Patents

Literature

32 results about "Unpaved road" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

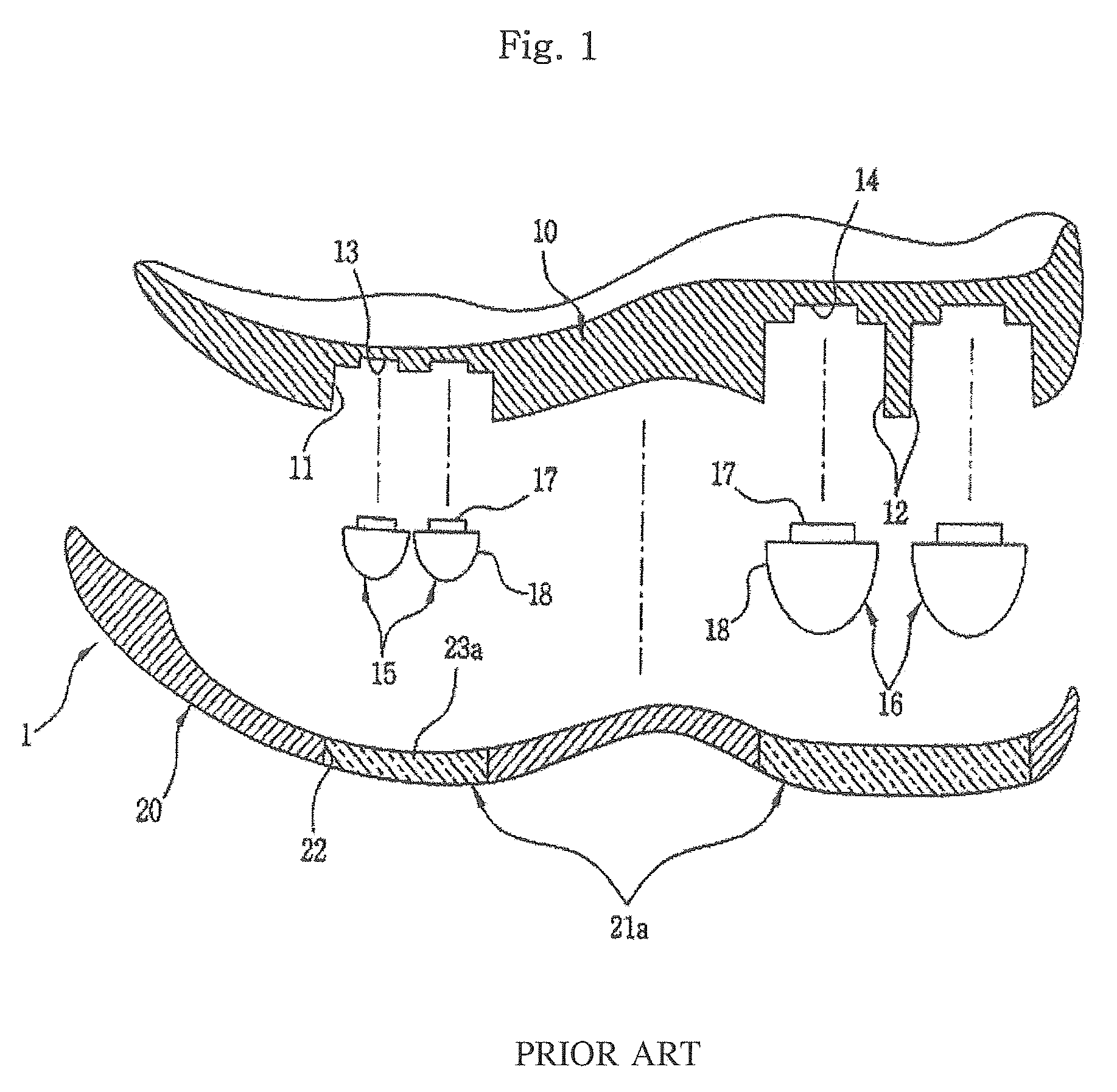

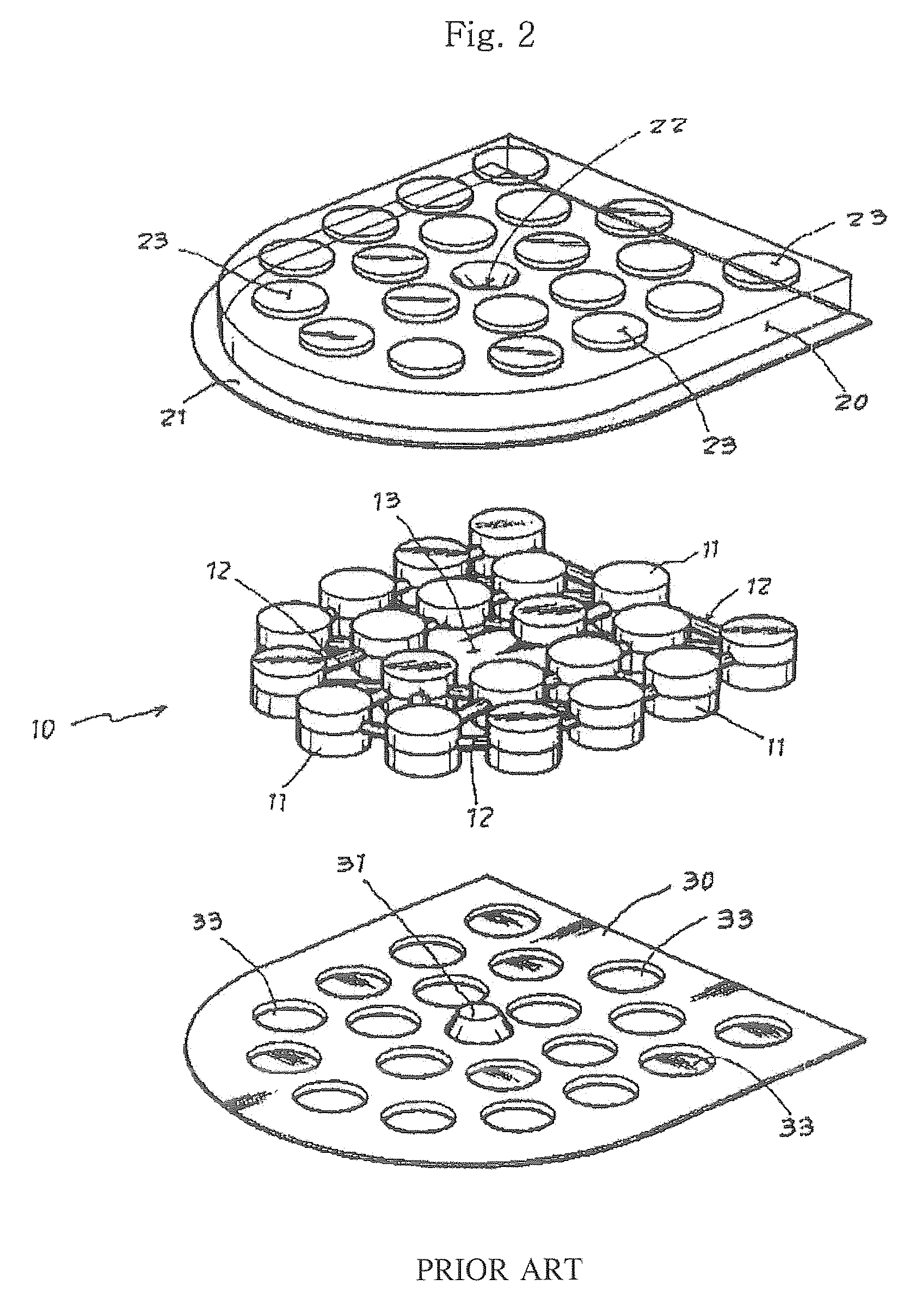

Shoe sole

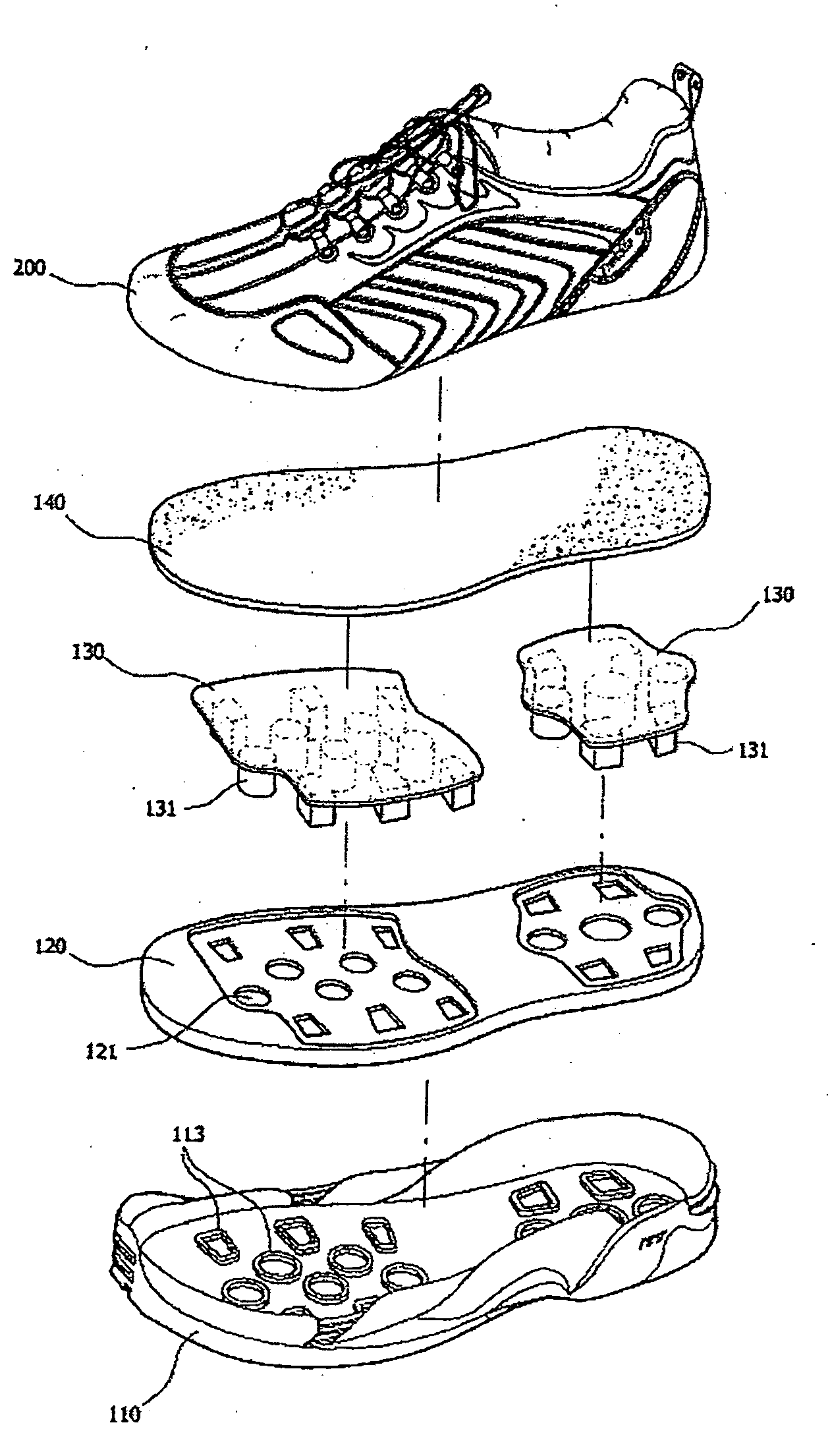

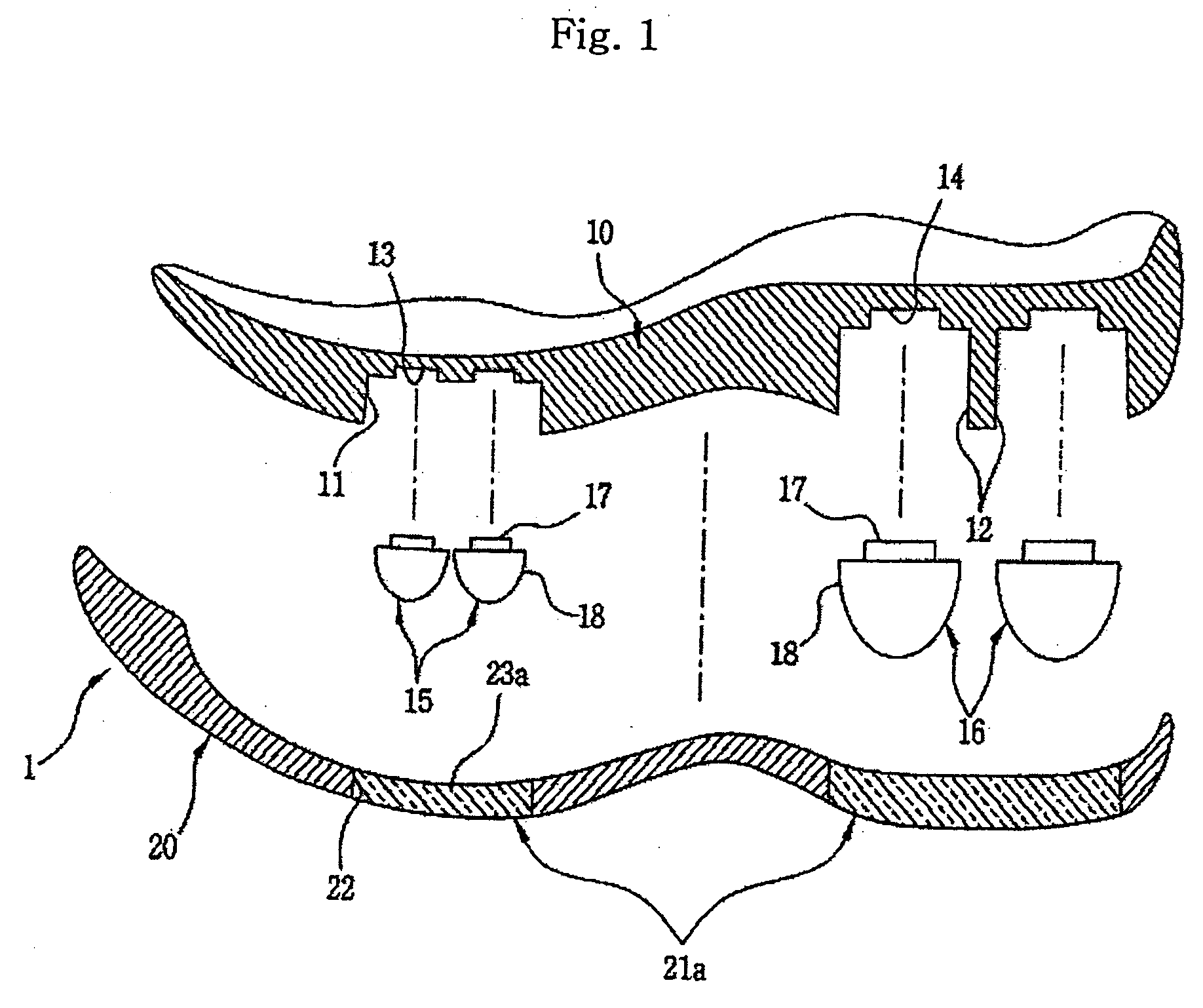

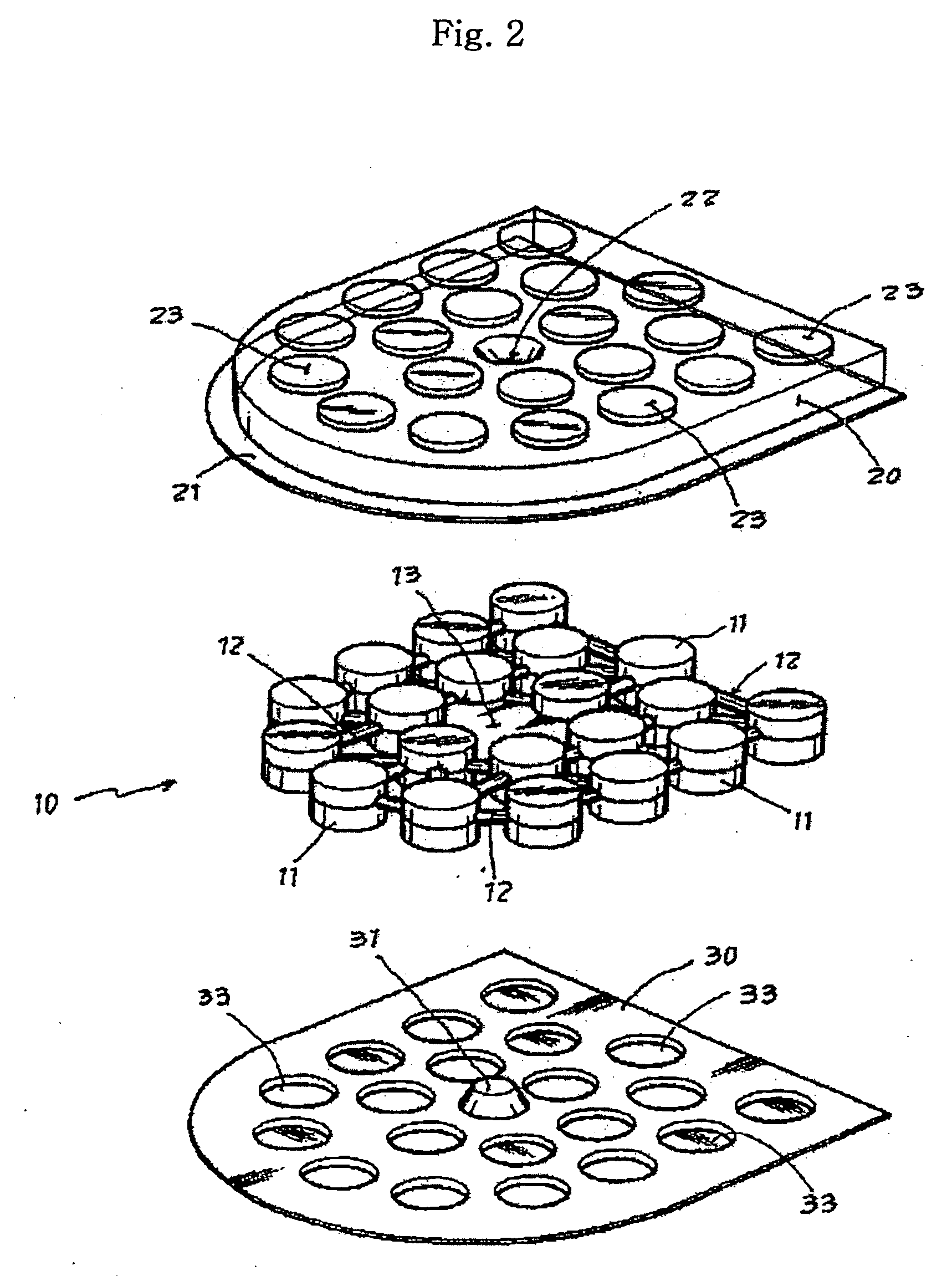

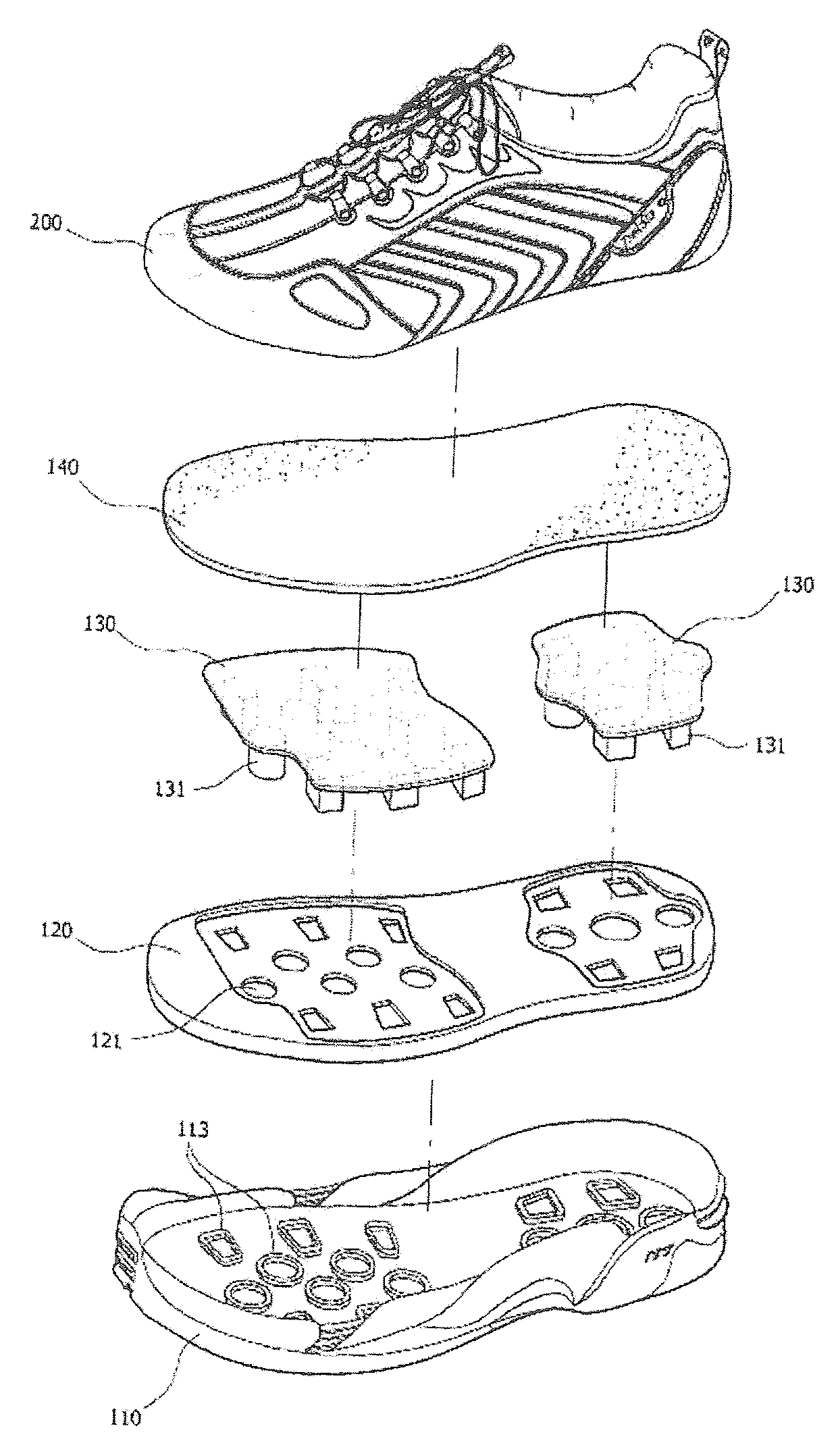

Disclosed is a shoe sole capable of horizontally maintaining an inner bottom section of footwear when the user walks. The shoe sole includes an outsole provided at front and rear portions thereof with a plurality of protrusions, a mid-sole stacked on the upper surface of the outsole and formed with a plurality of perforation holes, an insert provided at a bottom surface thereof with a plurality of protrusions, which are inserted into the outer wheels by passing through the perforation holes of the mid-sole, and a lasting board stacked on an upper surface of the insert coupled with the mid-sole. The inner bottom section of footwear is horizontally maintained. The shoe sole attenuates foot fatigue and provides comfortable wearing feeling when the user walks on an unpaved road or climbs a mountain.

Owner:TREKSTA

Shoe sole

Disclosed is a shoe sole capable of horizontally maintaining an inner bottom section of footwear when the user walks. The shoe sole includes an outsole provided at front and rear portions thereof with a plurality of protrusions, a mid-sole stacked on the upper surface of the outsole and formed with a plurality of perforation holes, an insert provided at a bottom surface thereof with a plurality of protrusions, which are inserted into the outer wheels by passing through the perforation holes of the mid-sole, and a lasting board stacked on an upper surface of the insert coupled with the mid-sole. The inner bottom section of footwear is horizontally maintained. The shoe sole attenuates foot fatigue and provides comfortable wearing feeling when the user walks on an unpaved road or climbs a mountain.

