 parts of gel plugging agents HLN-1, 10-15 parts of superfine calcium carbonate powder, and a weighting agent. Thethree-water-retention-base drilling fluid system has good inhibition performance and good plugging performance, and is used for drilling of mud rock-siltstone inclined shaft sections and horizontal sections. Therefore, a problem that the well wall is prone to instability in the drilling process of water-based drilling fluid is solved, and the three-protection function of protecting the well wall,protecting an oil-gas layer and protecting the environment is achieved.

Owner:石家庄华莱鼎盛科技有限公司

Lignosulfonate for drilling fluid and lignosulfonate preparation method

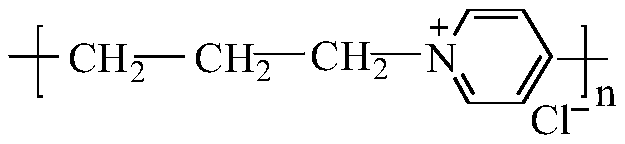

InactiveCN104892955AGood mud performanceImprove mud performanceDrilling compositionLignosulfonatesSodium lignosulfonate

The invention provides lignosulfonate for drilling fluid and a lignosulfonate preparation method. The lignosulfonate is obtained by mixed reaction of a complexing agent and sodium lignin sulfonate prepared from liquid glucose. By selection of special sodium salt of lignosulfonate and taking of the sodium lignin sulfonate prepared from liquid glucose as a starting material, the prepared lignosulfonate for drilling fluid has an excellent mud property no matter at the normal temperature or the high temperature, and generation of harmful waste residues in a preparation process is avoided.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

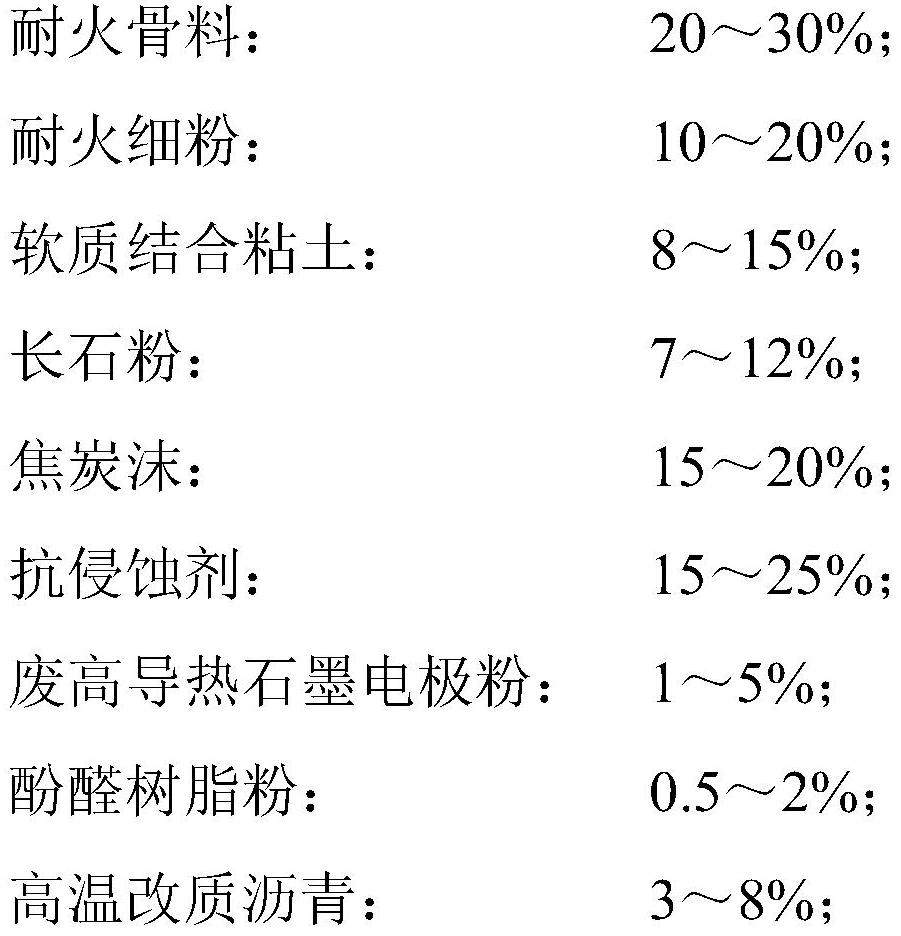

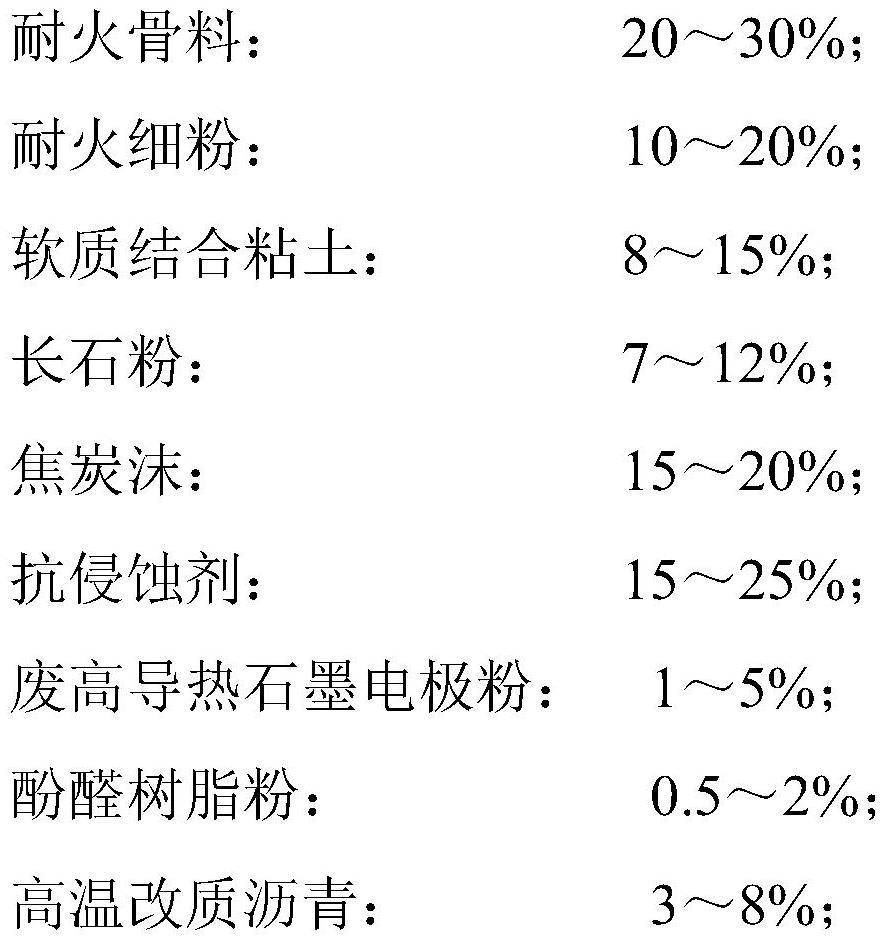

Single-field anhydrous stemming for high-strength smelting small blast furnace as well as preparation method and application of single-field anhydrous stemming

PendingCN113860891AHigh thermal conductivityFast sintering speedCeramic materials productionClaywaresGraphite electrodeCoke

The invention discloses single-field anhydrous stemming for a high-strength smelting small blast furnace as well as a preparation method and application of the single-field anhydrous stemming. The raw materials comprise, by mass, 20-30% of refractory aggregate, 10-20% of refractory fine powder, 8-15% of soft binding clay, 7-12% of feldspar powder, 15-20% of coke foam, 15-25% of an anti-erosion agent, 1-5% of waste high thermal conductivity graphite electrode powder, 0.5-2% of phenolic resin powder, and 3-8% of high temperature modified asphalt; the raw materials are mixed according to the proportion, tar serves as a binding agent, mud is discharged after the mixture is mixed and ground to a proper state, and the anhydrous stemming is obtained through mud extrusion forming. And the anhydrous stemming is transferred to a site, and is put into the furnace from an iron notch channel by using a mud gun machine to form a mud drum on the furnace wall. The water-free stemming has the advantages of favorable mud making performance, high curing speed, short blasting time, favorable sintering property, no dense smoke in the tapping process, basically no need of baking an iron notch, 25-30 minutes of tapping interval, short splashing time and favorable scouring and erosion resistance, and can meet the harsh requirements of high-strength smelting of small blast furnaces on the water-free stemming.

Owner:中冶检测认证有限公司 +1

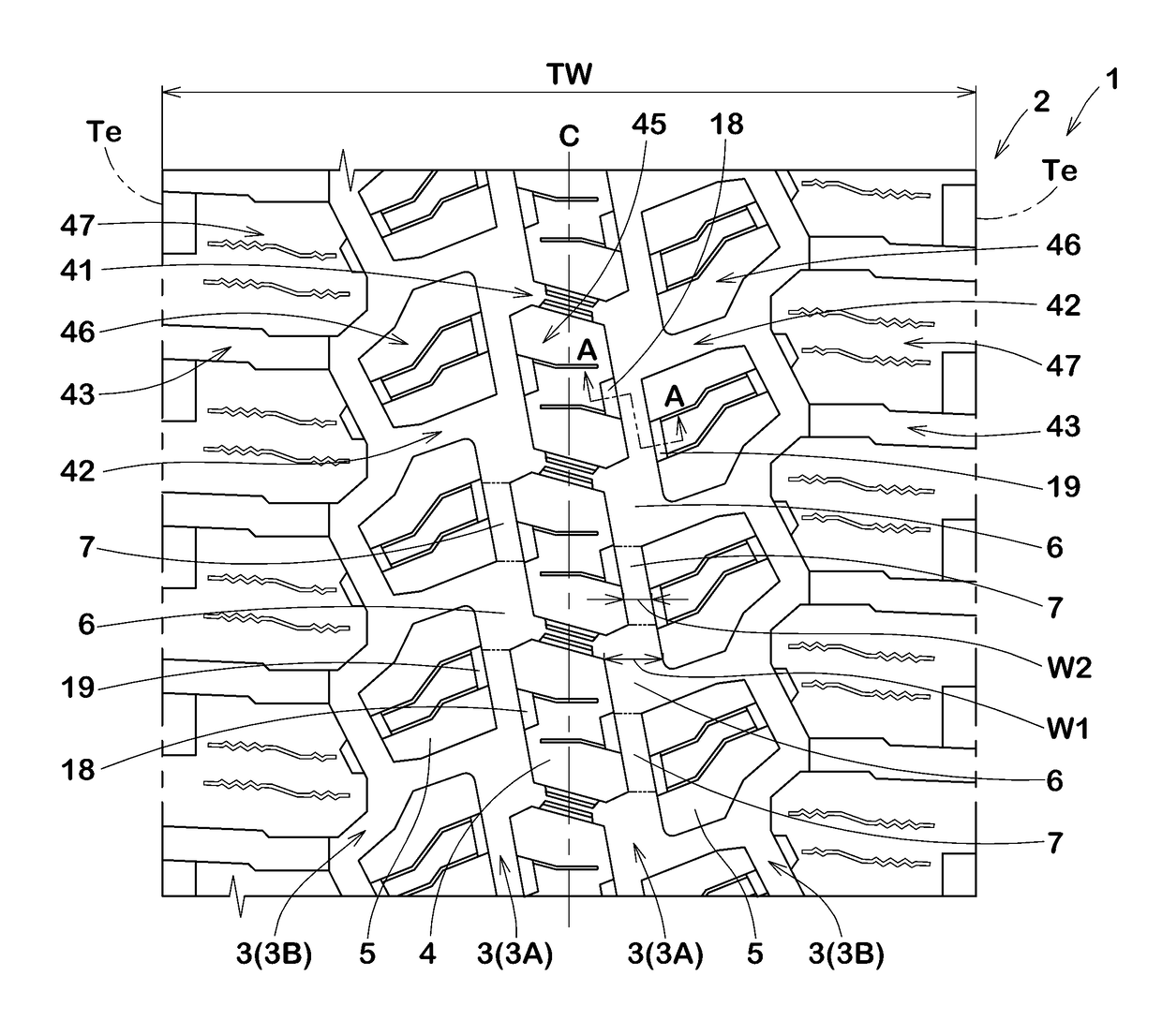

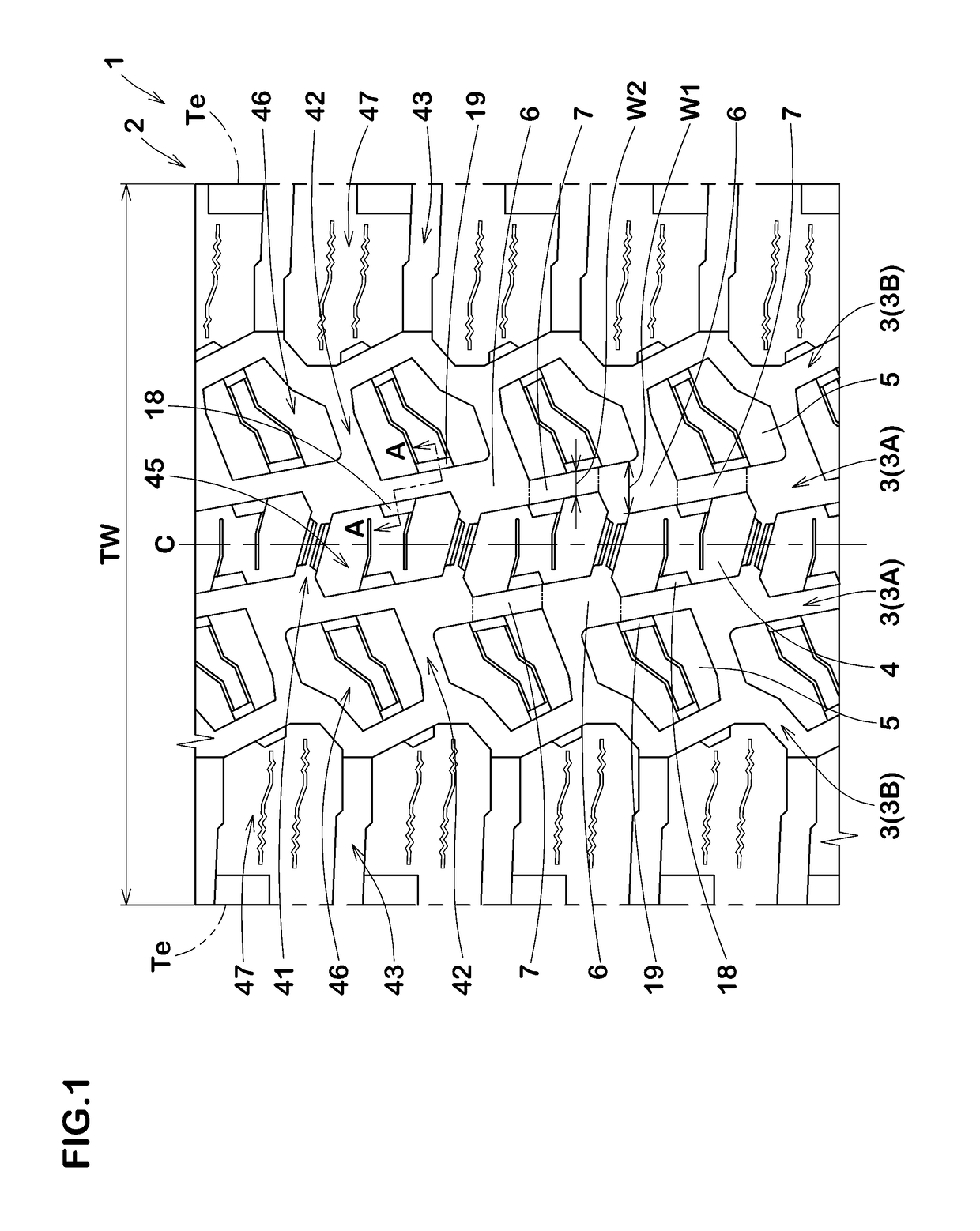

Tire

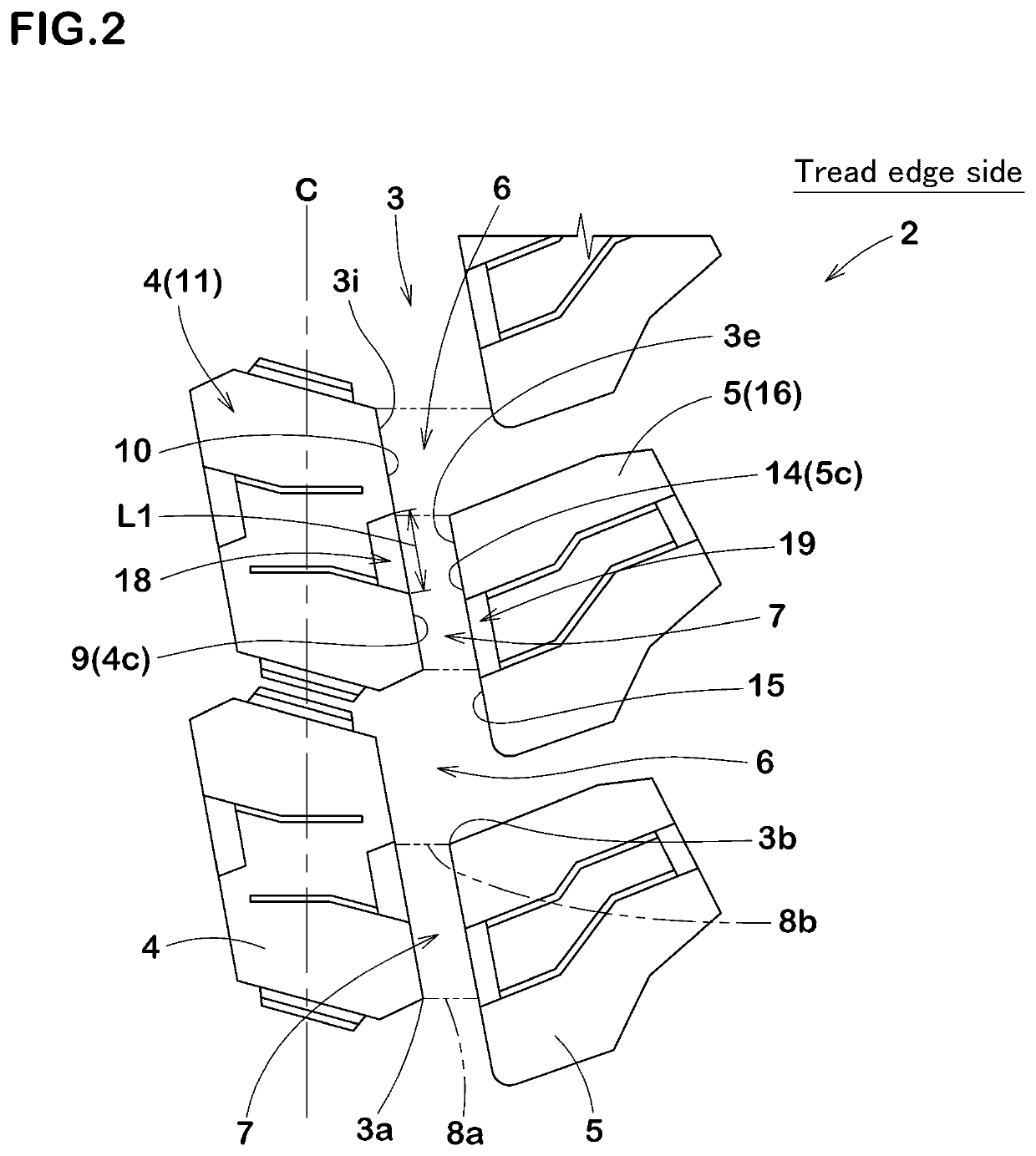

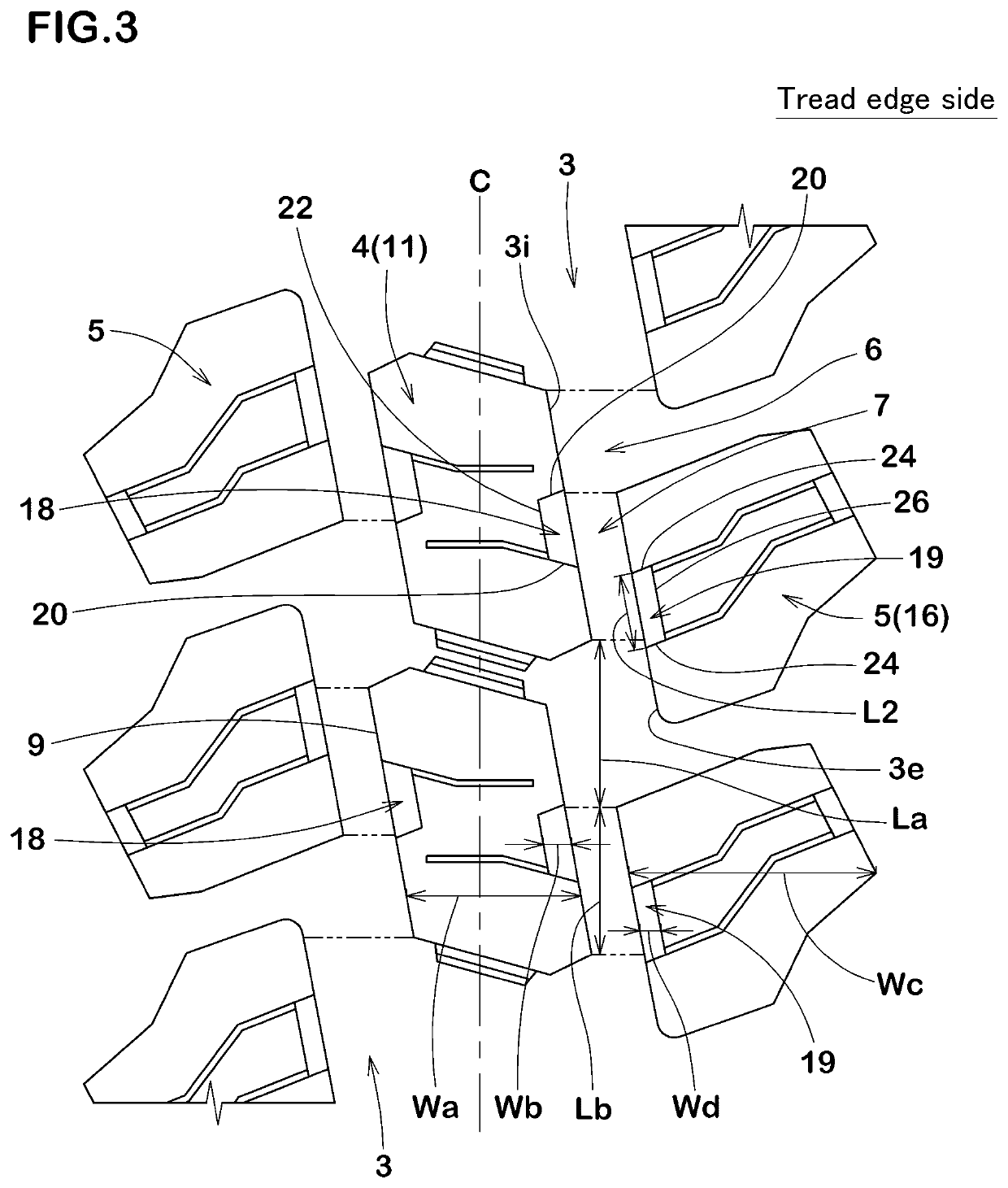

ActiveCN108688412AImprove mud performanceImprove Noise PerformanceTyre tread bands/patternsGround contactGroove width

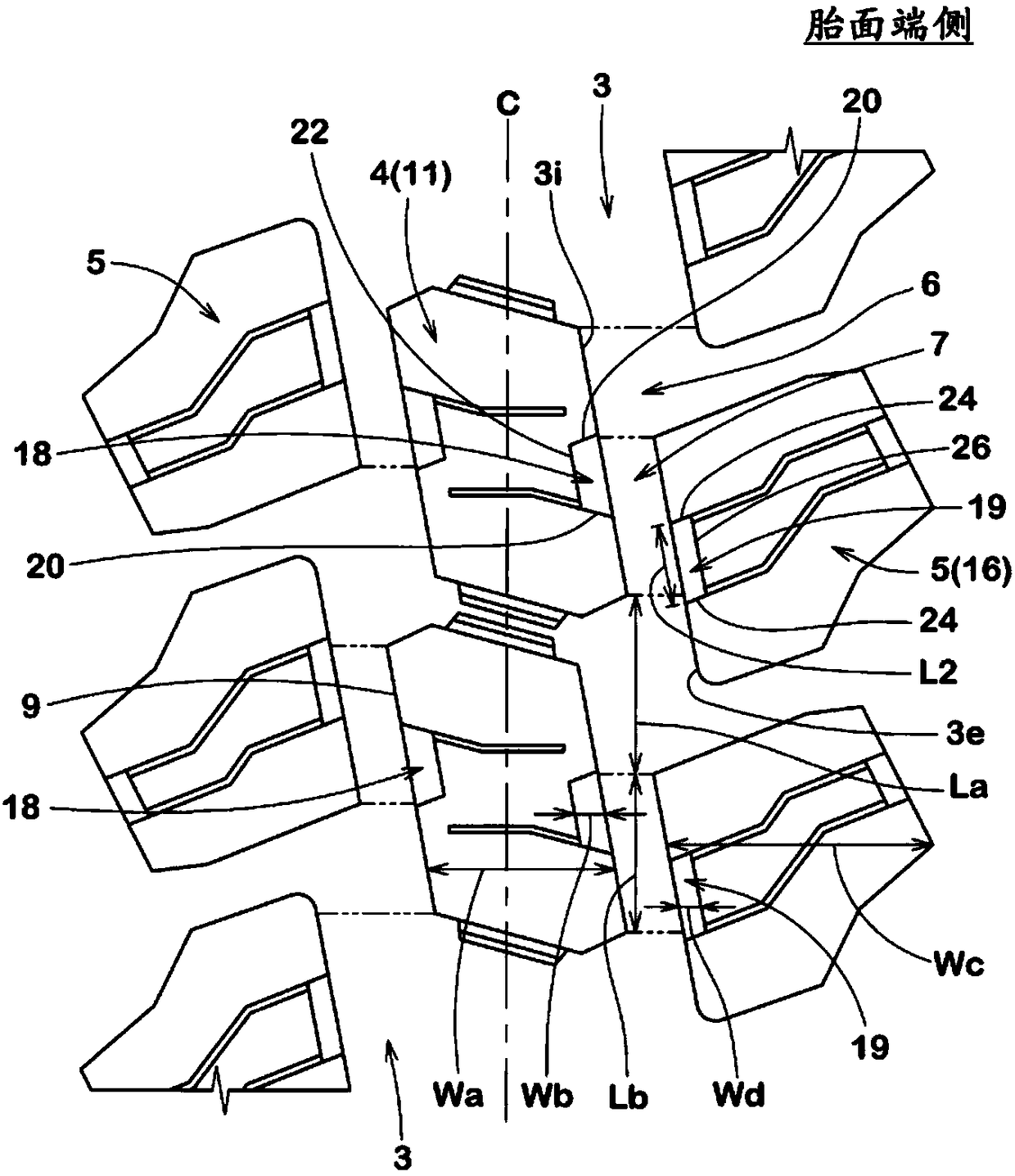

The invention provides a tire capable of exerting good mud performance and dirt performance. A tire(1) includes a tread portion including a main groove(3), a first block(4) and a second block(5) whichare adjacent to one another in a tire axial direction through the main groove. The main groove includes first groove elements(6) and second groove elements(7) having groove widths smaller than that of the first groove elements. The first block includes a first ground contact surface(4a), a first sidewall(9) facing one of the second groove elements(7), a first corner portion between the first ground contact surface and the first sidewall, and a first recess(18) being cut out the first corner portion(4c) locally. The second block includes a second ground contact surface, a second sidewall(14) facing said one of the second groove elements(7), a second corner portion between the second ground contact surface and the second sidewall, and a second recess(19) being cut out the second corner portion(5c) locally.

