Drilling mud formula and automatic mud circulation purification device

A technology for drilling mud and circulation purification, which is used in earth-moving drilling, wellbore/well components, construction, etc., and can solve the problem of unavoidable contamination of surrounding soil, the life of drilling pump wearing parts, and the failure of environmental protection construction to meet the requirements. and other problems, to achieve the effect of preventing mud seepage, less sand, and less resistance to rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A drilling mud formula, comprising raw materials for preparing mud, and the raw materials for preparing mud include the following percentage components: 1000 parts of clear water, 20 parts of bentonite, 4 parts of polyacrylamide, 4 parts of vegetable gum, 6 parts of potassium humate, and carboxymethyl fiber 3 parts of plain sodium salt, 3 parts of ferrochromium lignosulfonate sodium salt, 4 parts of sodium carbonate, 4 parts of barite fine powder, 3 parts of dry sawdust, 4 parts of asbestos and 5 parts of polyacrylamide flocculant.

[0054] The formula for calculating the amount of raw materials for the modulation mud is:

[0055] M=Vρ 1 = (ρ 2 -ρ 3 ) / (ρ 1 -ρ 2 )-ρ 1 ;

[0056] In the formula: M—the weight of the raw material required for each m3 of mud (t), V—the volume of the raw material required for each m3 of mud (m3), ρ 1 The density of (t / m³), ρ 2 —Required mud density (t / m³), ρ 2 =Vρ 1 t(1-v)ρ 3 , ρ 3 - Density of water, take ρ 3 =1t / m³.

[0057] l...