Owner:TREKSTA

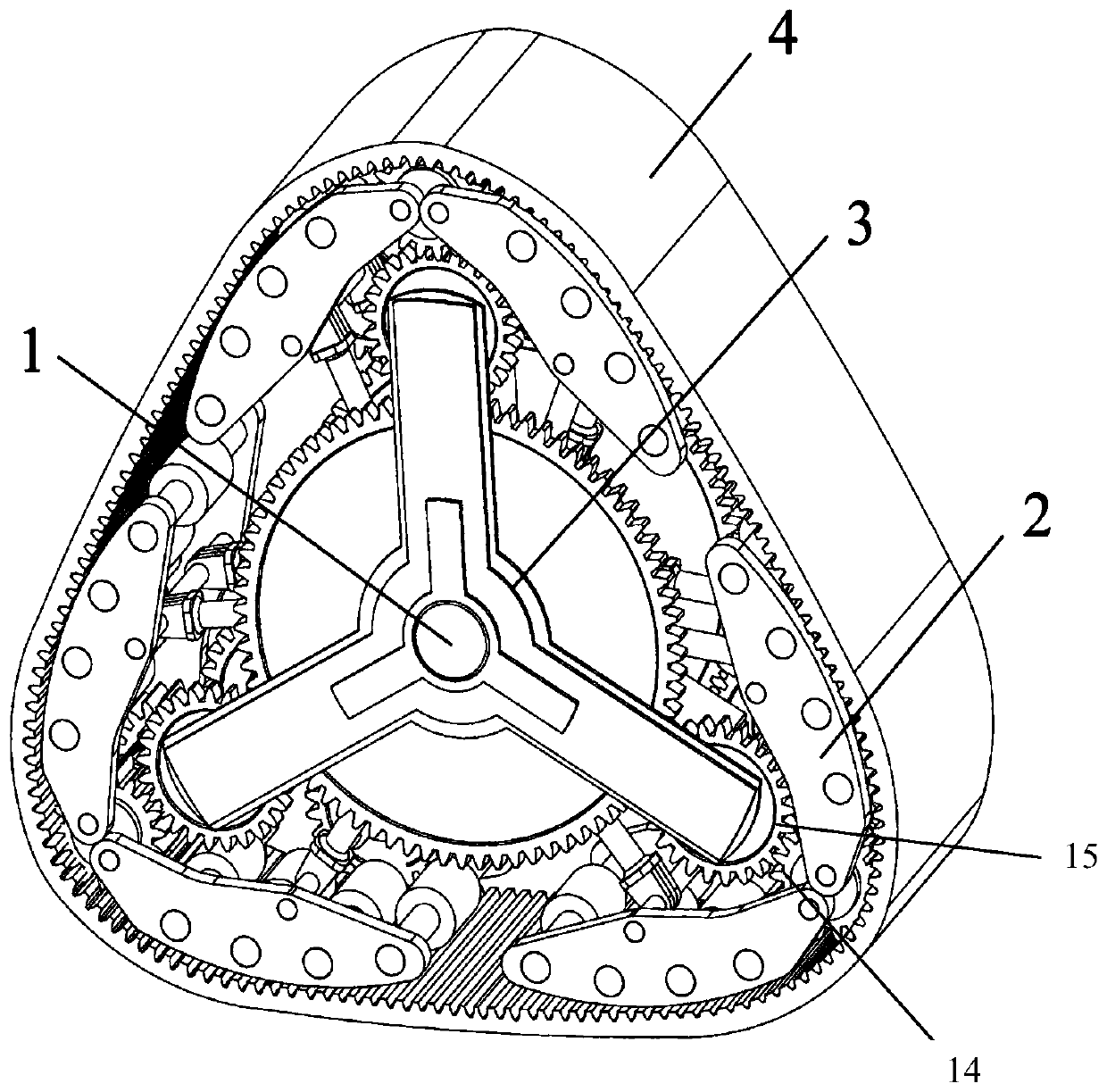

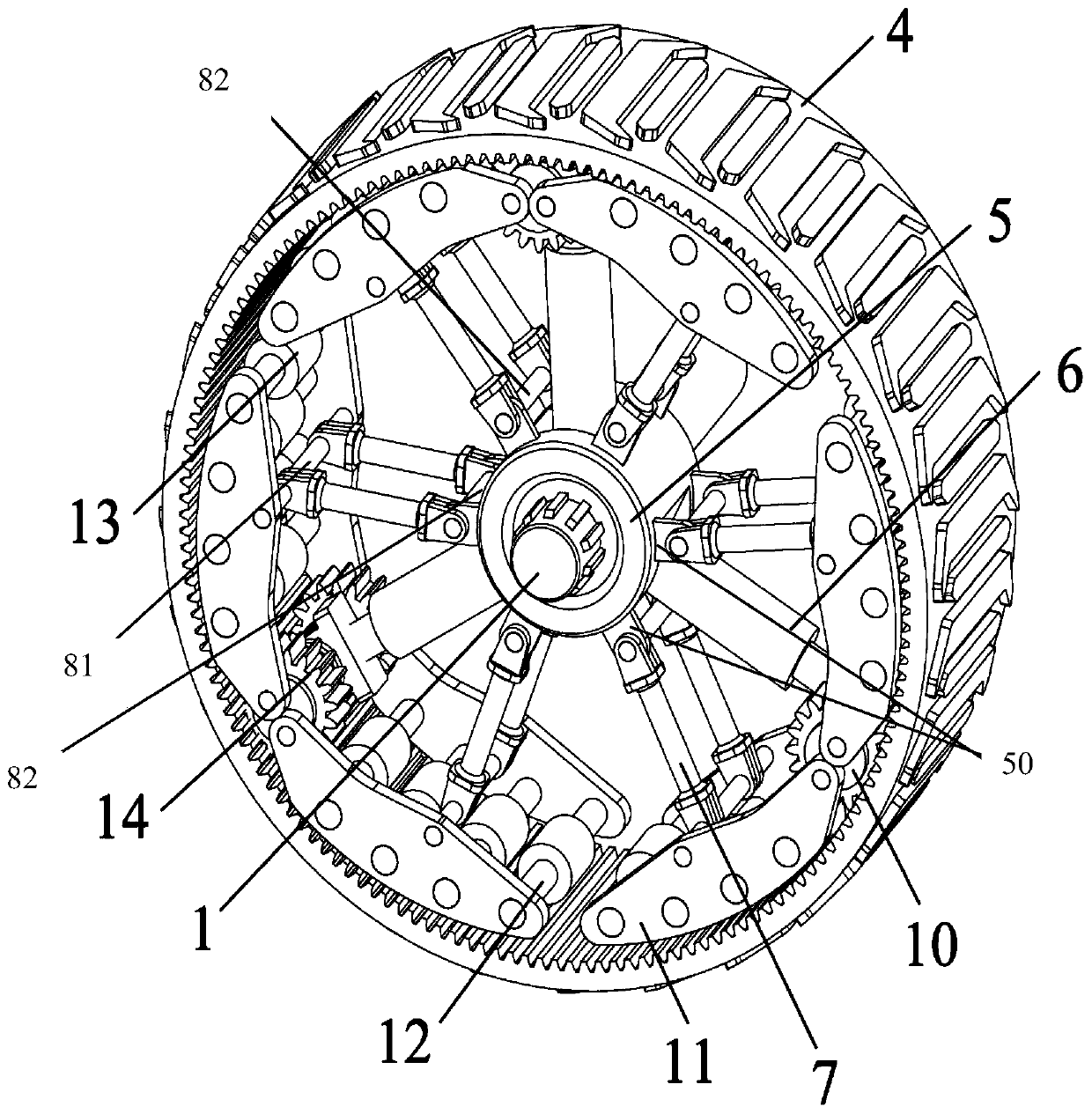

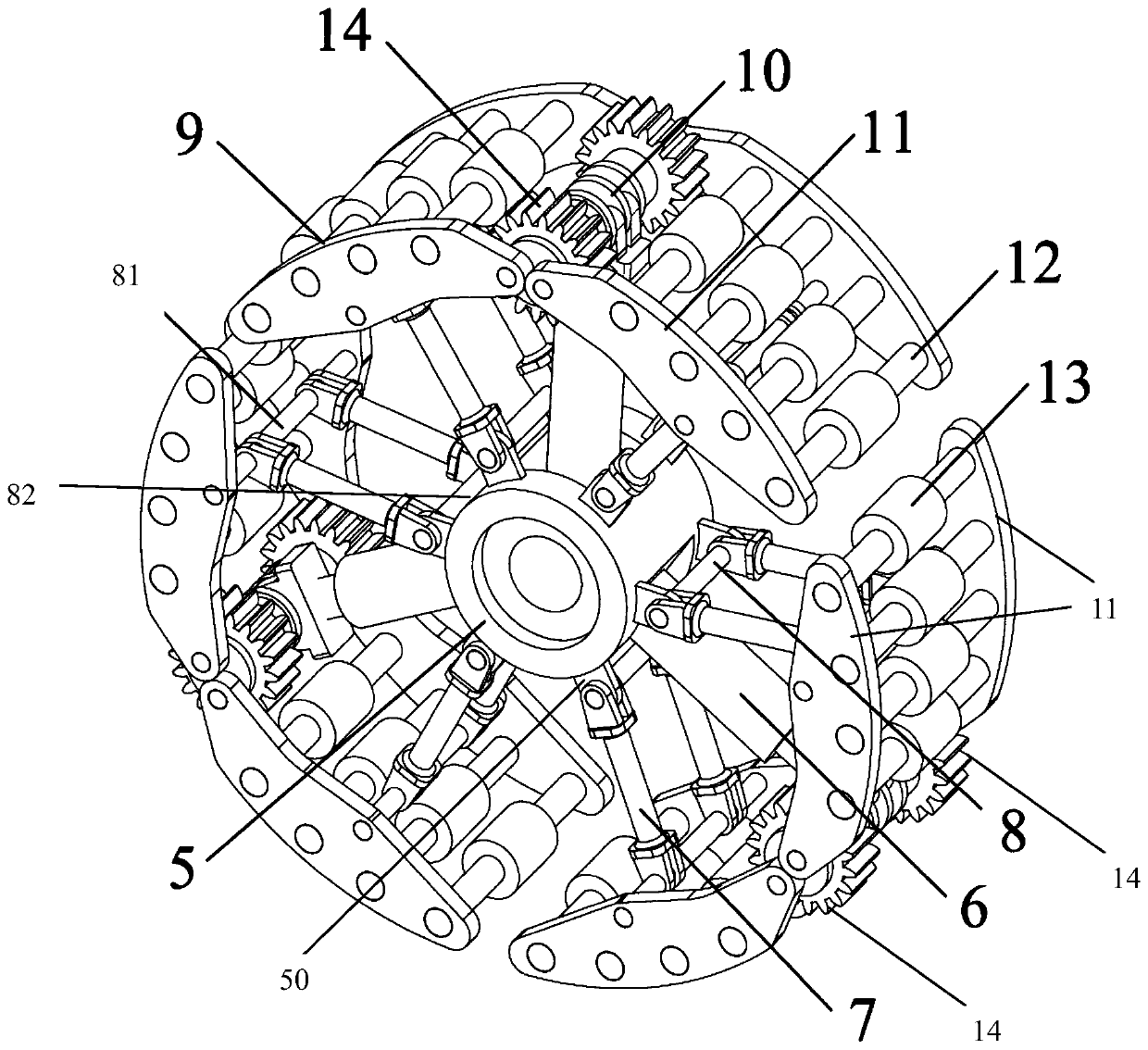

Novel wheel-track composite variable structure wheel

PendingCN111572272AStructural Design ScienceImprove environmental adaptabilityEndless track vehiclesWheelsDrive shaftGear wheel

The invention discloses a novel wheel-track composite variable structure wheel which comprises a driving shaft (1), a telescopic deformation mechanism (2), a gear transmission mechanism (3) and a rubber track (4). The telescopic deformation mechanism and the gear transmission mechanism are installed on the driving shaft; the driving shaft is used for transmitting power input by an external vehicleengine and driving the whole wheel-track composite variable structure wheel body to rotate; the gear transmission mechanism comprises two planet-like gear sets which are installed on a front side anda rear side of the wheel-track composite variable structure wheel body respectively; and the rubber track is tightly hooped on the outer side of the wheel-track composite variable structure wheel body and is used for driving after deformation switching between a wheel type state and a track type state. In the invention, mutual conversion of wheel shapes in circles and approximate triangles duringadvancing can be realized so that a mobile chassis has characteristics of quickness, flexibility, high environmental adaptability, high maneuverability and the like when operating in unstructured complex environments such as unpaved road surfaces, disaster relief and the like.

Owner:MILITARY TRANSPORTATION UNIV PLA

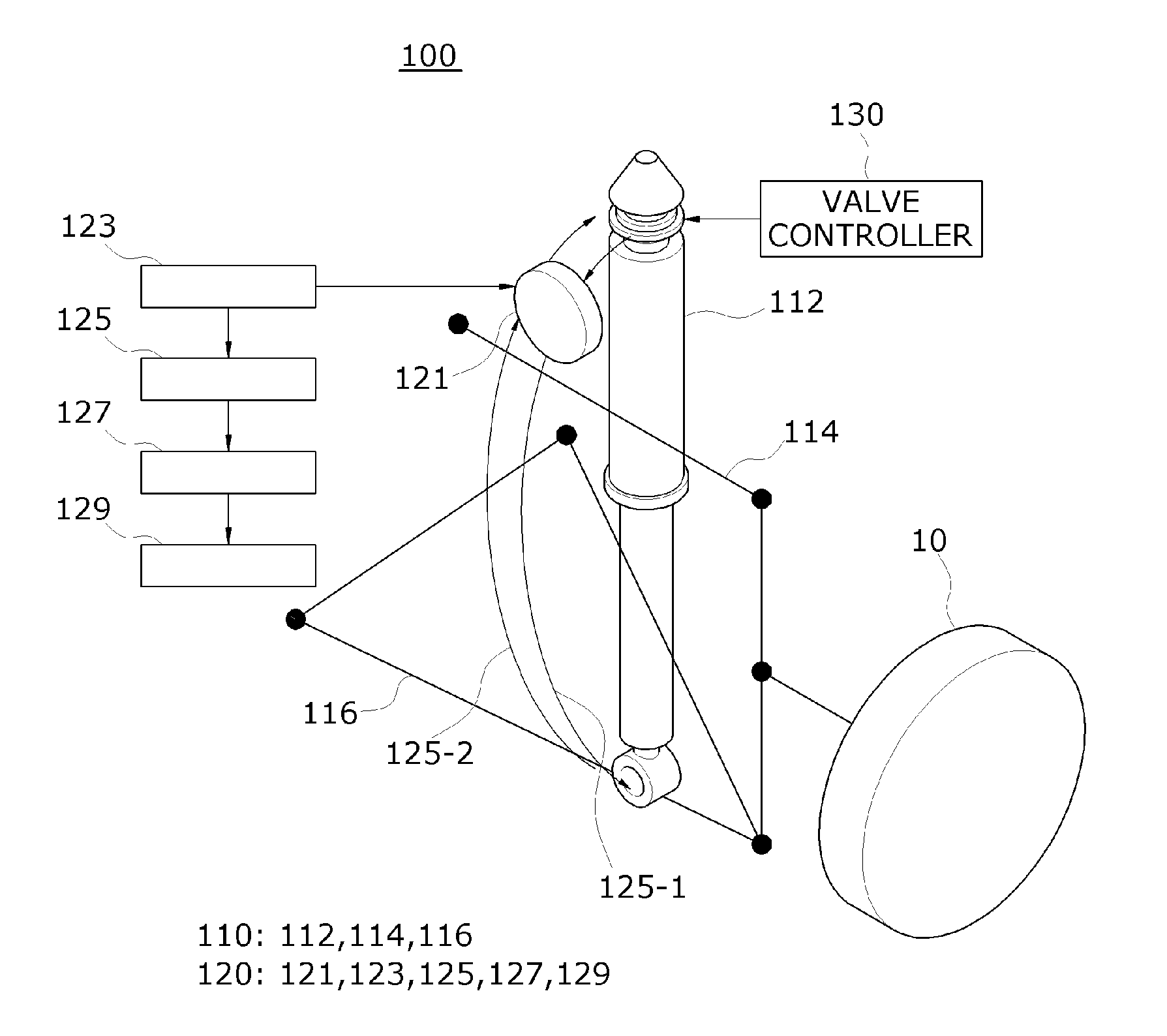

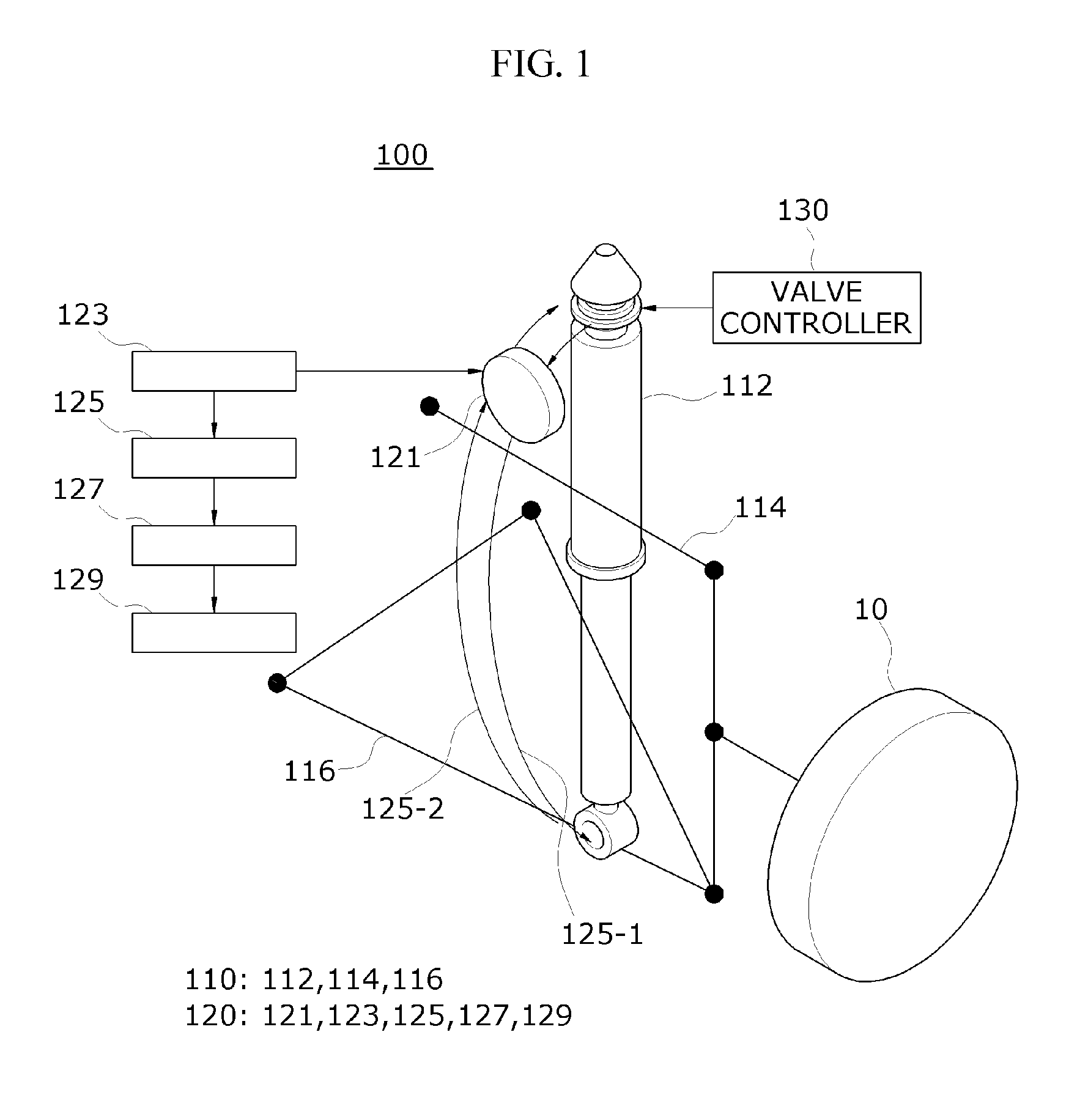

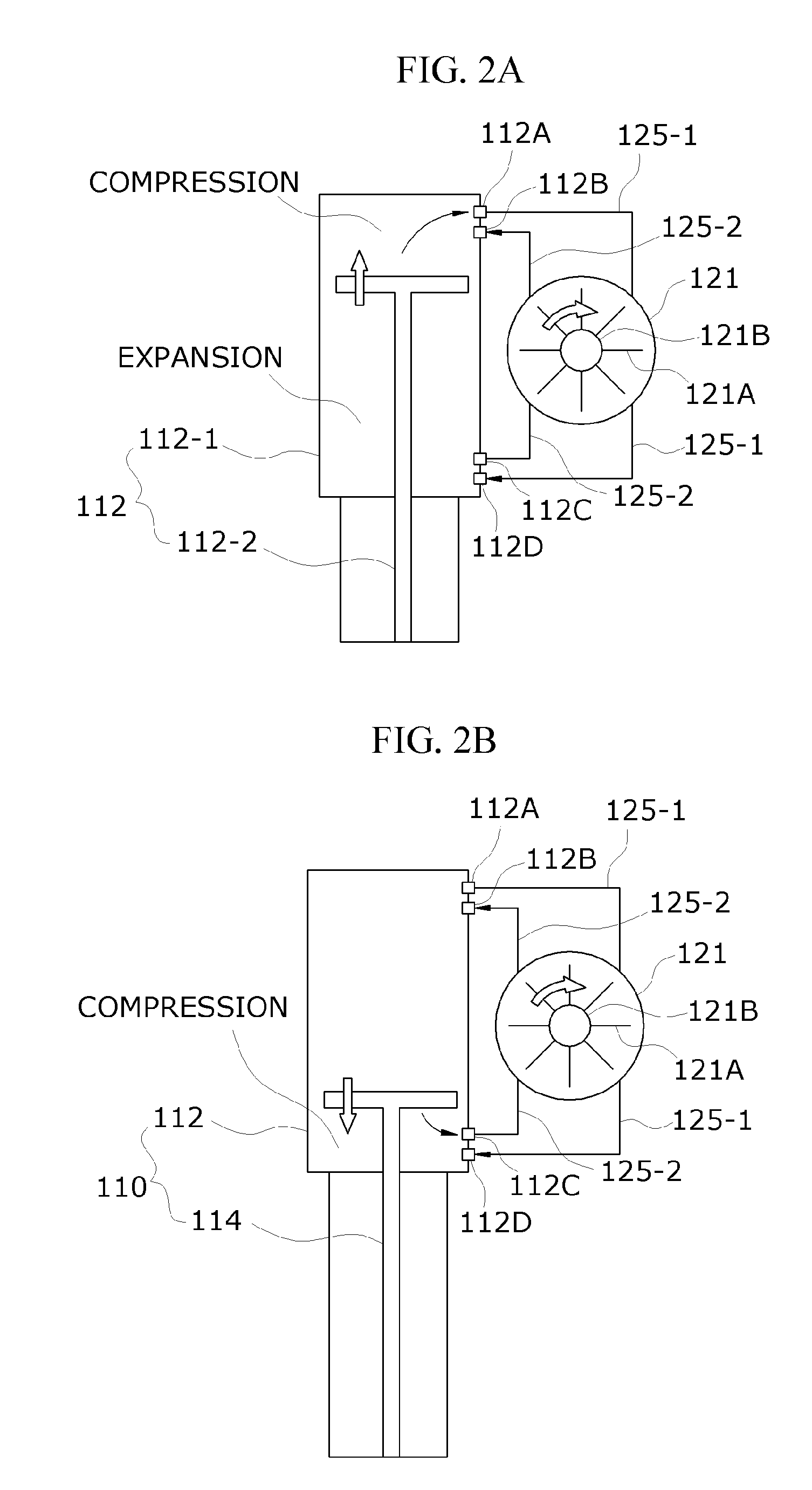

Electric power generating apparatus using suspension device

ActiveUS20160121683A1Improve suspension performanceLower performance requirementsAuxillary drivesSpringsElectric power systemEnergy recovery

In an electric power generating apparatus using a suspension device according to an embodiment of the present invention, provided is a valve structure for partially disconnecting a suspension device (or a damper) from an energy recovery device (or a turbine unit) when a vehicle is driving on an under-construction road or an unpaved road from which a large bump is expected.

Owner:HYUNDAI MOBIS CO LTD

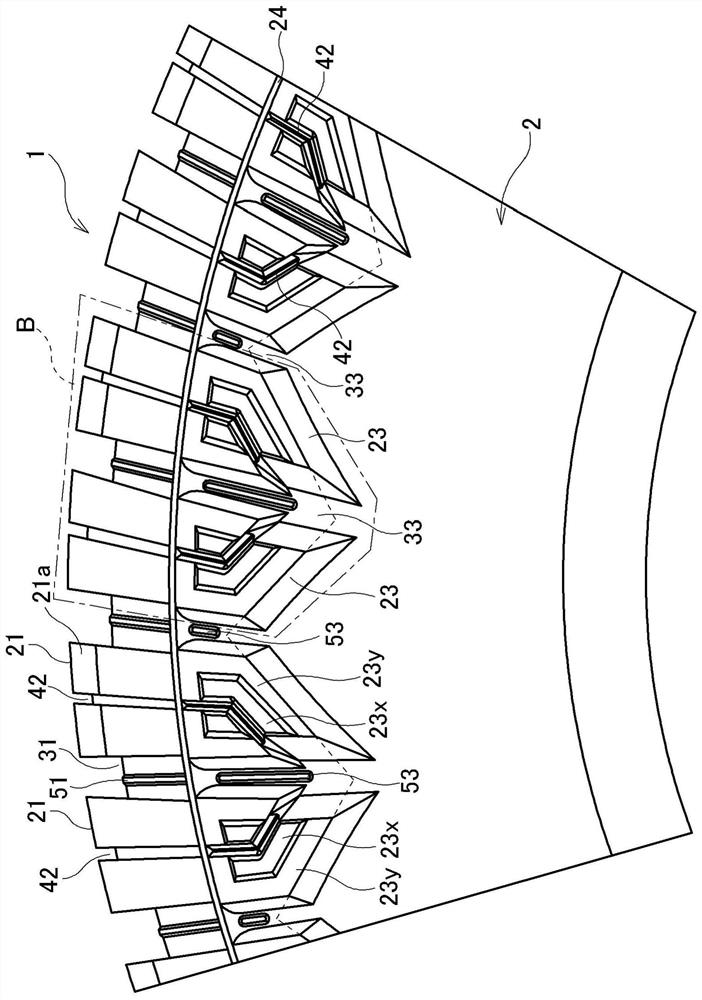

Pneumatic tire

ActiveCN112689566AEfficient dischargeImprove soil dischargeOff-road vehicle tyresTyre tread bands/patternsClassical mechanicsMechanical engineering

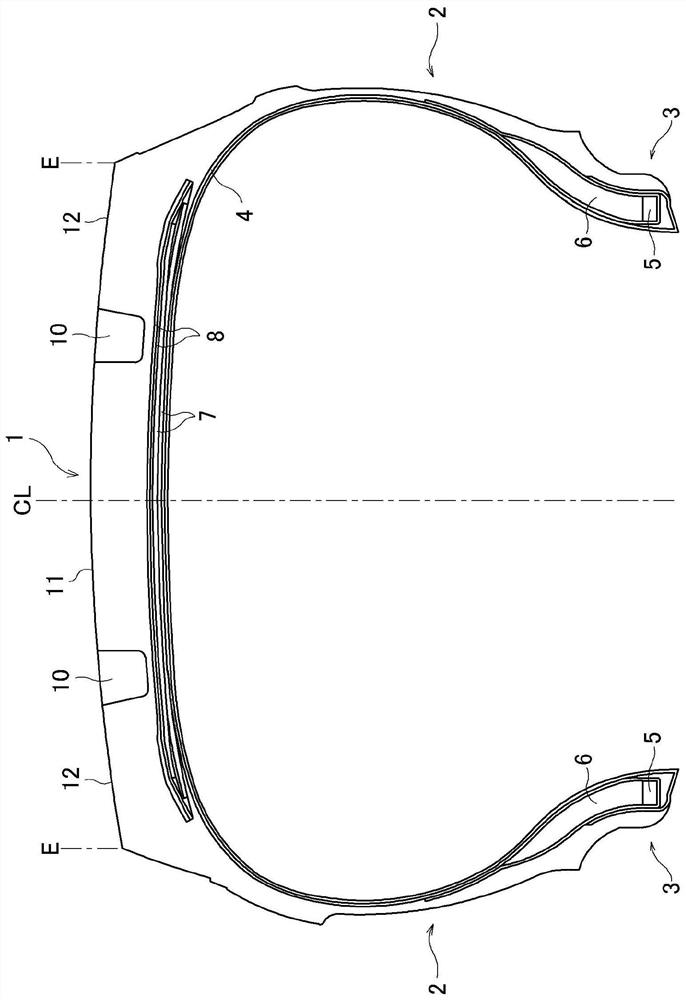

Provided is a pneumatic tire that has improved travel performance and cut resistance on unpaved roads. According to the present invention, block groups B comprise: a pair of adjacent shoulder blocks 21 that sandwich a shoulder lug groove 31; and a pair of adjacent side blocks 23 that sandwich a side groove 33 that is positioned on a line that extends from the shoulder lug groove 31 that is between the pair of shoulder blocks 21. Contour lines L1 of tire-width-direction outside side surfaces of the shoulder blocks 21 and contour lines L3 of top surfaces of the side blocks 23 extend along the same straight lines. Contour lines L3 that, of the contour lines L3 of the top surfaces of the side blocks 23, are on the side that is away from the side groove 33 that is between the pair of side blocks 23 and contour lines L4 of narrow grooves 42 that are formed in the side blocks 23 are formed from straight portions L3a, L4a that extend along the tire radial direction on the shoulder block 21 side and inclined portions L3b, L4b that extend so as to converge toward the side groove 33 that is between the pair of side blocks 23.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveCN110958948AImprove driving performanceImprove mud performanceOff-road vehicle tyresTyre tread bands/patternsTransverse grooveEngineering