Owner:SUMITOMO RUBBER IND LTD

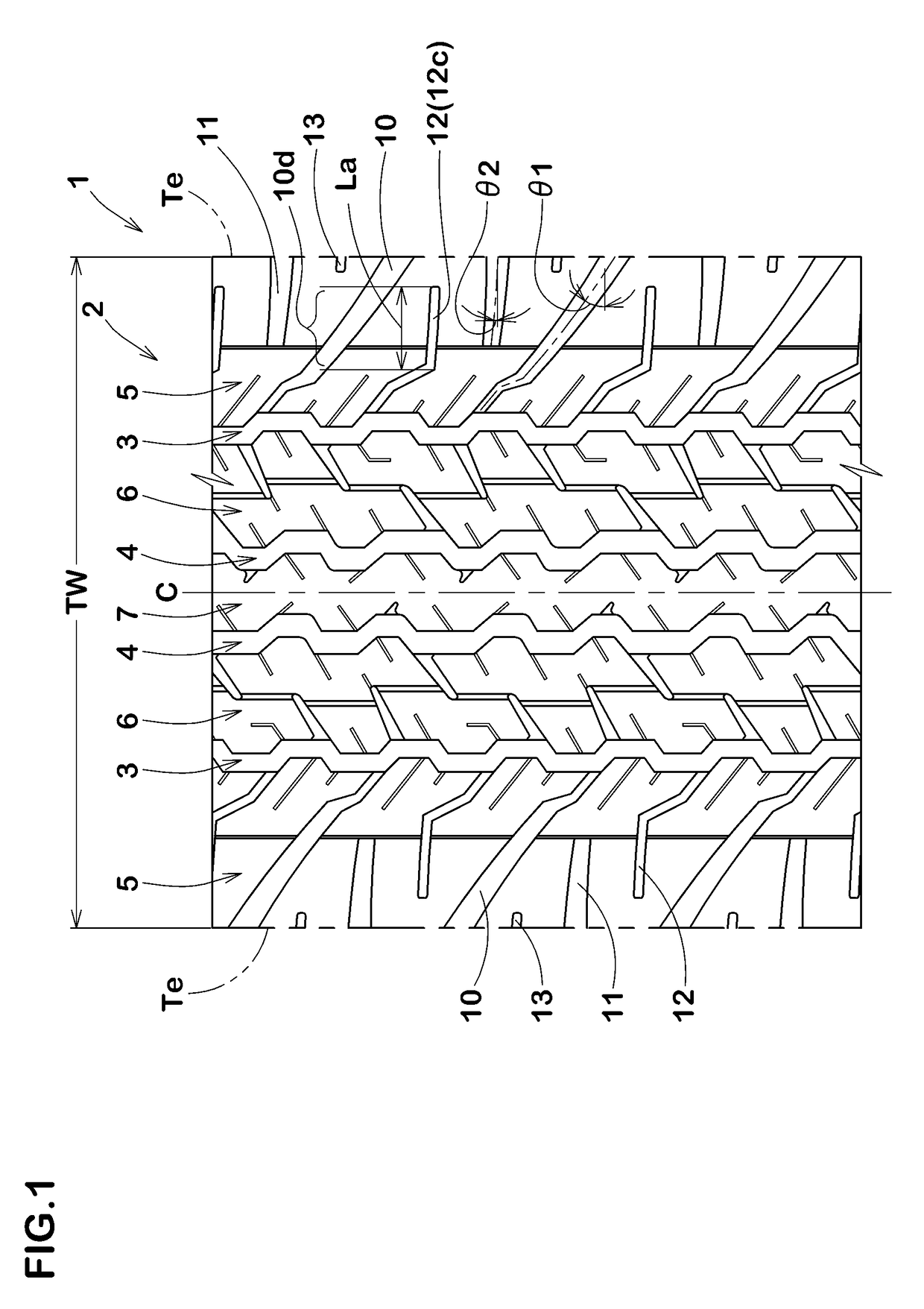

Tire

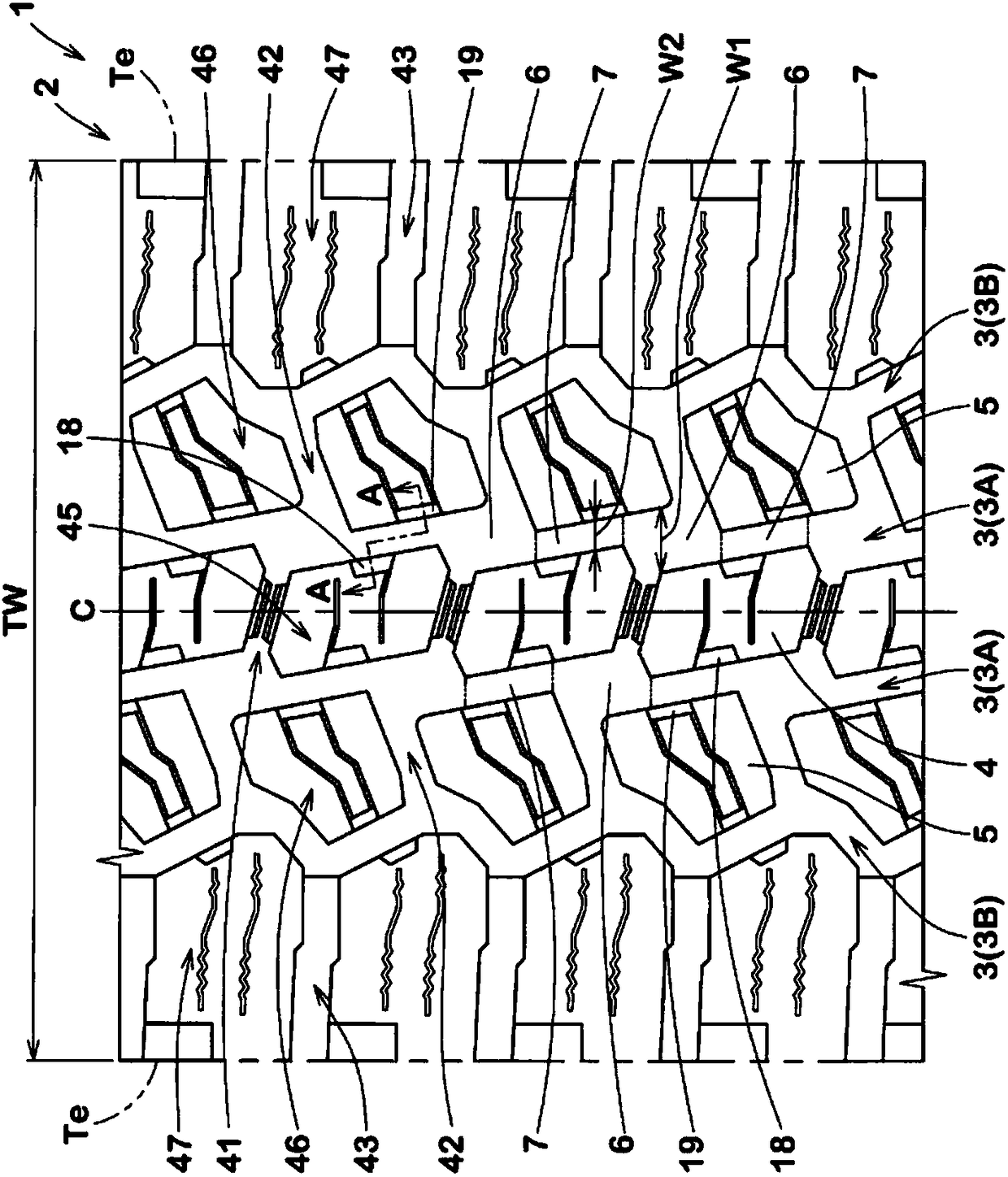

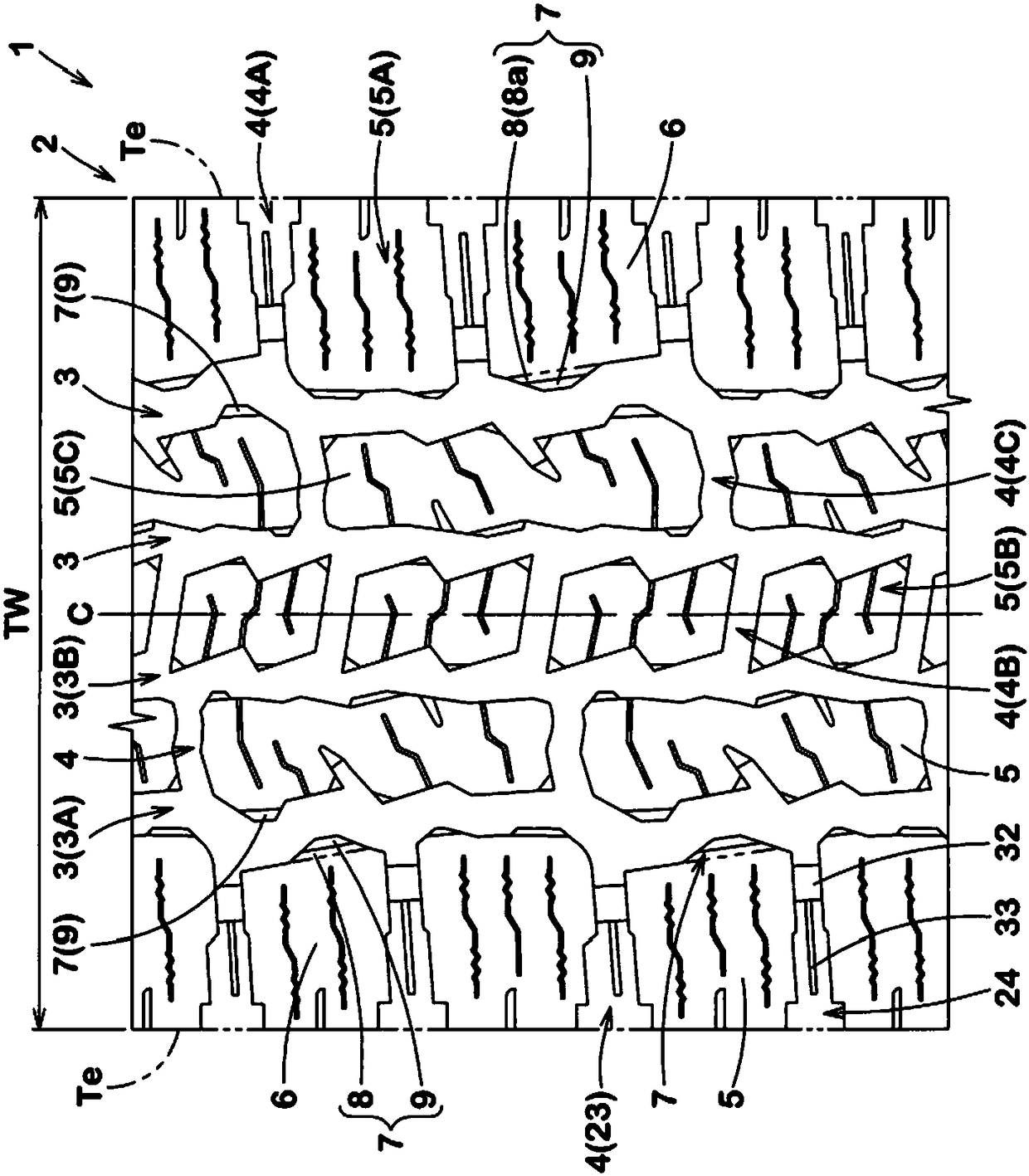

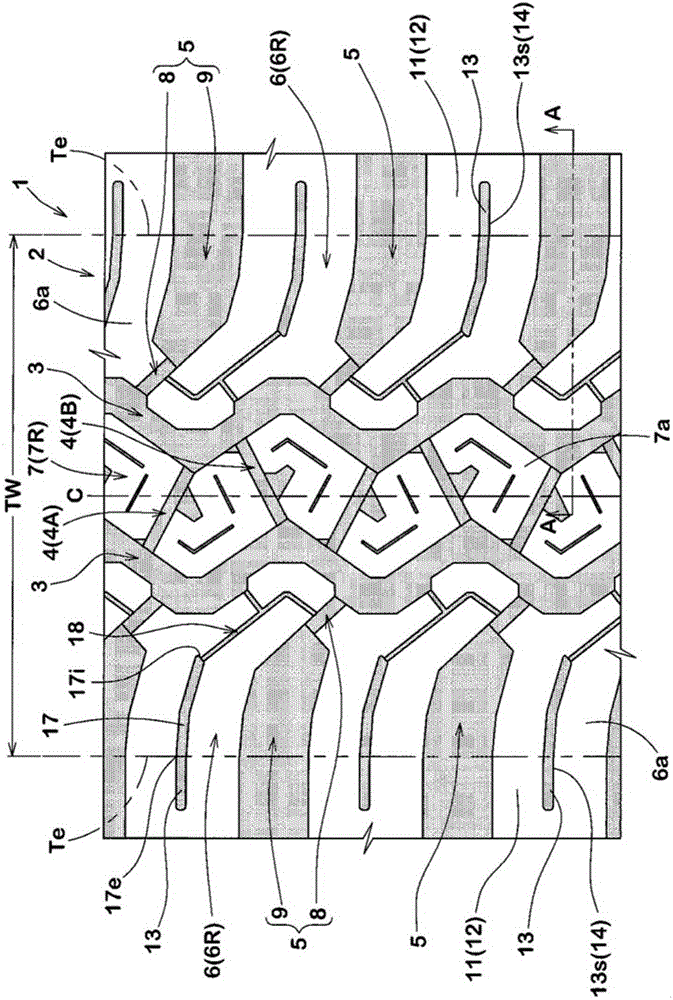

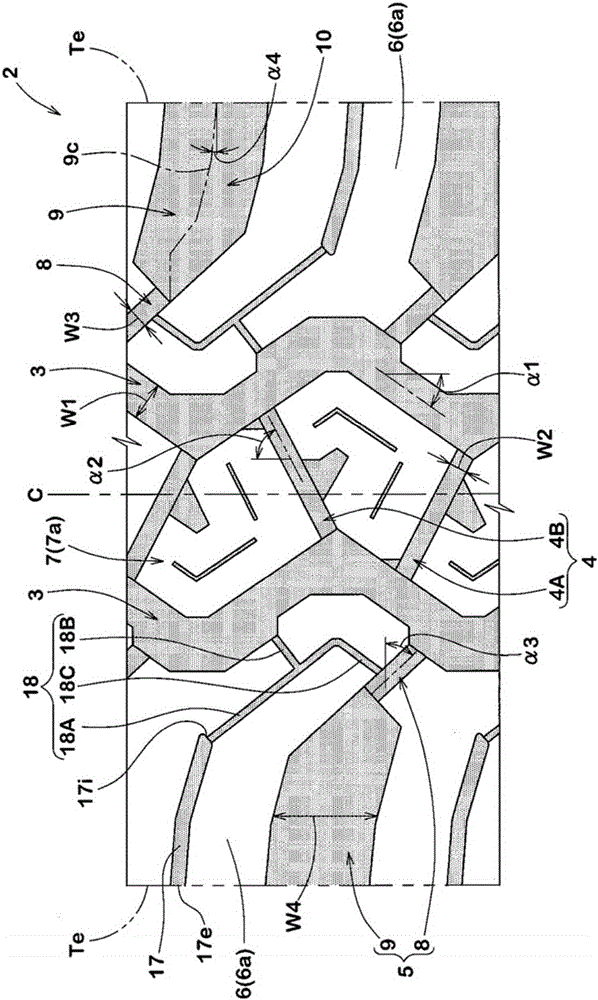

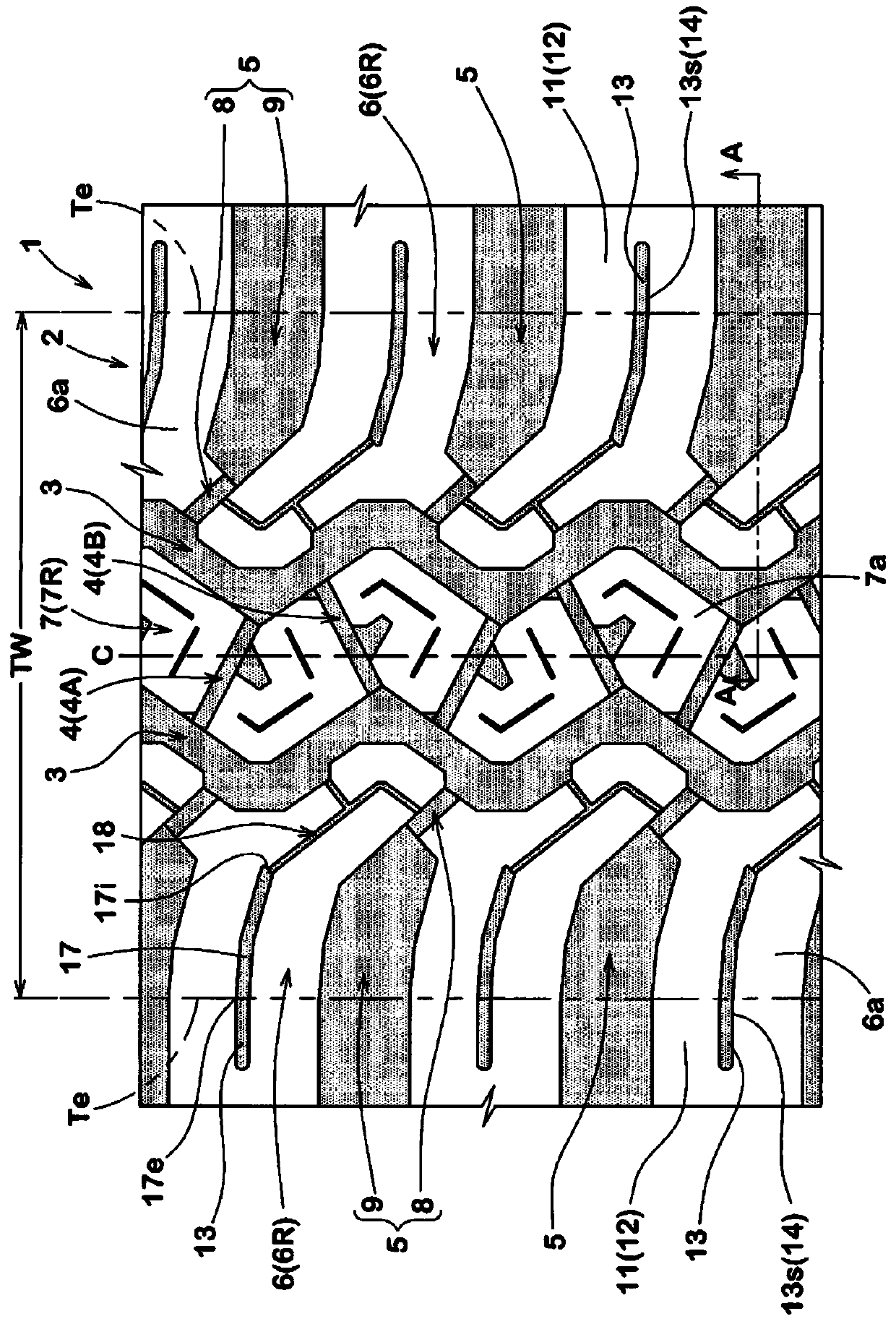

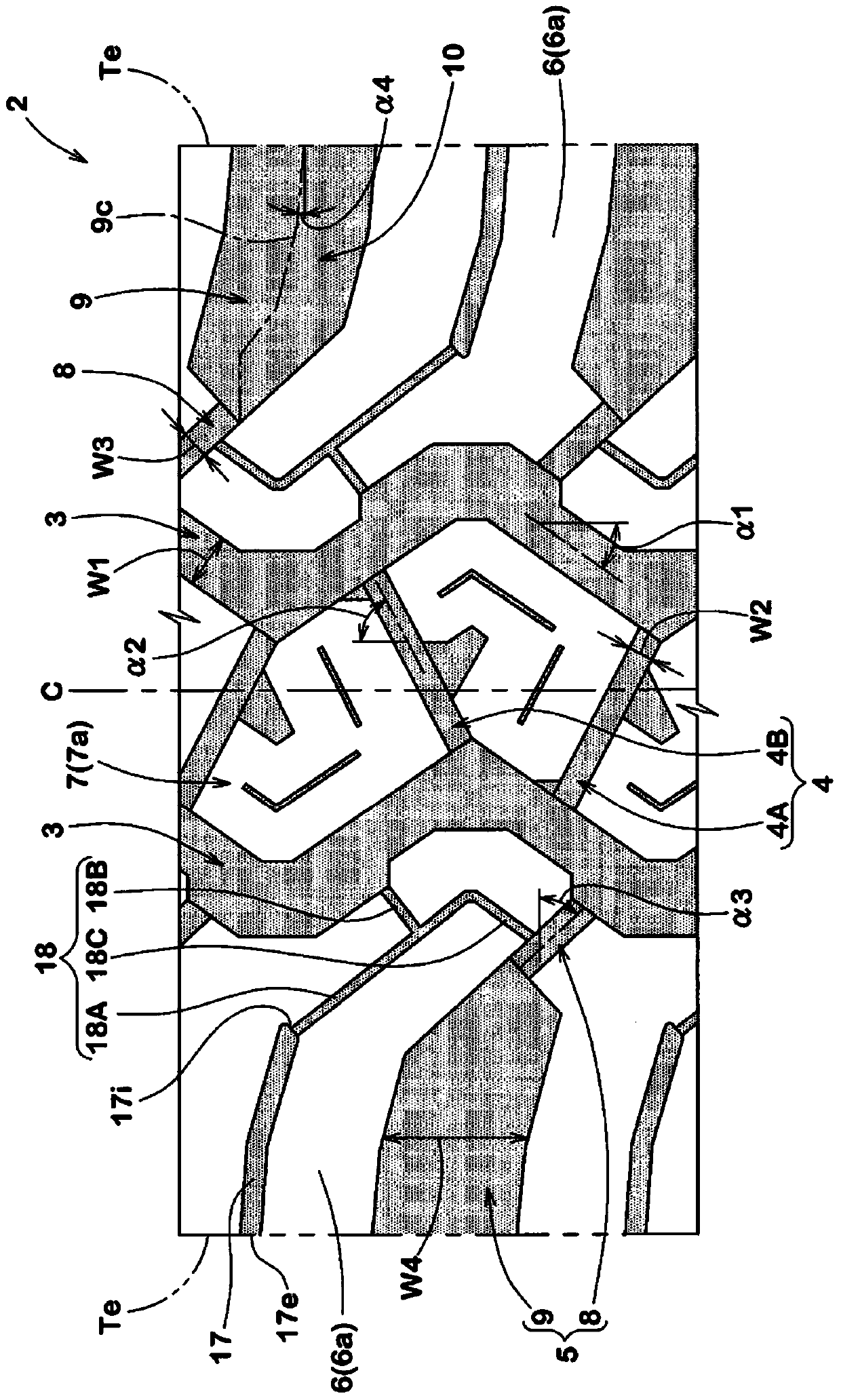

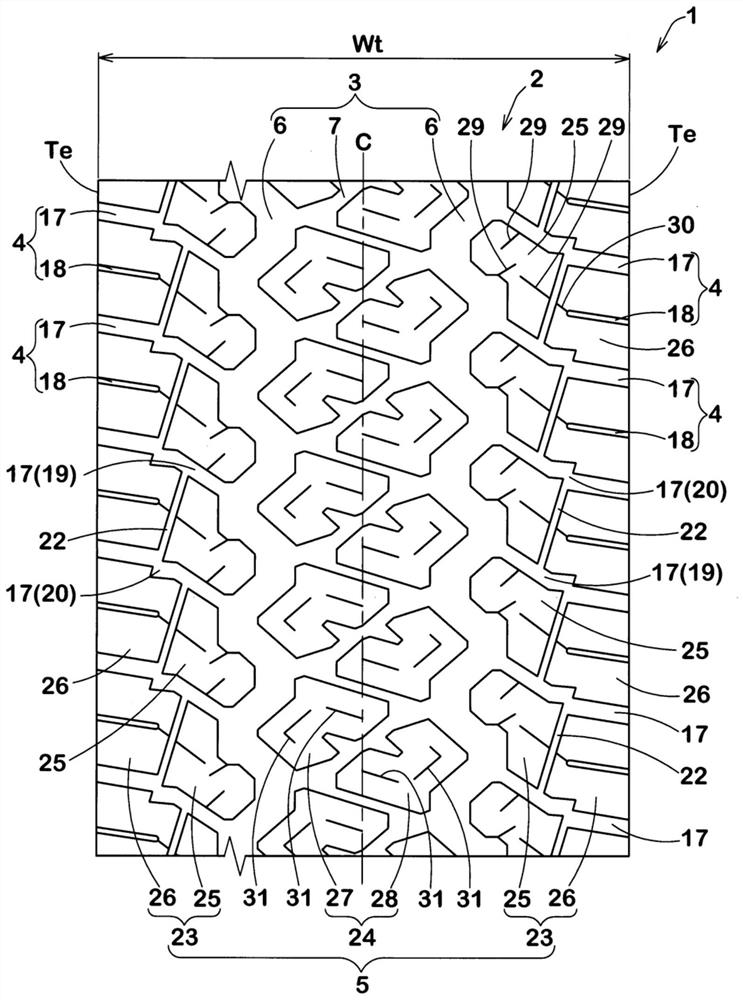

PendingCN108340739AEasy dischargeMaintain muddy performanceOff-road vehicle tyresTyre tread bands/patternsGround contactMechanical engineering

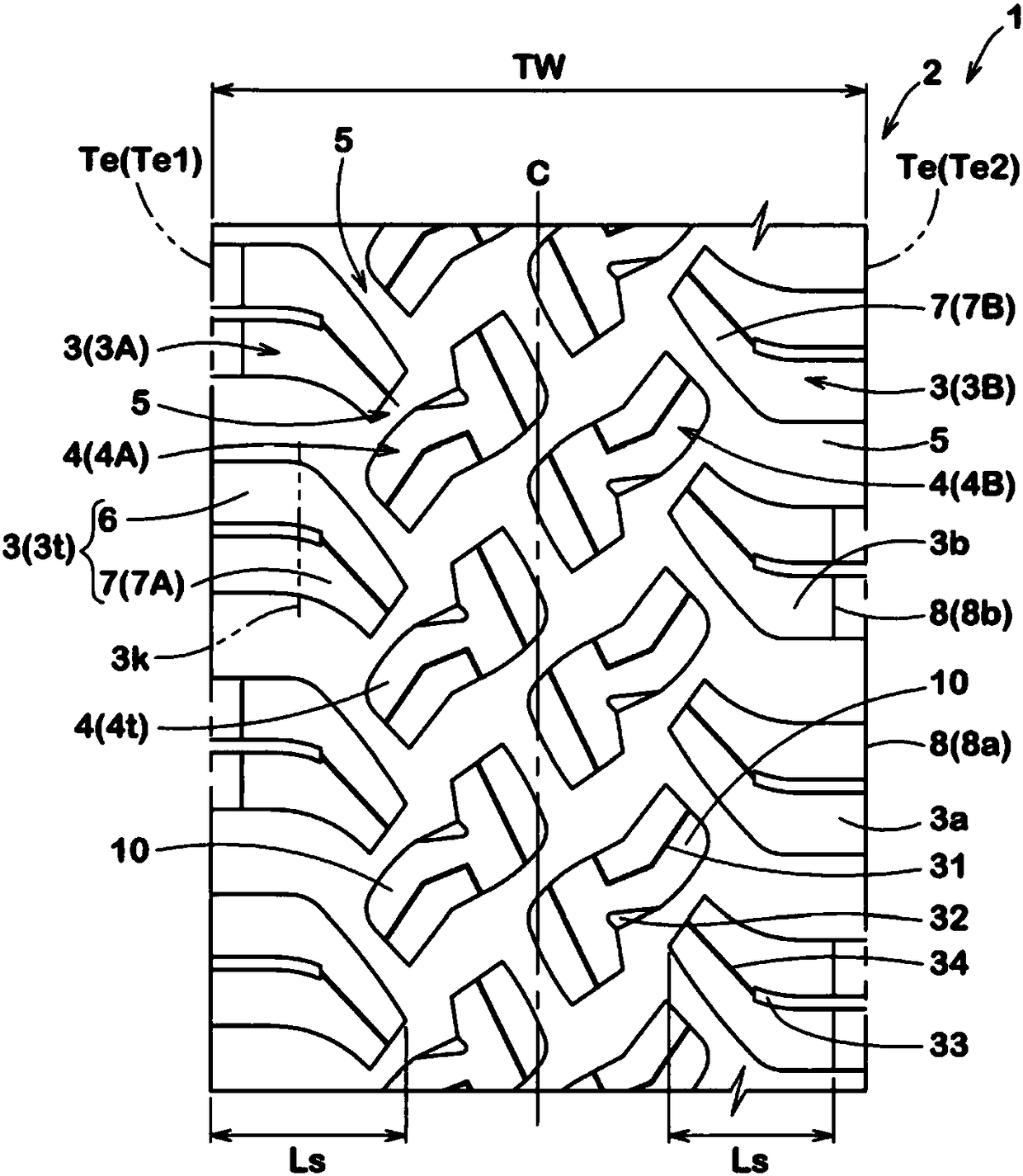

The invention provides a tire capable of improving the sand road performance and the highway performance while maintaining the mud performance. The tire (1) comprises a tread portion (2) comprising shoulder pattern blocks (3) and crown pattern blocks (4). The shoulder pattern blocks (3) each have a ground contacting surface (3t) comprising a gently oblique portion (6) extending to the axial innerside of the tire from the tread edge (Te) side and a steeply oblique portion (7) connected with the gently oblique portion (6) and having a larger inclination angle with respect to the tire axial direction than the gently oblique portion (6). The crown pattern blocks (4) each have a ground contacting surface (4t) comprising a first oblique portion (10) inclined oppositely to the steeply oblique portion (7) and a second oblique portion (11) which is connected to the first oblique portion (10), opposite to the first oblique portion (10) and inclined toward the tread edge (Te) side. In a development view of the tread portion (2), long side directions of the steeply oblique portion (7) and the first oblique portion (10) intersect at an angle from 70 to 110 degrees.

