A kind of high-efficiency sludge dewatering method

A kind of sludge and high-efficiency technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low efficiency and long stagnation time of sludge, and solve the difficulties of sludge transportation and storage, save medicine and reduce The effect of disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

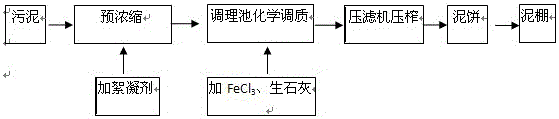

[0016] Such as figure 1 as shown, figure 1 It is a schematic flow sheet of the present invention; the present embodiment takes the sludge dehydration production of a large-scale sewage treatment plant in Nanjing as an example, and its steps are:

[0017] 1. Sludge pre-concentration: The measured moisture content of the sludge from the sewage plant is 98.9%. The sludge is transported into the sludge concentration tank through the sludge pump, and the sludge moisture content is reduced to 97.4% by gravity concentration.

[0018] 2. Sludge chemical conditioning: the concentrated sludge is transported into the sludge conditioning tank A through the sludge pump A, and the actual volume of the tank is about 56m 3 The liquid level in the pool is measured by the ultrasonic liquid level gauge and the data is transmitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com