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

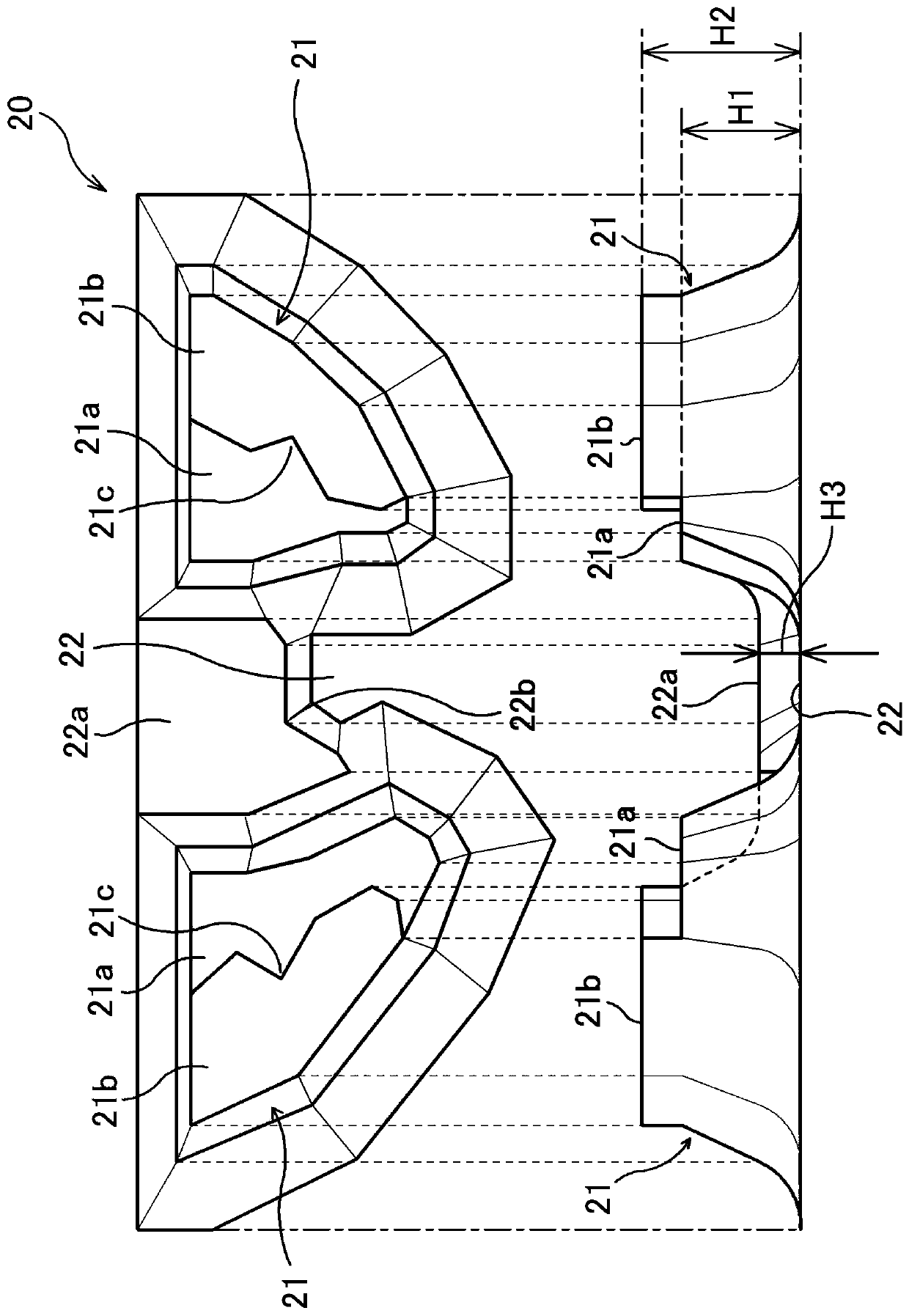

PendingCN110914075AIncrease the edgeImprove rigidityOff-road vehicle tyresTyre tread bands/patternsShoulder regionStructural engineering

Provided is a pneumatic tire that is suitable as a tire for traveling on an unpaved road and that allows improvement of traveling performance and cut resistance on the unpaved road. A pair of side blocks 21, which extend in the tire width direction and face each other with a side groove 22 interposed therebetween, are provided in side regions located on the outer sides in the tire width directionof shoulder regions of a tread portion 1. Repetition elements 20 each comprising the side groove 22 and the pair of side blocks 21 are arranged at an interval in the tire circumferential direction. Atread of each of the side blocks 21 is formed into a protrusion and recess shape that comprises a reference surface 21a located on the side groove 22 side and a step portion 21b which is located on the side opposite to the side groove 22 side and protrudes from the reference surface 21a. A bottom raising portion 22a, which protrudes from the groove bottom and couples the pair of side blocks 21, isprovided in the side groove 22.

Owner:THE YOKOHAMA RUBBER CO LTD

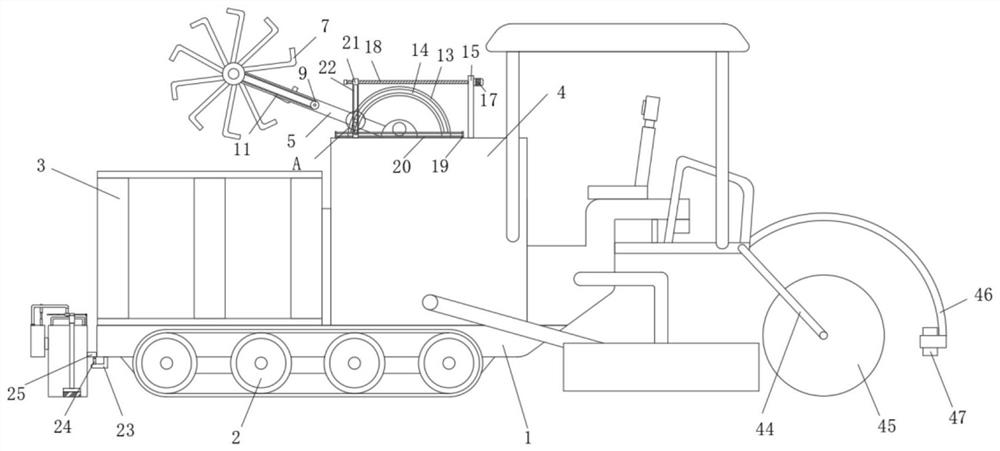

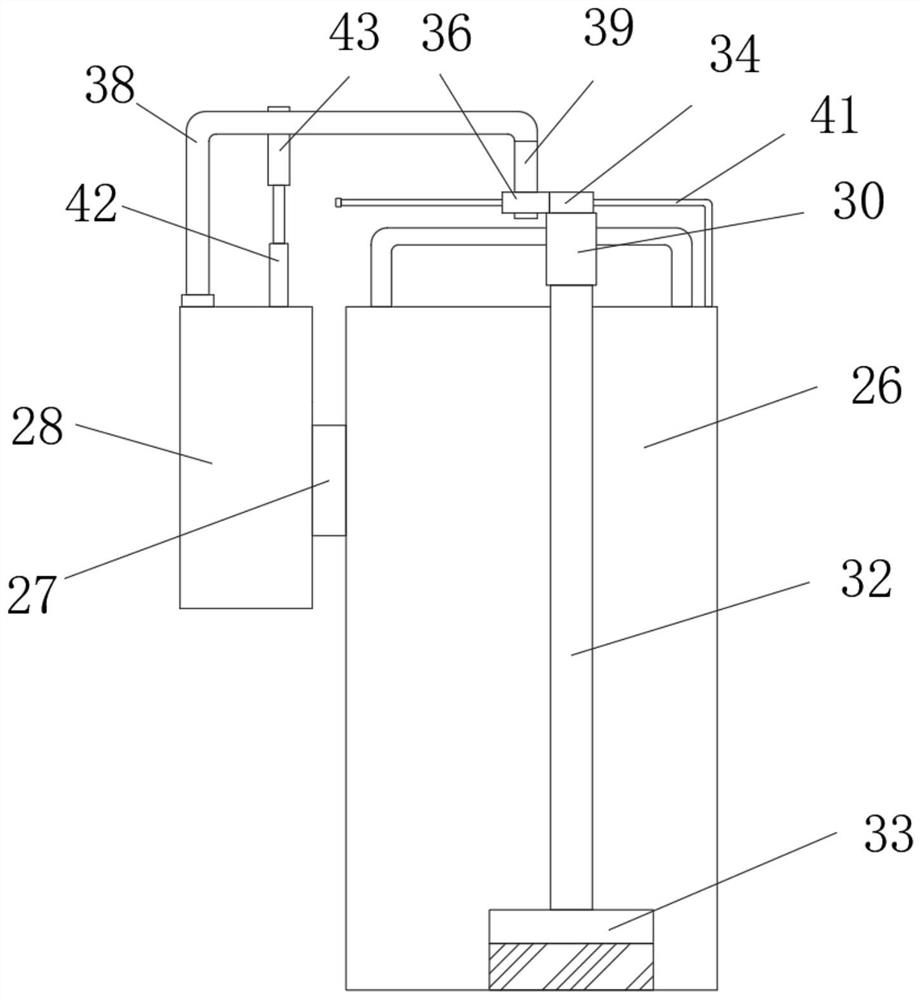

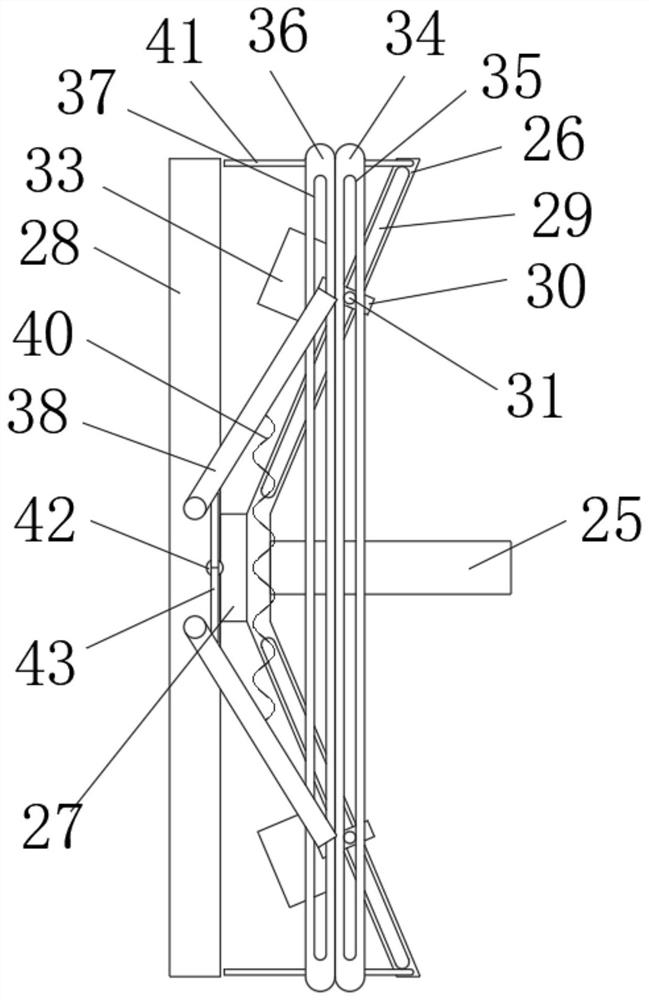

Road paver with automatic asphalt feeding structure

InactiveCN112458842AAvoid accumulationImprove work efficiencyRoad cleaningRoads maintainenceStructural engineeringRoad surface

The invention relates to the technical field of paving vehicles, and concretely relates to a road paver with an automatic asphalt feeding structure. The road paver comprises a vehicle body, an asphalttank mounted on the left side of the upper surface of the vehicle body, a shell mounted on the right side of the upper surface of the vehicle body, a shifting device movably mounted on the upper surface of the shell, and a first limiting rod mounted on one side of the shifting device. An angle control device is installed on the upper surface of the shell, an L-shaped supporting plate is installedon the left side of the vehicle body, a first hydraulic rod is installed on the upper surface of the L-shaped supporting plate, a connecting plate is installed at the upper end of the first hydraulicrod, and a pushing plate is installed at the left end of the connecting plate. Through mutual cooperation of the structures, an asphalt raw material feeding function is conveniently achieved, asphaltis prevented from difficultly entering the asphalt material box due to too large resistance, the asphalt feeding speed is conveniently adjusted through active feeding, dust, impurities and the like on an unpaved road surface can be conveniently swept, and the asphalt paving quality is improved.

Owner:翁雨薇

Pneumatic tire

ActiveCN110177699AEasy dischargeImprove traction performanceHeavy duty tyresHeavy duty vehicleEngineeringMechanical engineering

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveCN111615459AAvoid transmissionEnhance the edge effectOff-road vehicle tyresTyre tread bands/patternsMechanical engineeringTread

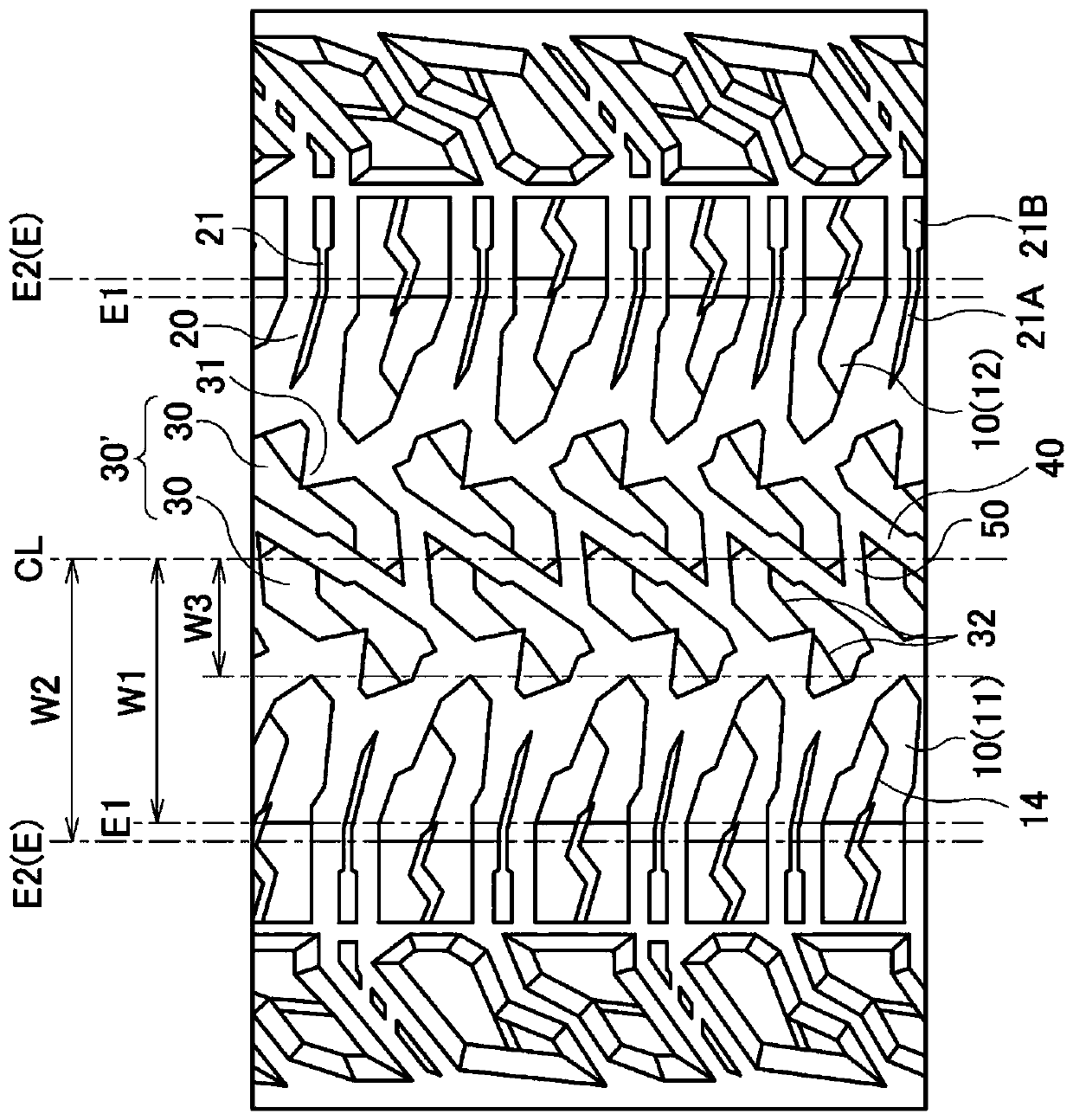

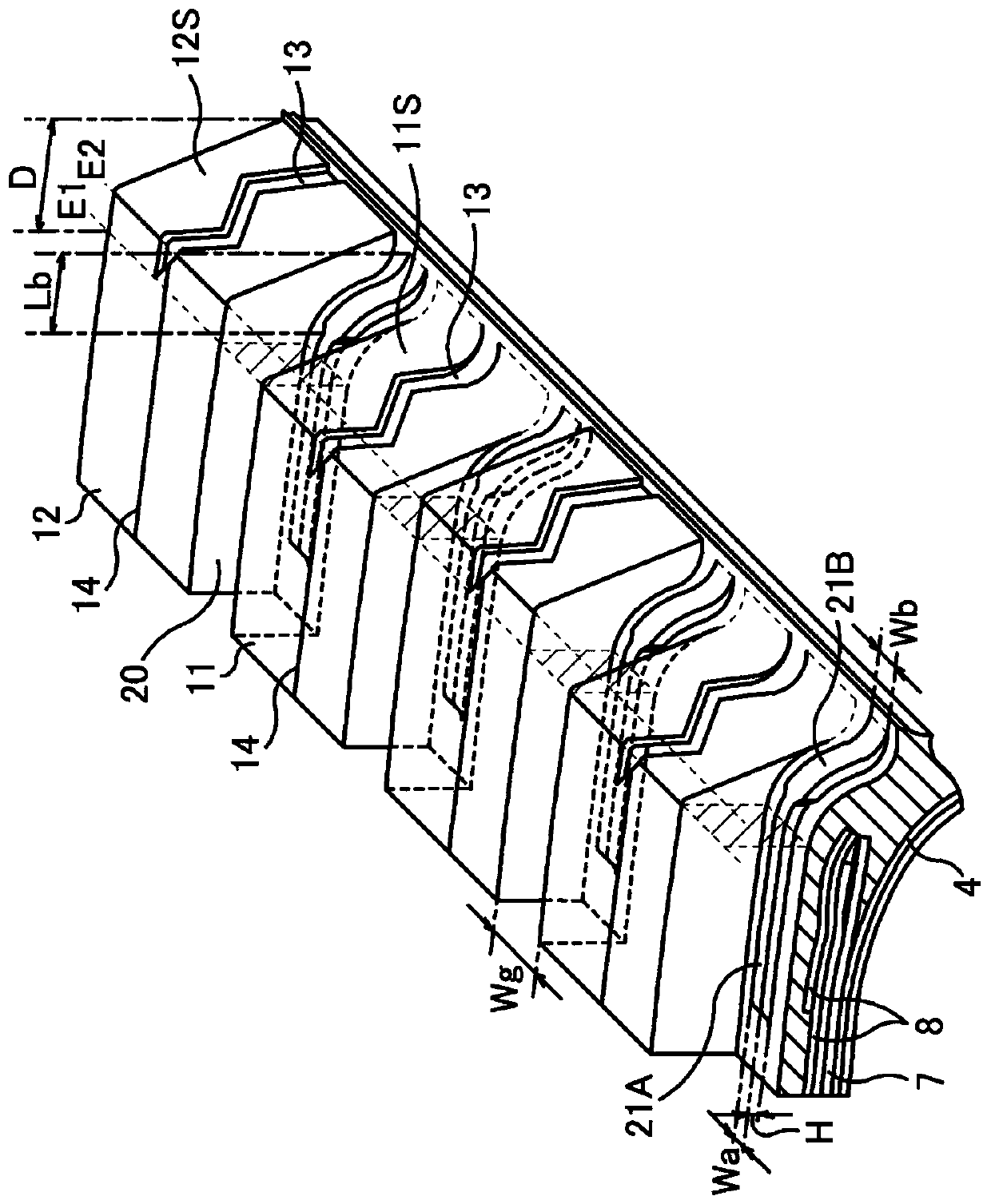

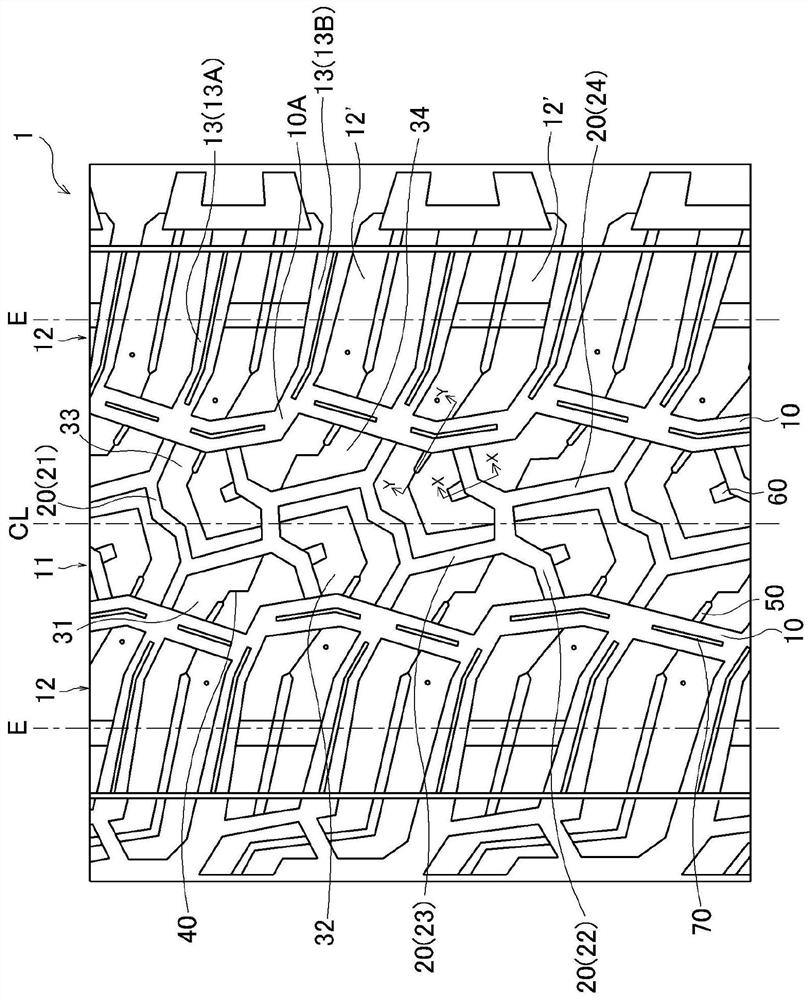

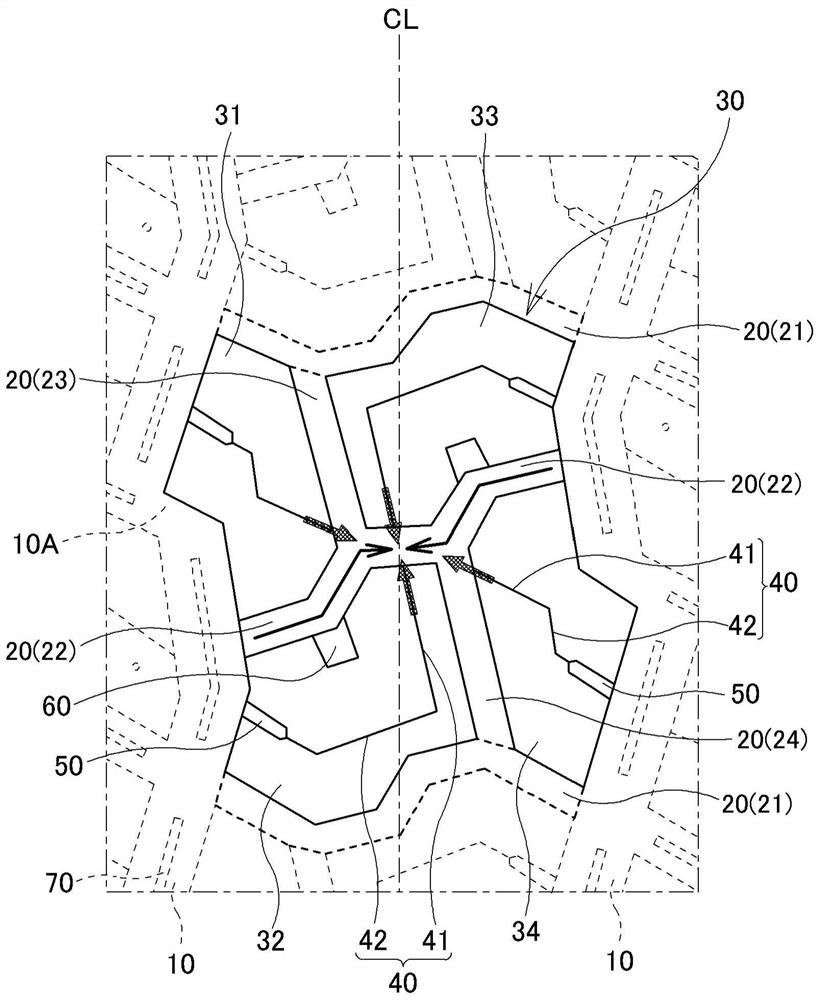

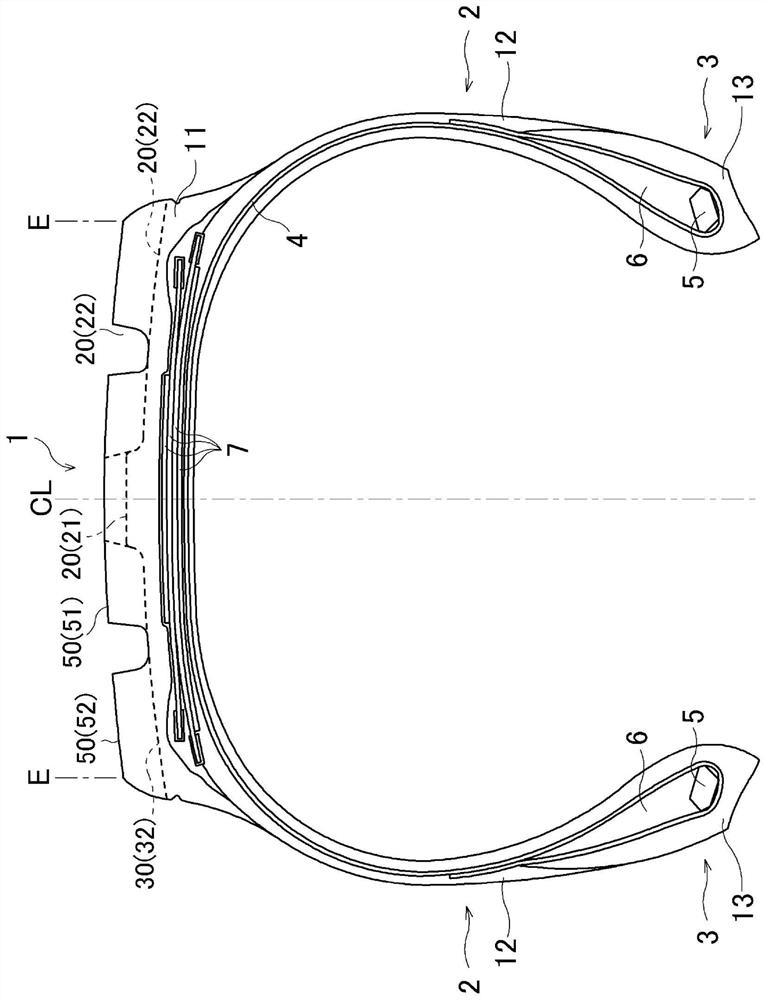

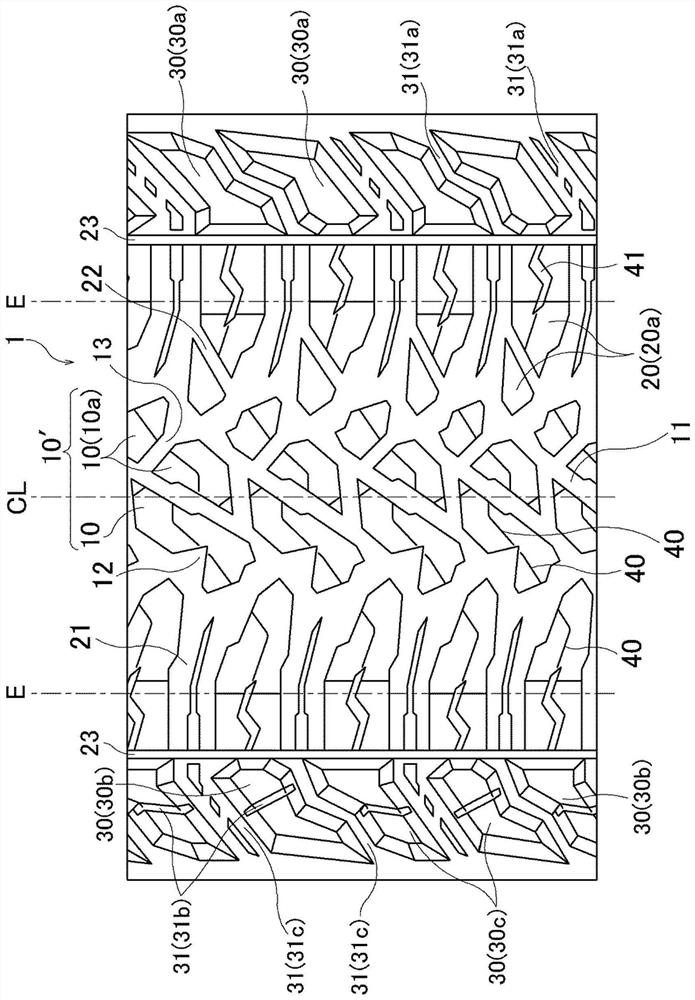

Provided is a pneumatic tire which exhibits improved noise performance and traveling performance on unpaved roads. A center land part 11, which is defined by a pair of main grooves 10 that extend in azigzagging manner along the tire circumferential direction on both sides of a tire center line CL of a tread part 1, is subdivided into a plurality of repeating units 30 by a plurality of first shallow grooves 21 which are positioned at intervals in the tire circumferential direction so as to extend in the tire width direction and have both ends thereof connected to portions of the main grooves 10 other than bent sections 10A thereof. Each of the repeating units 30 comprises an aggregate of four blocks 31-34 that are partitioned by: a pair of second shallow grooves 22 which extend from the main grooves 10 in the tire width direction so as to converge at a single point on the tire center line CL; a third shallow groove 23 which extends from one of the pair of first shallow grooves 21 adjacent to the repeating unit 30 toward one of the pair of second shallow grooves 22; and a fourth shallow groove 24 which extends from the other of the pair of first shallow grooves 21 adjacent to the repeating unit 30 toward the other of the pair of second shallow grooves 22.