Owner:SUMITOMO RUBBER IND LTD

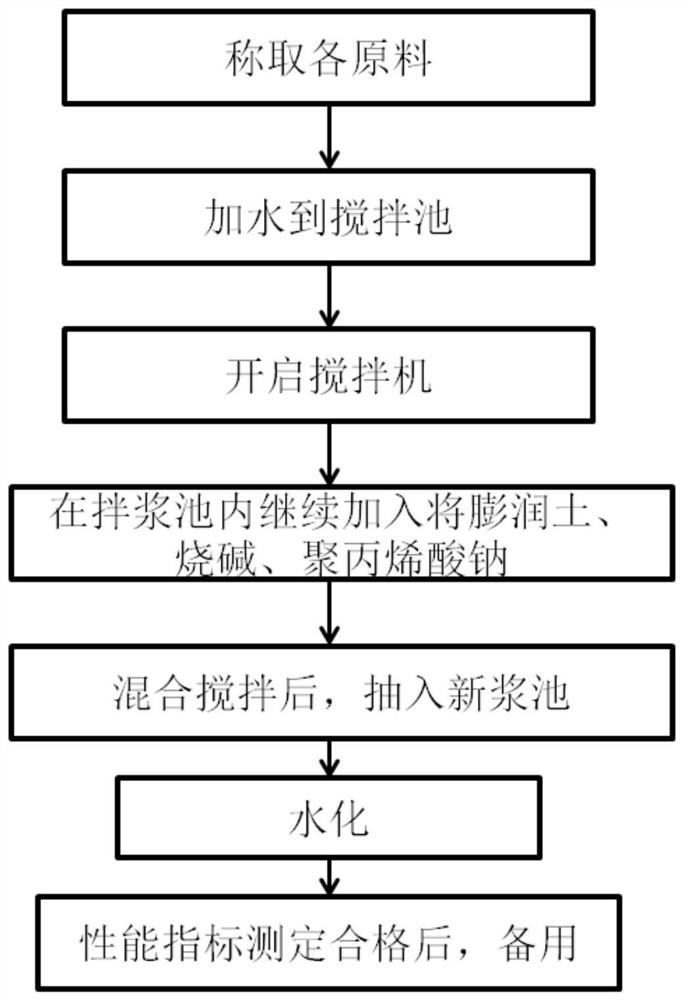

Pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry and preparation method thereof

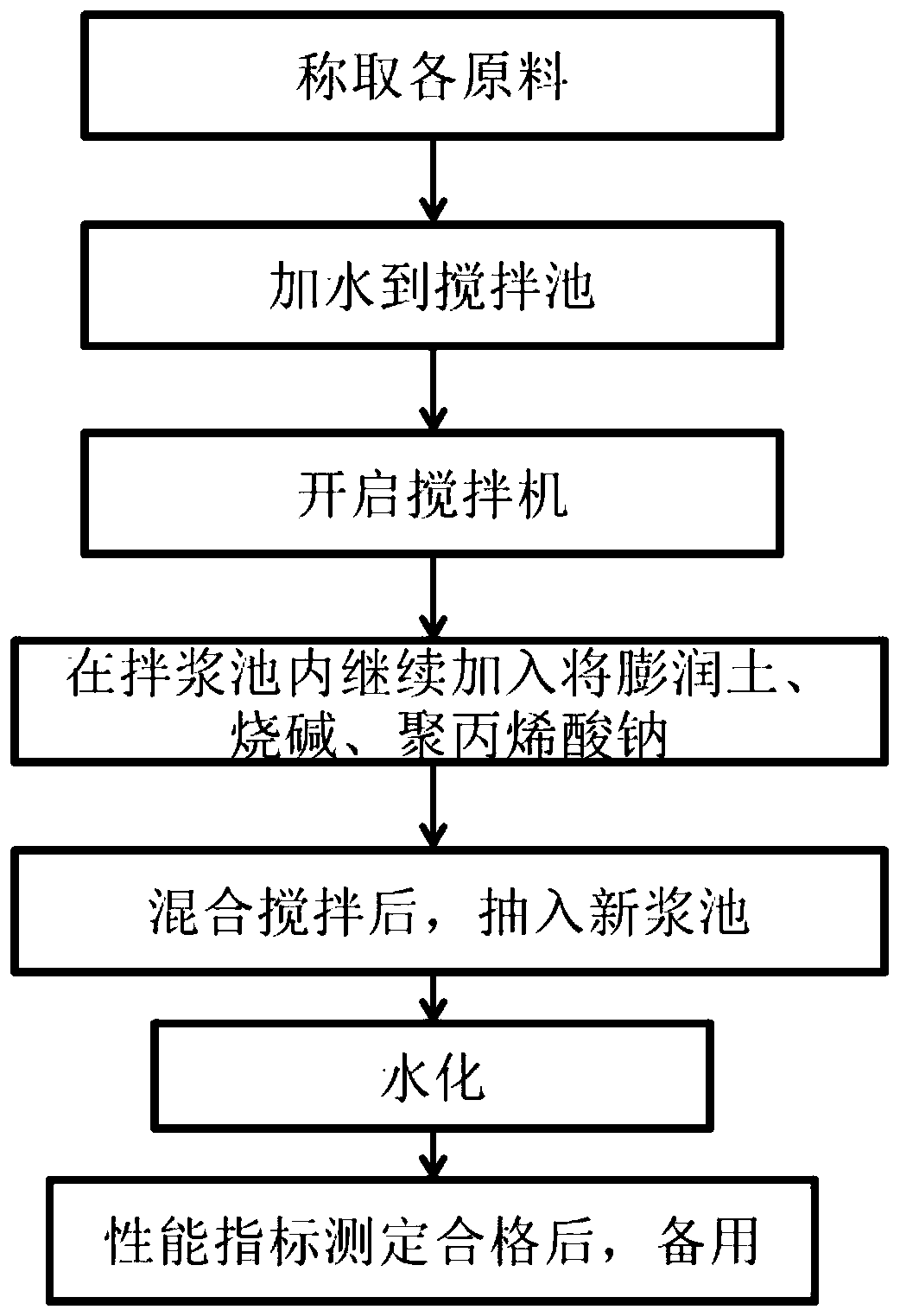

ActiveCN110066661AWall protection effect is goodImprove recycling ratesBuilding constructionsOrganic fertilisersSlurry wallMaterial consumption

The invention relates to the field of building construction, and provides pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry. The pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry is prepared from, by weight, 1,000 parts of water, 75-85 parts of bentonite, 3-5 parts of sodium carbonate and 0.5-1.5 parts of sodium polyacrylate. The invention further provides a preparation method of the pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry. The pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry has the advantages that sodium polyacrylate is adopted for replacing traditional CMC, the slurry wall protecting performance and theslurry recycling rate are greatly increased, and meanwhile corresponding environment contamination and material consumption are reduced; meanwhile, various indexes of the slurry prepared through theformula can meet the requirement of circulating slurry indexes, the wall protecting effect is good, and the groove wall stability is good.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

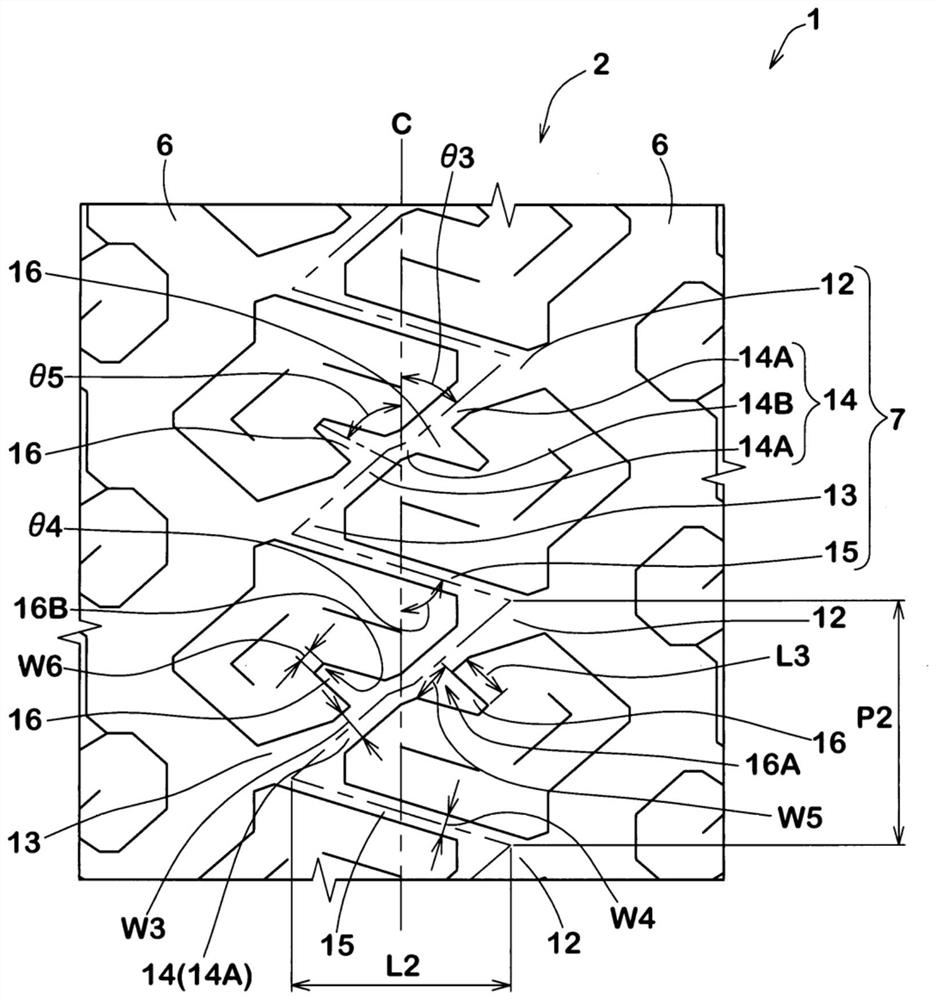

Tire

ActiveCN108569086AImproved performance on dirt roadsIncrease shear forceOff-road vehicle tyresTyre tread bands/patternsGround contactRoad surface

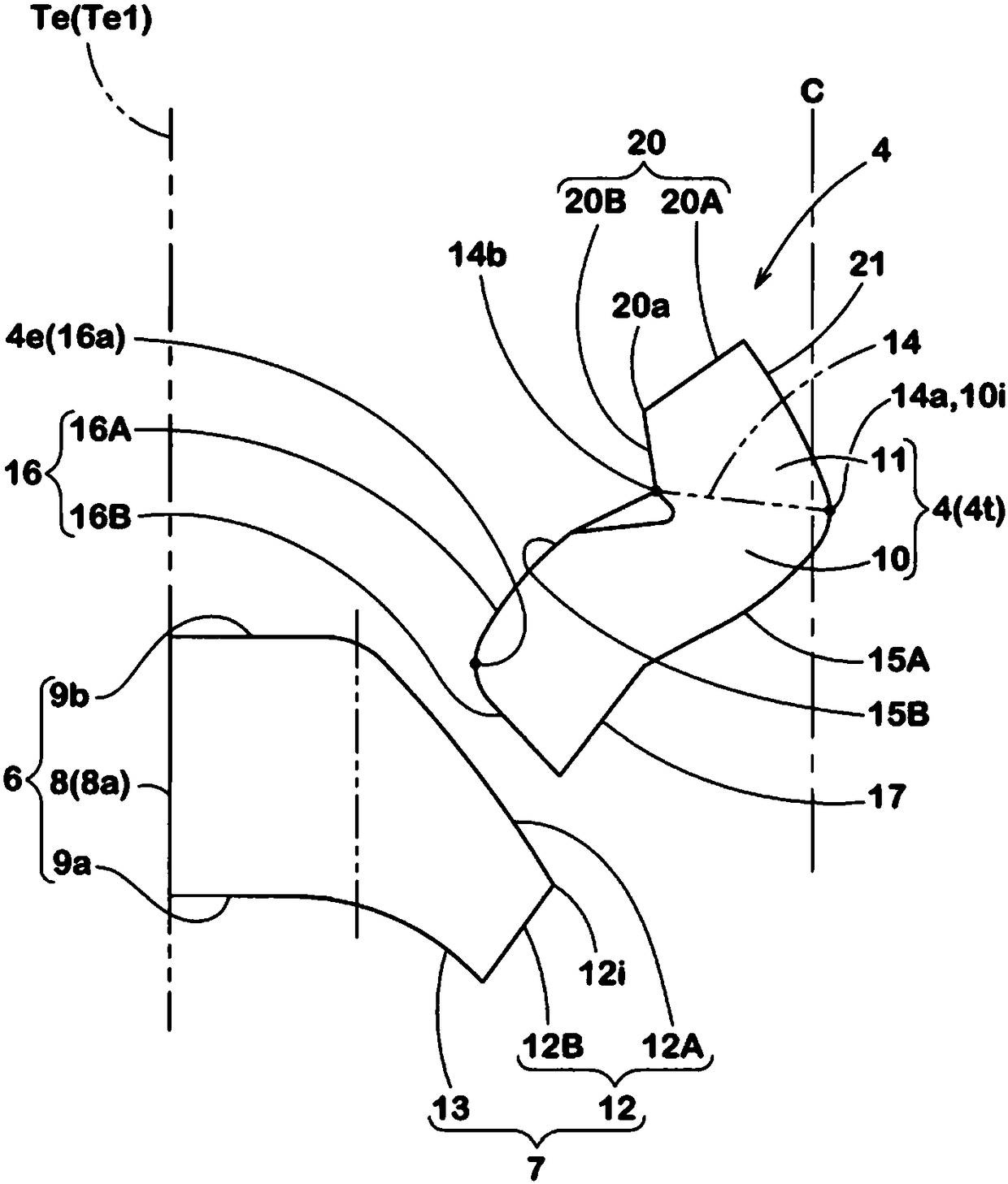

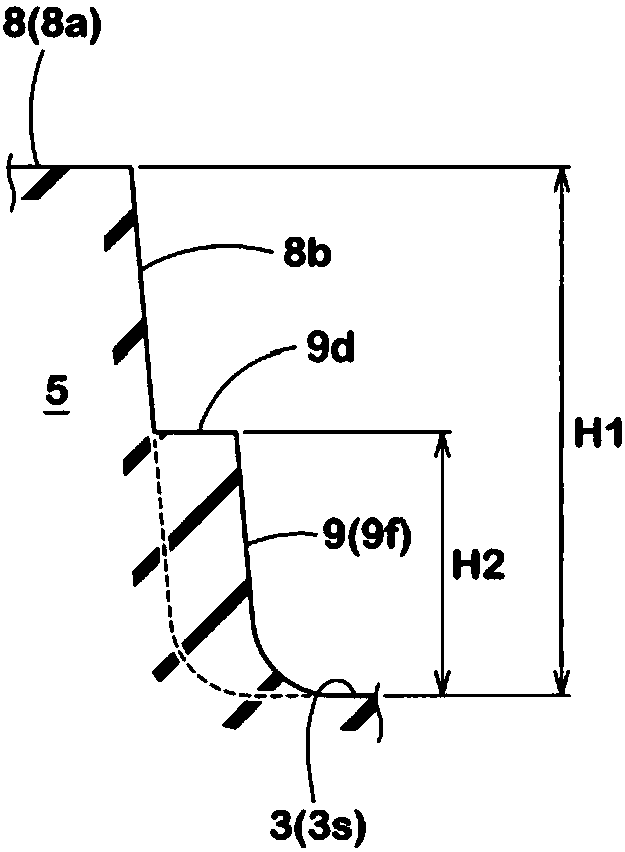

A tire of the present invention can exhibit good mud path performance, wet performance, and steering stability performance on a dry road surface. A tire 1 comprises a tread portion 2 comprising a plurality of blocks 5. In a development view of the tread portion 2, at least one of the blocks 5 include a block body 6 arranged between lateral grooves 4 and a protruding portion 7 protruding from the block body 6 toward a main groove 3. The protruding portion 7 comprises a first part 8 having a ground contacting surface (8a) extending continuously from the block body 6 and a second part 9 arrangedcloser to the main groove 3 than the first part 8 and on an inner side of the ground contacting surface (8a) in a tire radial direction.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

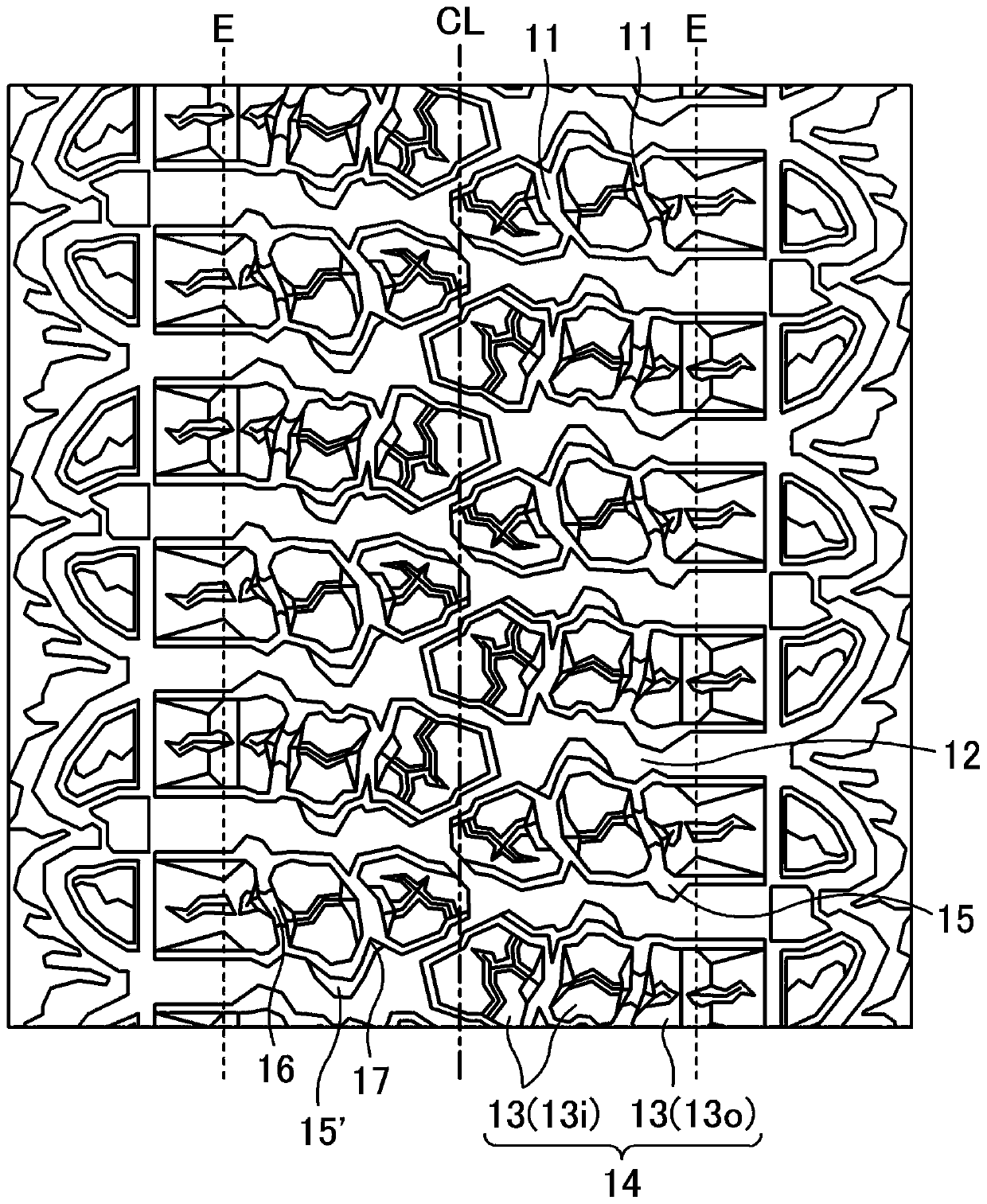

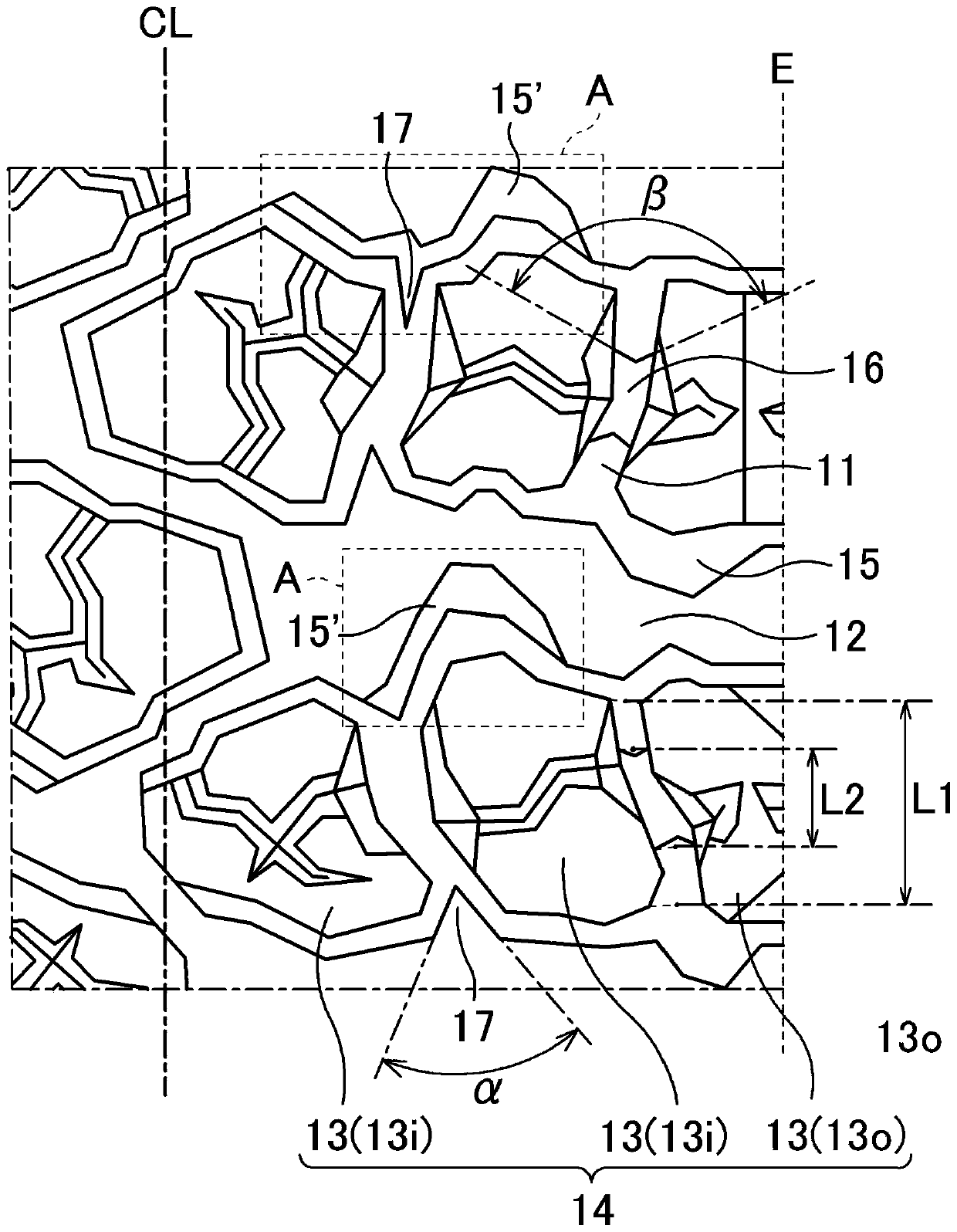

ActiveCN110958948AImprove driving performanceImprove mud performanceOff-road vehicle tyresTyre tread bands/patternsTransverse grooveEngineering

Owner:THE YOKOHAMA RUBBER CO LTD

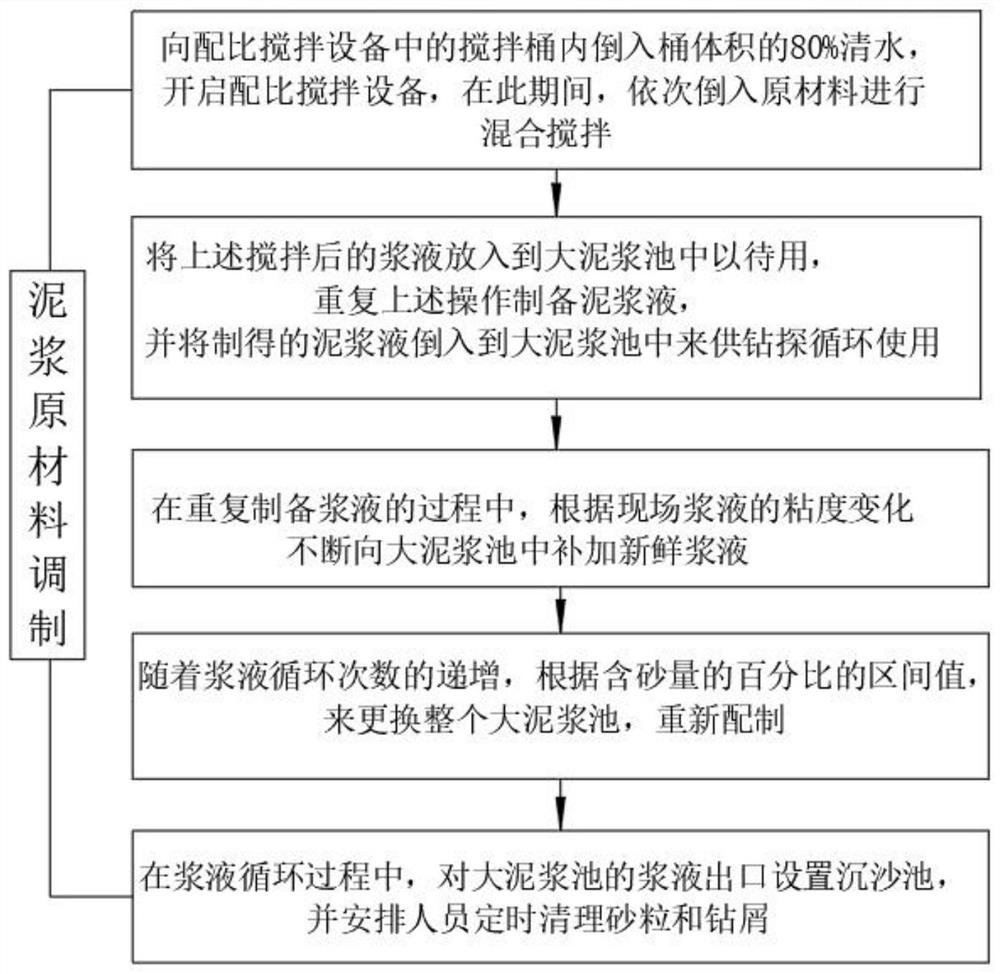

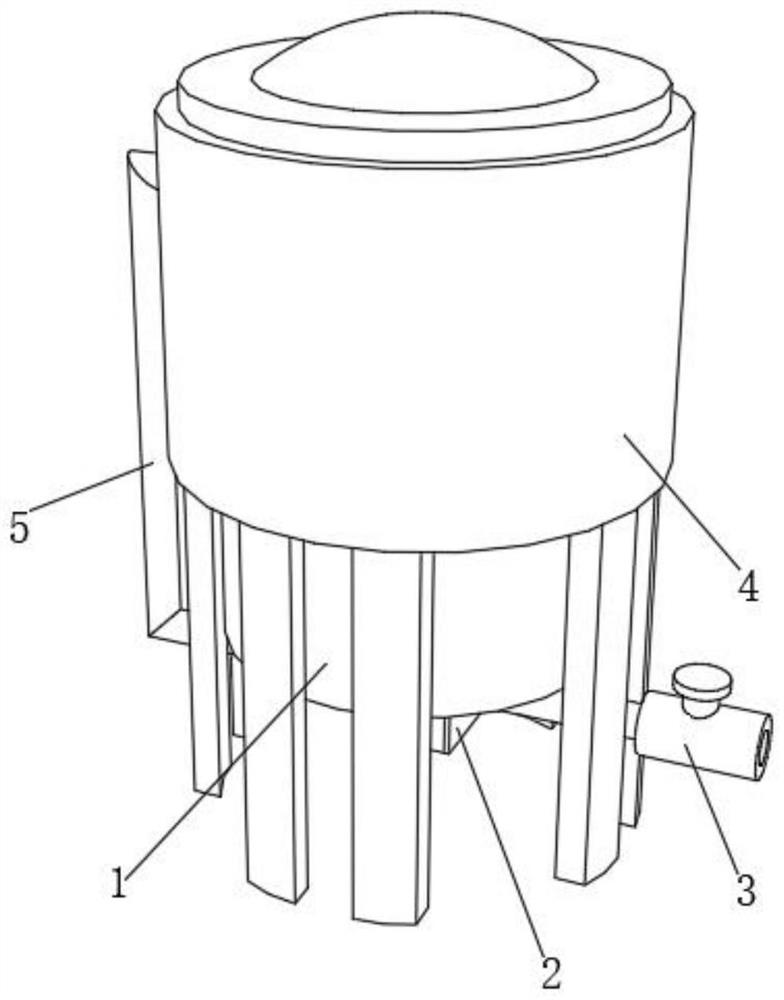

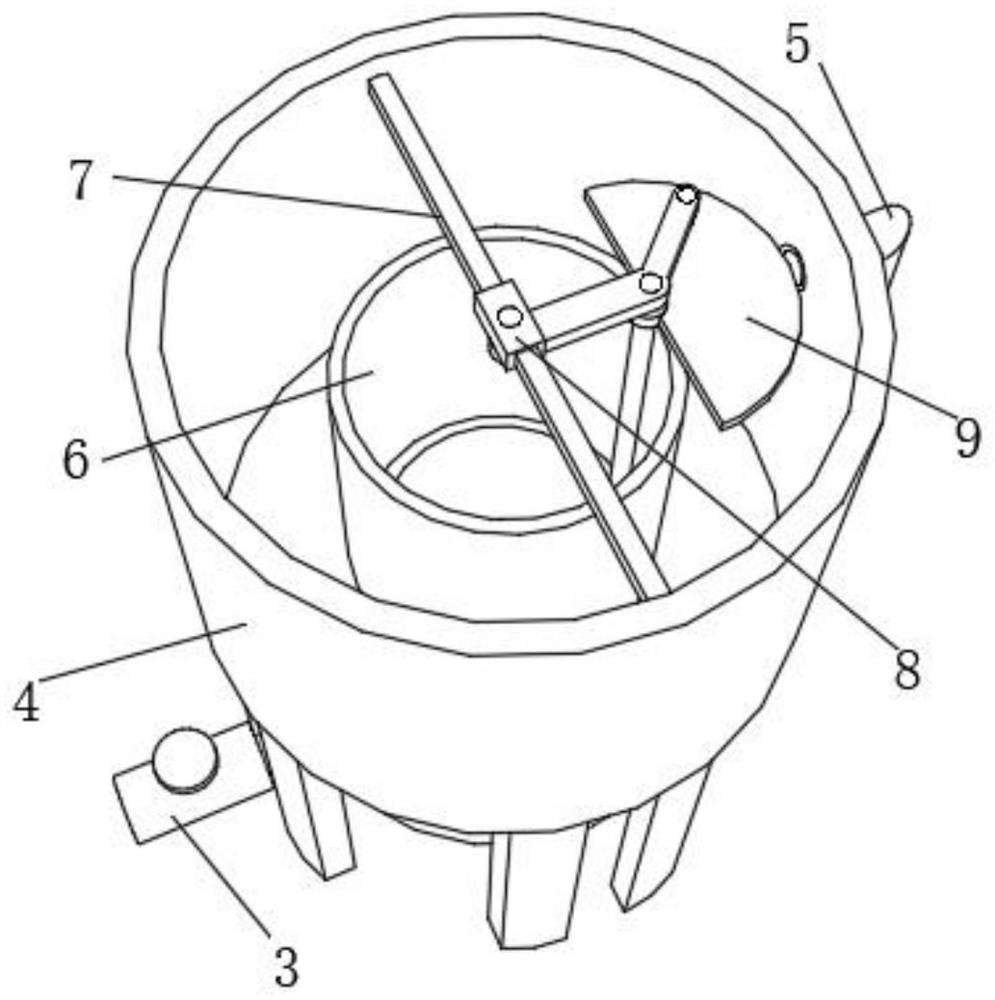

Drilling mud formula and automatic mud circulation purification device

PendingCN114687686ALow turning resistanceHigh turning resistanceConstructionsFlushingCellulosePlant Gums

The invention discloses a drilling mud formula and an automatic mud circulation purification device, and relates to the technical field of drilling mud. The mud specifically comprises mud raw materials, and the mud raw materials comprise, by weight, 1000 parts of clear water, 20 parts of bentonite, 4 parts of polyacrylamide, 4 parts of vegetable gelatin, 6 parts of potassium humate, 3 parts of sodium carboxymethyl cellulose, 3 parts of ferrochrome sodium lignin sulfonate, 4 parts of sodium carbonate, 4 parts of barite fine powder, 3 parts of dry sawdust, 4 parts of asbestos and 5 parts of polyacrylamide flocculant. The high-quality bentonite is selected, so that the slurry has the advantages of low relative density, low viscosity, small sand amount, small water loss, thin mud cake, strong stability, strong wall fixing capability, small rotation resistance of a drilling tool, high drilling rate, high slurry making capability and the like; the viscosity of the slurry can be increased by using sodium carboxymethyl cellulose, so that a thin film is formed on the surface of the soil layer to prevent the hole wall from peeling off, and the effect of reducing the water loss is achieved.