Embodiment 2

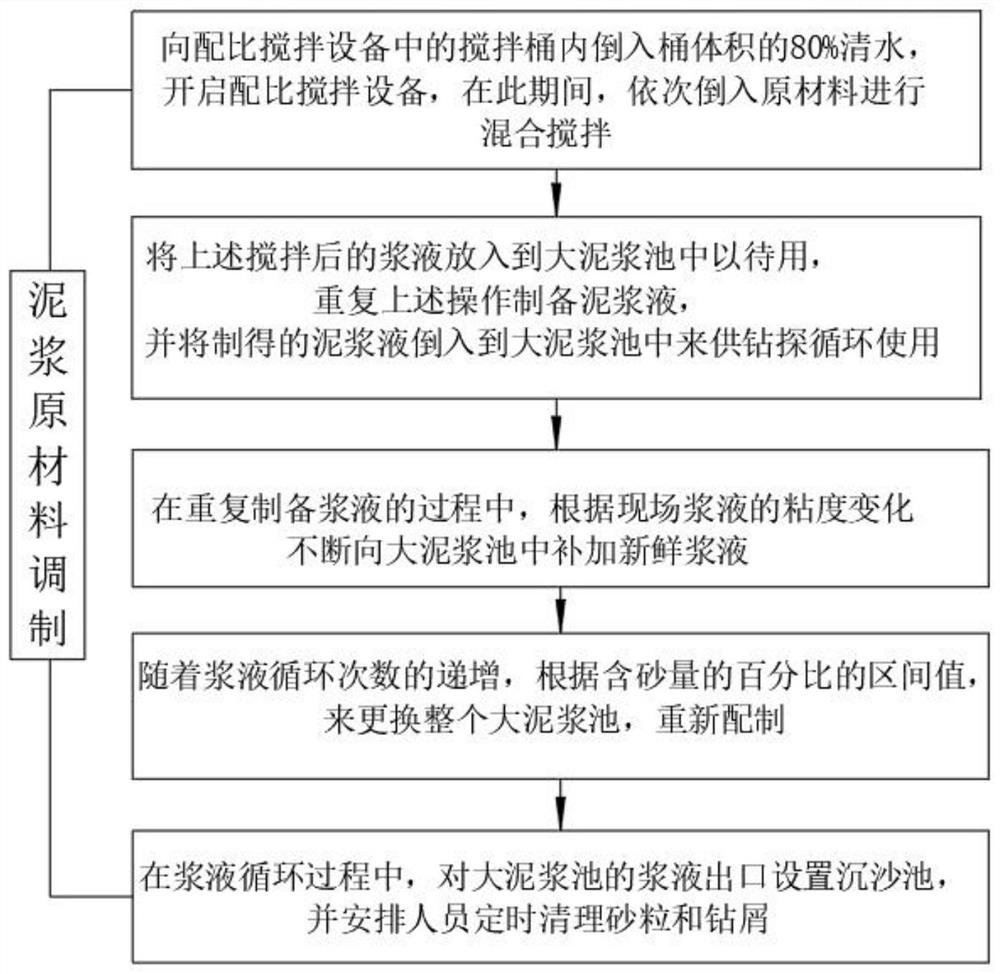

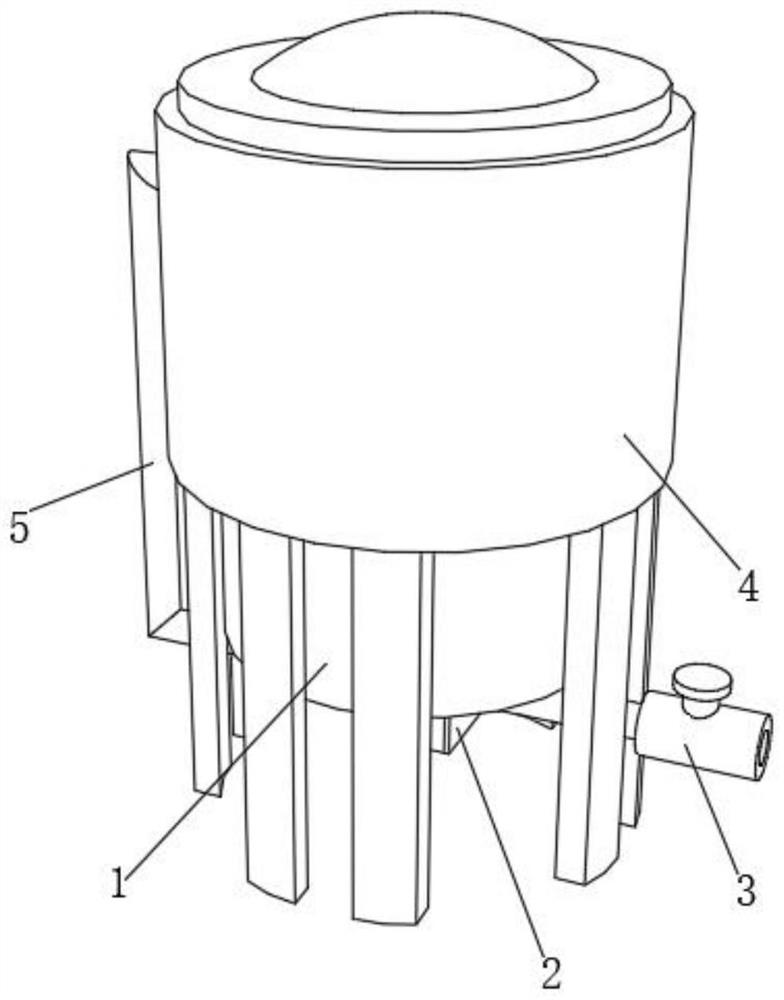

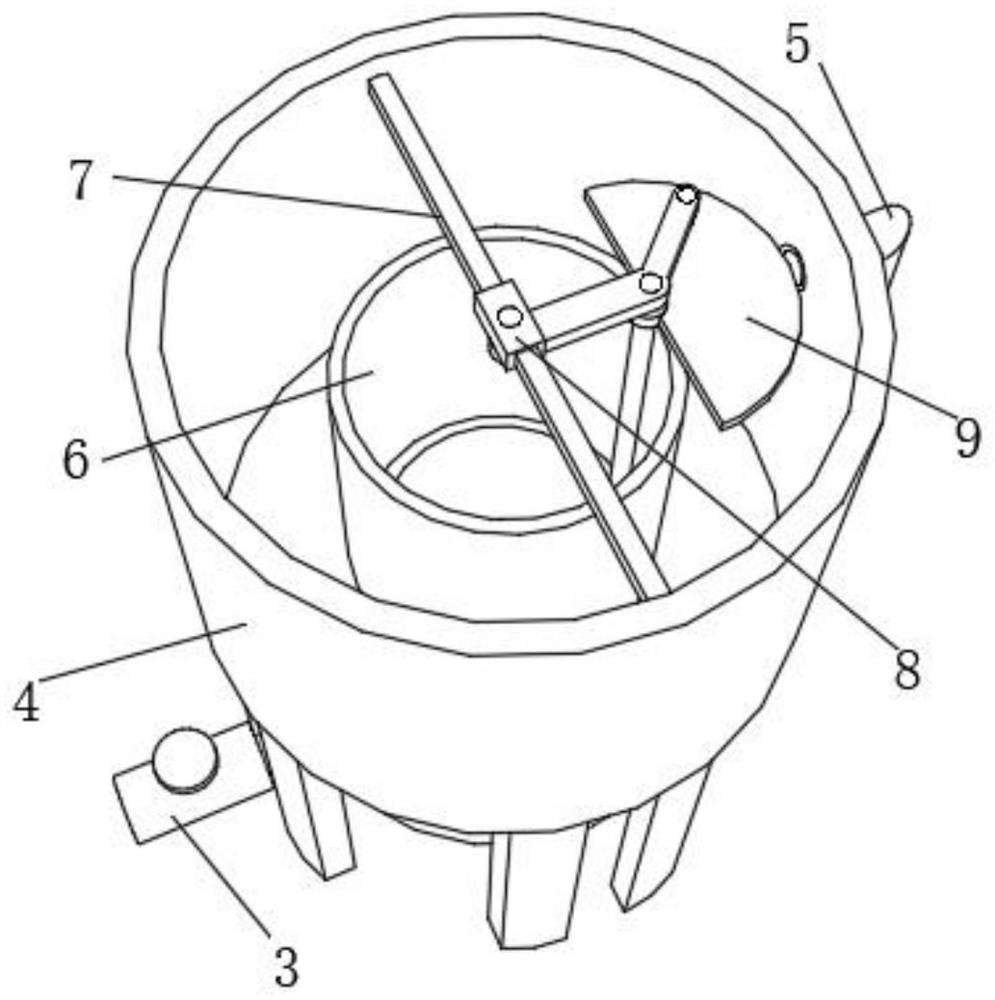

[0067] A kind of automatic mud circulation purification device of drilling mud, in order to carry out circulation purification to mud liquid in large mud pool, the present embodiment makes the following improvements on the basis of embodiment 1: Figure 2-6 As shown, it includes a bottom barrel 1, a primary filter box 2 and a main filter barrel 4, the bottom barrel 1 is connected with the bottom of the main filter barrel 4 through threads, and the primary filter box 2 is connected with the bottom outer wall of the bottom barrel 1 through bolts. The bottom inner wall of the main filter barrel 4 is connected with an isolation barrel 6 through threads, and the bottom barrel 1 and the main filter barrel 4 are respectively provided with an arc reciprocating mechanism and a circular motion mechanism, and the swing end of the arc reciprocating mechanism is provided with two L The rotating end of the circular motion mechanism of the filter plate 19 is provided with a particle adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com