Owner:THE YOKOHAMA RUBBER CO LTD

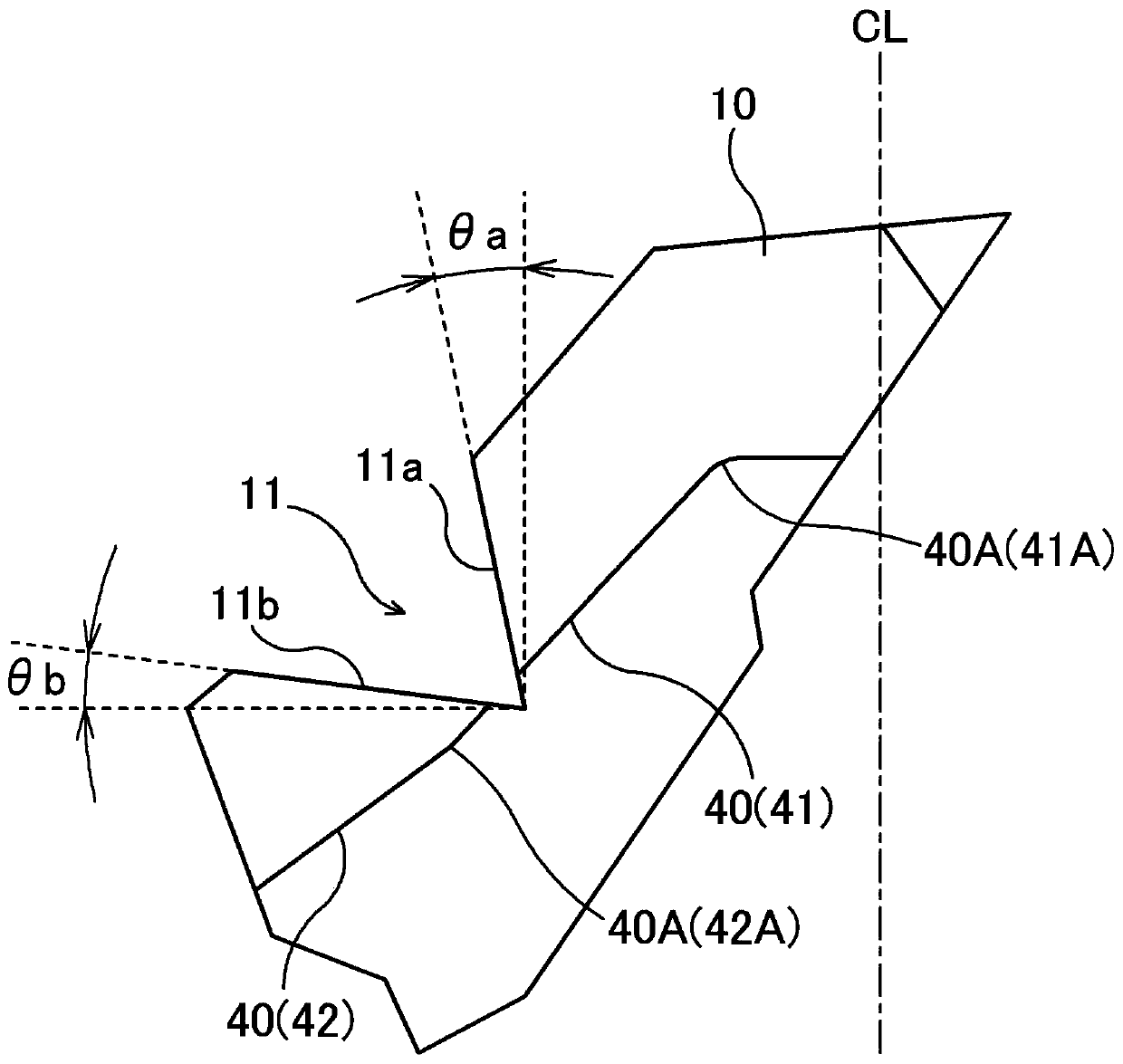

Pneumatic tire

ActiveCN110214090AIncrease the edgeEffective controlHeavy duty tyresHeavy duty vehicleGroove widthEngineering

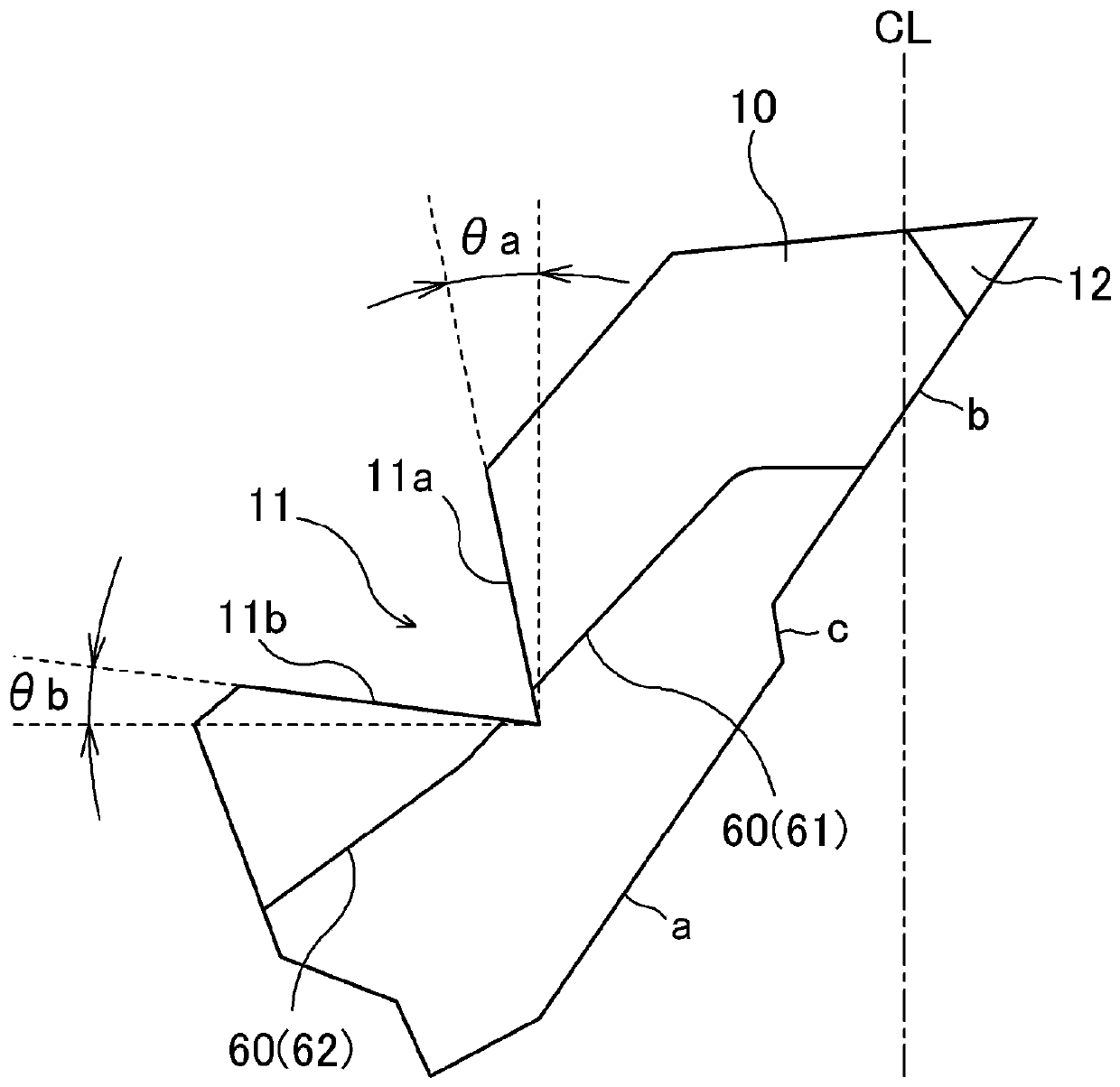

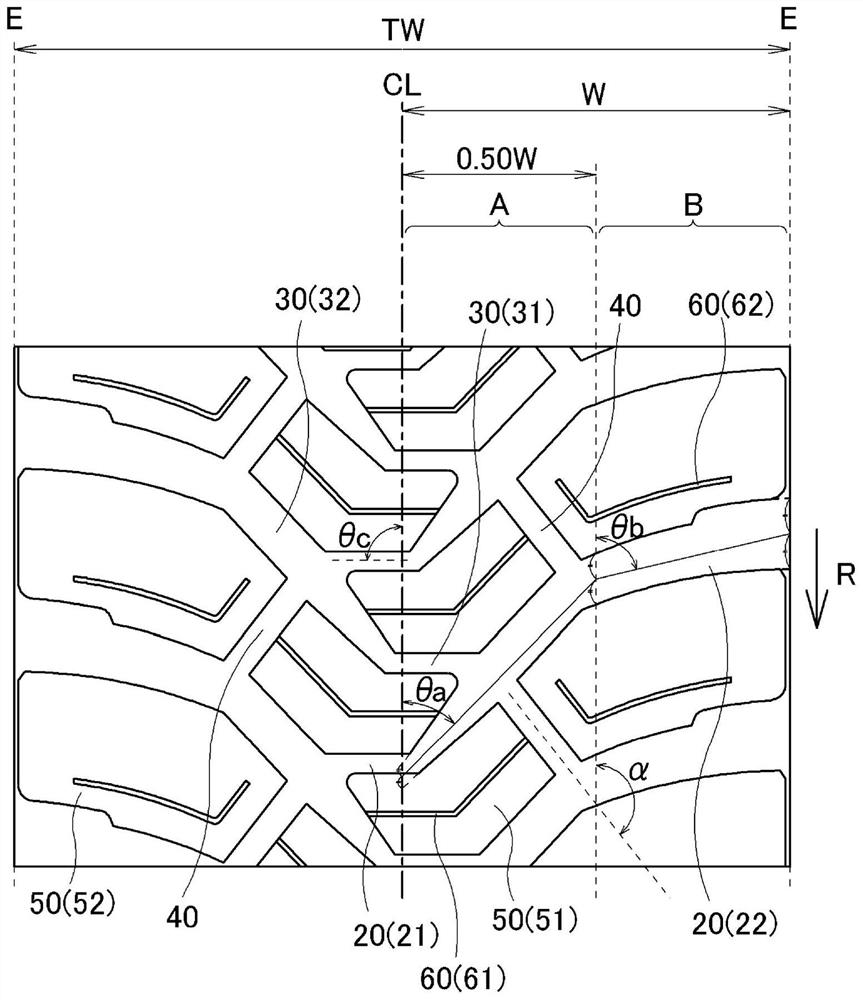

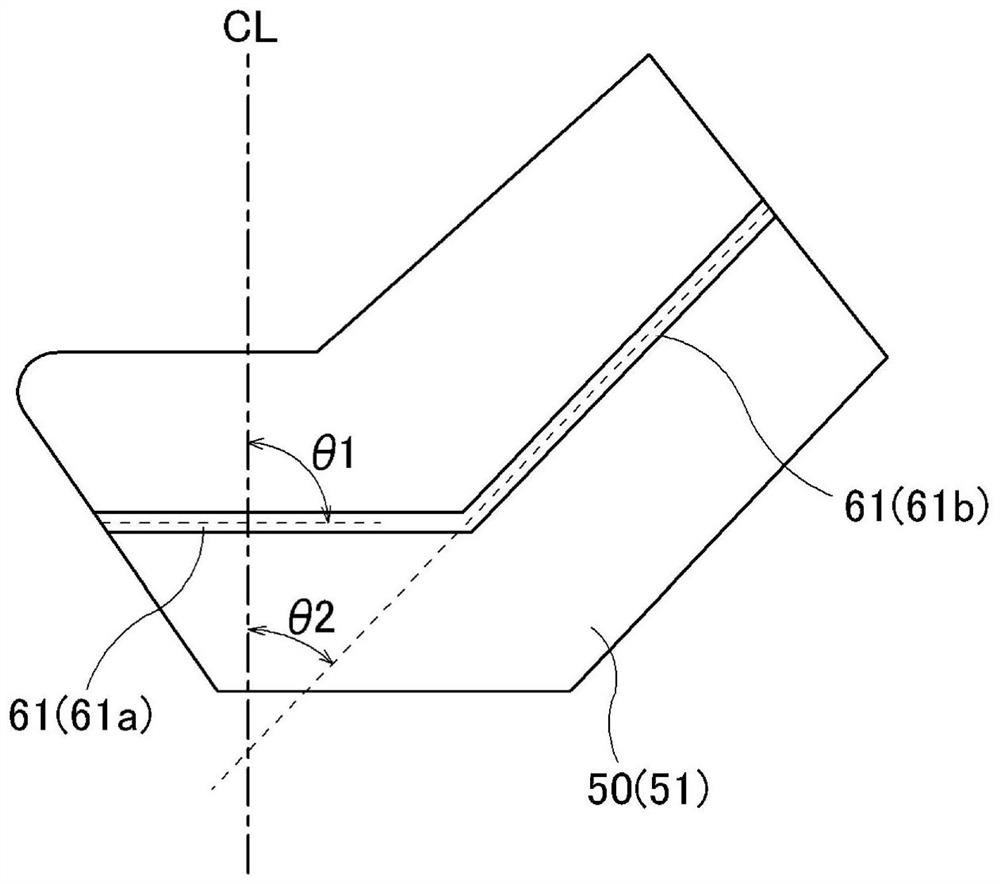

Provided is a pneumatic tire that is suitable for use as a tire for traveling on unpaved roads and that improves traveling performance on unpaved roads. Center blocks 10, which are provided in a center region of a tread section 1, are arrayed so as to form a pair of center blocks 10 between which there are interposed inclined grooves 30 that extend in an inclined direction with respect to a tire circumferential direction. The center blocks 10 are made to extend so as to straddle a tire equator CL from one side to the other side of the tire equator CL. Notches 11, which are each composed of a first wall 11a and a second wall 11b connected to each other in a V shape, are provided in treads in each center block CL. The first walls 11a are made to extend at an angle within + / -20 degrees with respect to the tire circumferential direction. The second walls 11b are made to extend at an angle of + / -10 degrees with respect to a tire width direction. Inclined grooves 20 are each constituted by asee-through portion 21 and an expanded portion 22 having a larger groove width than the see-through portion 21. A width SW of a see-through region S that can extend without intersecting an extensionline of the see-through portion 21 is made to be equal to or greater than 30% of a tread width TW.