Owner:山东省地质矿产勘查开发局第五地质大队

Iron-chromium sodium lignin sulfonate and preparation method thereof

InactiveCN104987514AImprove mud performanceHigh viscosity reduction rateDrilling compositionSulfonateSulfate

The invention provides iron-chromium sodium lignin sulfonate and a preparation method thereof. Sodium lignin sulfonate prepared through a sulfate method, a sugar solution and a complexing agent are mixed for a reaction, and the iron-chromium sodium lignin sulfonate can be obtained, wherein sodium salt in specific lignosulfonate is selected, mixtures of the sugar solution and the sodium lignin sulfonate prepared through the sulfate method serve as initial raw materials, and the prepared iron-chromium sodium lignin sulfonate has very good mud property at both normal temperature and high temperature.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

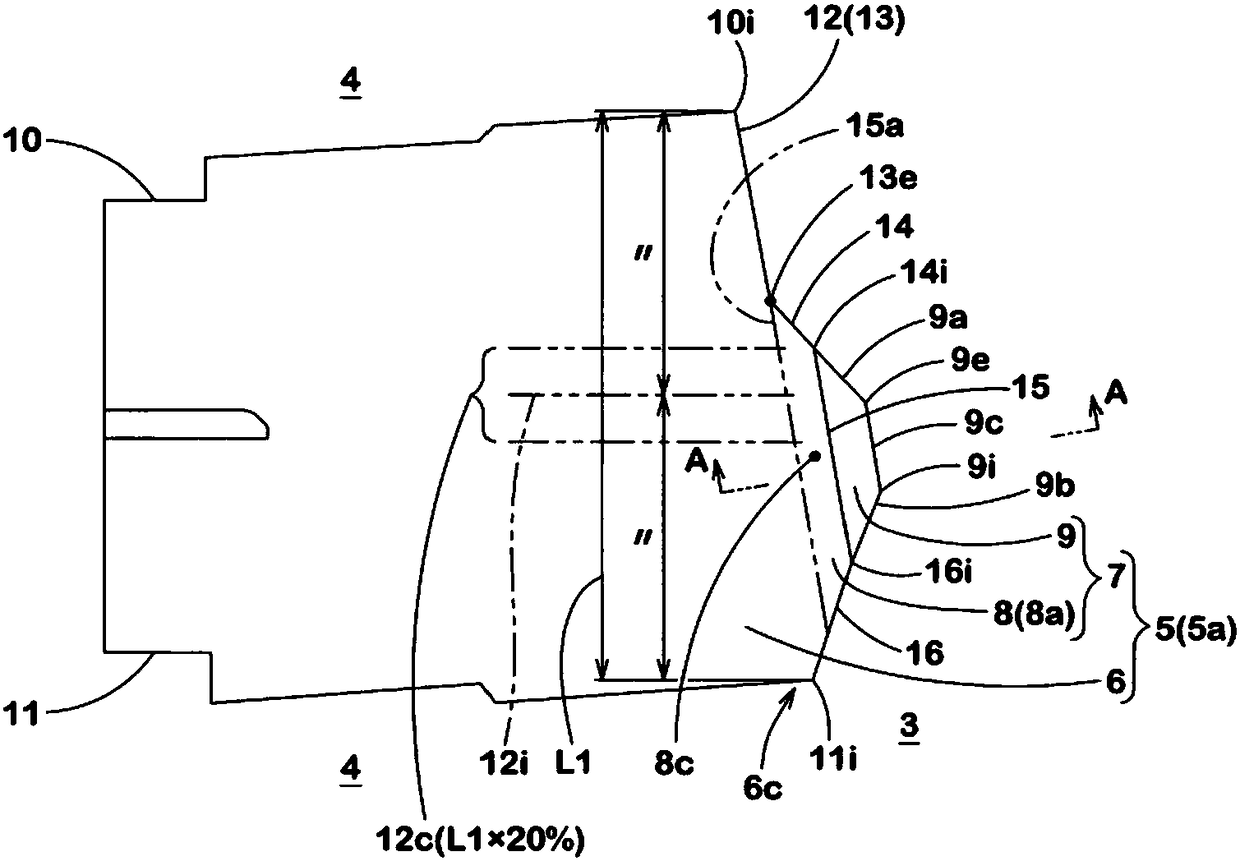

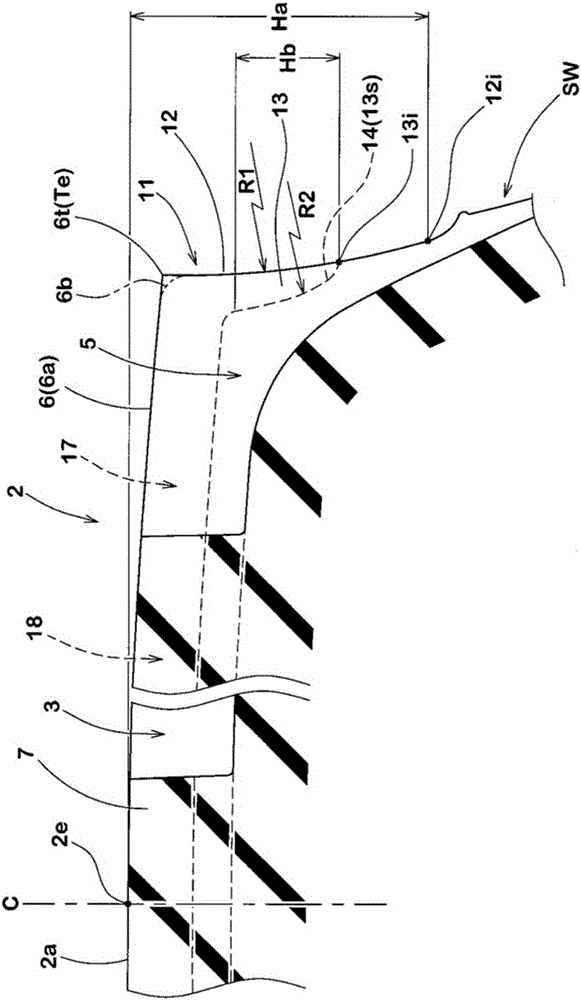

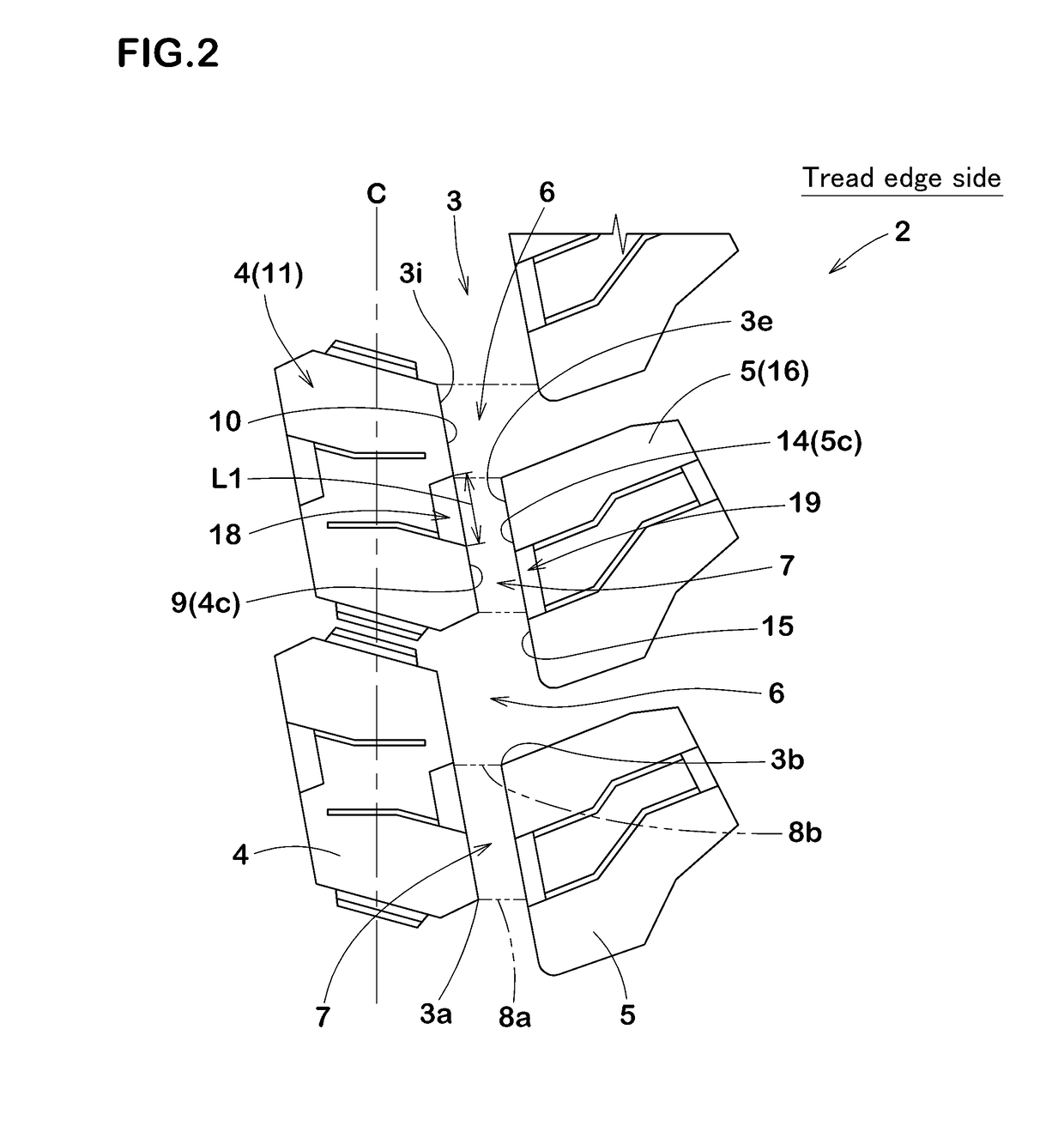

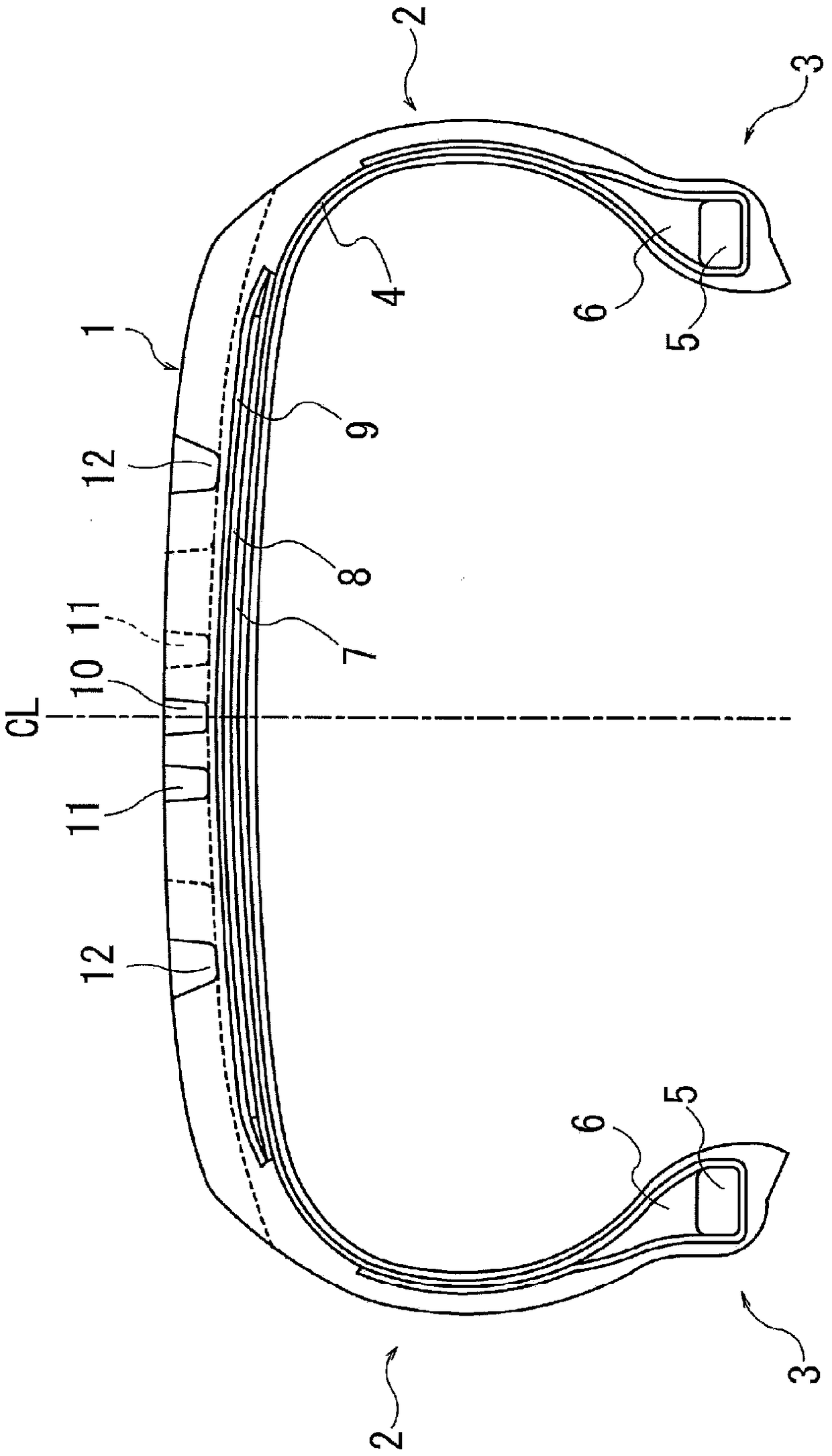

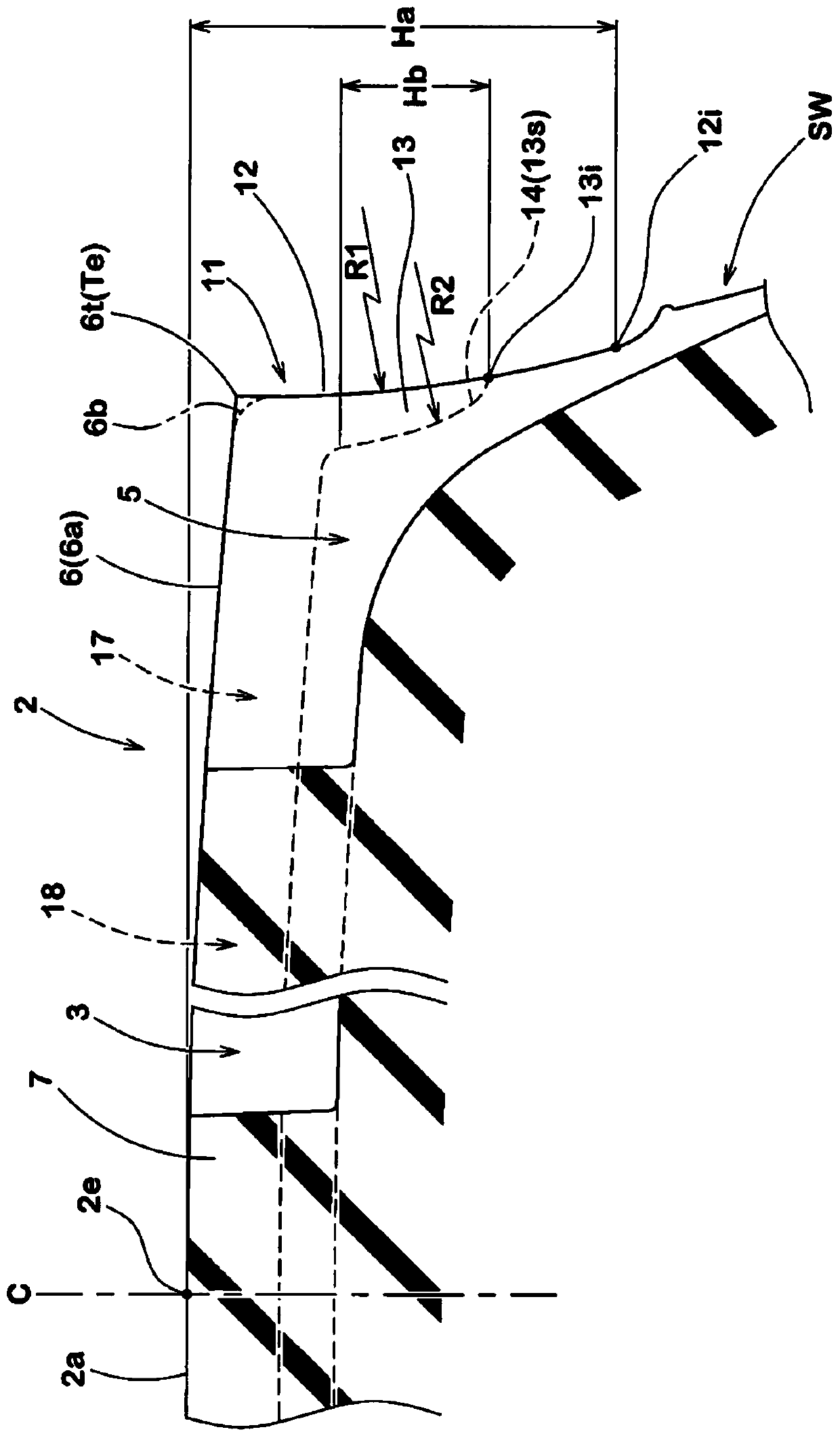

Pneumatic tire

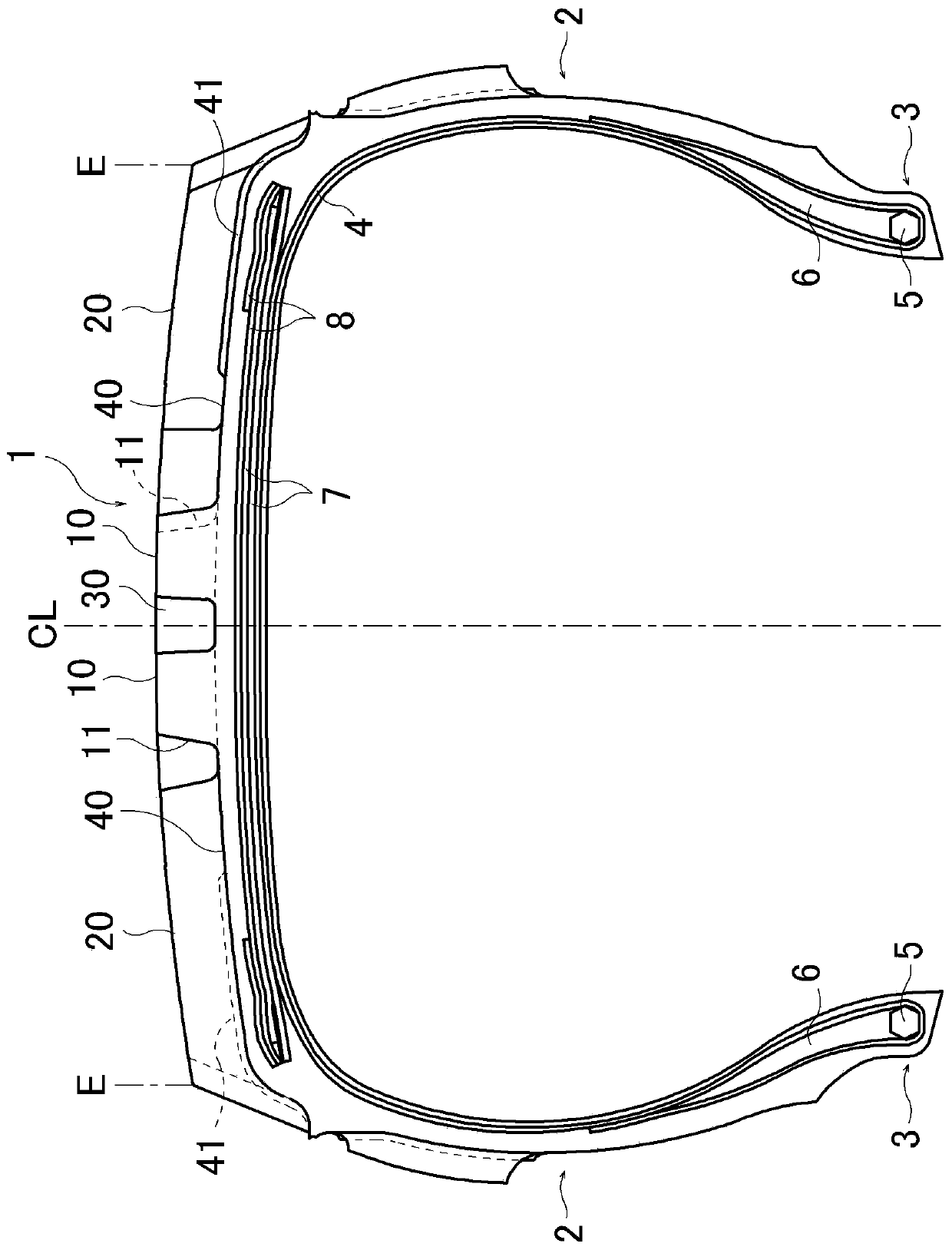

ActiveCN105480024AReduce rigidityImprove deformationTyre tread bands/patternsMechanical engineeringTread

The invention relates to a pneumatic tire which improves mud road performance and durability. A plurality of tire shoulder pattern blocks (6) of the pneumatic tire (1) are arranged along a circumferential direction of the tire. Each tire shoulder pattern block (6) has a side face (11) extending from a grounding end (6t) of a tire axial outer side of a tread (16) towards a tire radial inner side. In a tire meridian section containing a tire rotating shaft under a normal state, the side face (11) includes a first arc part (12) having a concave arc-shaped profile, the concave arc shape has a center in a position closer to the tire axial outer side than the ground end (6t) and the radius of curvature is 50% to 100% of a tread grounding width (TW). A tire radial distance (Ha) between the outermost end (2e) in a tire radial direction of a tread (2a) of a tread part (2) and an inner end (12i) of the tire radial direction of a first arc part (12) is 5% to 10% of a tire maximum width.

Owner:SUMITOMO RUBBER IND LTD

Tire

ActiveUS20180290496A1Improve mud performanceMaintaining noise performanceTyre tread bands/patternsGroove widthGround contact

A tire includes a tread portion including a main groove, a first block and a second block which are adjacent to one another in a tire axial direction through the main groove. The main groove includes first groove elements and second groove elements having groove widths smaller than that of the first groove elements. The first block includes a first ground contact surface, a first sidewall facing one of the second groove elements, a first corner portion between the first ground contact surface and the first sidewall, and a first recess being cut out the first corner portion locally. The second block includes a second ground contact surface, a second sidewall facing said one of the second groove elements, a second corner portion between the second ground contact surface and the second sidewall, and a second recess being cut out the second corner portion locally.

Owner:SUMITOMO RUBBER IND LTD

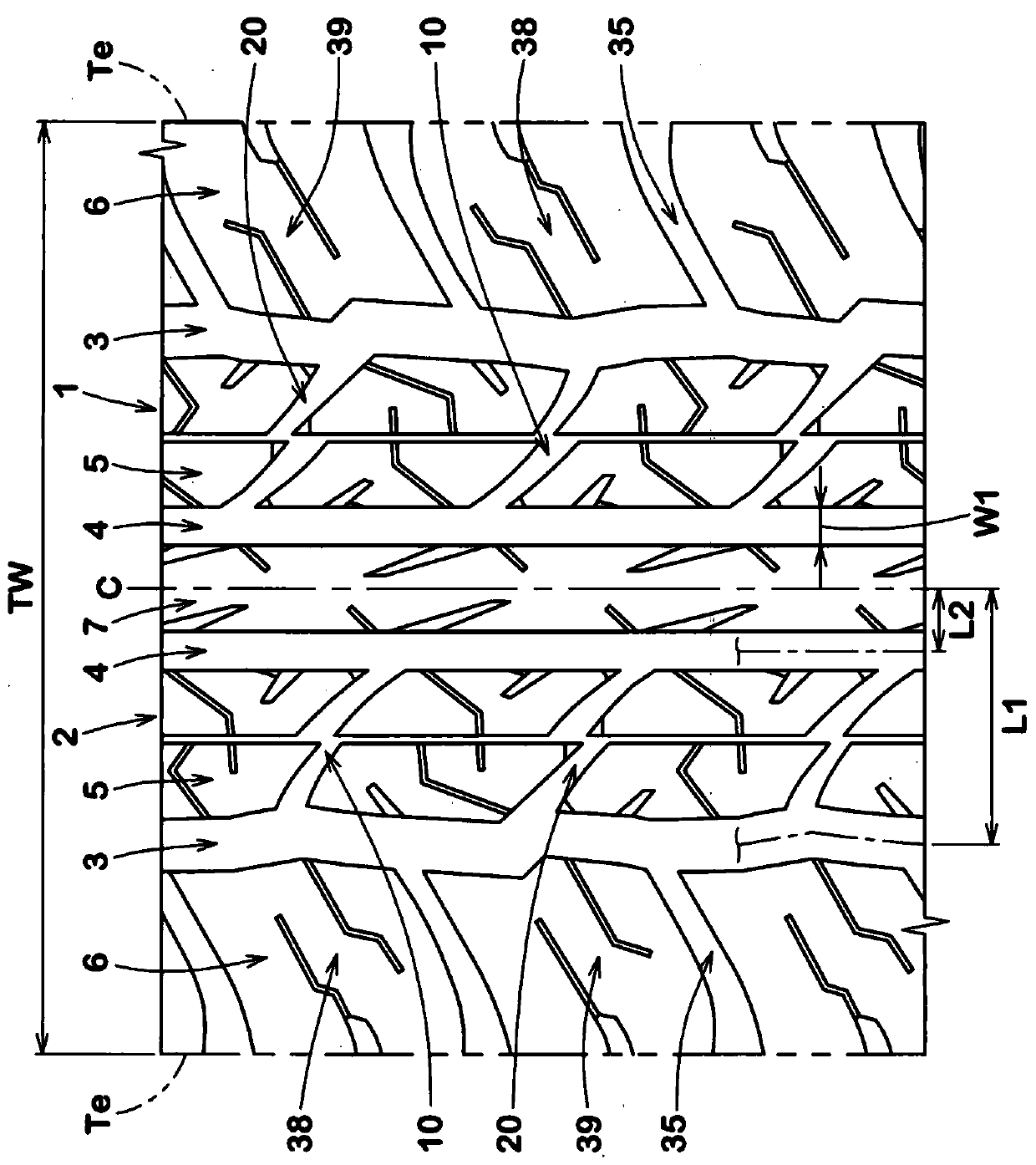

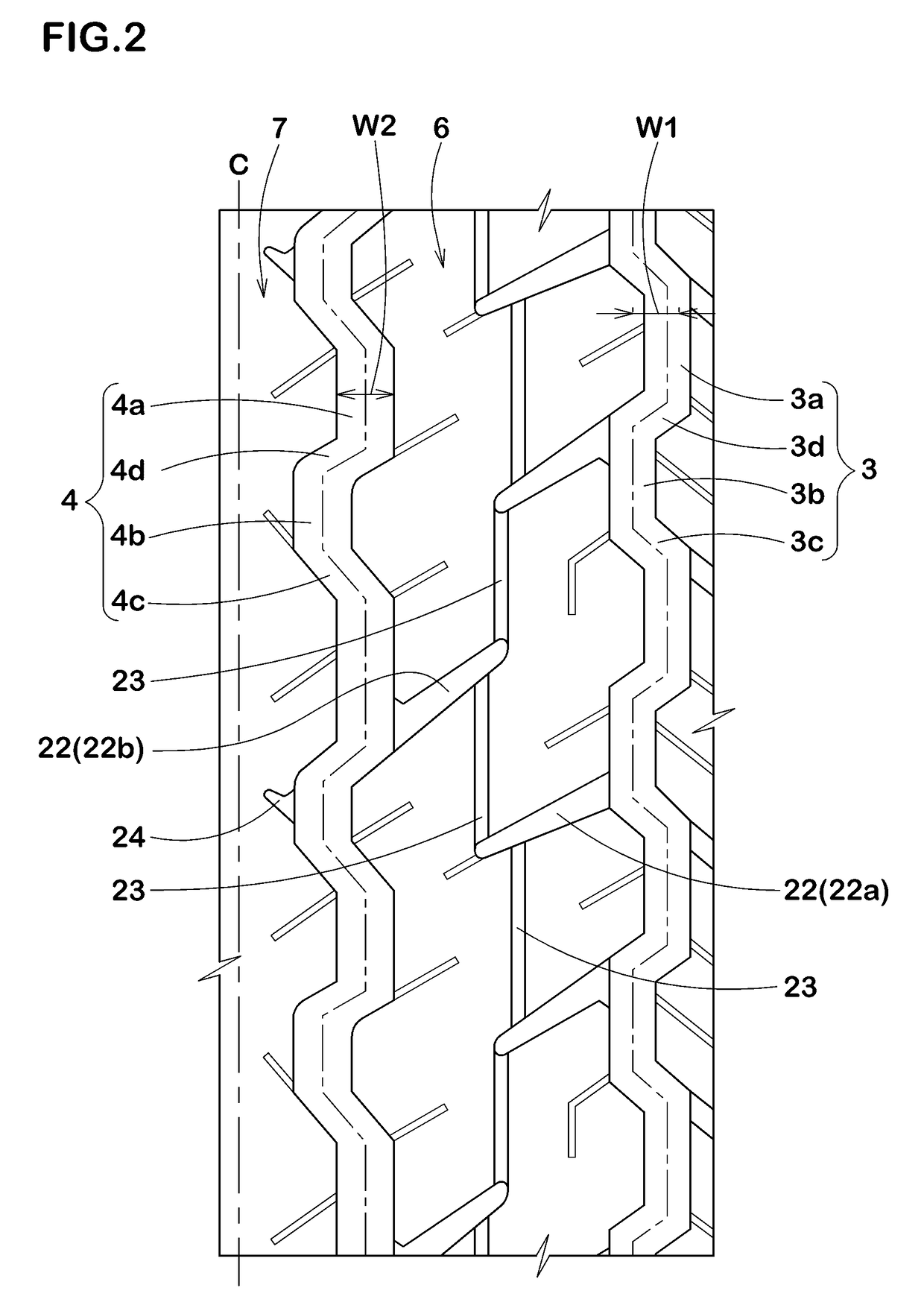

Tire

ActiveCN110194030AReduce pumping soundImprove traction performanceTyre tread bands/patternsGroove widthEngineering

The invention provides a tire capable of maintaining excellent noise performance and improving muddy performance. The tire has a tread portion (2). The tread portion (2) includes a shoulder main groove (3) on a tread edge (Te) side, a crown main groove (4) on a tire equator (C) side, and a middle land portion (5) defined between the shoulder main groove and the crown main groove. The middle land portion (5) is provided with first middle lateral grooves (10). Each first middle lateral groove (10) is formed by communicating an inner side groove (11) extending from the crown main groove (4) to the outer side in the tire axial direction and an outer side groove (12) extending from the shoulder main groove (3) to the inner side in the tire axial direction in a staggered mode in the circumferential direction of the tire. The groove width of the outer side groove (12) is smoothly and gradually increased from a communication part (13) communicated with the inner side groove (11) to the tire shoulder main groove (3).