Owner:THE YOKOHAMA RUBBER CO LTD

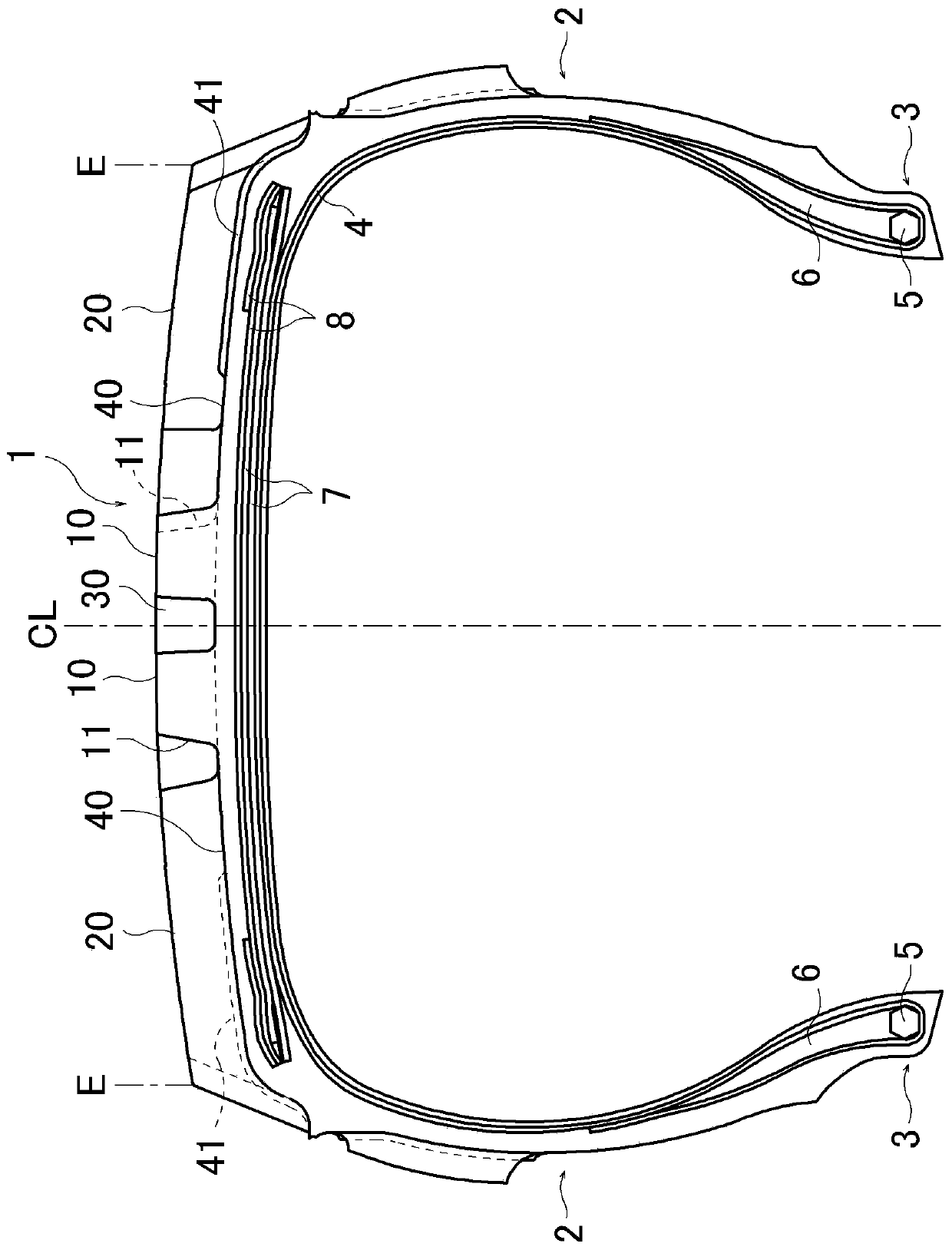

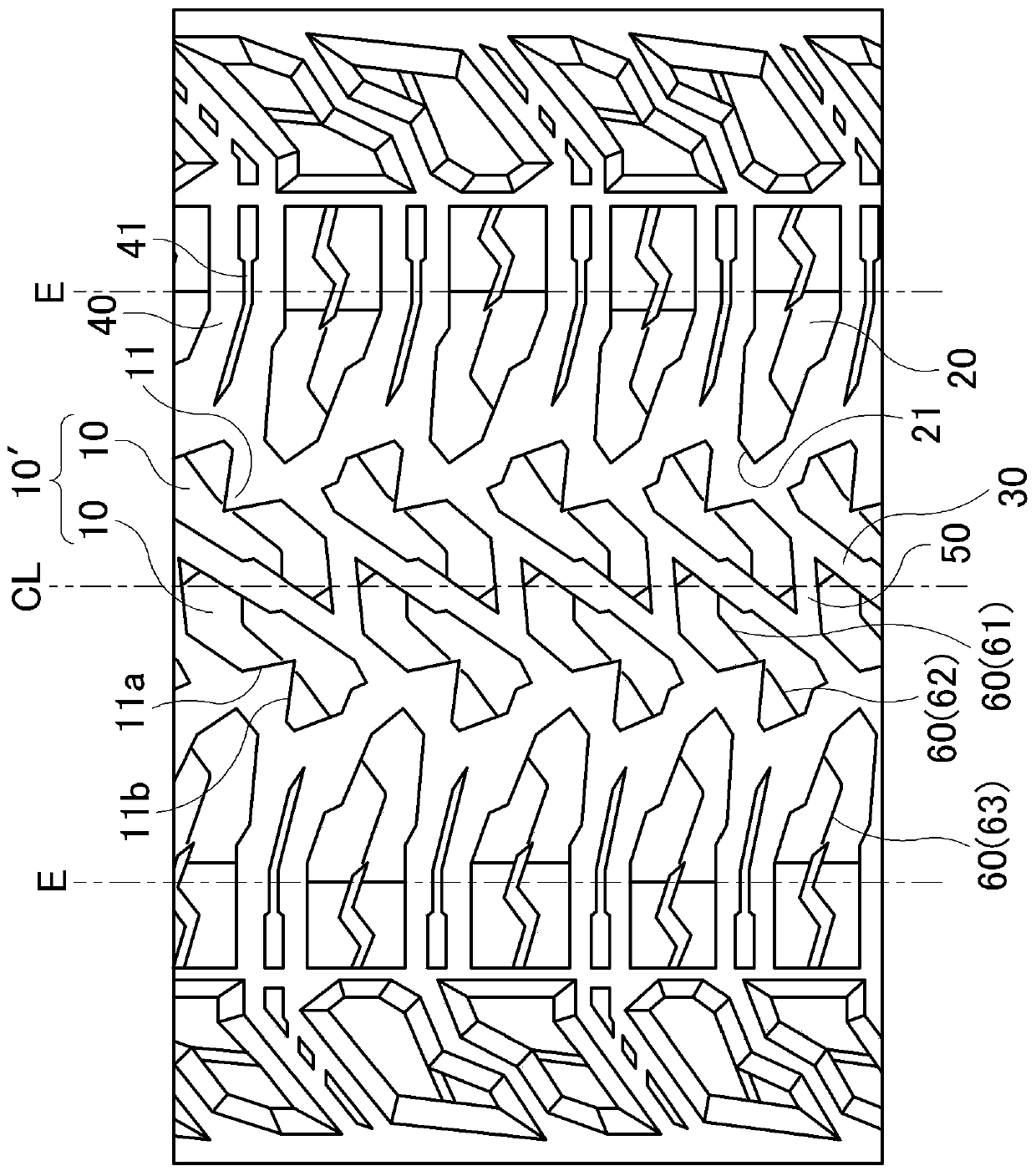

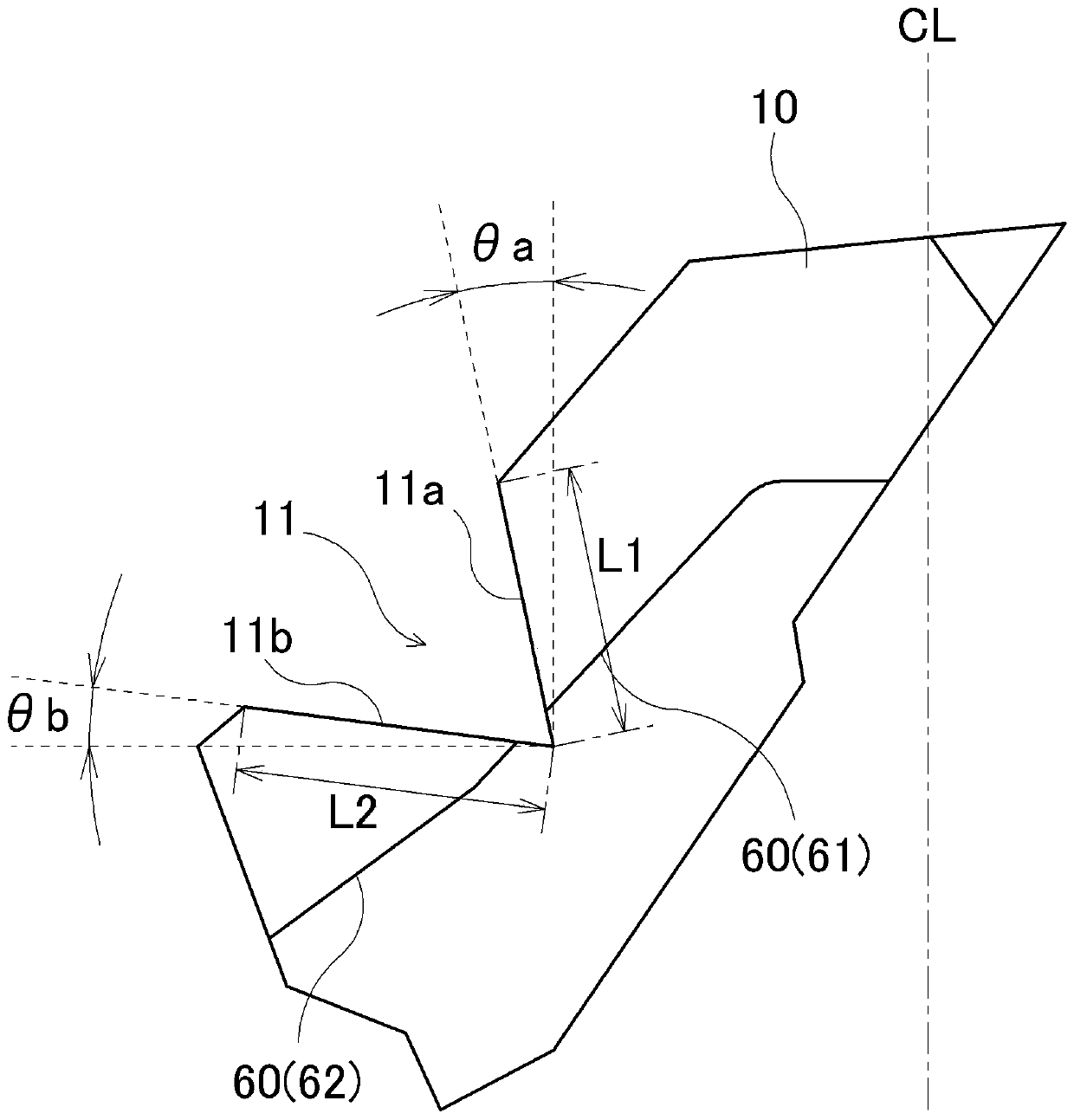

Pneumatic tire

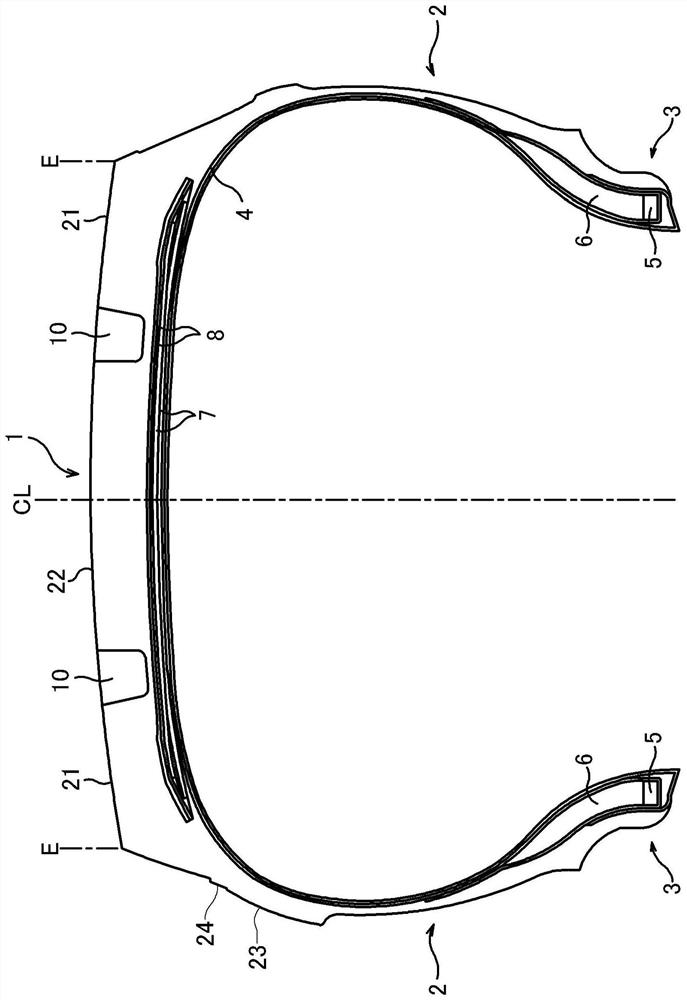

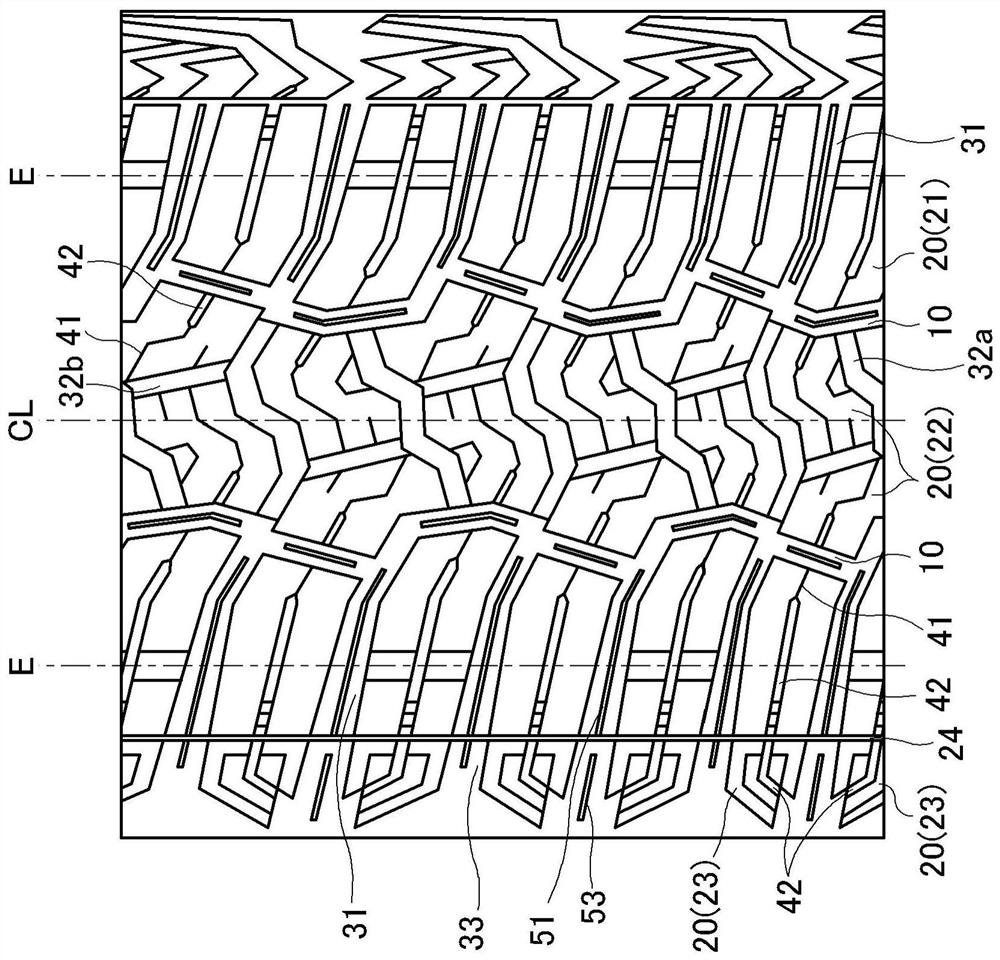

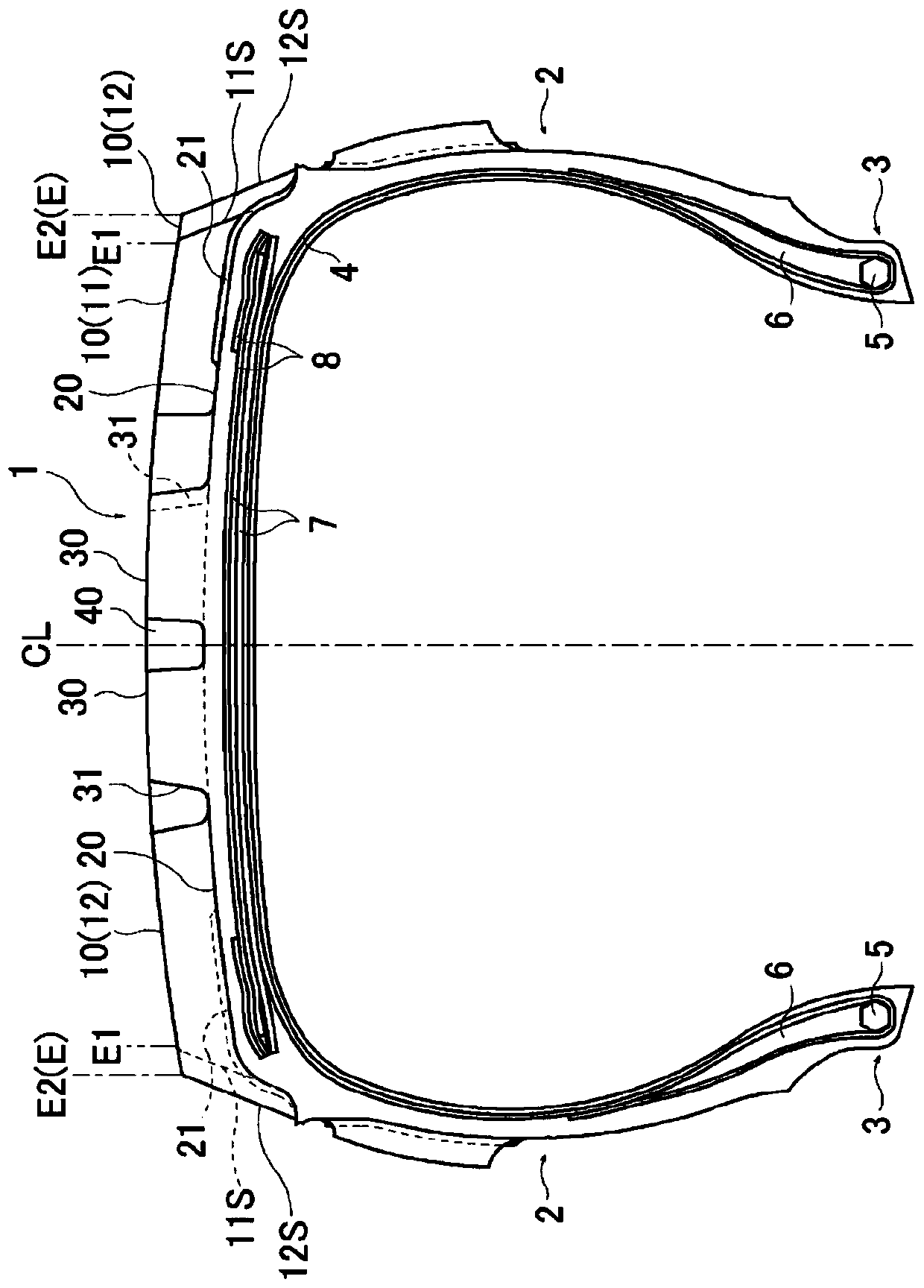

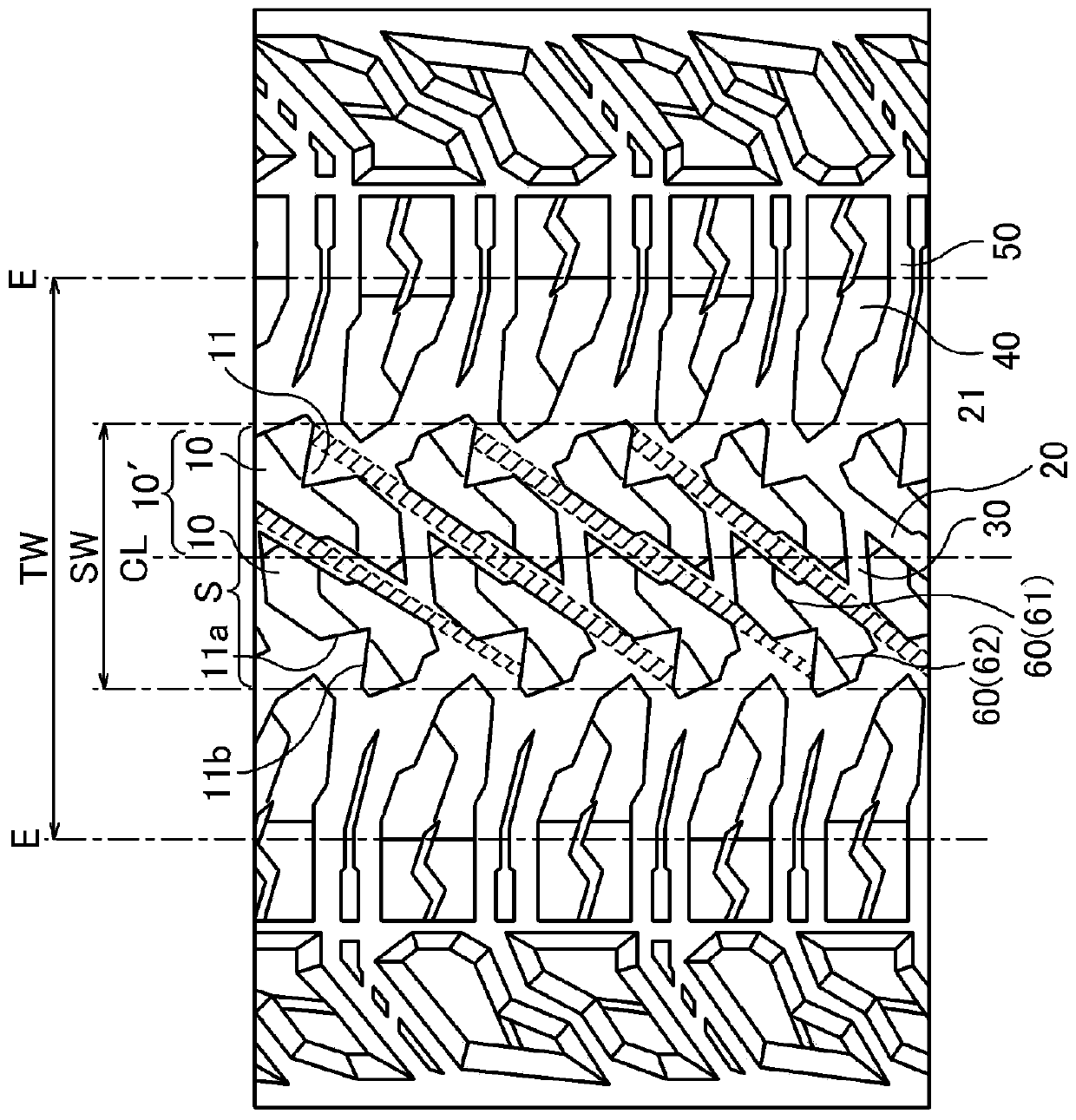

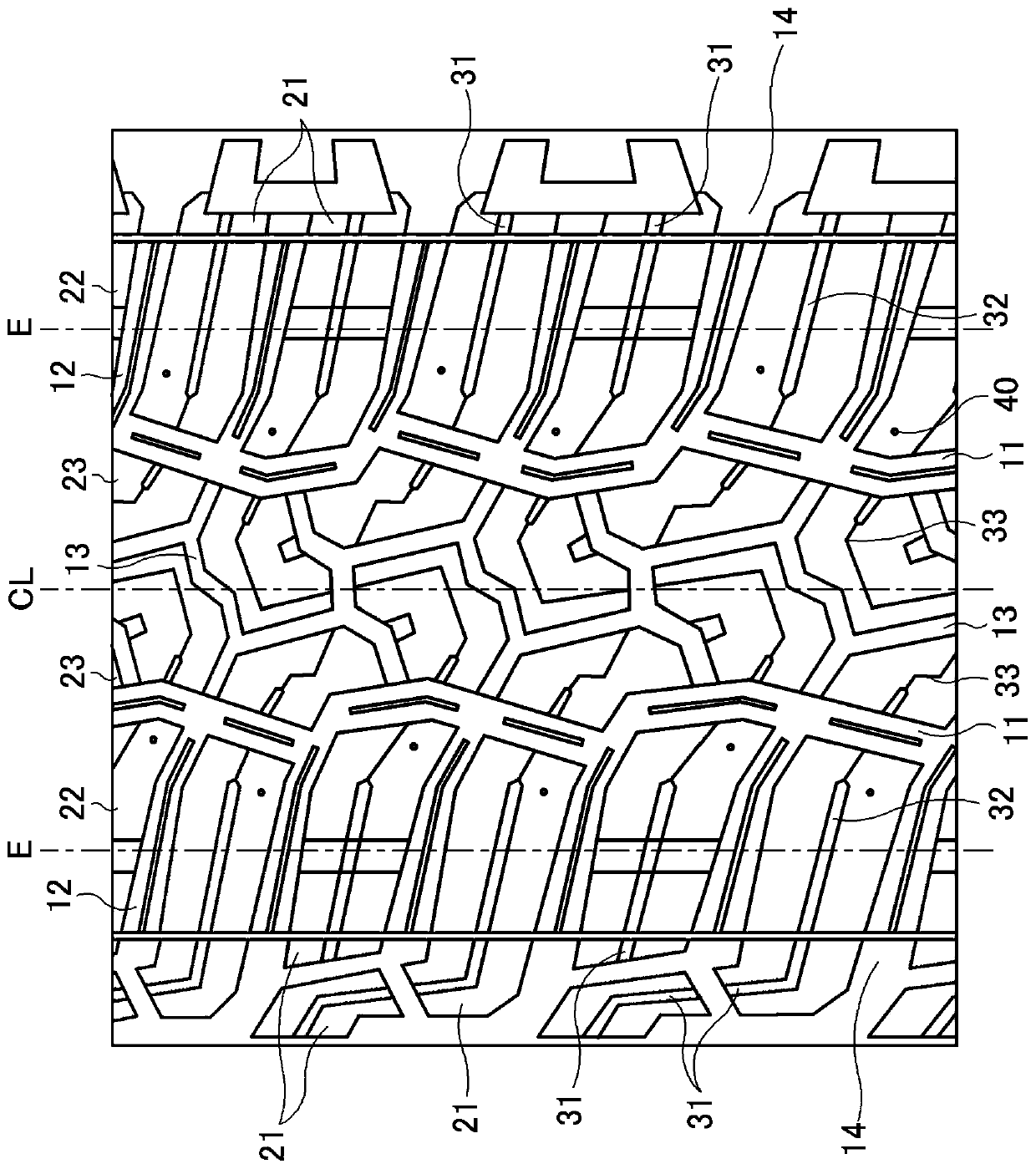

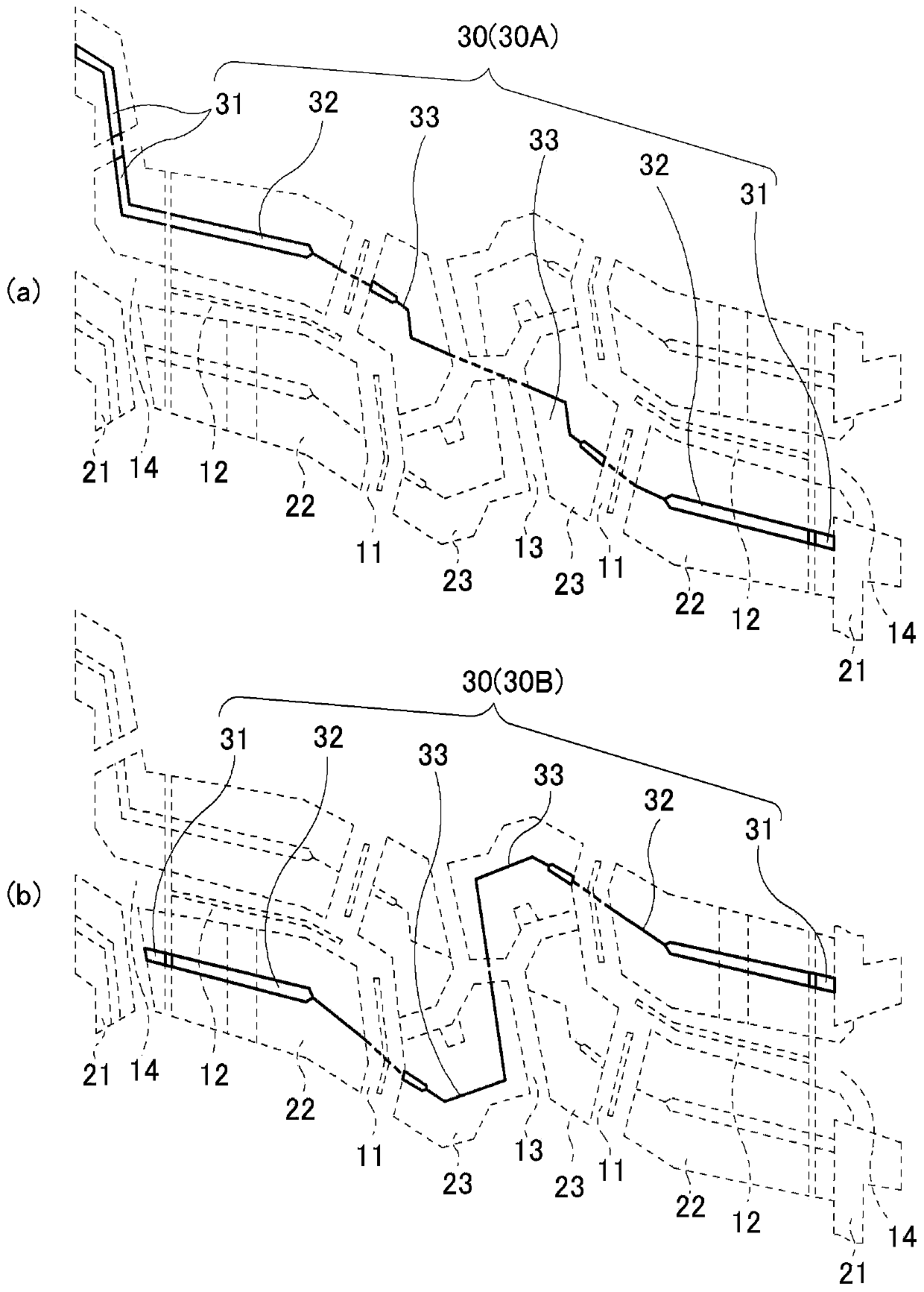

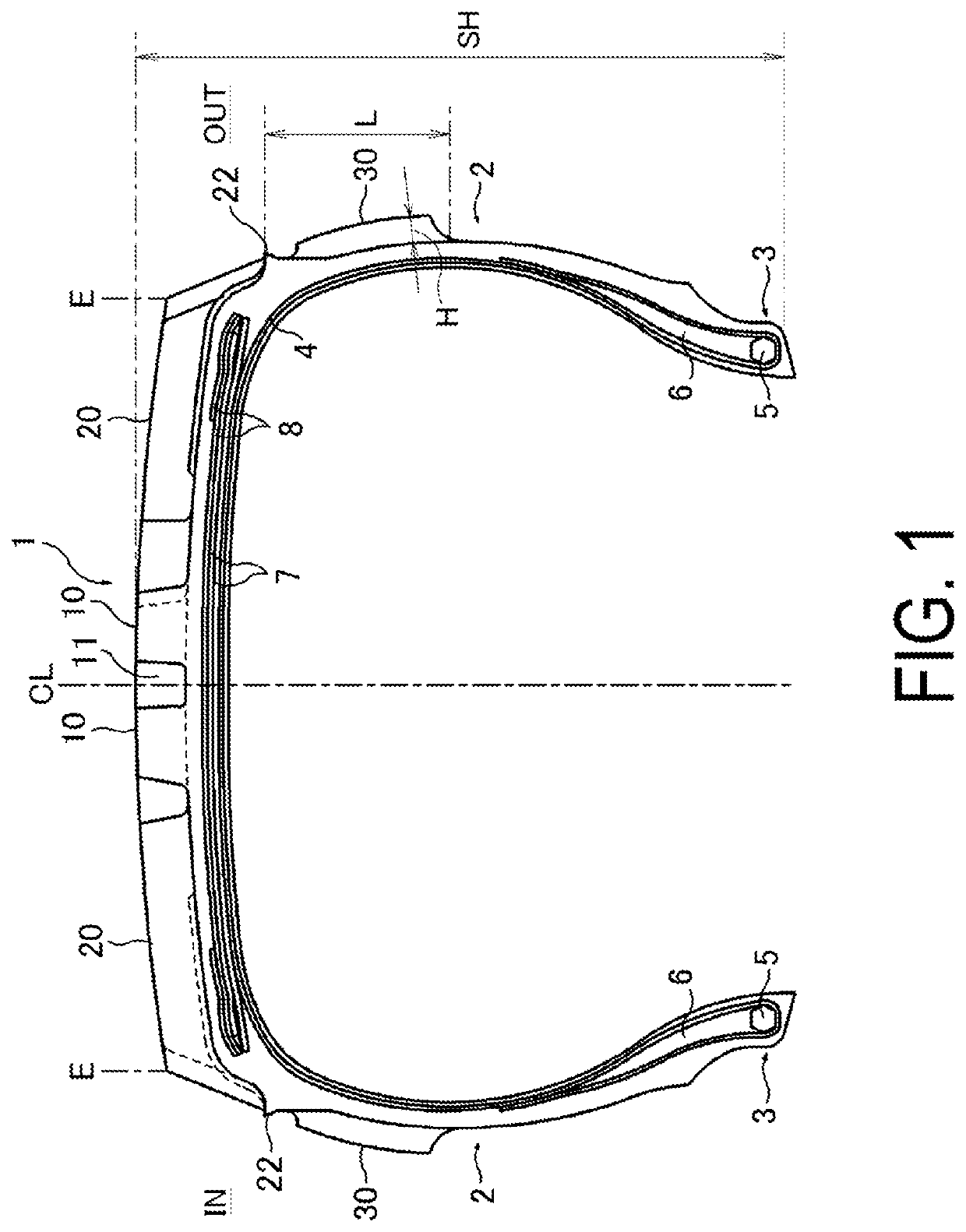

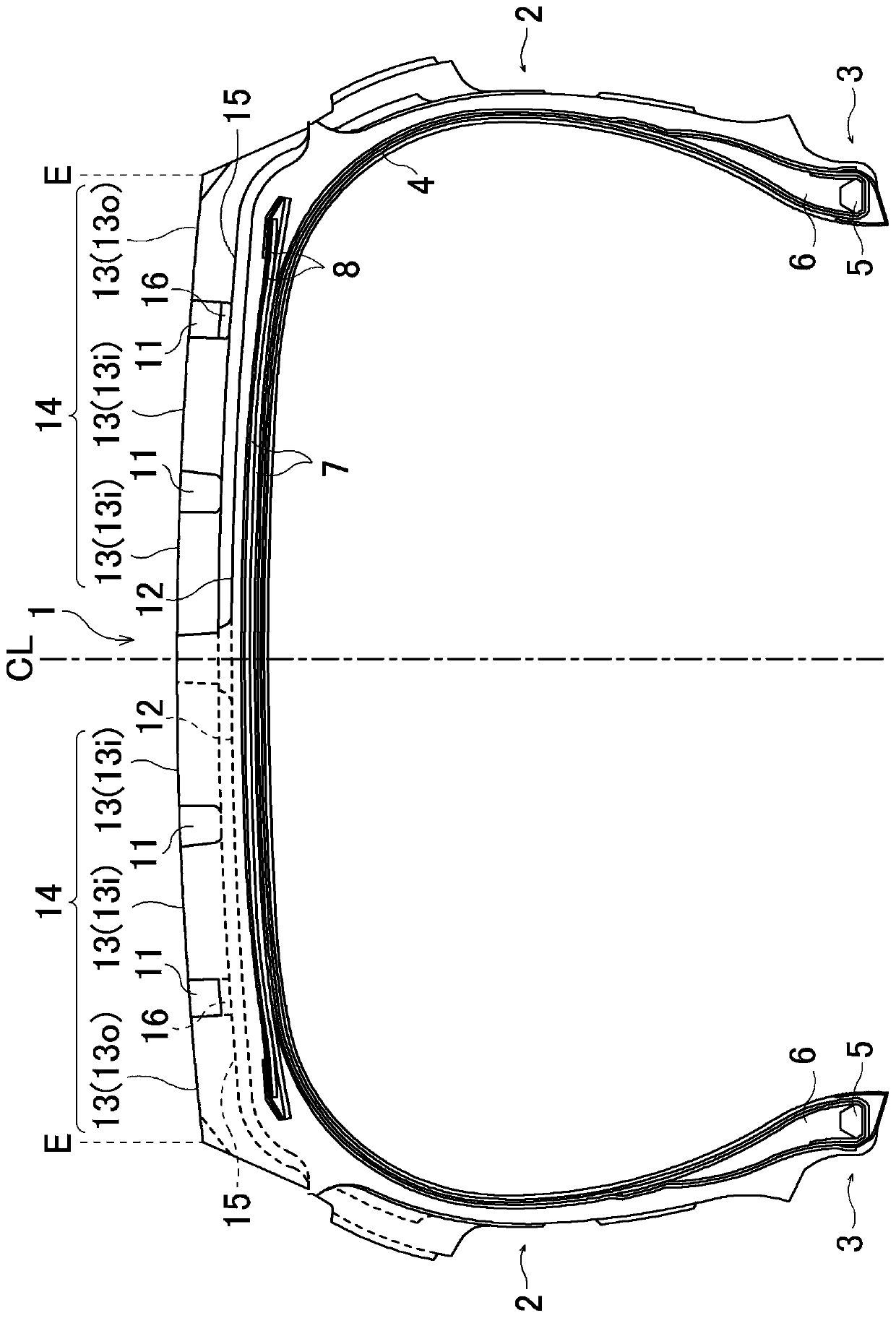

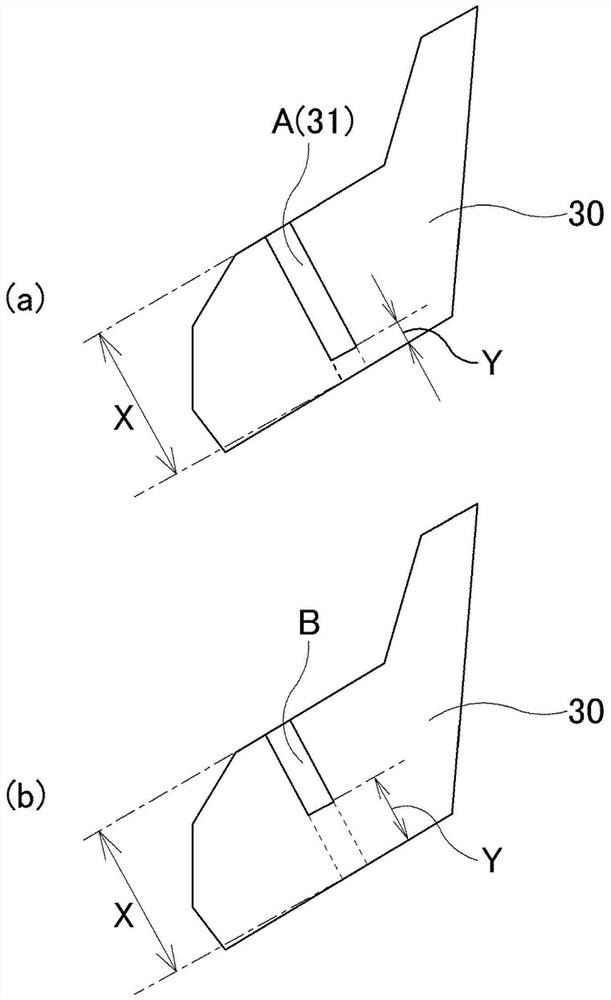

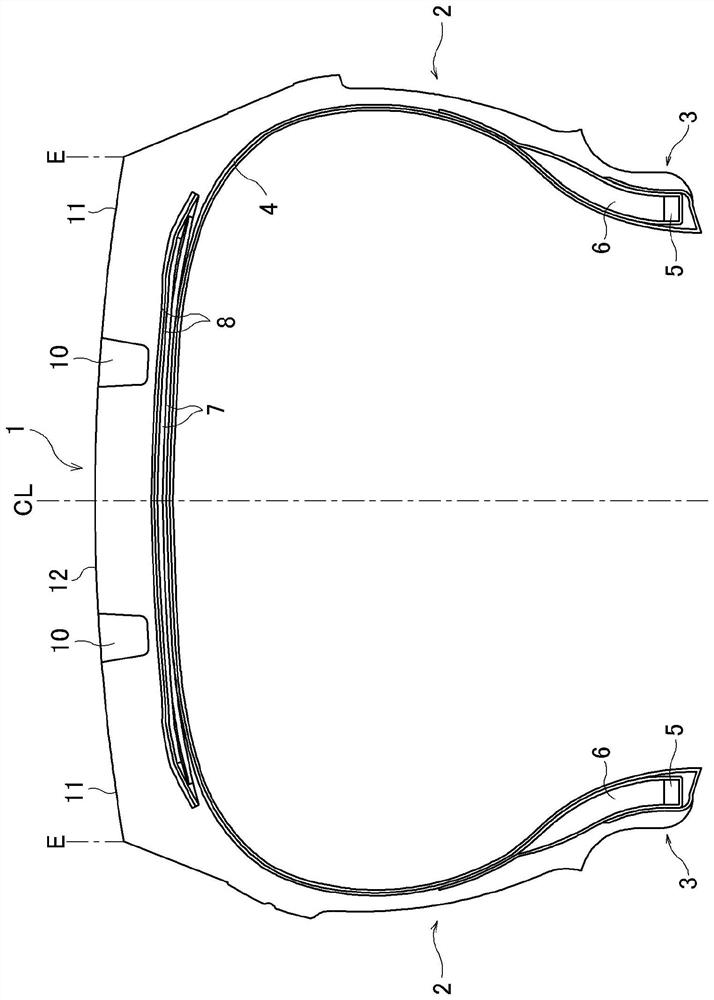

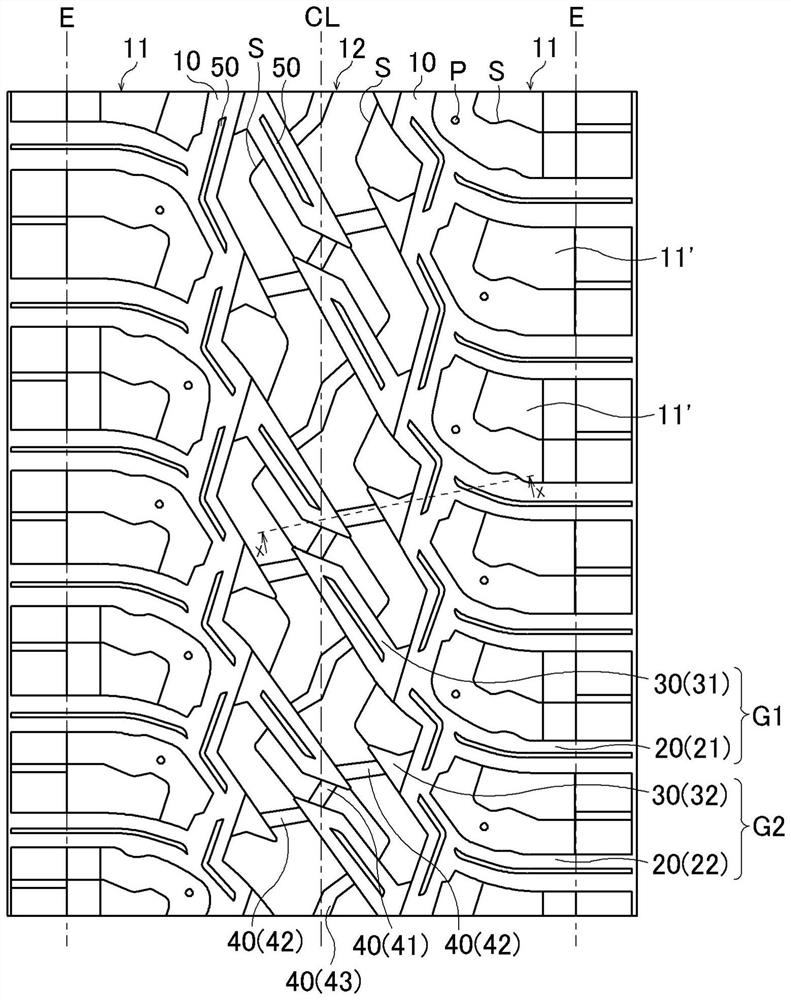

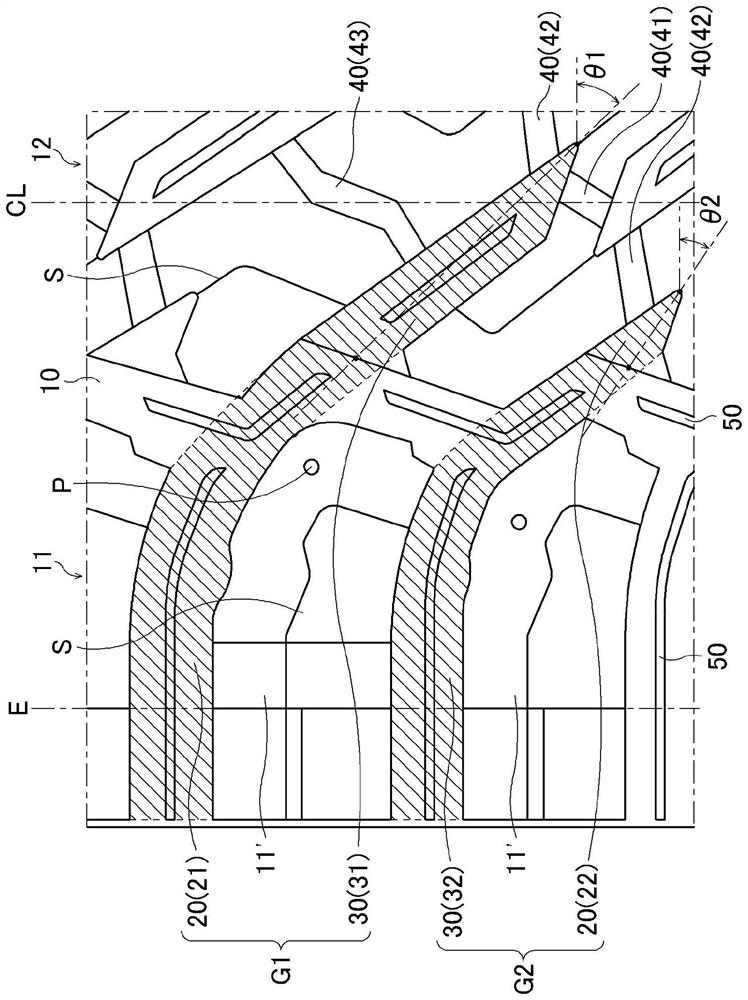

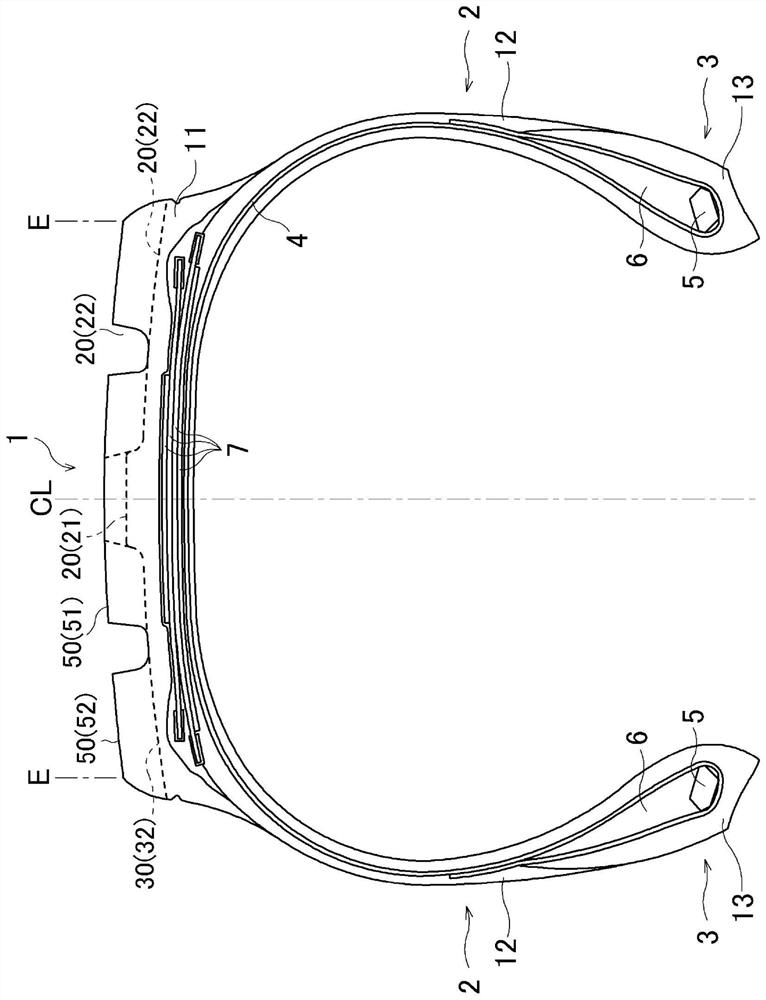

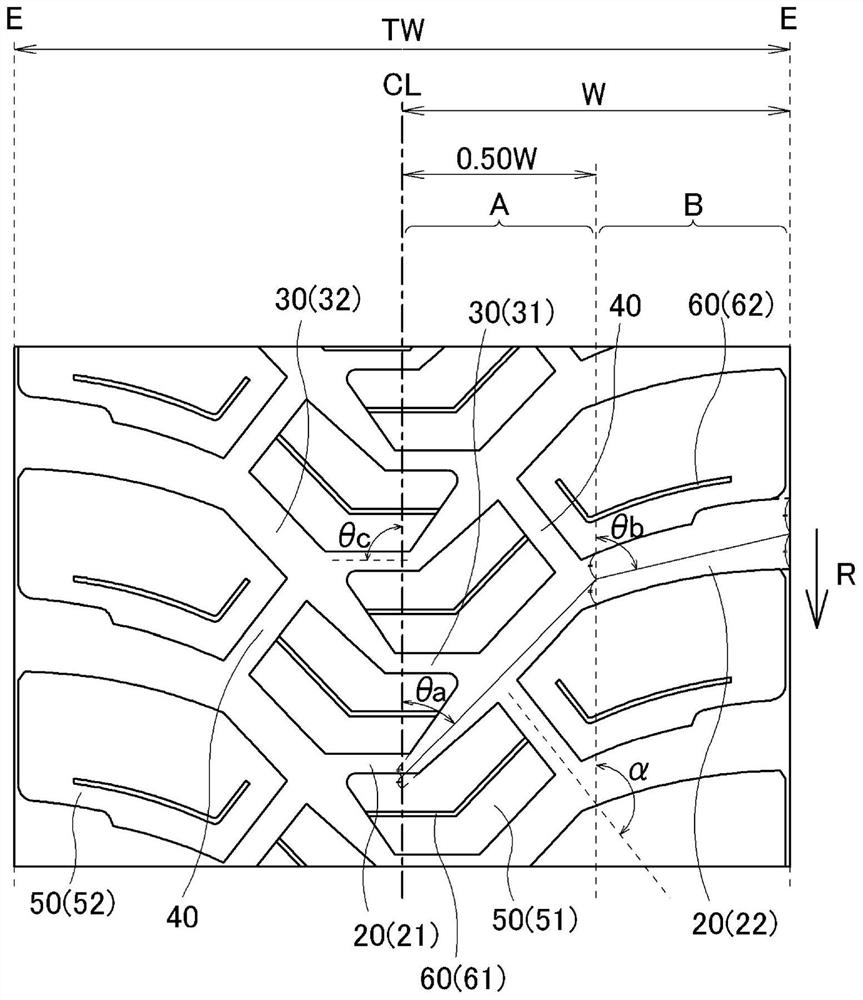

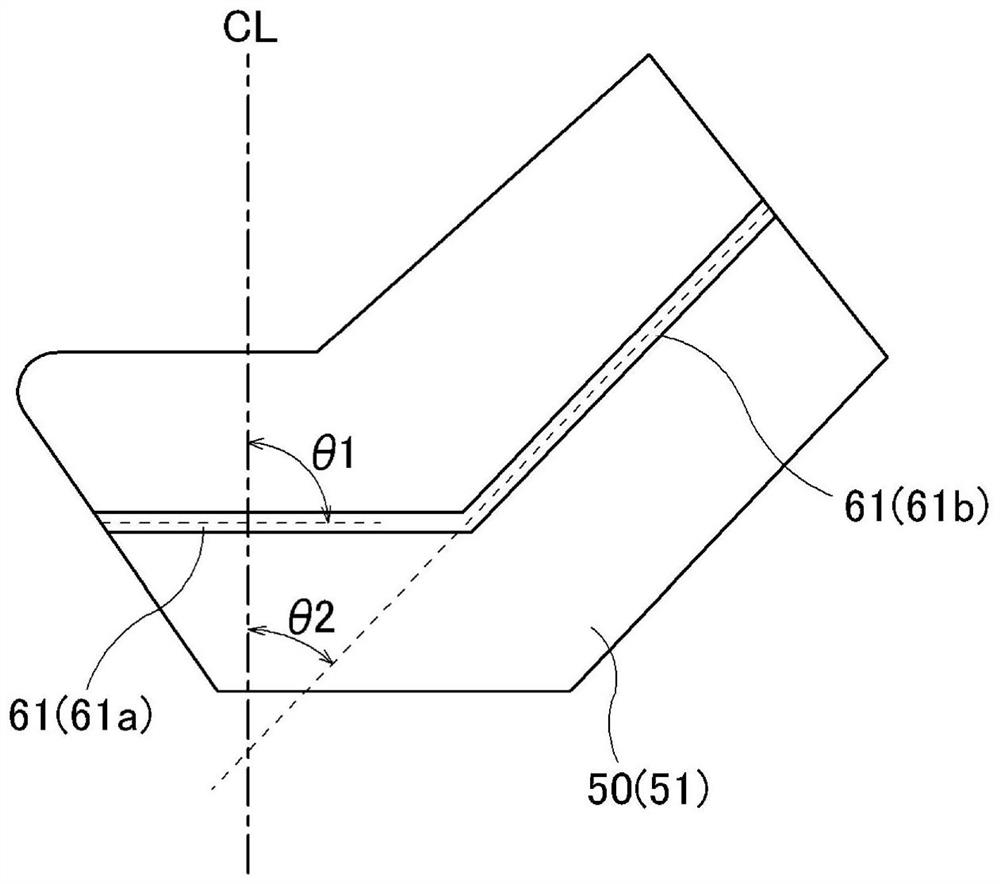

ActiveCN111989229AIncrease the edgeImprove traction performanceHeavy duty tyresHeavy duty vehicleAcute angleRoad surface

Provided is a pneumatic tire that allows improvement of snow traction performance while favorably maintaining performance in resistance to uneven wear and maintaining traveling performance on an unpaved road. Lug grooves (20, 30) are alternately arranged, the lug grooves (20, 30) comprising first groove portions (21, 31) intersecting with a tire center line CL and extending in the tire width direction and second groove portions (22, 32) respectively inclined, from ends of the first groove portions (21, 31), at acute angles in the tire circumferential direction relative to the first groove portions (21, 31) so as to extend to tread ends E on one side and the other side relative to the tire center line. The other ends of the first groove portions (21, 31) are in communication with the respective second groove portions (32, 22), of the lug grooves (30, 20), adjacent to each other in the tire circumferential direction. The first groove portions (21, 31) are arranged on a stepping-in side relative to the ends of the tread end E sides of the lug grooves (20, 30). The second groove portions (22, 32) are curved or bent such that the average angle theta in an inner side region A of the second groove portions (22, 32) becomes smaller than the average angle theta in an outer side region B of the second groove portions (22, 32). A shallow groove (60) is formed on a tread surface of ablock (50) demarcated by the lug grooves (20, 30) and circumferential narrow grooves (40) for connecting the adjacent second groove portions (22) and the adjacent second groove portions (32) in the tire circumferential direction, in such a manner that the shallow groove (60) has at least one bent point.

Owner:THE YOKOHAMA RUBBER CO LTD

pneumatic tire