Owner:SUMITOMO RUBBER IND LTD

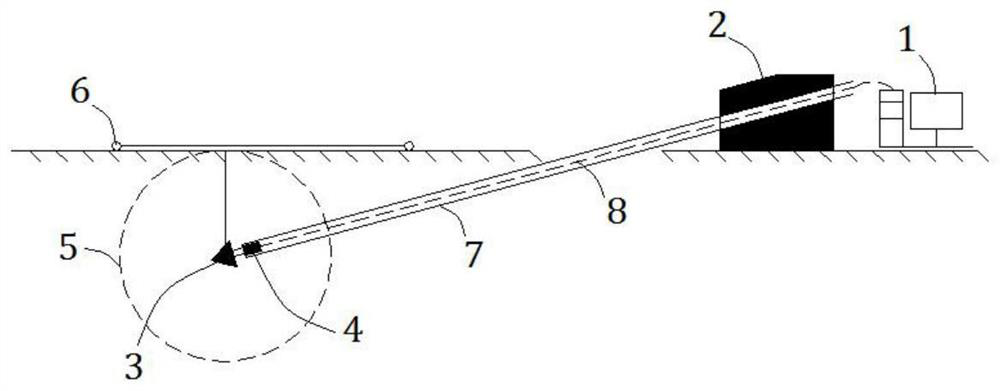

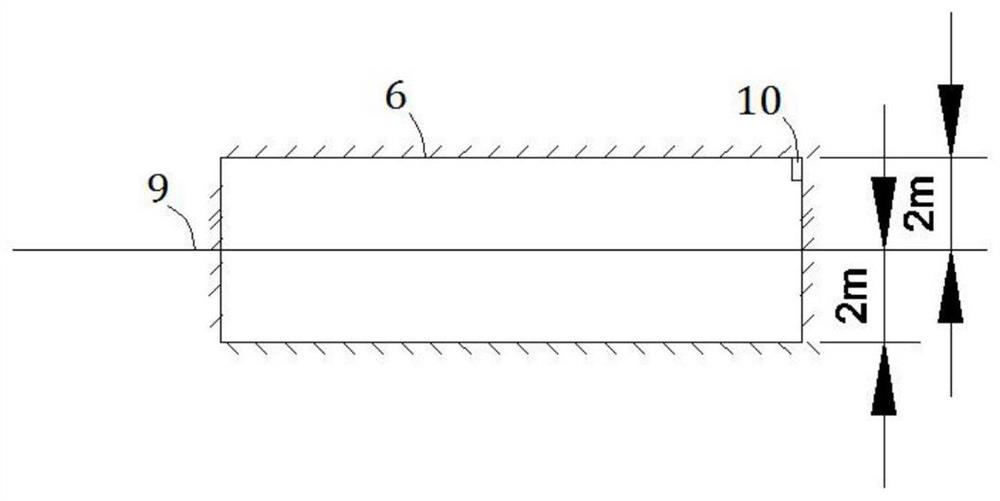

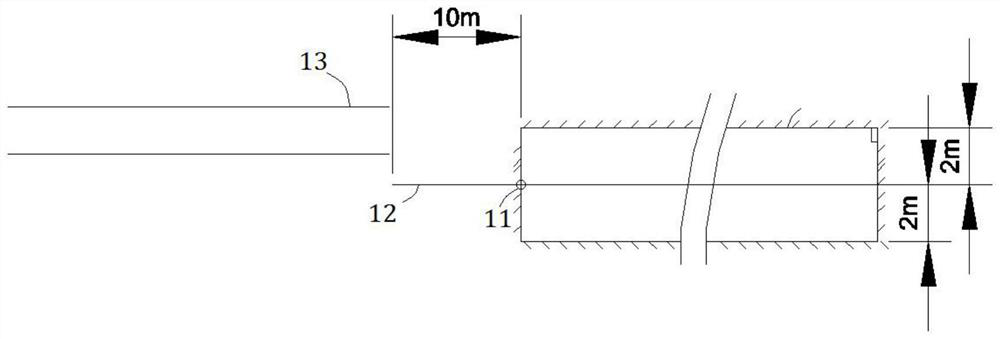

Long-distance pipeline laying construction method

PendingCN114370530AStable and reliable implementation of drillingImprove mud performancePipe laying and repairPipeline systemsUnderground pipelineDrill bit

The invention belongs to the technical field of underground pipeline construction, and discloses a long-distance pipeline laying construction method which comprises the steps of guide hole manufacturing and pipeline back dragging. The guide hole manufacturing comprises the steps that a ground magnetic field is established with a preset pipeline route as the center, and interference of a high-voltage electromagnetic field is eliminated; positioning information based on the ground magnetic field and the pipeline route is obtained through detection guiding control equipment carried on a drill bit drill rod, the positioning information is transmitted back to a ground control terminal, and the drilling angle and direction are controlled based on a received control instruction; and after the guide hole is drilled through, chambering and hole cleaning operations are executed until the guide hole is manufactured. According to the long-distance pipeline laying construction method, stable construction in a high-voltage electromagnetic field area can be guaranteed, and the long-distance pipeline laying construction method can adapt to pipeline back-dragging construction in a small space.

Owner:首钢滦南马城矿业有限责任公司

Pneumatic tire

InactiveCN109195818ASuppress noiseEasy dischargeOff-road vehicle tyresTyre tread bands/patternsEngineeringMechanical engineering

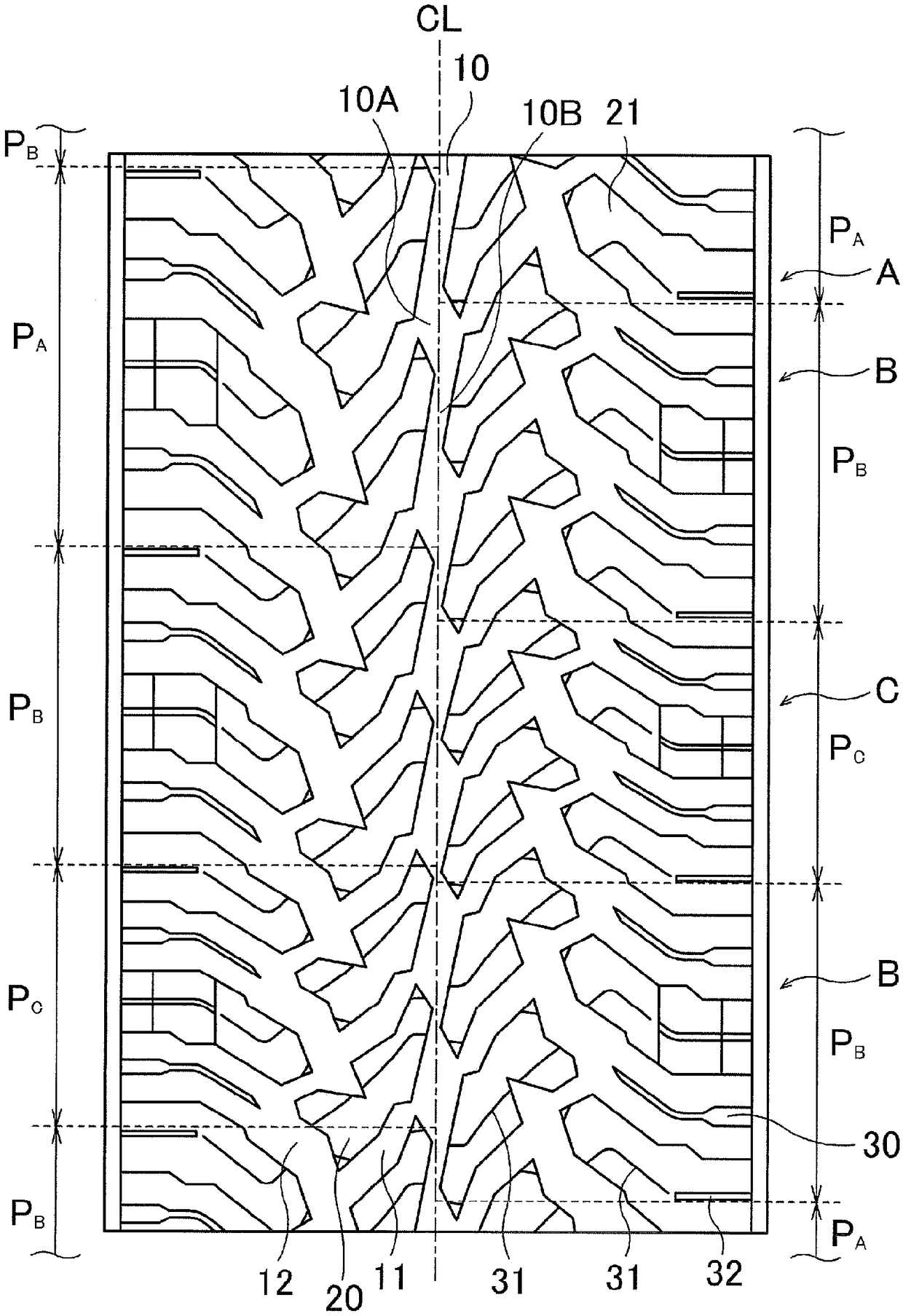

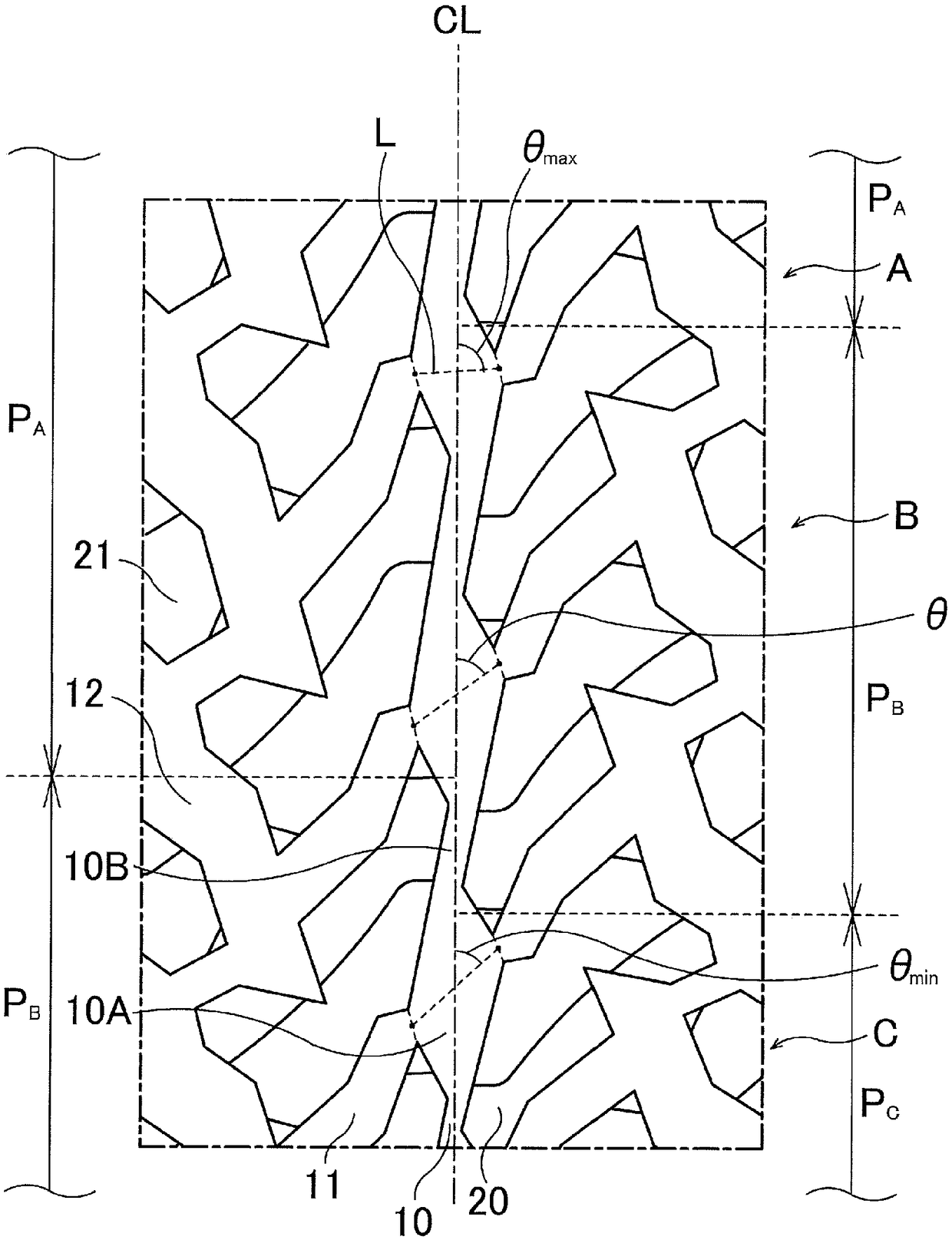

Provided is a pneumatic tire capable of improving noise performance and wet performance while maintaining steering stability. Disclosed is a pneumatic tire wherein: center blocks 20 and shoulder blocks 21 are partitioned by a circumferential-direction groove 10 extending in the tire circumferential direction, a plurality of inner slanted grooves 11 that communicate with the circumferential-direction groove 10 while slanting in one direction with respect to the tire circumferential direction, and a plurality of outer slanted grooves 12 that communicate with the inner slanted grooves 11 while slanting in another direction with respect to the tire circumferential direction; the pitch of each repeating element consisting of these grooves and blocks changes along the tire circumferential direction; the circumferential-direction groove 10 is constituted by a plurality of wide-width parts 10A and a plurality of narrow-width parts 10B arranged alternately in the tire circumferential direction;the inner slanted grooves 11 communicate with the wide-width parts 10A; and, the smaller the pitch of the repeating element is, the smaller the slanting angle theta formed between the tire circumferential direction and an imaginary line L connecting the respective centers of opening ends of a pair of said inner slanted grooves 11, 11 that is in communication with said wide-width part 10A.

Owner:THE YOKOHAMA RUBBER CO LTD

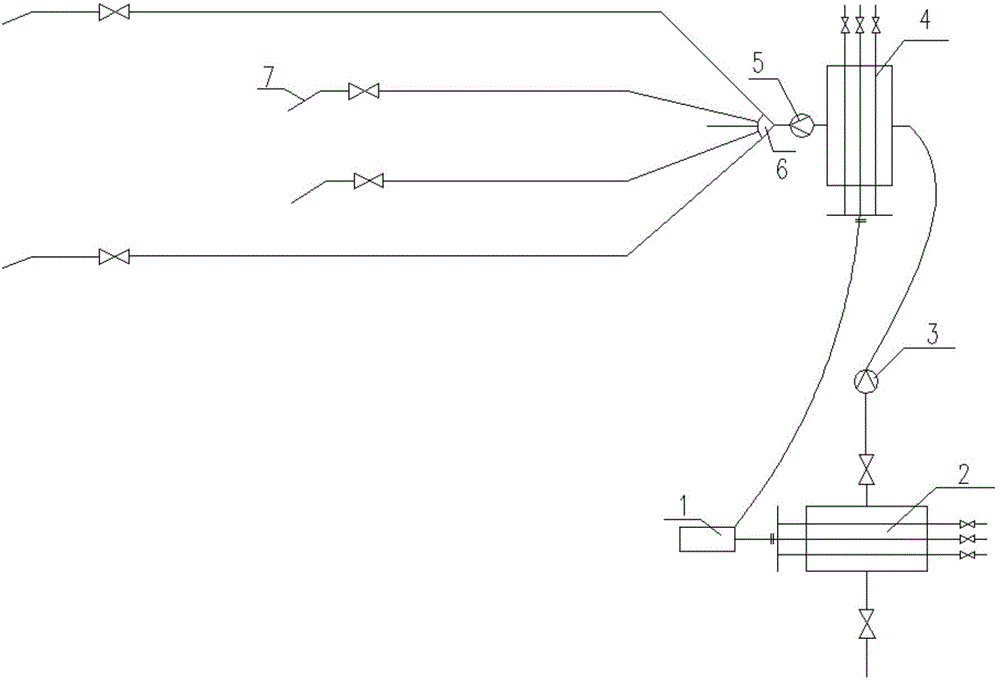

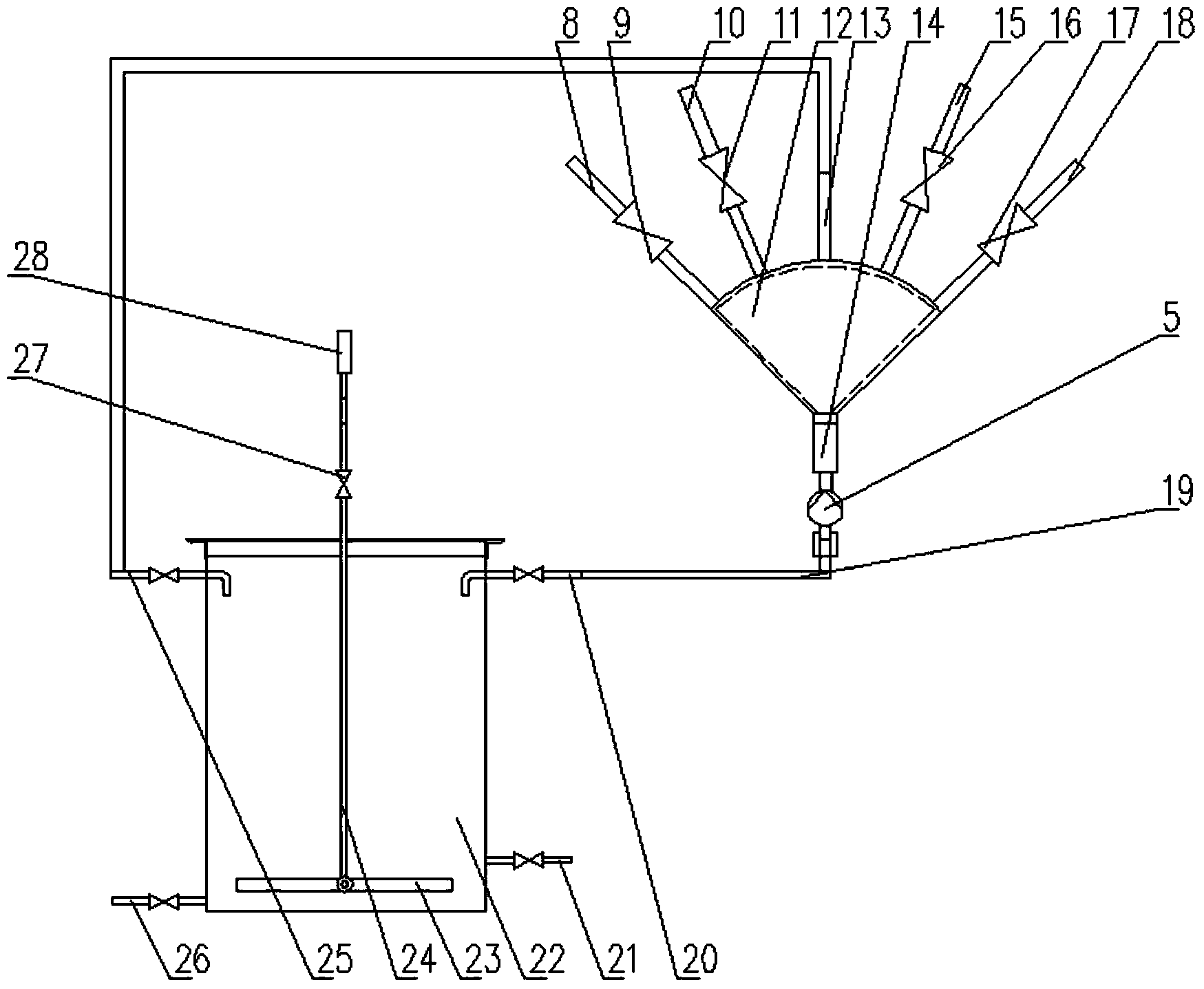

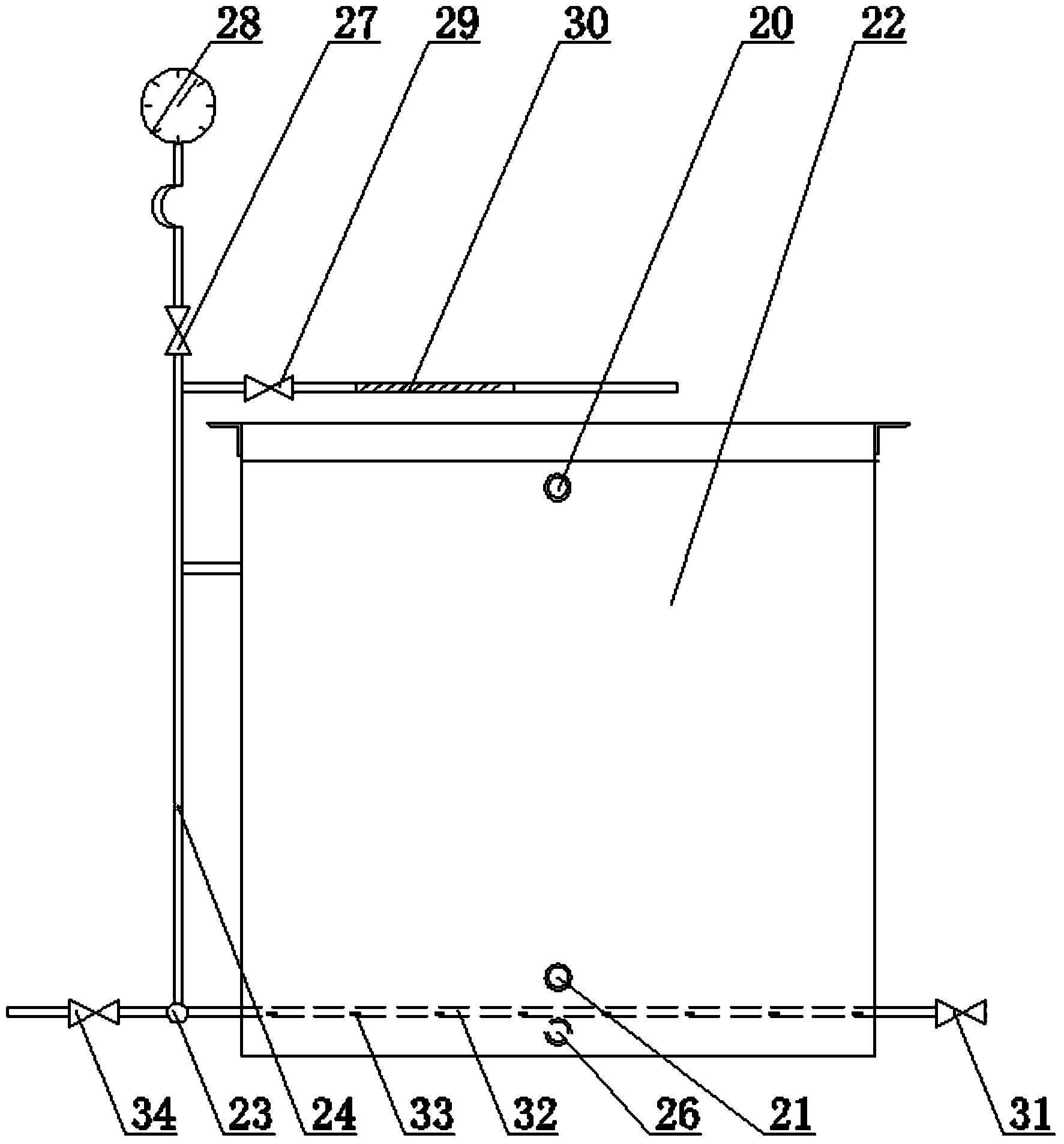

Grouting construction method of coke oven hot roof mud

ActiveCN103642505BImprove performanceSimple construction methodCoke oven detailsCoke ovenDistributor

The invention relates to a grouting construction method of coke oven hot roof mud. The construction method comprises the following steps: (1) assembling a mud fabrication system; (2) preparing the mud; (3) continuing to stew the mud in a second mud mixer, and separating out large-particle impurities, so as to form final casting mud. The casting mud is directly conveyed to the required part of the coke oven hot roof through a second mud delivery pump and a mud pressure uniform distributor, and directly grouted into a coke oven gap, and the coke oven hot roof mud is grouted and constructed. The construction method disclosed by the invention is simple, low in cost, high in efficiency, free of pollution, and good in construction mud performance, and the labor intensity of a worker is effectively reduced.