ActiveCN110914074BAvoid abrasionImprove driving performanceOff-road vehicle tyresTyre tread bands/patternsTransverse grooveControl theory

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

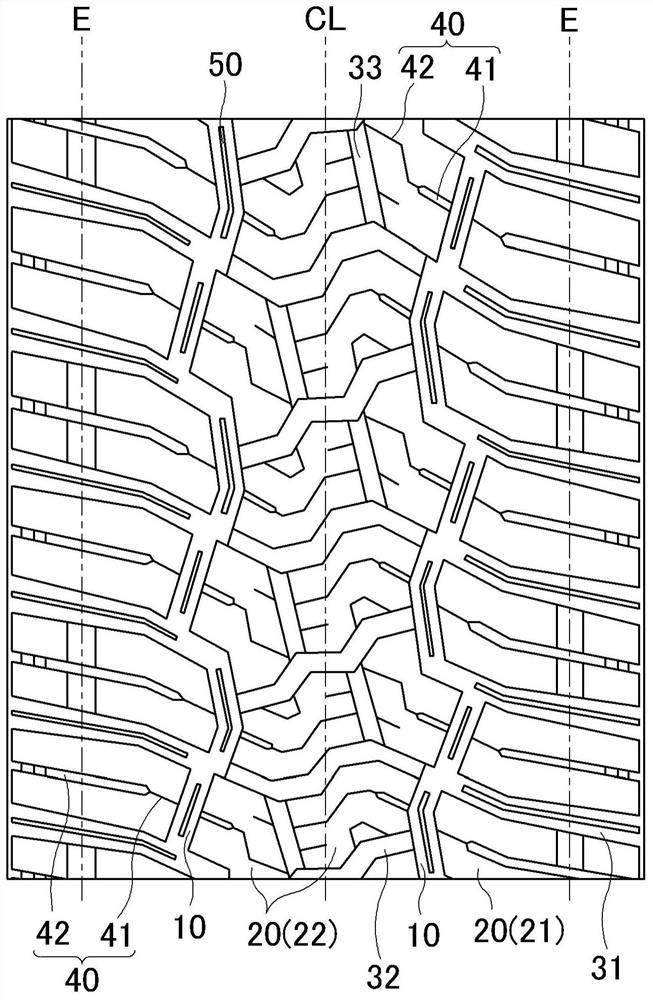

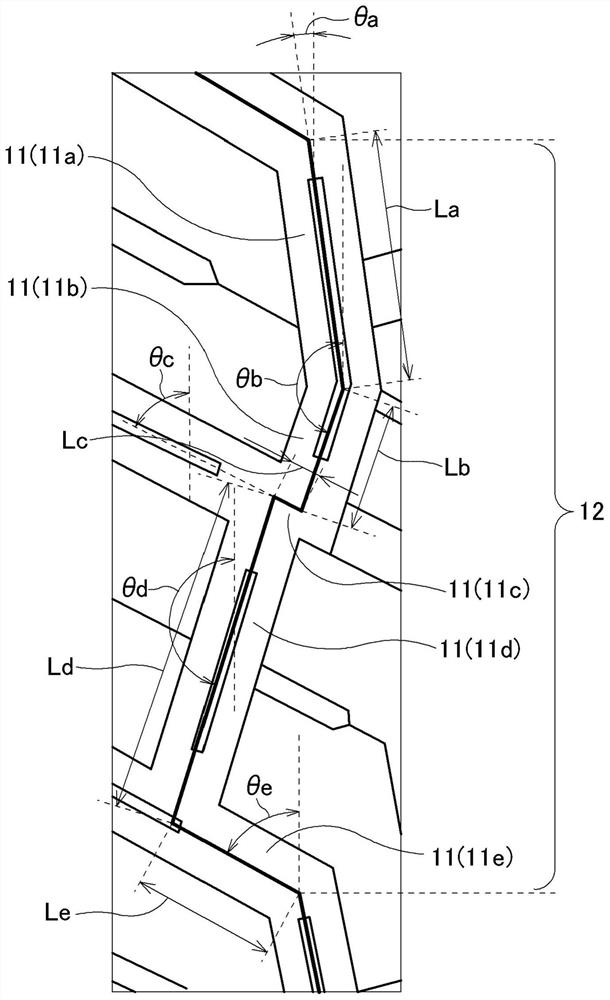

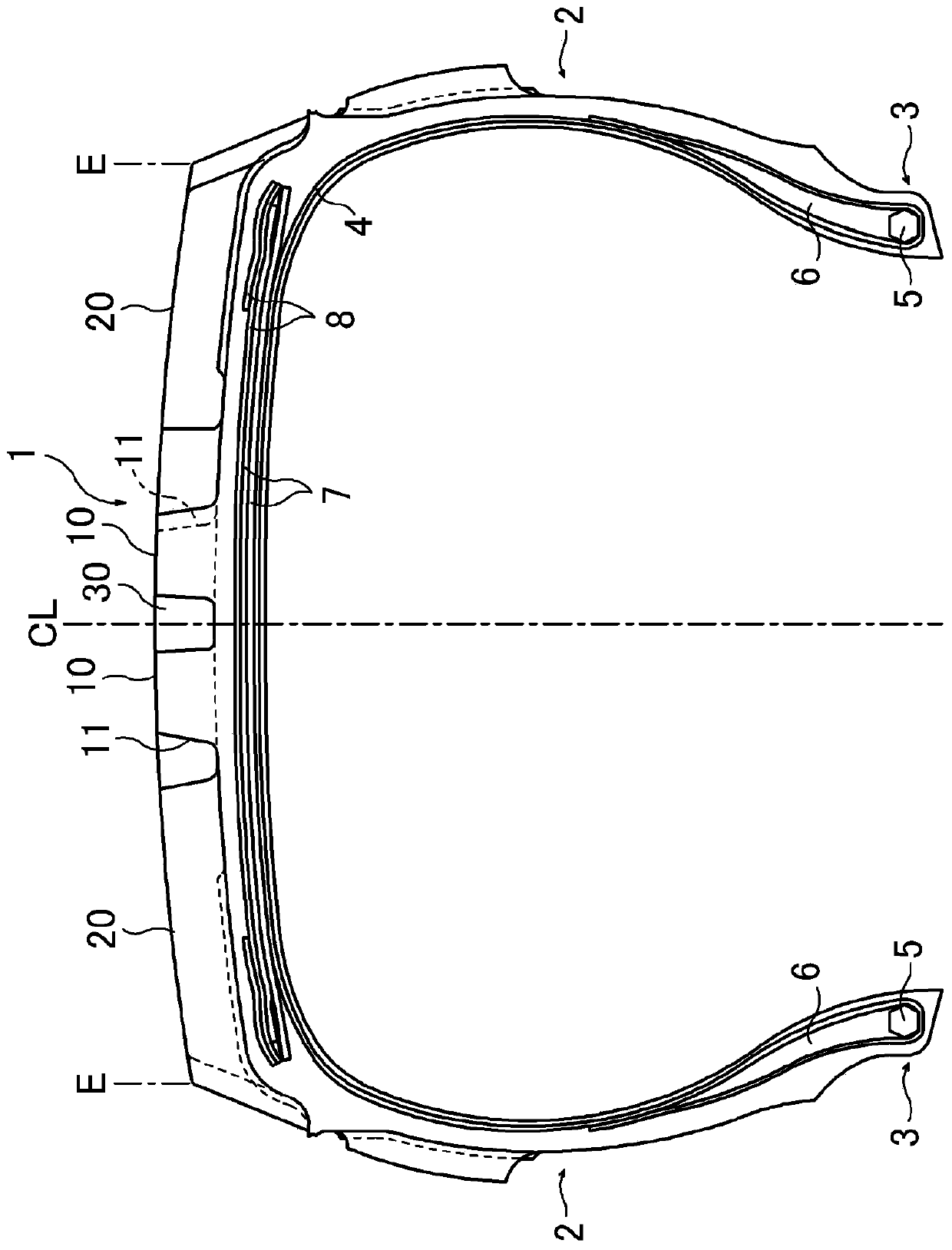

PendingCN112384380AAvoid transmissionPlay efficientlyTyre tread bands/patternsMechanical engineeringAutomotive engineering

Provided is a pneumatic tire having improved noise performance and improved traveling performance on unpaved roads. In the present invention, a pair of main grooves 10 arranged on the respective sidesof the tire equator CL and extending in the tire circumferential direction are configured such that a series of bent elements 12 formed by connecting at least five linear groove sections 11 via bending points are continuously and repeatedly arranged in the tire circumferential direction. The at least five linear groove sections 11 included in each of the bent elements 12 have three of more different angles of inclination with respect to the tire circumferential direction, and have five or more different lengths.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveCN110198848ACurb dumpingEffective controlOff-road vehicle tyresTyre tread bands/patternsMechanical engineeringTread

The present invention provides a pneumatic tire that is suitable for use as a tire for traveling on unpaved roads, and that improves traveling performance and damage resistance on unpaved roads. Center blocks 10, which are provided in a center region of a tread section 1, are arrayed so as to form a pair of center blocks 10 between which there are interposed inclined grooves 30 that extend in an inclined direction with respect to a tire circumferential direction. The center blocks 10 are made to extend so as to straddle a tire equator CL from one side to the other side of the tire equator CL.Notches 11, which are each composed of a first wall 11a and a second wall 11b connected to each other in a V shape, are provided in treads in each center block CL. The first walls 11a are made to extend at an angle within + / -20 degrees with respect to the tire circumferential direction; the second walls 11b are made to extend at an angle of + / -10 degrees with respect to a tire width direction; andthe average angle of sipes, which are respectively formed in the center blocks 10 and shoulder blocks 20, lies within 90 degrees + / -10 degrees in a first region C, lies within 130 degrees + / -10 degrees in a second region M, and lies within 70 degrees + / -10 degrees in a third region S with respect to the tire equator CL. Each sipe is configured to have at least one curved portion.

Owner:THE YOKOHAMA RUBBER CO LTD

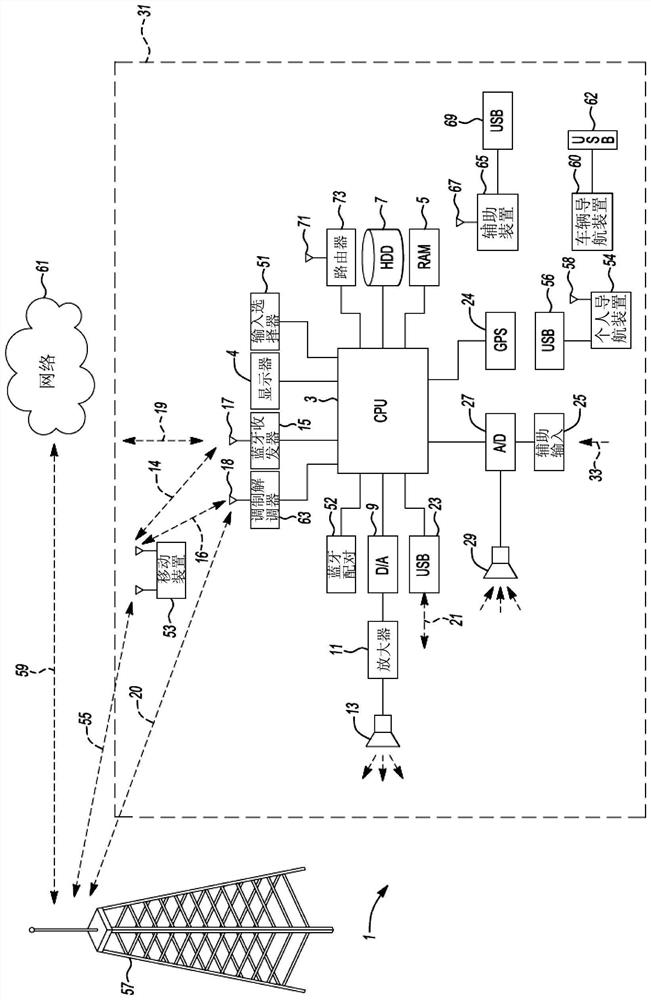

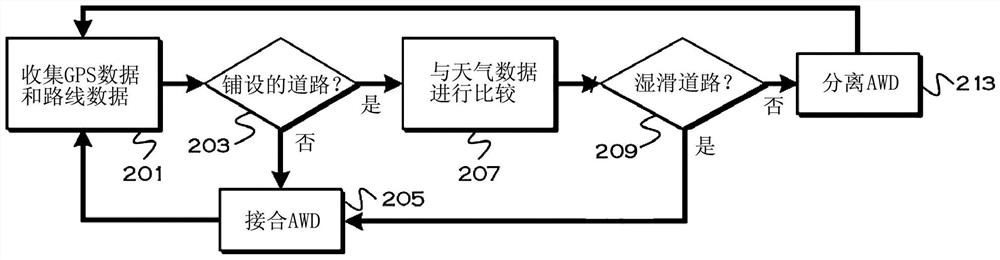

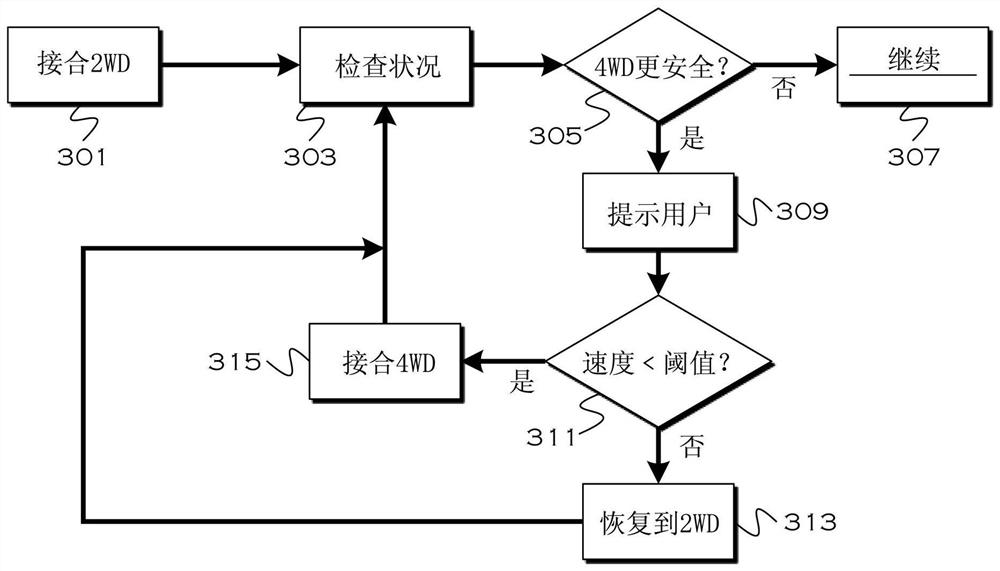

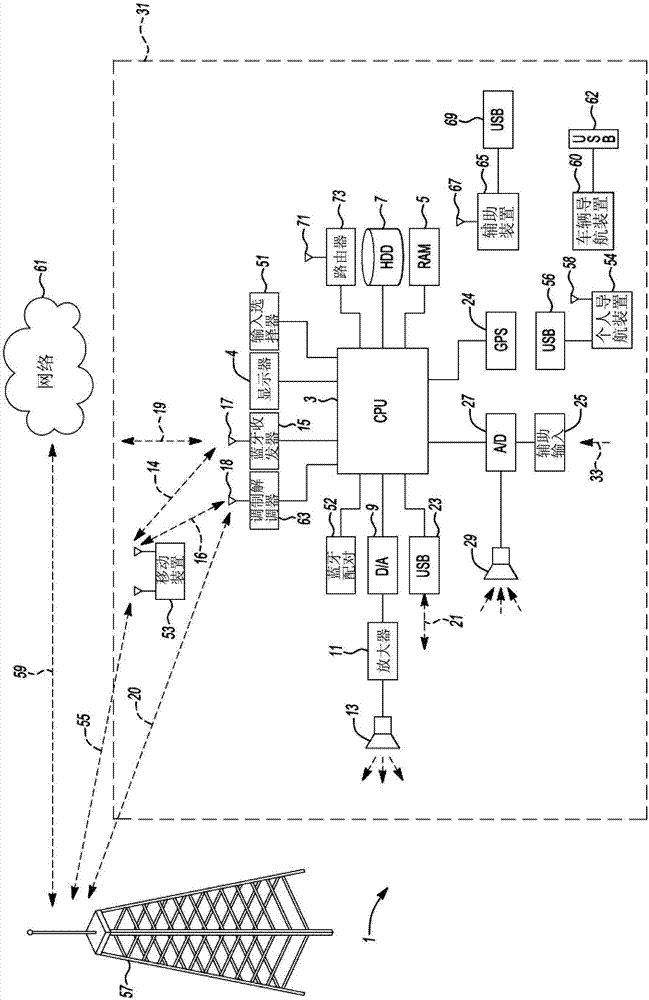

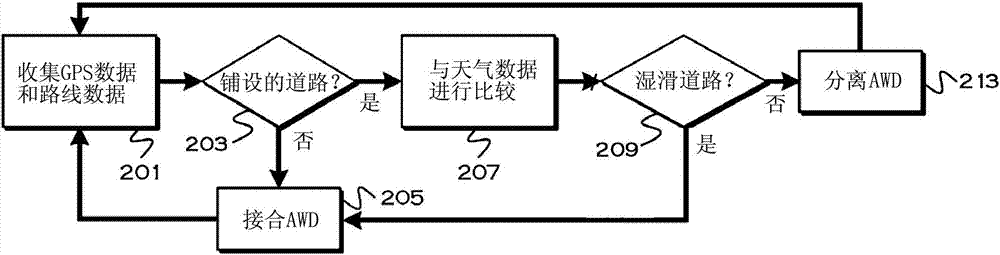

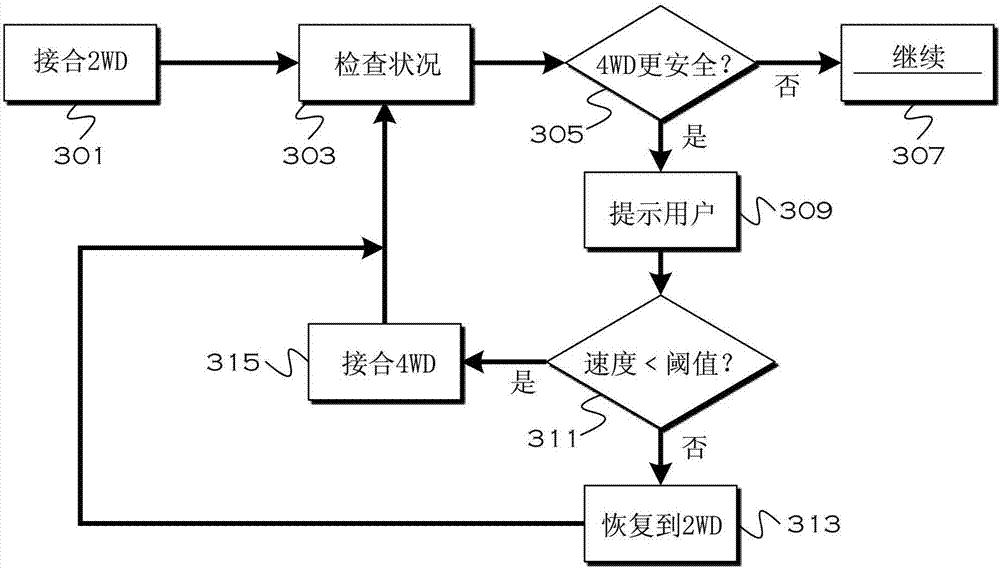

Method and apparatus for prospective all-wheel drive engagement and four-wheel drive engagement

The present disclosure relates to methods and apparatus for anticipating all-wheel drive engagement and four-wheel drive engagement. A system includes a processor configured to automatically engage all-wheel drive (AWD) when a vehicle reaches an area along a route that is pre-marked as slippery in a memory in communication with the processor. . Said marking may eg have occurred based on the presence of unpaved roads or precipitation in said area.

Owner:FORD GLOBAL TECH LLC

Pneumatic tire

ActiveCN111587187AImprove driving performanceEnsure edge effectOff-road vehicle tyresTyre tread bands/patternsTransverse grooveStructural engineering

Owner:THE YOKOHAMA RUBBER CO LTD

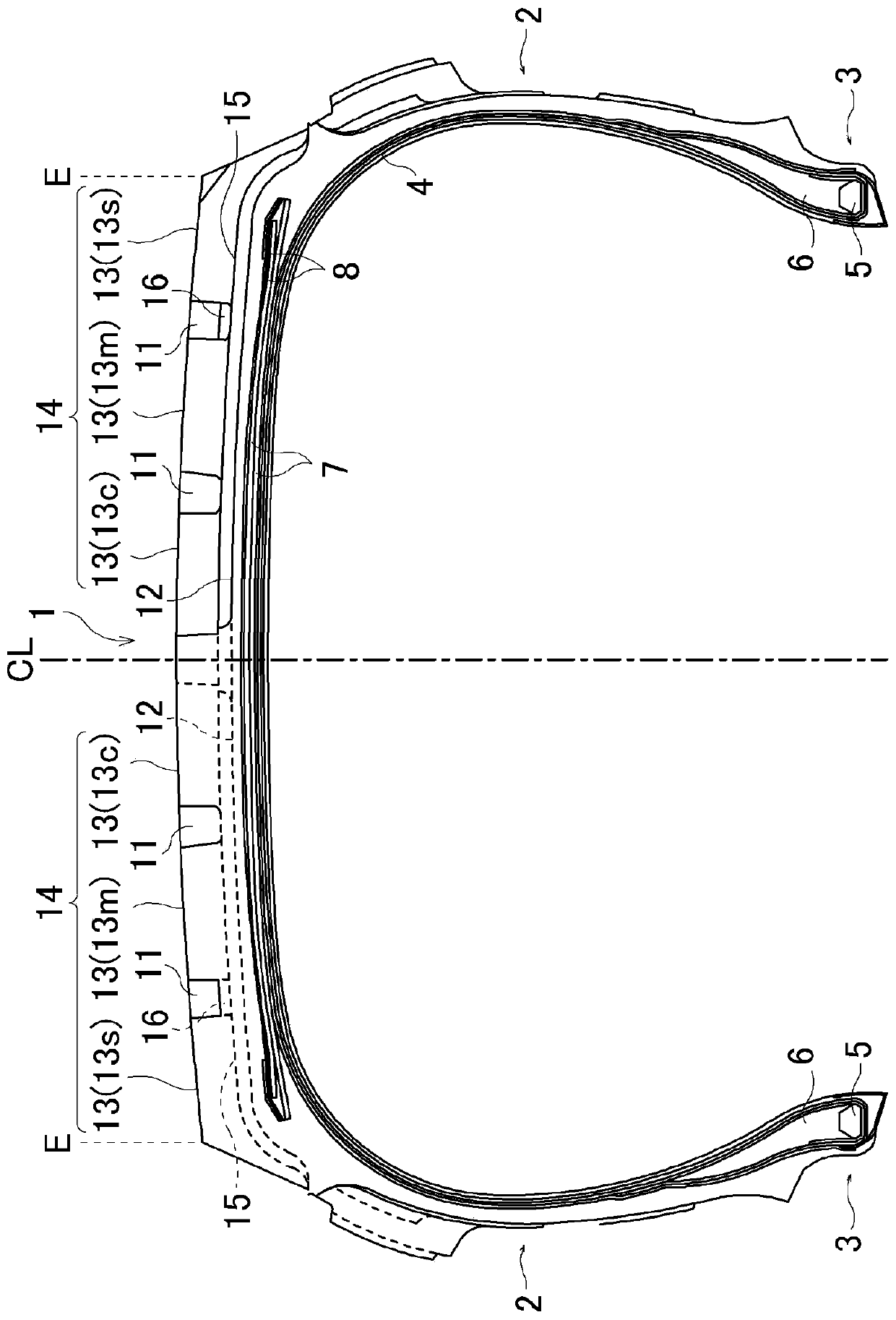

Pneumatic tire

ActiveCN110914074AAvoid abrasionAvoid the situationOff-road vehicle tyresTyre tread bands/patternsControl theoryMechanical engineering