Owner:MCC TIANGONG GROUP

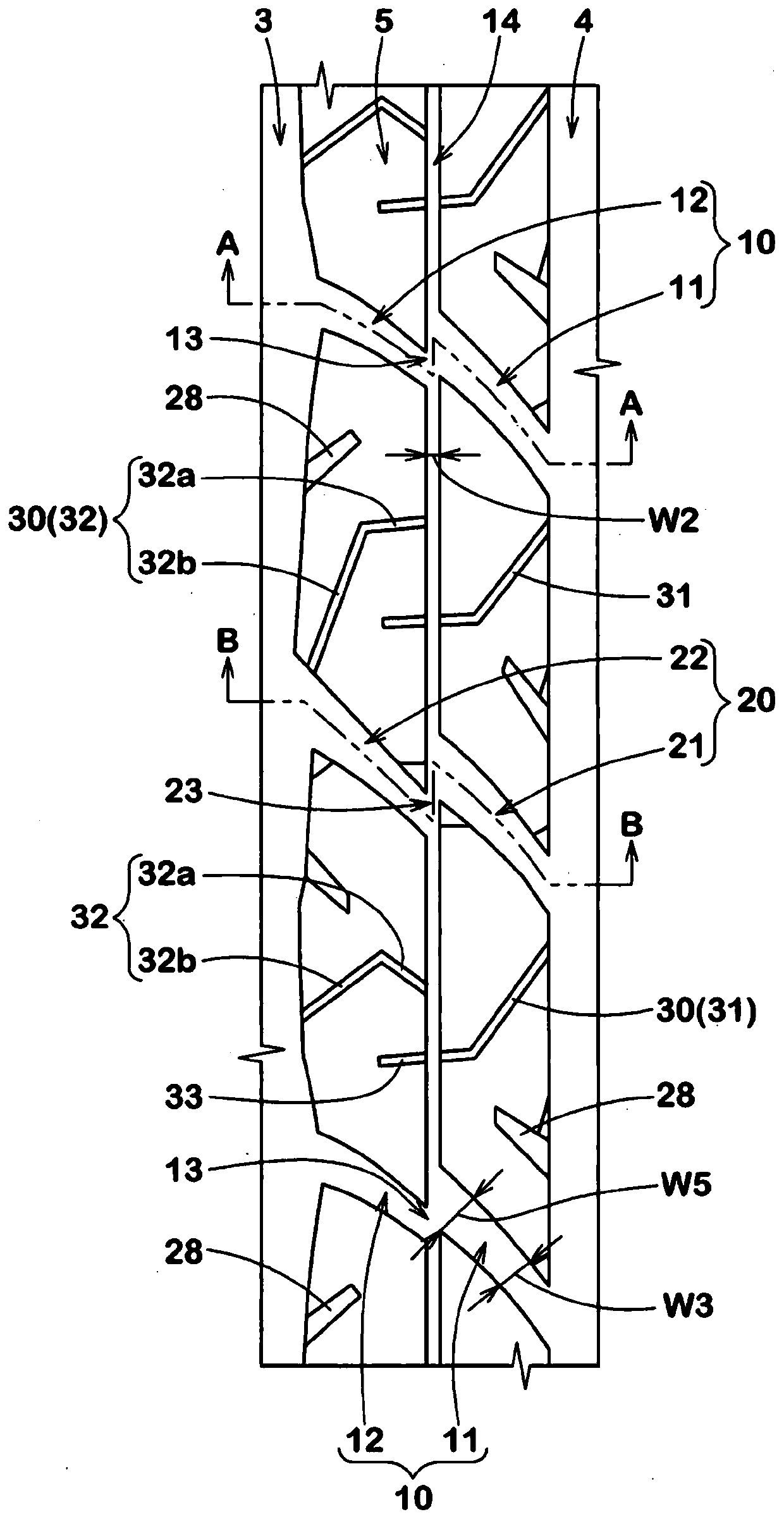

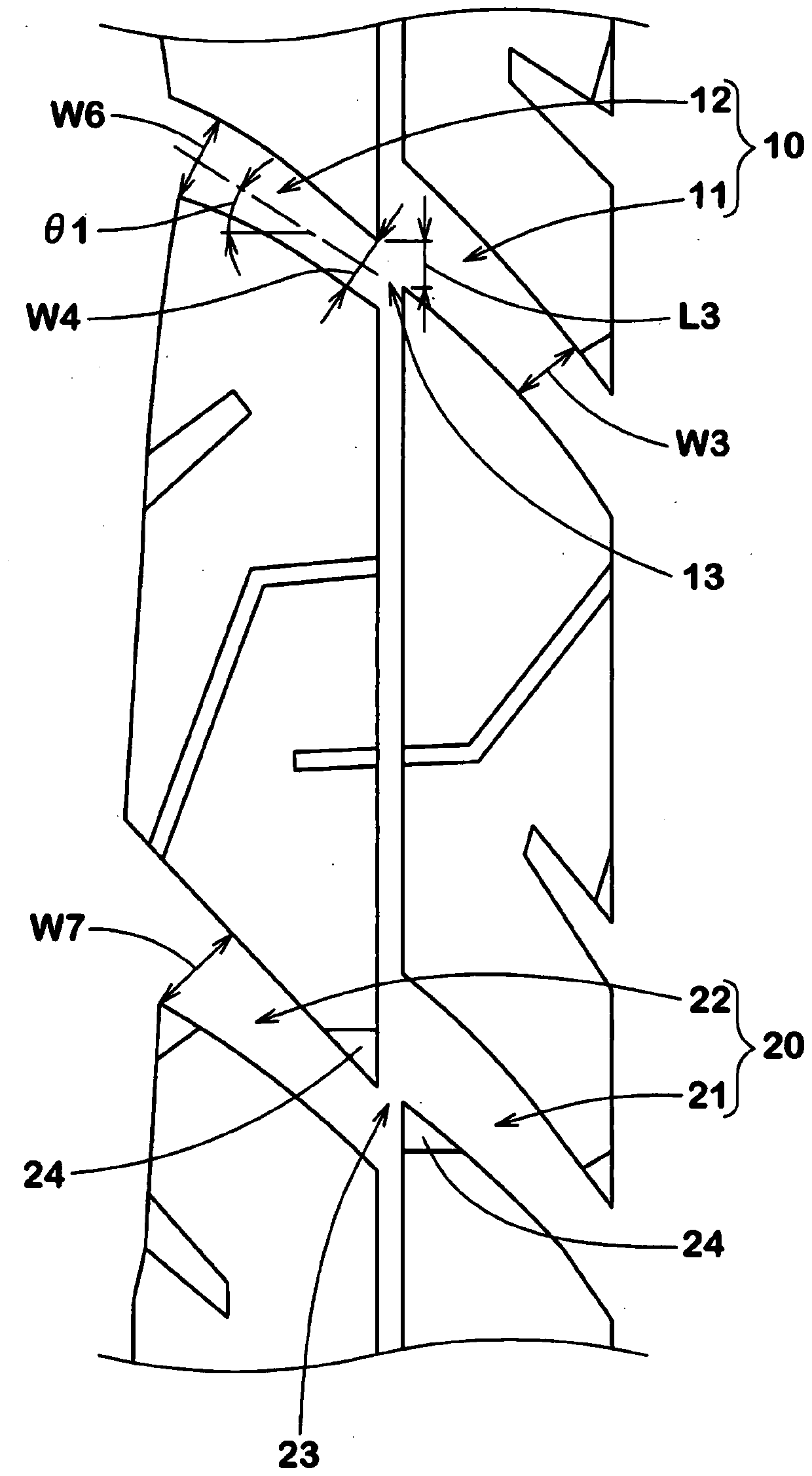

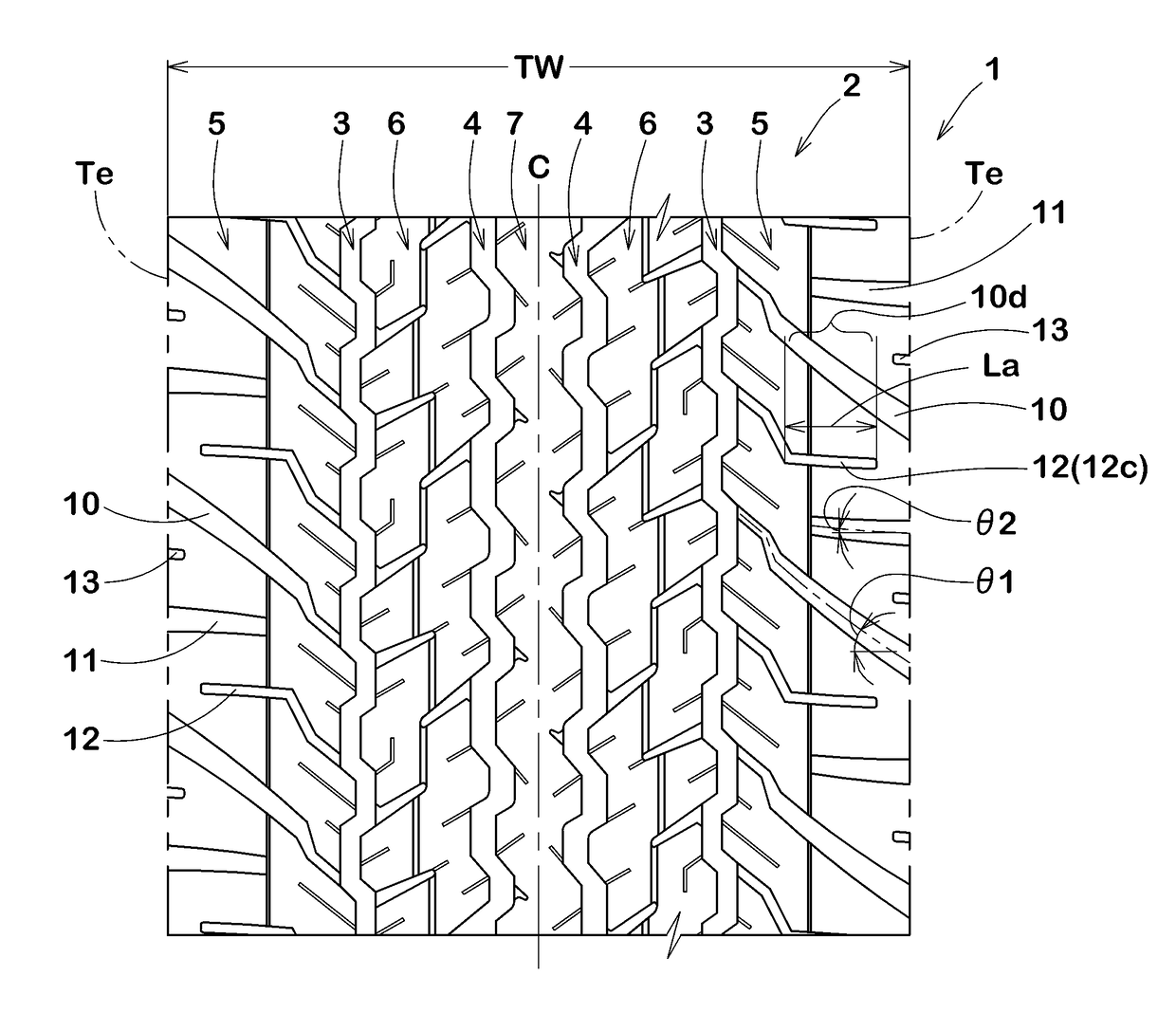

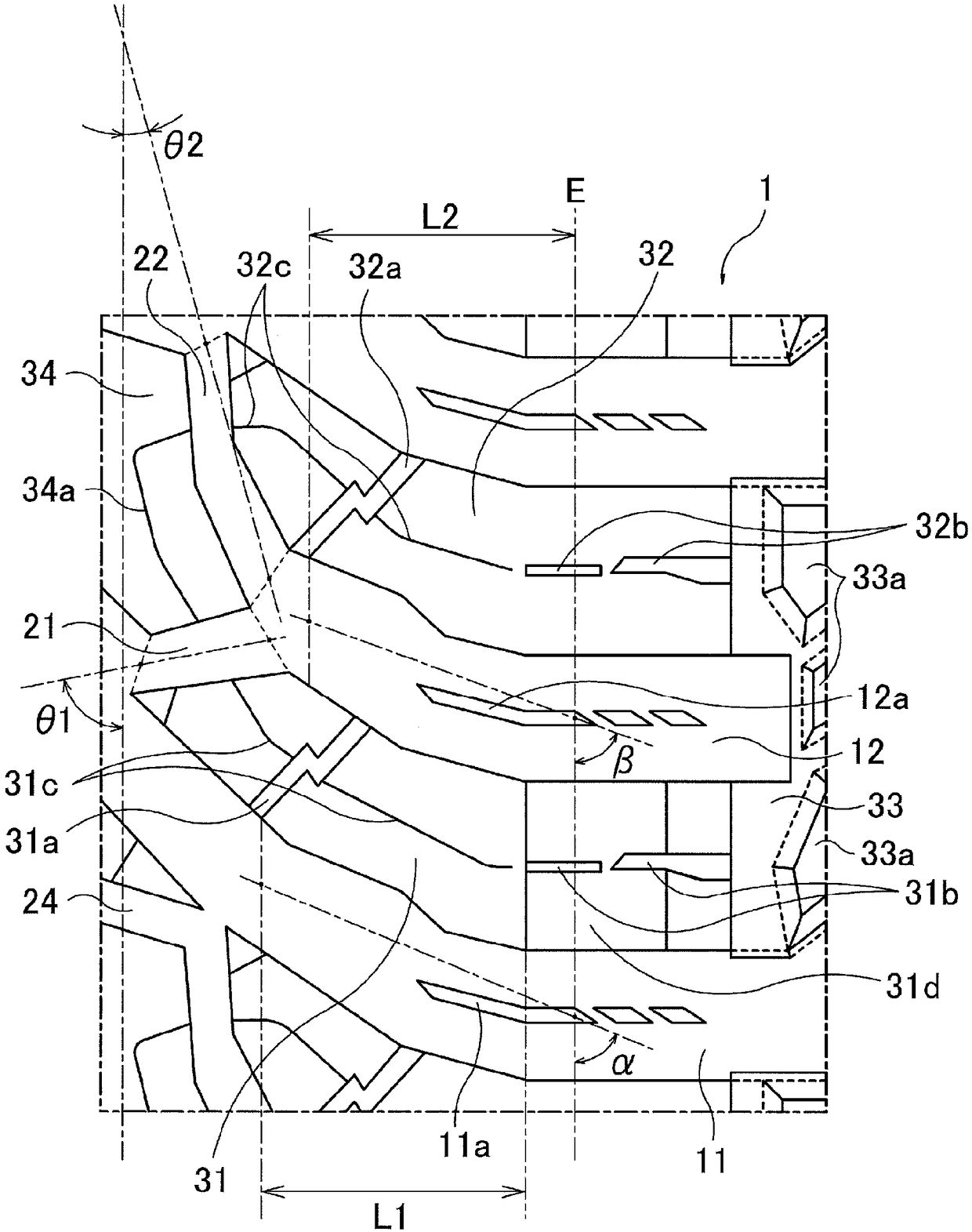

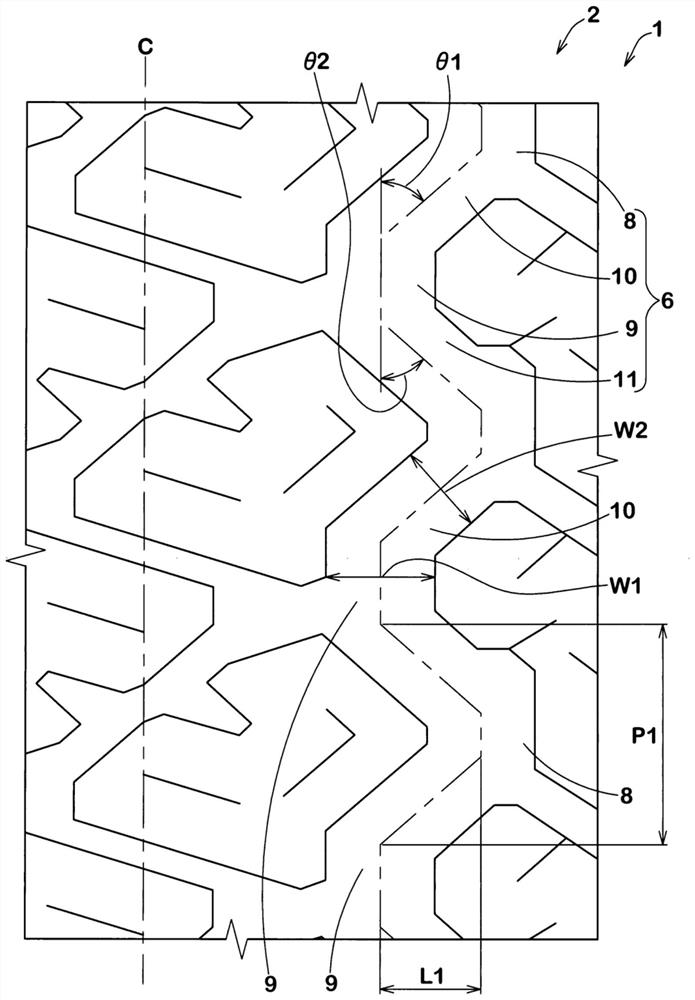

Tire

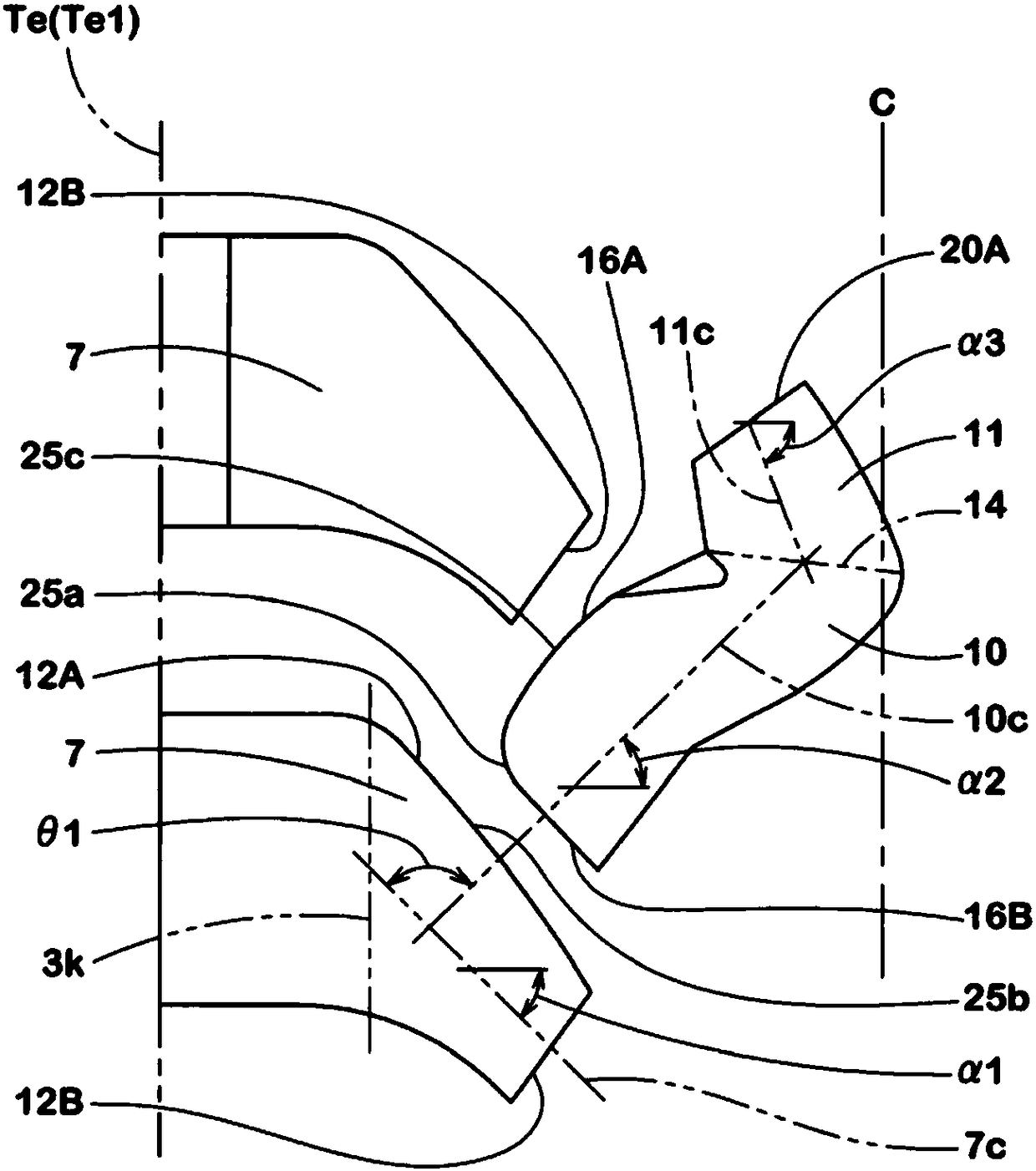

ActiveUS20180022165A1Improve Noise PerformanceImprove mud performanceRoad vehicle tyresOff-road vehicle tyresEngineeringTread

A tire 1 comprises a tread portion 2, a tread edge Te provided in the tread portion 2, a shoulder main groove 3 extending continuously in the tire circumferential direction in the tread portion 2, and a shoulder land region 5 being defined between the tread edge Te and the shoulder main groove 3. The shoulder land region 5 is provided with a shoulder lateral groove 10 connecting between the shoulder main groove 3 and the tread edge Te and a first shoulder lug groove 11 extending axially inwardly from the tread edge Te and terminating within the shoulder land region 5. An angle θ1 of the shoulder lateral groove 10 with respect to the tire axial direction is larger by 10 to 40 degrees than an angle θ2 of the first shoulder lug groove 11 with respect to the tire axial direction.

Owner:SUMITOMO RUBBER IND LTD

pneumatic tire

ActiveCN105480024BReduce rigidityImprove deformationTyre tread bands/patternsEngineeringMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

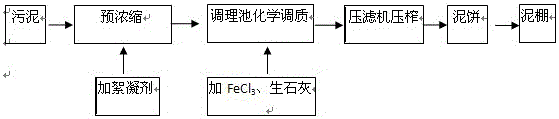

A kind of high-efficiency sludge dewatering method

ActiveCN103896474BEfficient dehydrationReduce moisture contentSludge treatment by de-watering/drying/thickeningSewagePre treatment

The invention discloses an efficient dehydrating method for sludge. The method realizes automatic and efficient operation of a sludge treatment system through a self-control system. The method comprises the following steps: first, pre-concentrating sludge by means of a natural gravitational field or a manual gravitational field generated by machinery (by adopting concentration or floating manner); adding an inorganic conditioner in the sludge tempering process for further pre-treatment; and dehydrating by means of filter pressing equipment which is higher in pressure to further improve the dehydrating effect so as to efficiently dehydrate sludge in an urban sewage plant. The method can remarkably reduce the moisture content of sludge, reduce the volume of sludge, improve the sludge character, solves the difficulty in conveying and storing the sludge and lower the disposal cost of the sludge, thereby laying a good foundation for final disposal and utilization of the sludge.

Owner:江苏道科环境科技有限公司

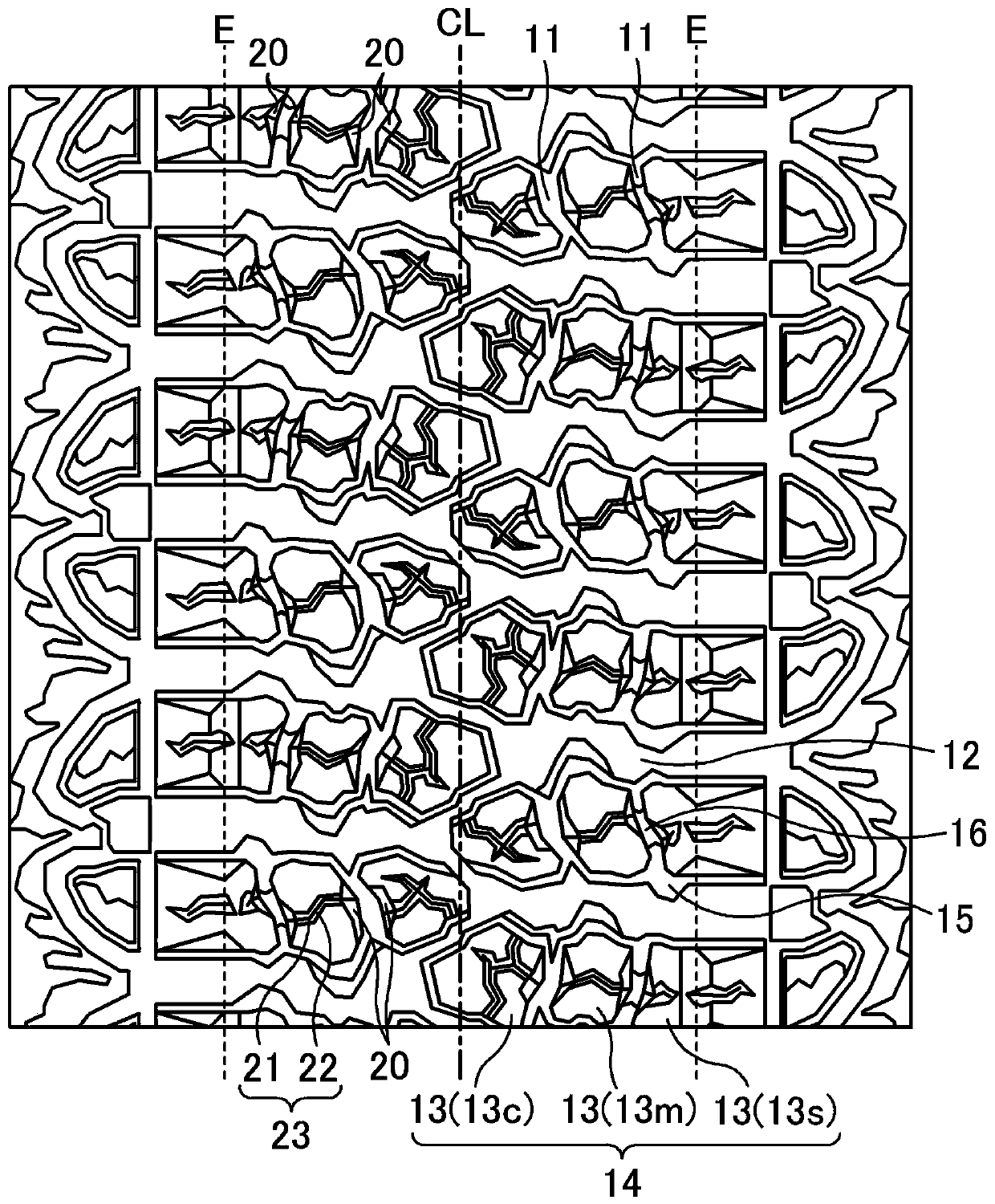

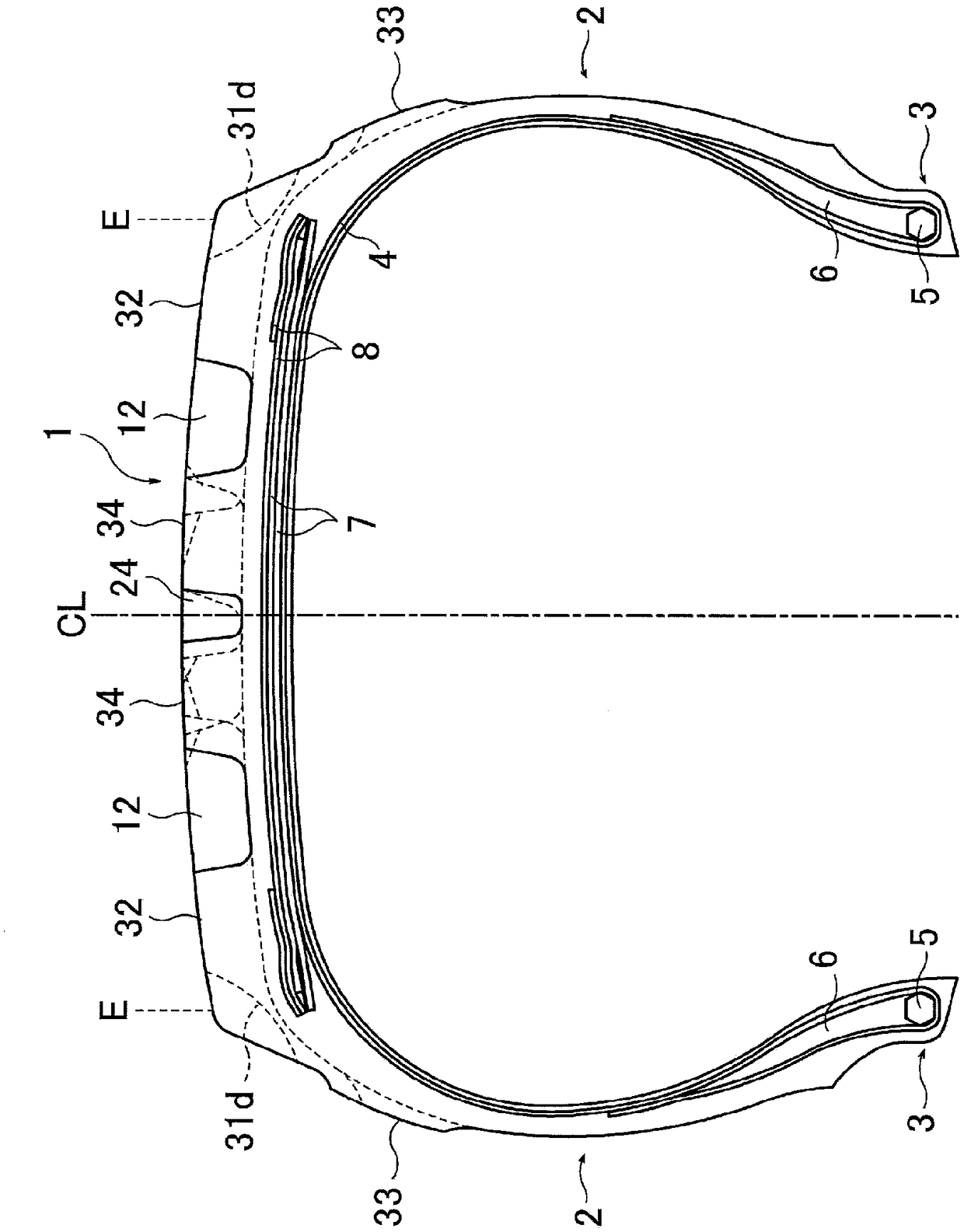

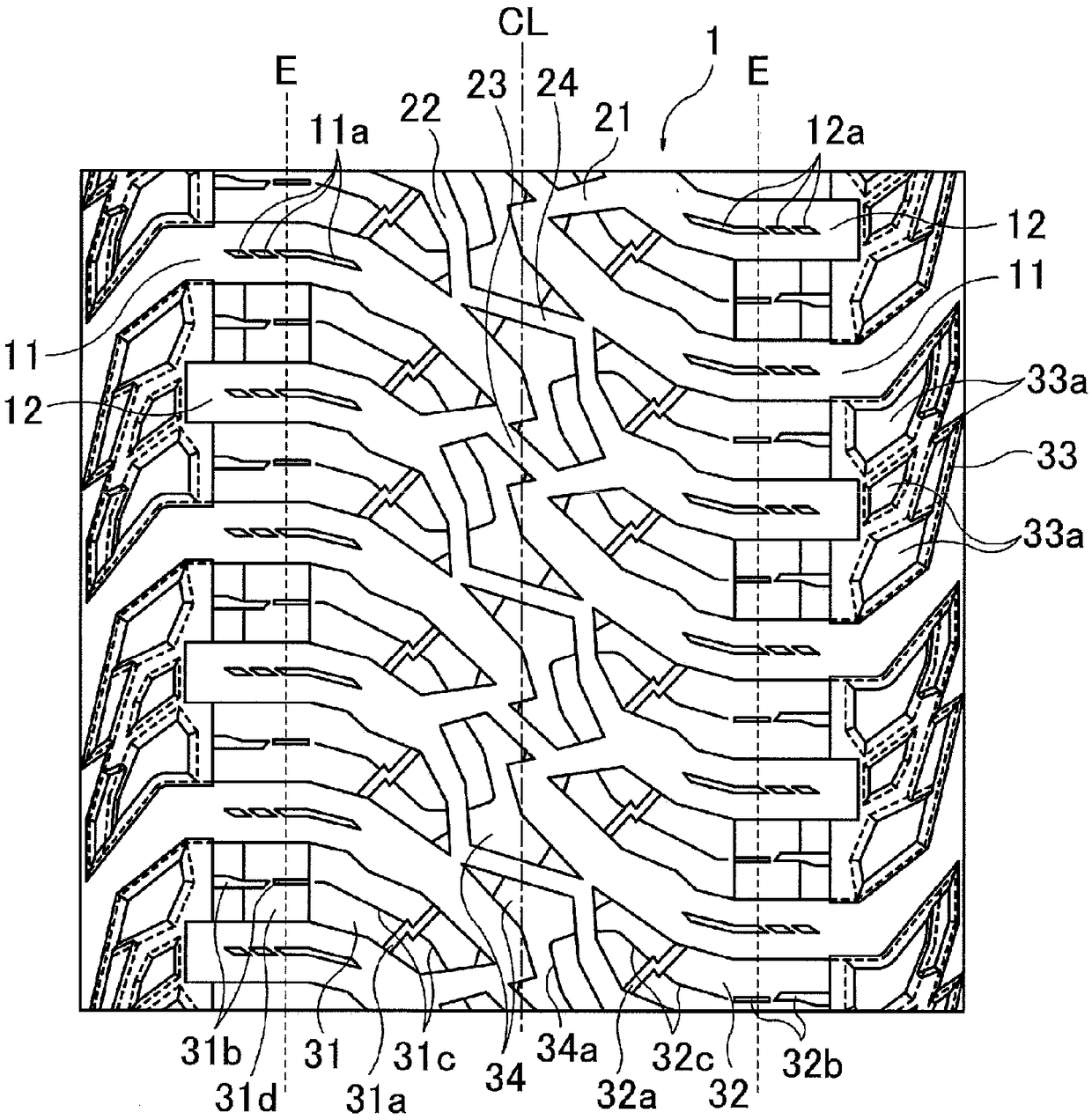

Pneumatic tire

InactiveCN109311350AImprove mud discharge effectEfficient dischargeOff-road vehicle tyresTyre tread bands/patternsShoulder regionRoad surface

Provided is a pneumatic tire capable of improving uneven-wear resistance and driving performance on muddy road surfaces, and achieving both these properties in a balanced manner. A plurality of firstlug grooves (11) and a plurality of second lug grooves (12) shorter than the first lug grooves (11) are provided alternately along the tire circumferential direction in a shoulder region of a tread part (1). A first connection groove (21) that connects the second lug groove (12) and a tip end part of the first lug groove (11) is provided, and a second connection groove (22) that connects the firstlug groove (11) and a tip end part of the second lug groove (12) is provided. An angle THETA 1 of the first connection groove (21) is greater than an angle THETA 2 of the second connection groove (22). A tire-widthwise inner end part of each of a plurality of first shoulder blocks (31) each partitioned by the first lug groove (11), the second lug groove (12), and the first connection groove (21)is arranged closer to the tire equator CL than a tire-widthwise inner end part of each of a plurality of second shoulder blocks (32) each partitioned by the first lug groove (11), the second lug groove (12), and the second connection groove (22). Each of the first and second shoulder blocks (31, 32) is provided with a traversal groove (31a, 32a) that traverses the block while being slanted with respect to the tire circumferential direction.

Owner:THE YOKOHAMA RUBBER CO LTD

A kind of retaining wall mud for underground diaphragm wall of deep and large foundation pit in round gravel formation and its configuration method

ActiveCN110066661BIncrease plastic viscosityIncrease dynamic shear forceBuilding constructionsOrganic fertilisersPolypropylenePollution

The invention relates to the field of building construction, and provides a mud for retaining wall of an underground diaphragm wall of a deep and large foundation pit in a round boulder formation, which comprises the following raw materials in parts by weight: 1000 parts of water, 75-85 parts of bentonite, 3-5 parts of soda ash, and polyacrylic acid Sodium 0.5‑1.5 parts. The invention also provides a method for configuring the slurry for the retaining wall of the underground diaphragm wall of the deep and large foundation pit in the round gravel formation. The advantage of the present invention is that: the present invention adopts sodium polyacrylate to replace traditional CMC, and its slurry retaining wall performance and slurry recycling rate will be greatly improved, and at the same time, corresponding environmental pollution and material consumption are reduced; at the same time, it is prepared according to the formula of the present invention The various indexes of the obtained mud can meet the requirements of the circulating mud index, the effect of wall protection is good, and the stability of the groove wall is good.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

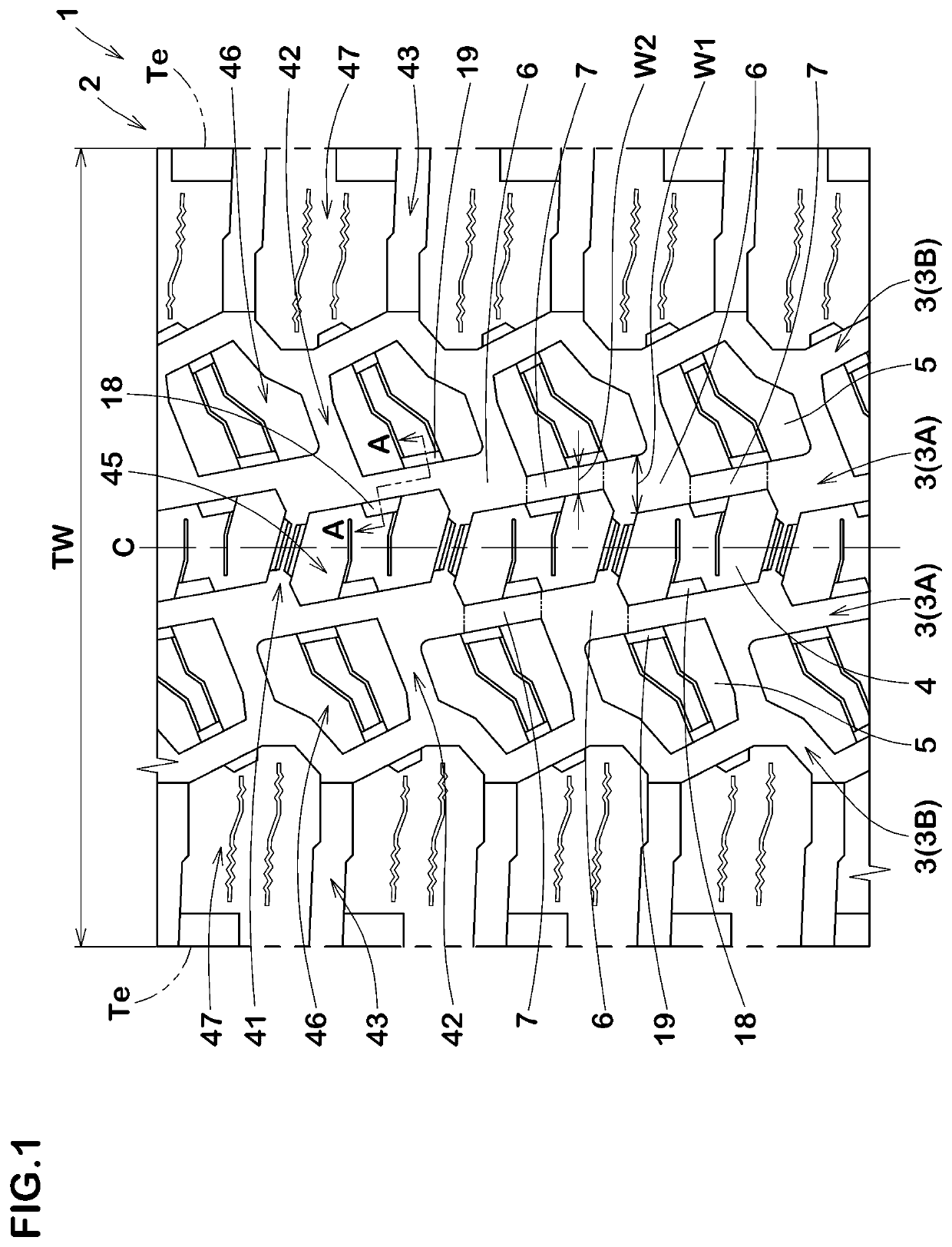

pneumatic tire

ActiveCN108081875BImprove wetting performanceImprove mud performanceOff-road vehicle tyresTyre tread bands/patternsControl theoryMechanical engineering

The present invention provides a pneumatic tire in which on-road performance, off-road performance, riding comfort performance, and noise performance are improved in a balanced manner. The pneumatic tire (1) of the present invention is provided with a plurality of main grooves (3) extending continuously in a zigzag shape in the tire circumferential direction and a plurality of lateral grooves (4) extending in the tire axial direction on the tread portion (2). . The main groove (3) includes a pair of shoulder main grooves (6) arranged on both sides of the tire equator C. The lateral grooves (4) include a plurality of shoulder lateral grooves (17) extending from each shoulder main groove (6) to a tread end (Te) on the tire axially outer side. The maximum groove width W8 of the shoulder transverse groove (17) is 0.2-0.6 times of the maximum groove width W1 of the shoulder main groove (6).

Owner:SUMITOMO RUBBER IND LTD

Tire

ActiveUS11077716B2Improve mud performanceMaintain performanceTyre measurementsTyre tread bands/patternsGround contactMechanical engineering

A tire includes a tread portion including a main groove, a first block and a second block which are adjacent to one another in a tire axial direction through the main groove. The main groove includes first groove elements and second groove elements having groove widths smaller than that of the first groove elements. The first block includes a first ground contact surface, a first sidewall facing one of the second groove elements, a first corner portion between the first ground contact surface and the first sidewall, and a first recess being cut out the first corner portion locally. The second block includes a second ground contact surface, a second sidewall facing said one of the second groove elements, a second corner portion between the second ground contact surface and the second sidewall, and a second recess being cut out the second corner portion locally.

Owner:SUMITOMO RUBBER IND LTD

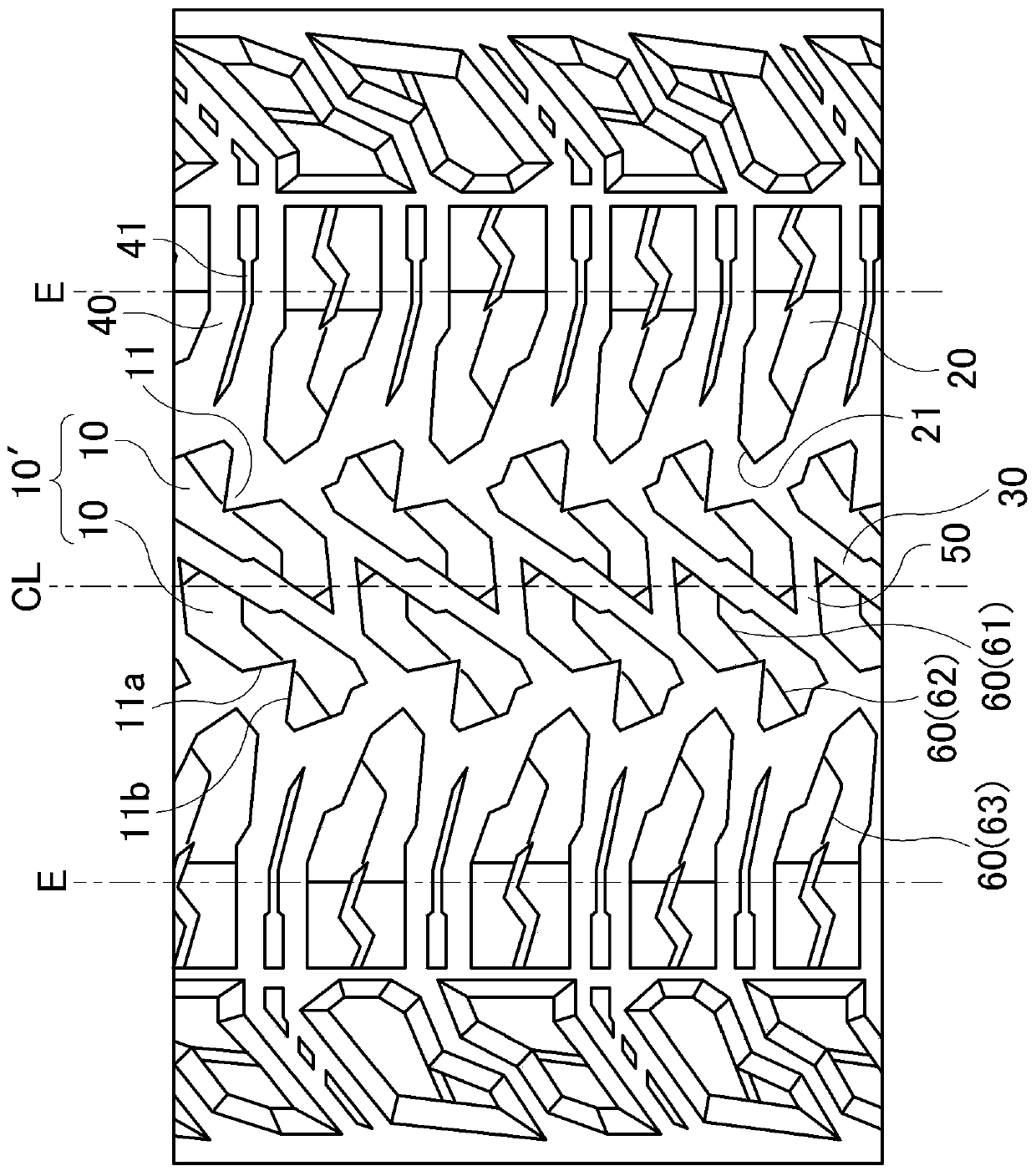

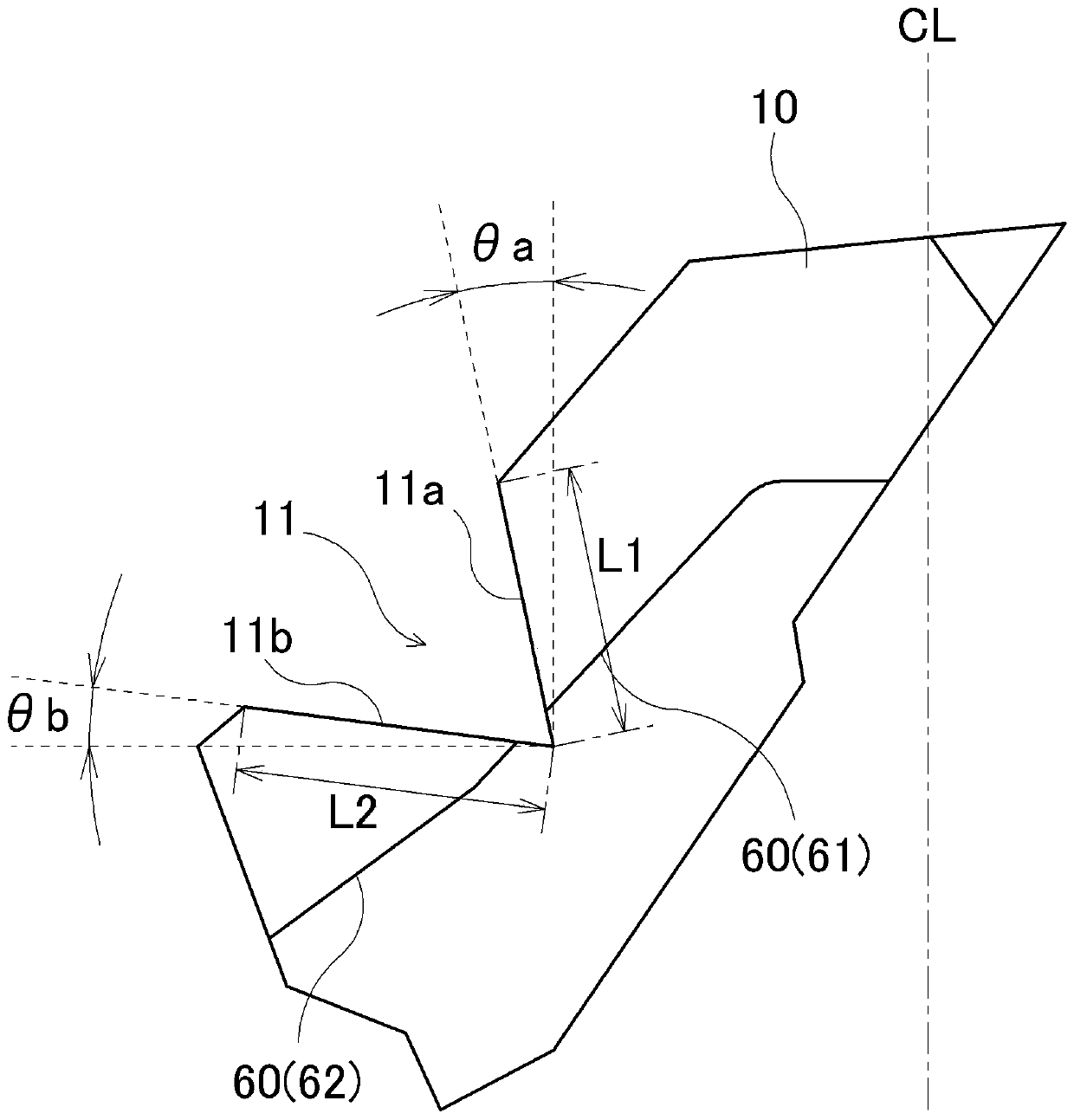

Pneumatic tire

ActiveCN110234519AIncrease the edgeEffective controlOff-road vehicle tyresTyre tread bands/patternsClassical mechanicsMechanical engineering

Provided is a pneumatic tire that is suitable for use as a tire for traveling on unpaved roads and that improves traveling performance on unpaved roads. Center blocks 10, which are provided in a center region of a tread section 1, are arrayed so as to form a pair of center blocks 10 between which there are interposed inclined grooves 30 that extend in an inclined direction with respect to a tire circumferential direction. The center blocks 10 are made to extend so as to straddle a tire equator CL from one side to the other side of the tire equator CL. Notches 11, which are each composed of a first wall 11a and a second wall 11b connected to each other in a V shape, are provided in treads in each center block CL. The first walls 11a are made to extend at an angle within + / -20 degrees with respect to the tire circumferential direction; the second walls 11b are made to extend at an angle of + / -10 degrees with respect to a tire width direction; and third walls 21 that each face a notch 11of a shoulder block 20 provided in a shoulder region of the tread section 1 are made to extend at an angle within + / -5 degrees with respect to a straight line A that connects an end point P1 of the first wall 11a on the shoulder block 20 side and an end point P2 of the second wall 11b on the shoulder block 20 side.

Owner:THE YOKOHAMA RUBBER CO LTD

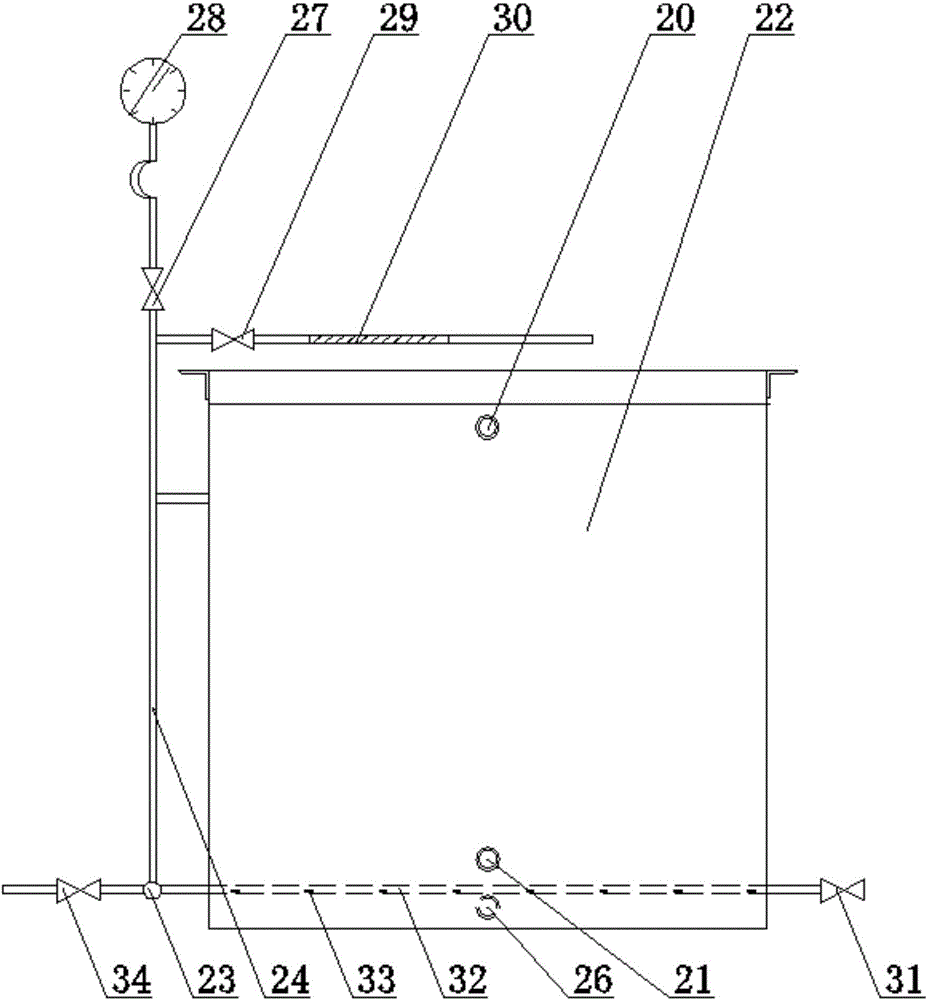

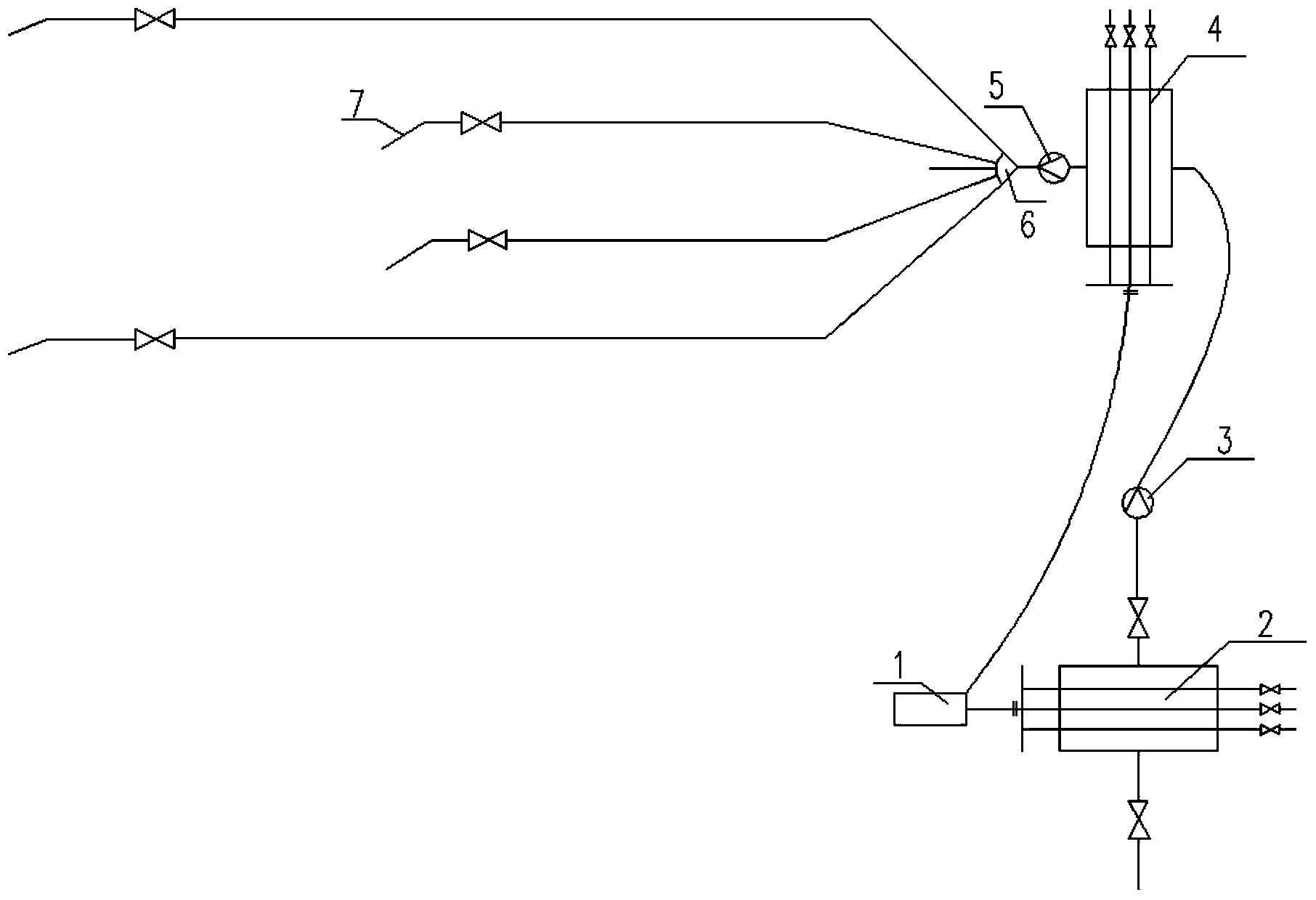

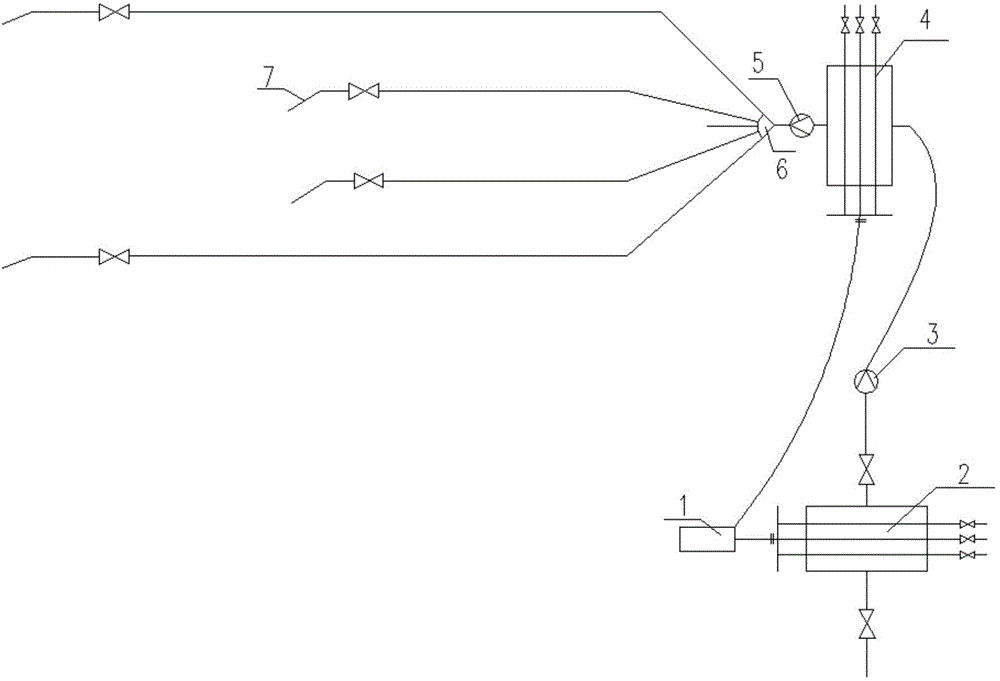

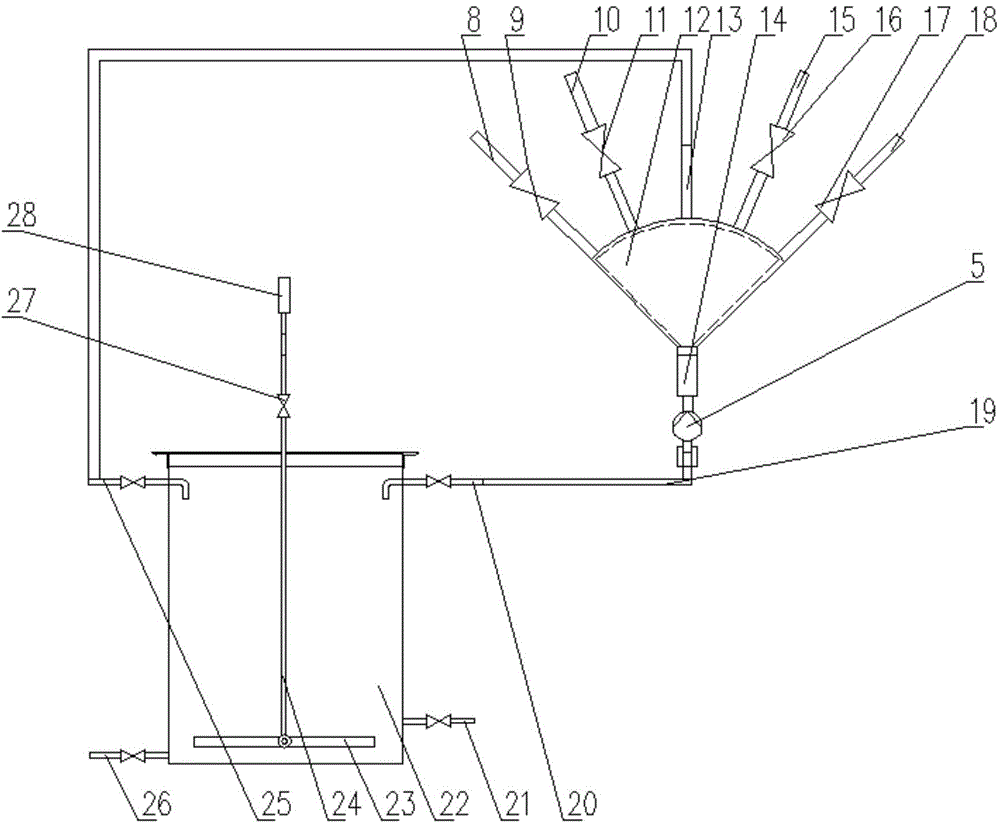

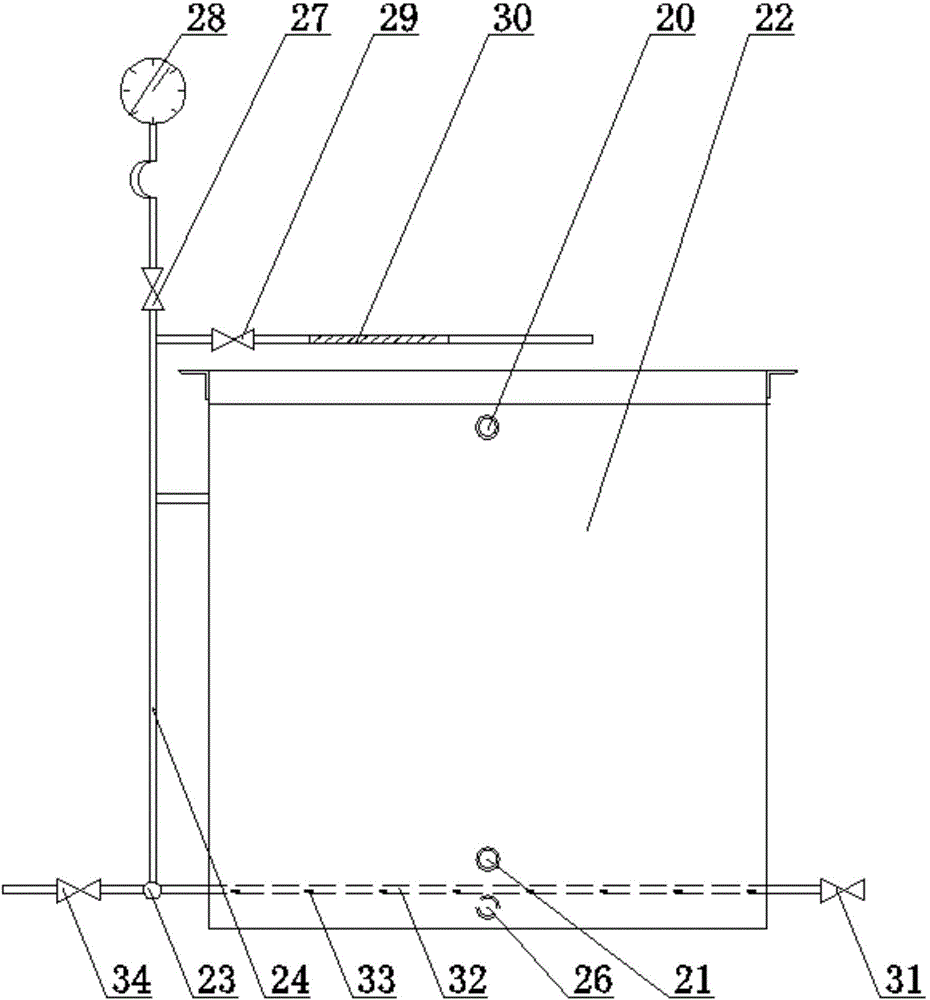

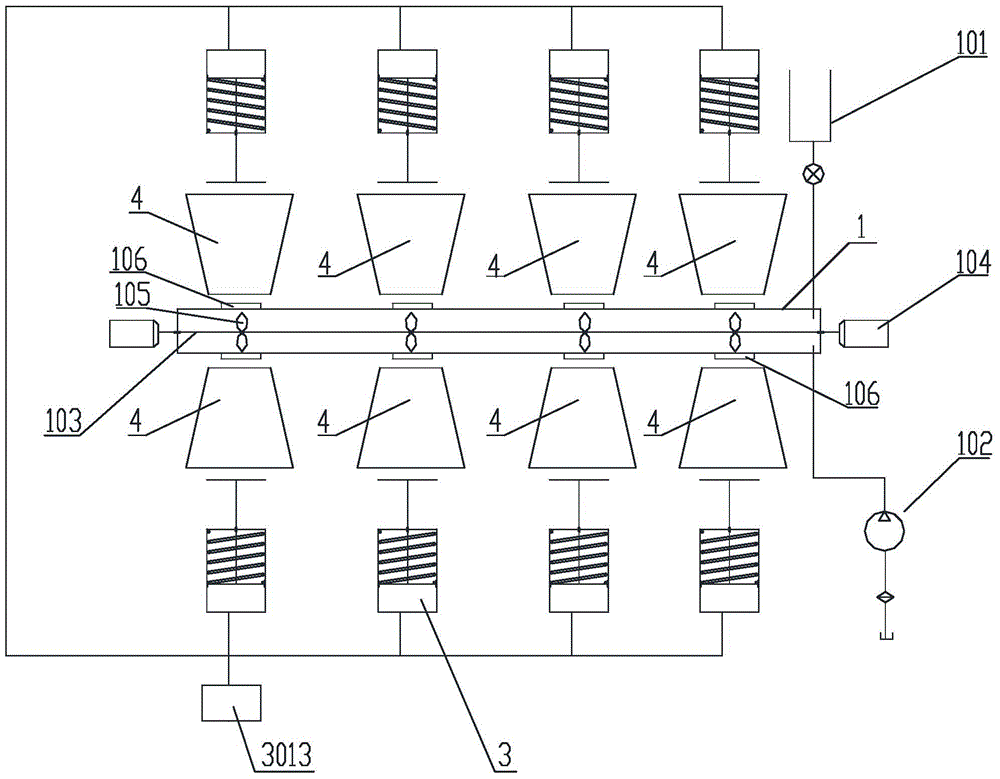

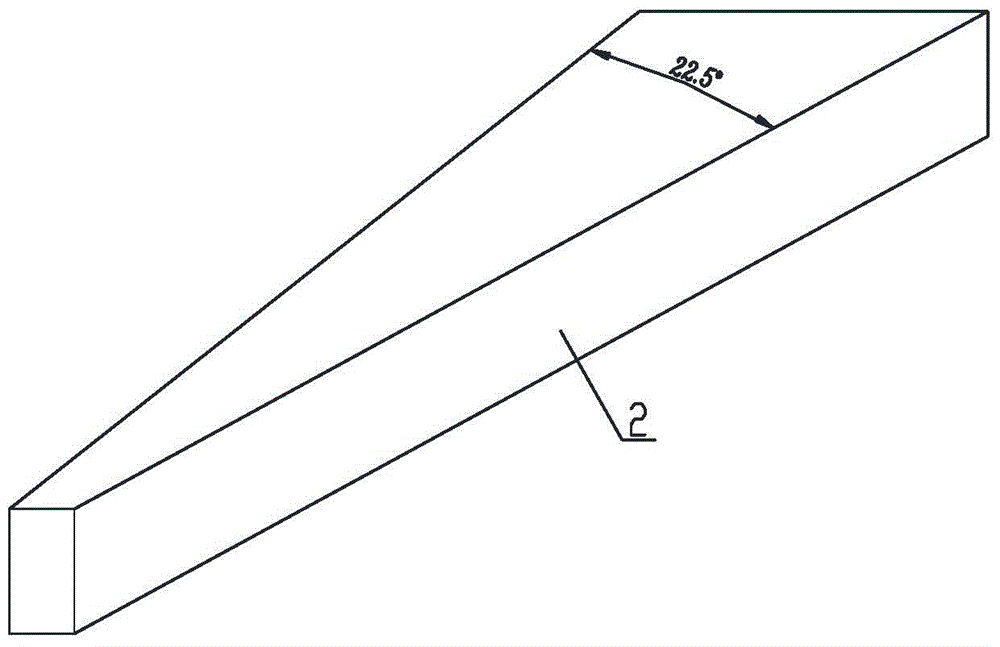

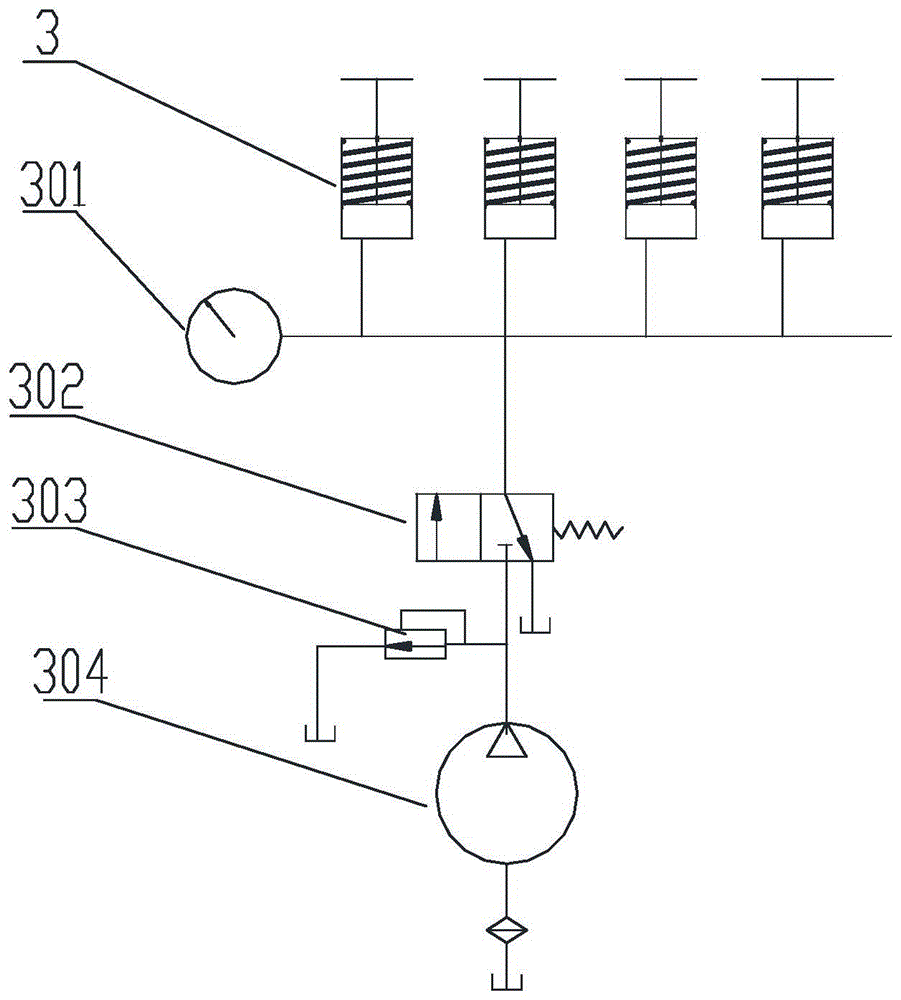

Continuous type coke furnace hot-state roof grouting system based on pressure balance of multiple group of delivery pipe

ActiveCN103642506ASimple structureScientific and reasonable designCoke oven detailsInlet valveSlurry

The invention relates to a continuous type coke furnace hot-state roof grouting system based on the pressure balance of multiple groups of delivery pipes. The continuous type coke furnace hot-state roof grouting system comprises an air compressor, a first slurry mixer, a first slurry delivery pump, a second slurry mixer, a second slurry delivery pump and a slurry pressure uniform distributor, wherein the air compressor is connected with the air inlet valve of the first slurry mixer through an air pipe; the slurry outlet of the first slurry mixer is connected with the water inlet of the second slurry mixer through the first slurry delivery pump; the slurry outlet of the second slurry mixer is connected with the slurry pipe inlet of the slurry pressure uniform distributor through the second slurry delivery pump; the first slurry output pipe, second slurry output pipe, third slurry output pipe and fourth slurry output pipe of the slurry pressure uniform distributor are respectively connected with respective grouting pipes. The continuous type coke furnace hot-state roof grouting system disclosed by the invention has the advantages of simple structure, scientificity and reasonability in design, lower cost, high production efficiency and good slurry property without pollution and effectively reduces the manual labor intensity.

Owner:MCC TIANGONG GROUP

Continuous type coke furnace hot-state roof grouting system based on pressure balance of multiple group of delivery pipe

ActiveCN103642506BSimple structureScientific and reasonable designCoke oven detailsInlet valveEngineering

The invention relates to a continuous type coke furnace hot-state roof grouting system based on the pressure balance of multiple groups of delivery pipes. The continuous type coke furnace hot-state roof grouting system comprises an air compressor, a first slurry mixer, a first slurry delivery pump, a second slurry mixer, a second slurry delivery pump and a slurry pressure uniform distributor, wherein the air compressor is connected with the air inlet valve of the first slurry mixer through an air pipe; the slurry outlet of the first slurry mixer is connected with the water inlet of the second slurry mixer through the first slurry delivery pump; the slurry outlet of the second slurry mixer is connected with the slurry pipe inlet of the slurry pressure uniform distributor through the second slurry delivery pump; the first slurry output pipe, second slurry output pipe, third slurry output pipe and fourth slurry output pipe of the slurry pressure uniform distributor are respectively connected with respective grouting pipes. The continuous type coke furnace hot-state roof grouting system disclosed by the invention has the advantages of simple structure, scientificity and reasonability in design, lower cost, high production efficiency and good slurry property without pollution and effectively reduces the manual labor intensity.

Owner:MCC TIANGONG GROUP

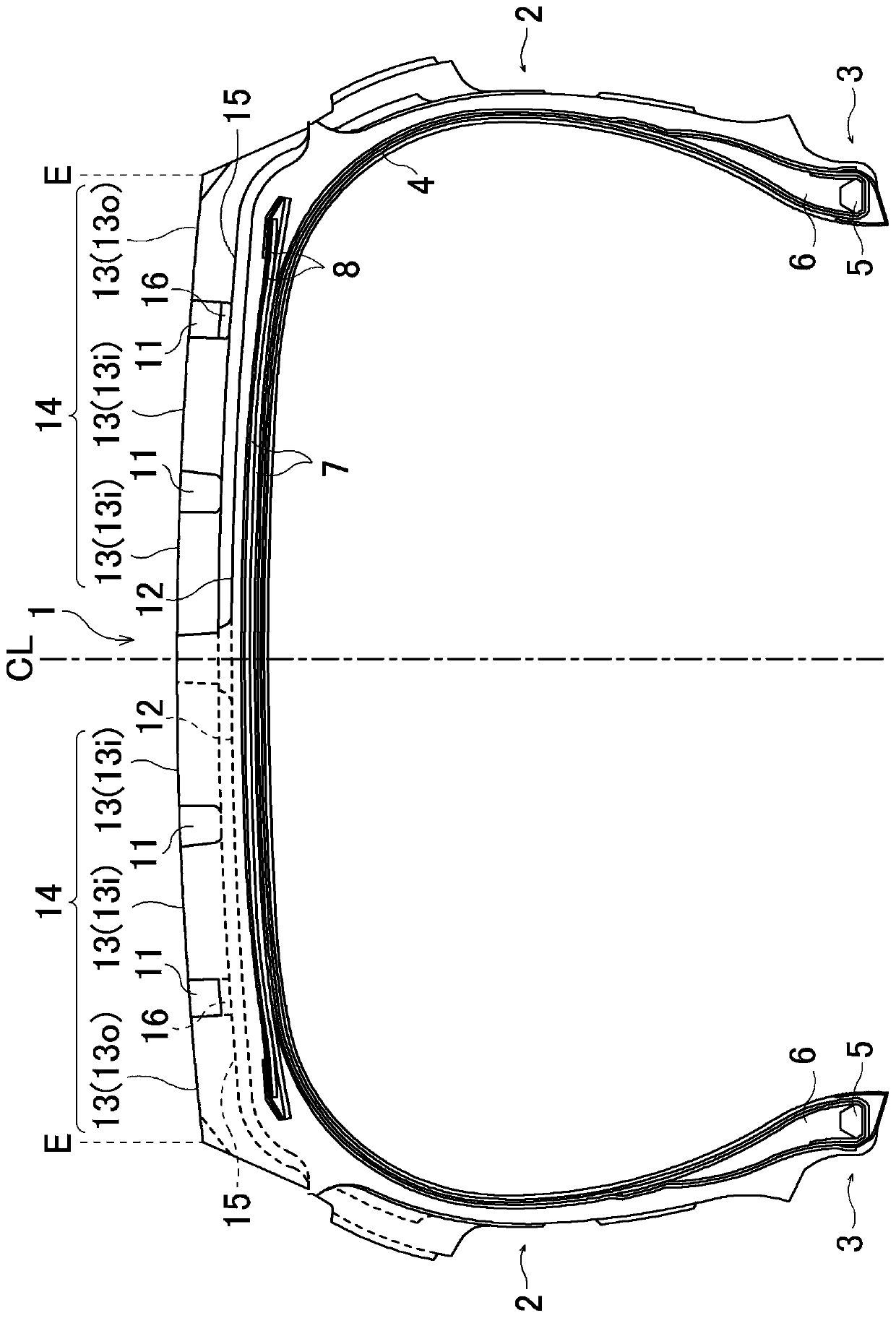

Pneumatic tire

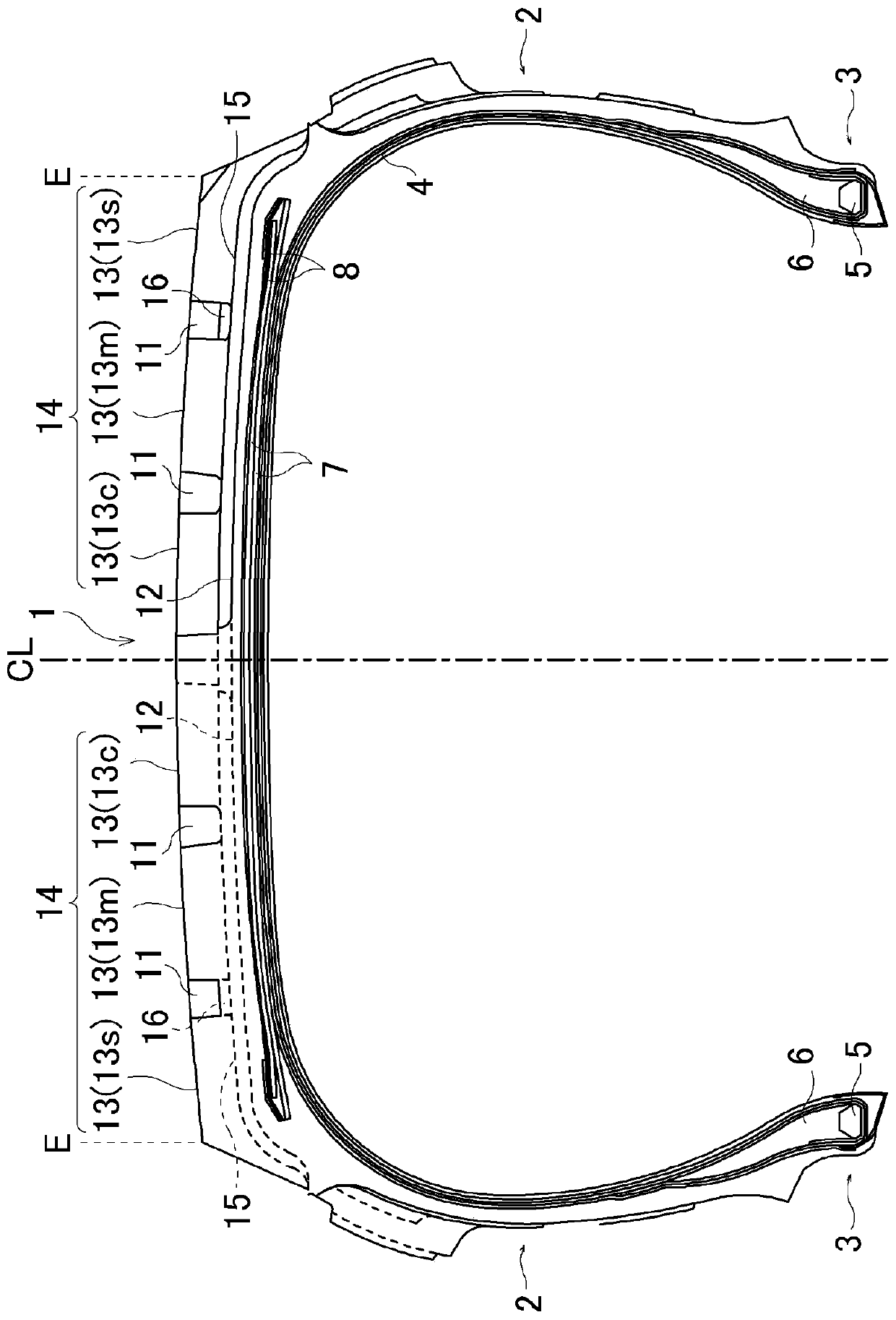

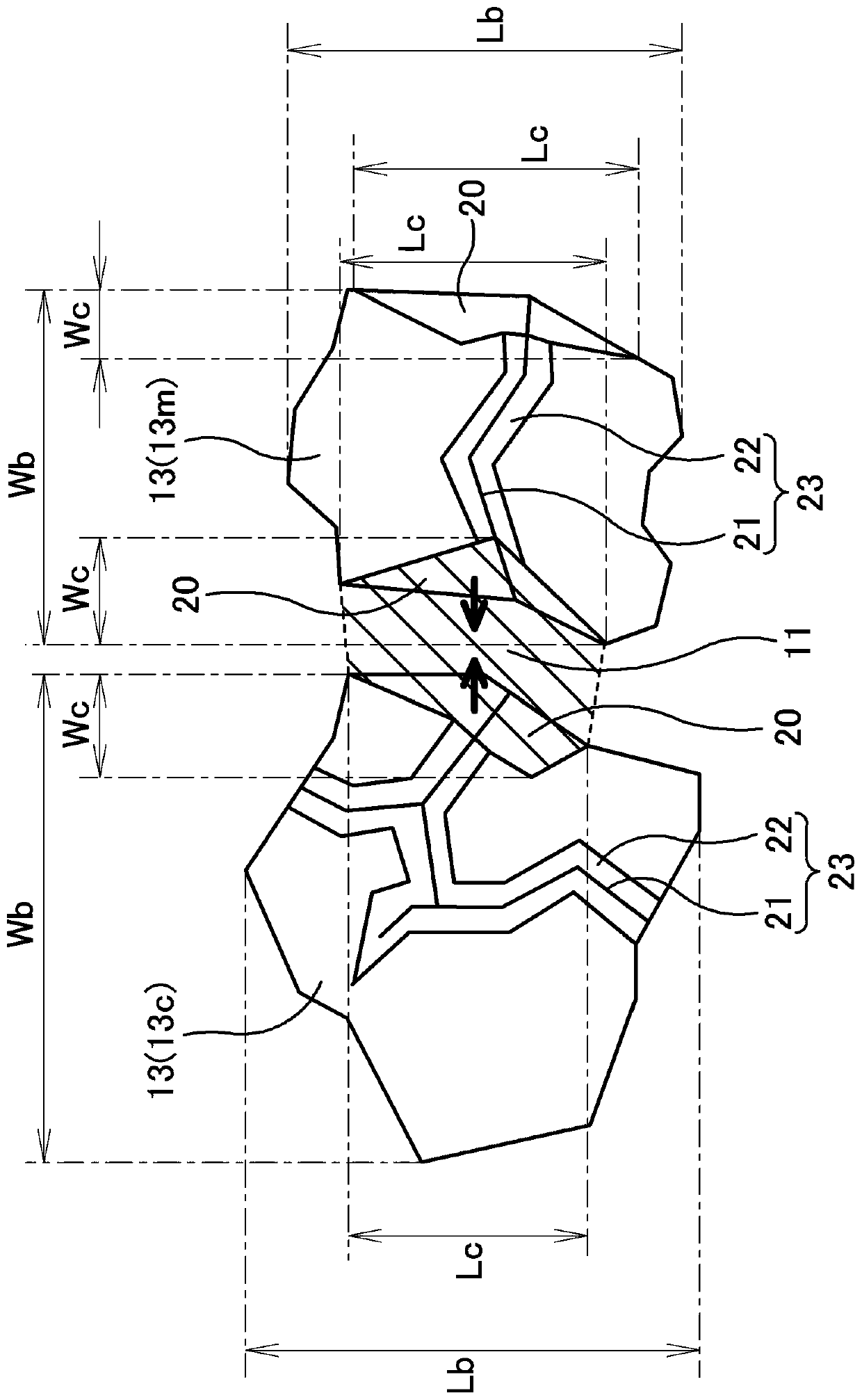

ActiveCN110914073AImprove rigidityImprove discharge effectOff-road vehicle tyresTyre tread bands/patternsMechanical engineeringTread

Provided is a pneumatic tire that is favorable for traveling on an unpaved road and shows improved traveling performance and anti-wear performance on an unpaved road. Of a plurality of blocks 13 formed in a tread portion, at least three blocks 13 that include an outermost block 13o located outermost in a tire width direction and are adjacent to each other in the tire width direction, and at leasttwo vertical grooves 11 located between these blocks 13, are arranged on a platform 15 that protrudes from a groove bottom of a horizontal groove 12, has a flat top surface, and projects to either side in a tire circumferential direction with respect to the at least three blocks 13, and a bottom raising portion 16 protruding from a groove bottom of the vertical groove 11 adjacent to the outermostblock 13o is provided on the groove bottom of the vertical groove 11, to connect the outermost block 13o to the block 13 adjacent to the outermost block 13o.

Owner:THE YOKOHAMA RUBBER CO LTD

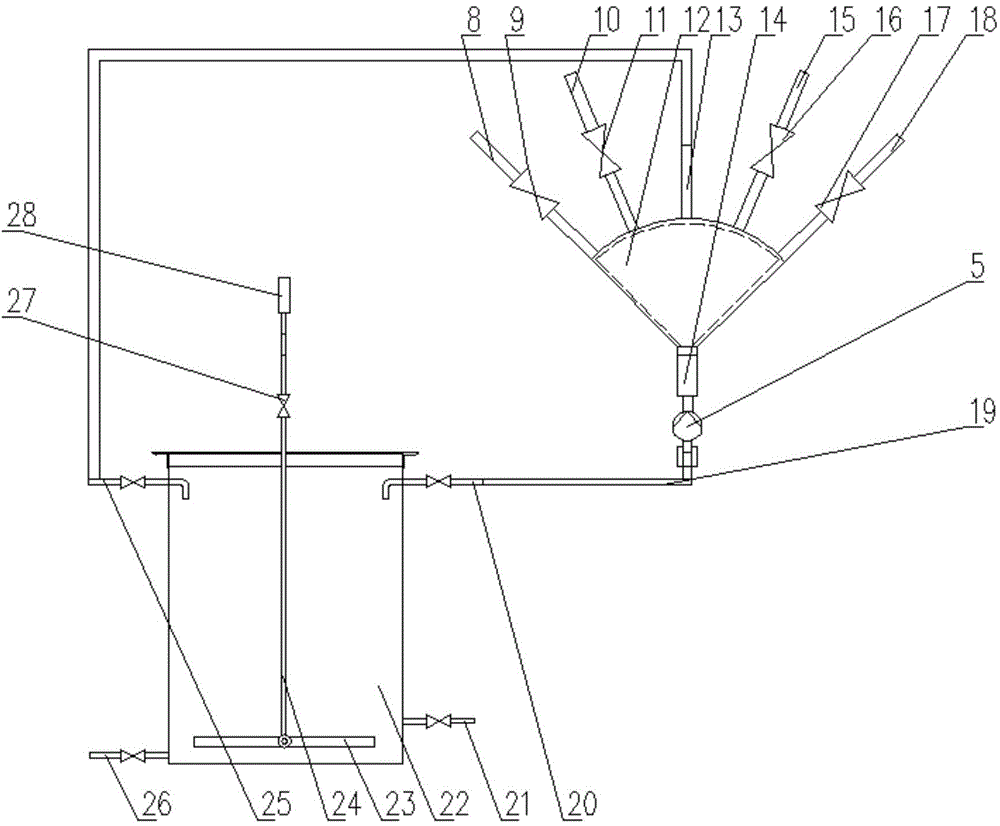

Experimental device for simulating mud cake formation process

The invention discloses an experimental device for simulating the formation process of mud cake, which comprises a simulated wellbore and an invasion chamber, the simulated wellbore is respectively connected with a feeding bin and a pressurized pump, and a stirring shaft is installed at the shaft of the simulated wellbore, and the stirring shaft and Stirring motor transmission connection, an impeller is set on the stirring shaft, a window is opened on the simulated wellbore, a formation module is installed in the invasion chamber, the invasion chamber is sealed and connected to the window of the simulated wellbore, and a Filtration flow measurement device. The invention realizes mud filtration experiments under different mud types, different mud pressures, and different hydrodynamic conditions, and creates favorable conditions for studying mud cake formation rules and evaluating mud filtration and wall-building properties, and is helpful for optimizing mud performance , It is of great significance to protect the reservoir productivity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com