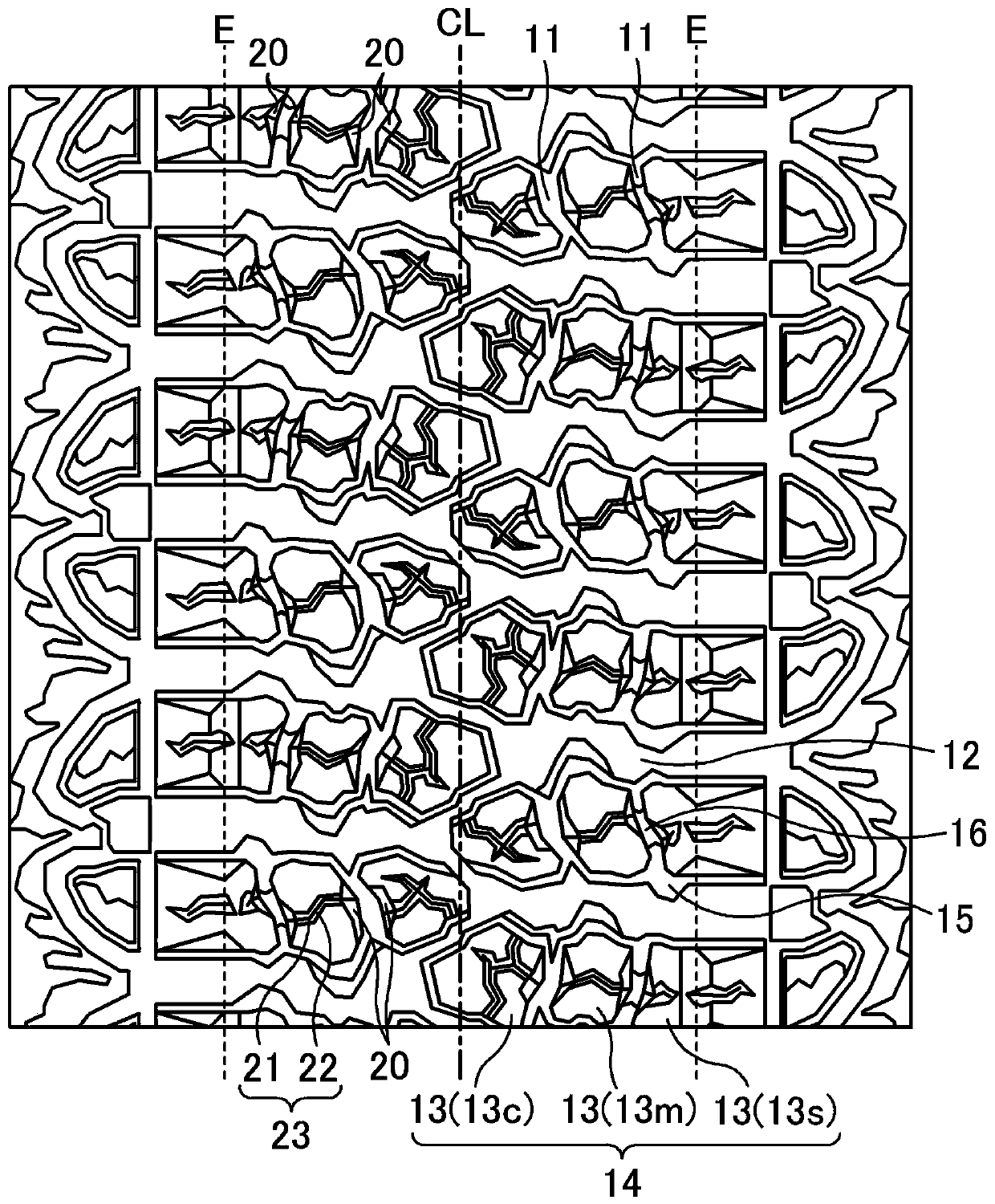

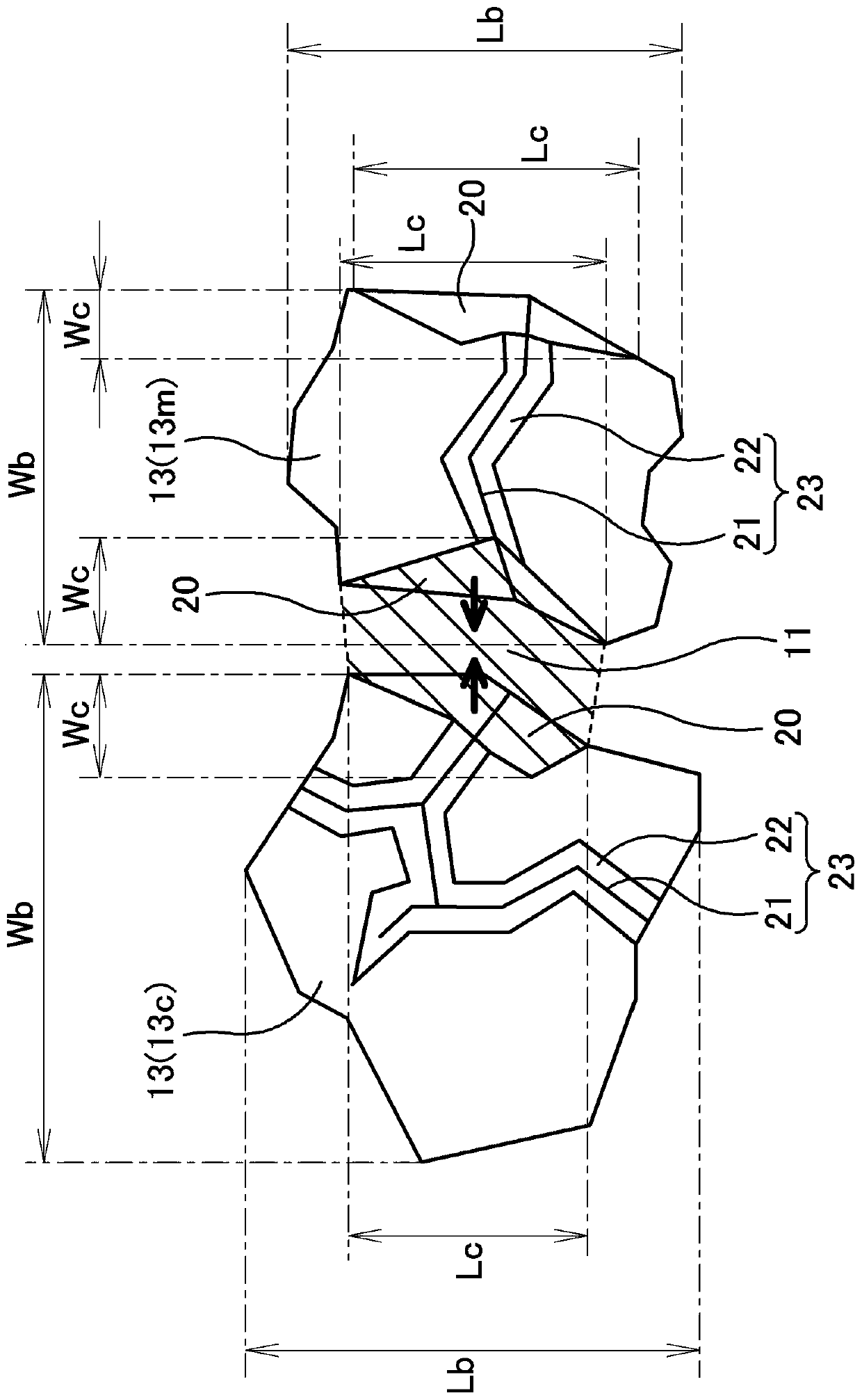

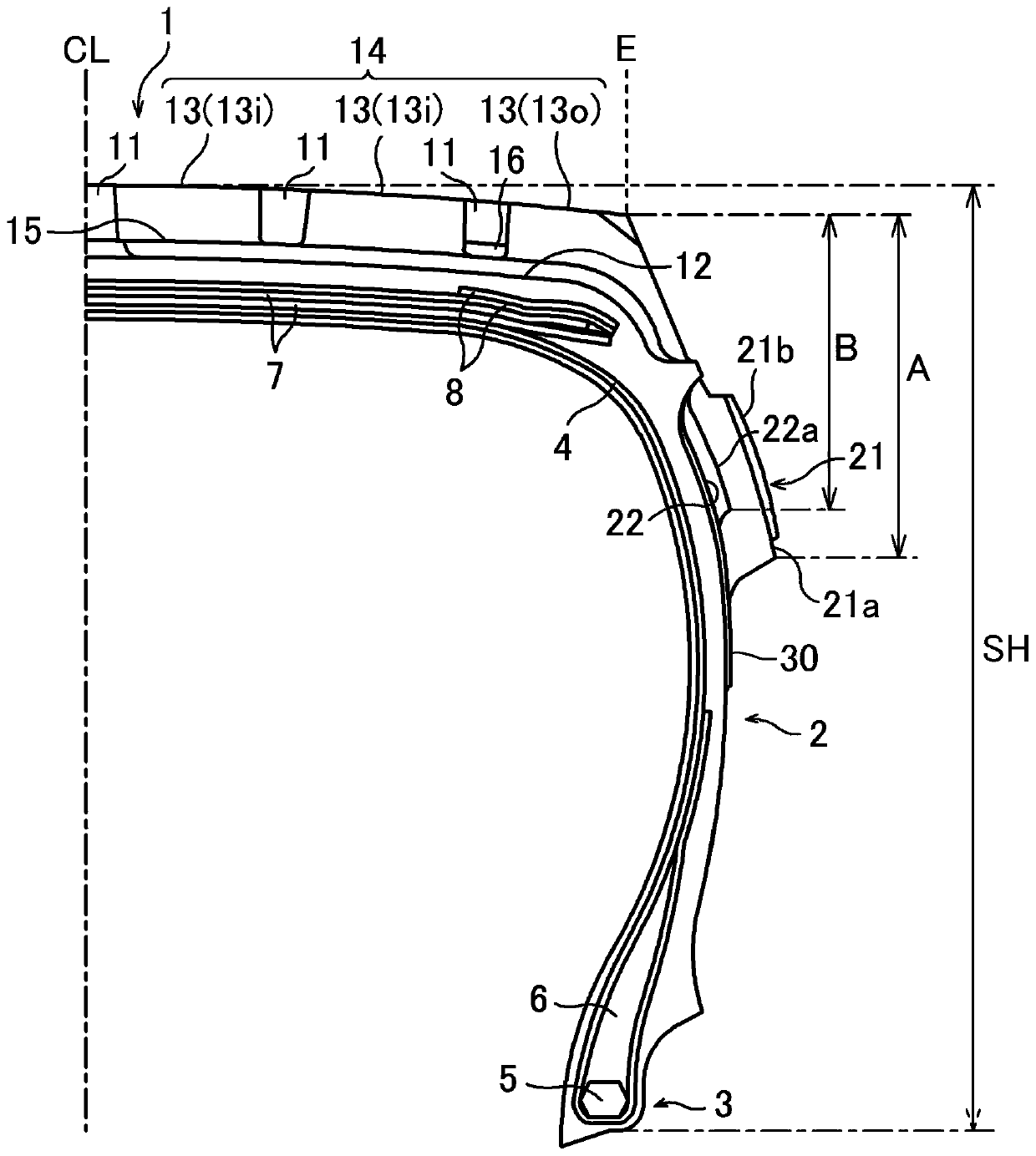

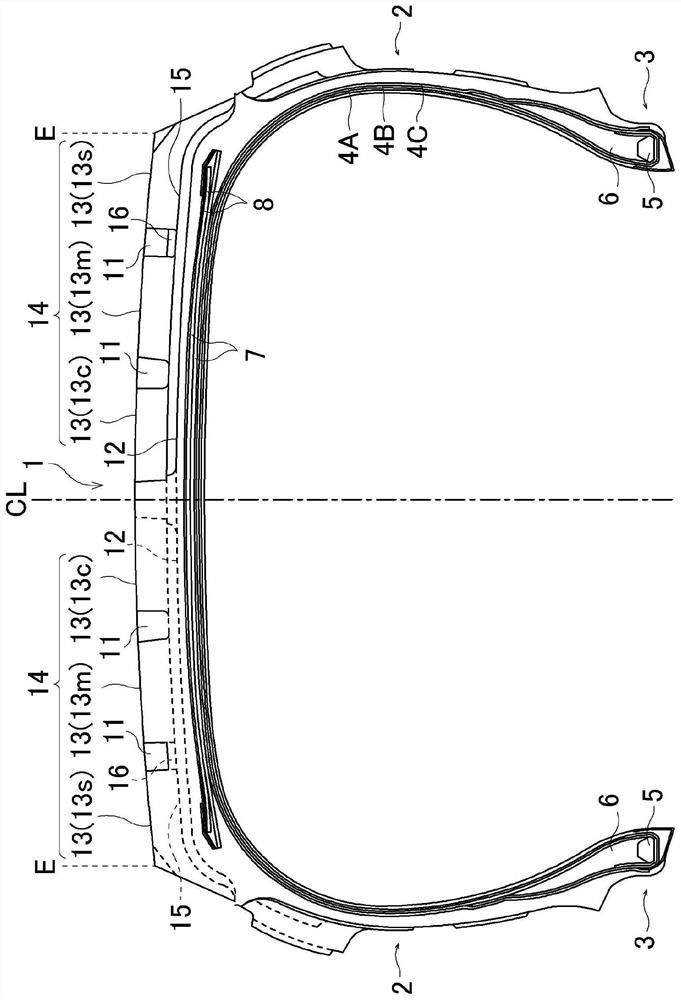

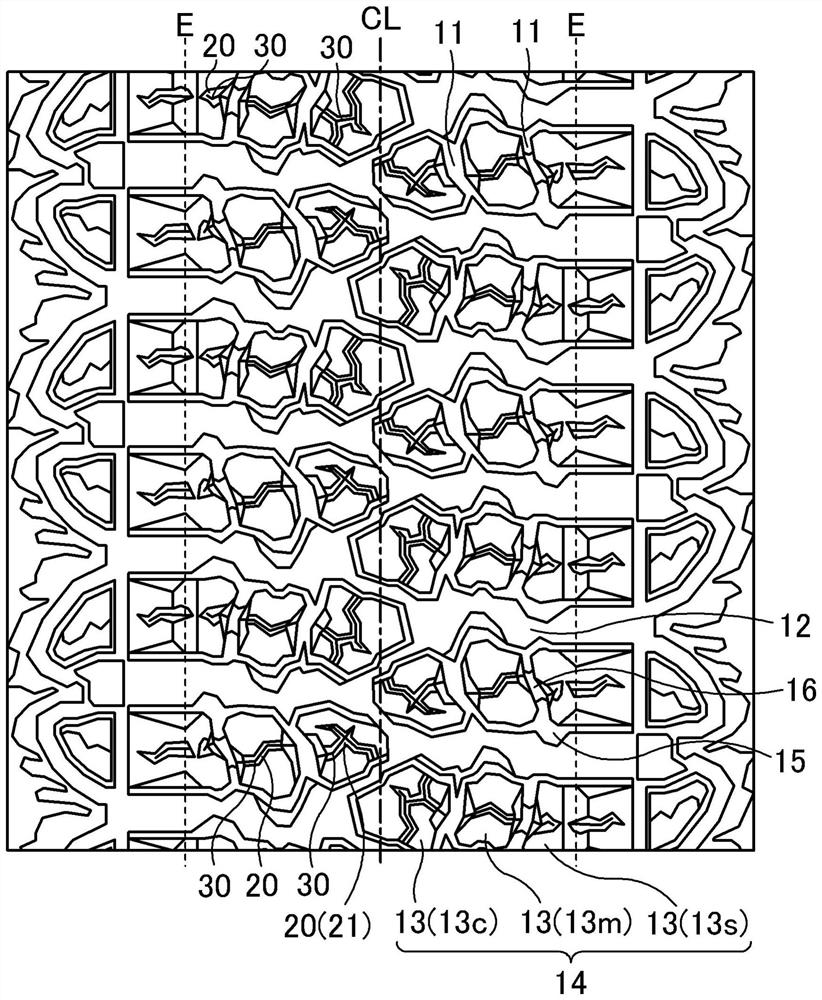

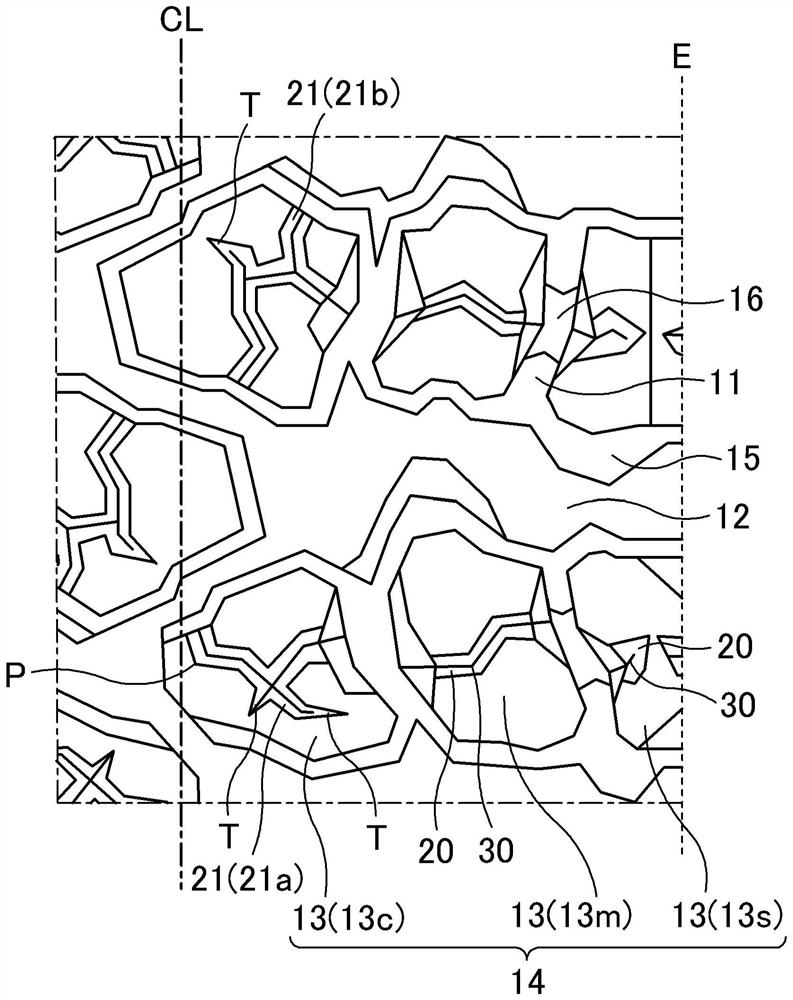

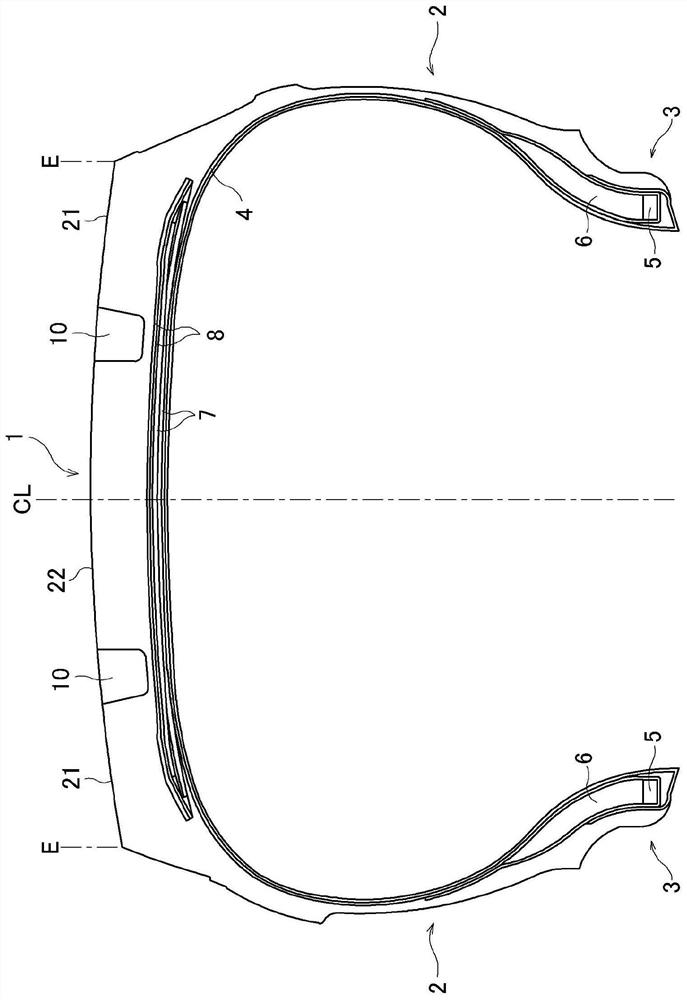

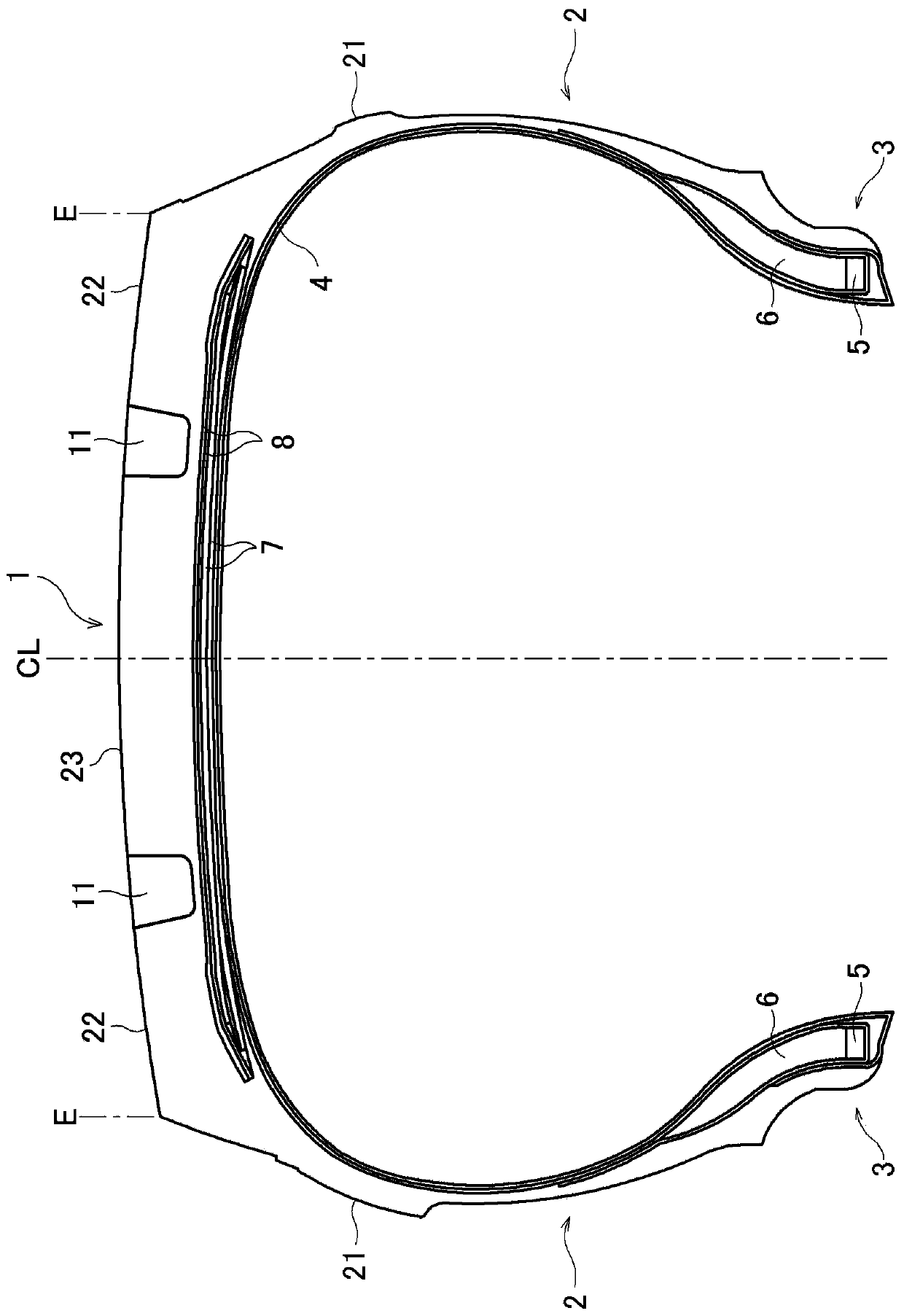

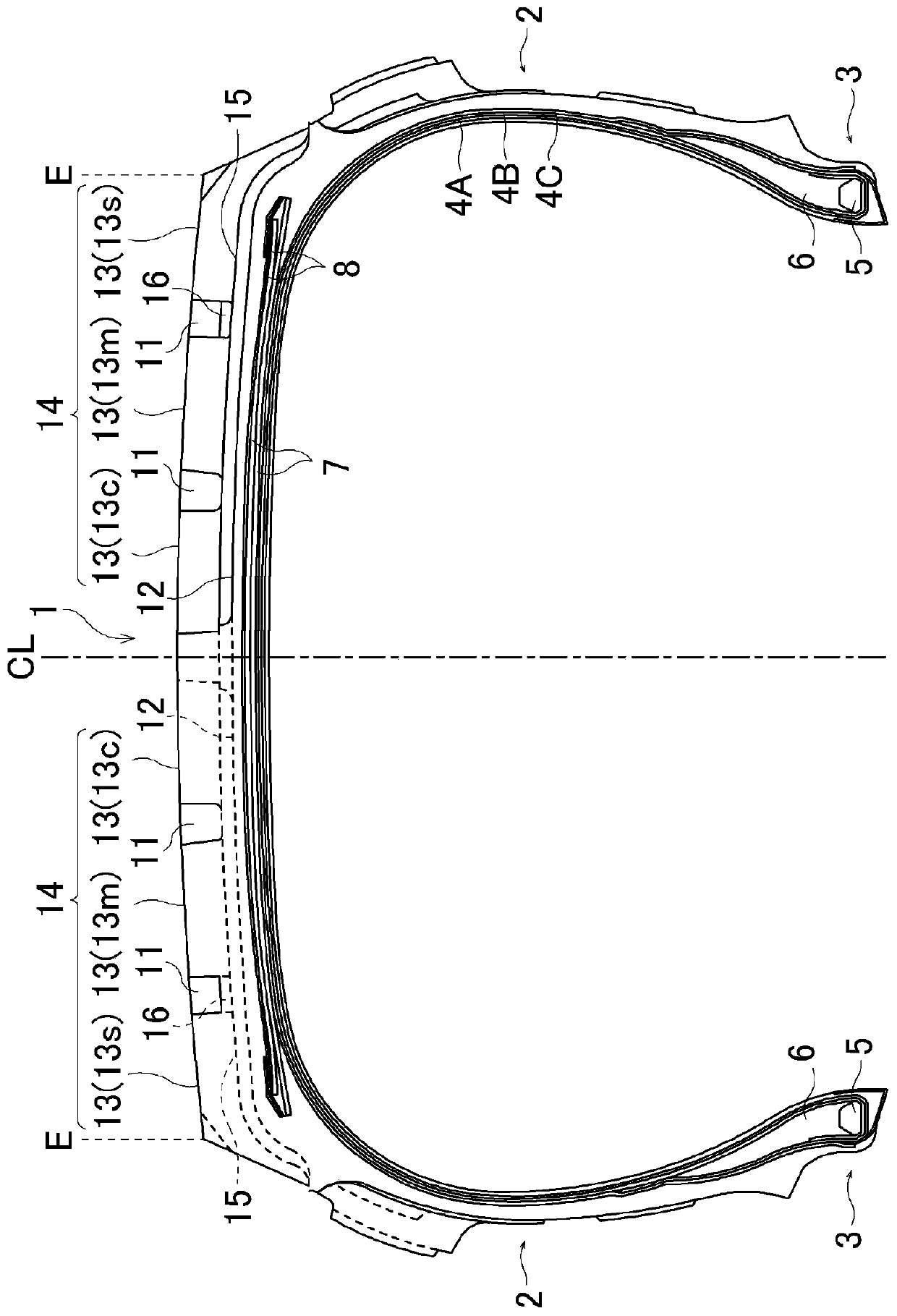

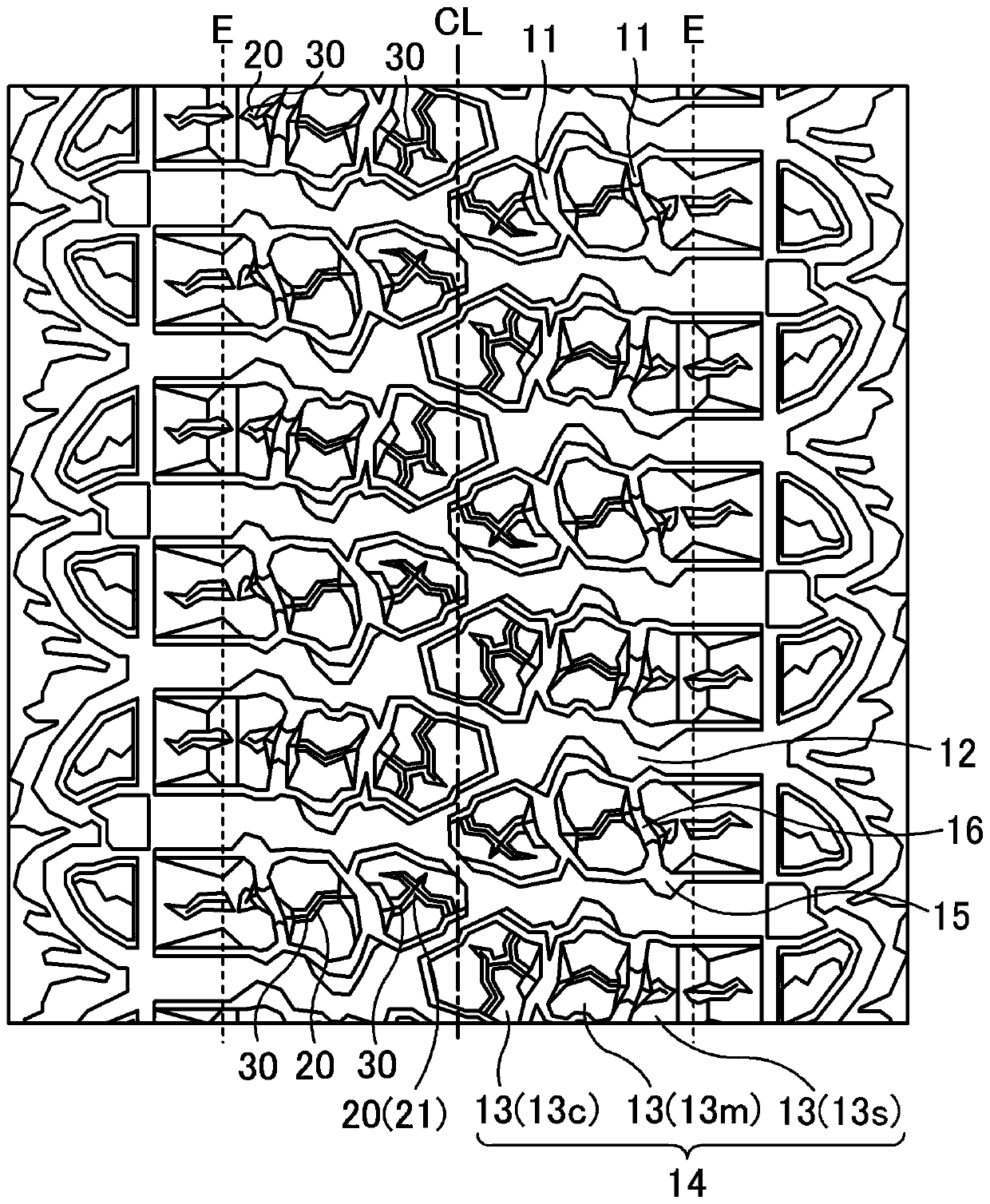

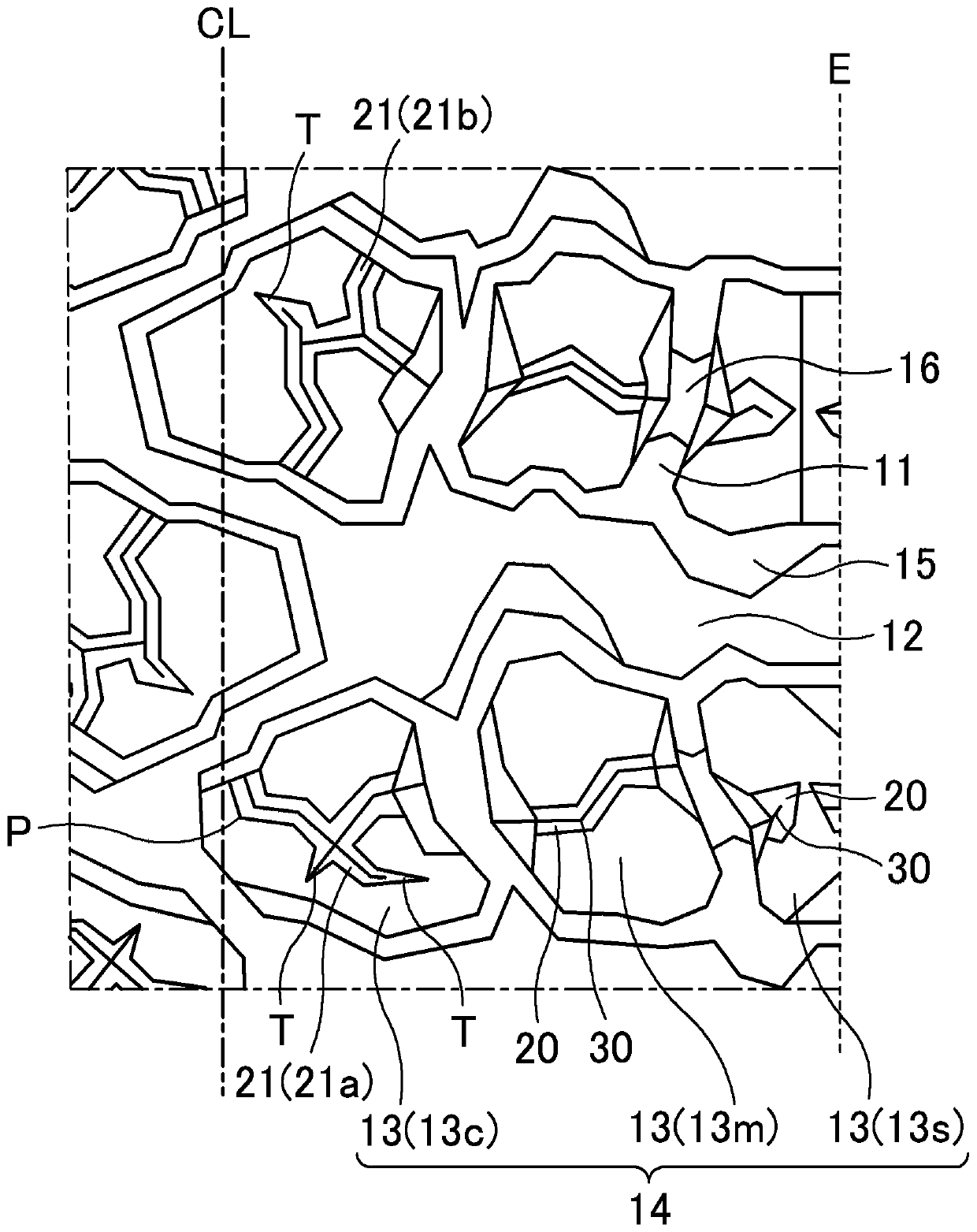

Provided is a pneumatic tire suitable for traveling on an unpaved road, the pneumatic tire being improved in running performance, abrasion resistance performance and steering stability performance onan unpaved road. In a tread portion 1, on each tread surface of a shoulder block 13s, an intermediate block 13m, and a center block 13c, which are defined by a plurality of longitudinal grooves 11 extending in the tire circumferential direction and a plurality of lateral grooves 12 extending in the tire width direction, a shallow groove 20 having a groove depth smaller than that of the longitudinal groove 11 and the lateral groove 12 is formed. The shallow groove 20 extends along the tire width direction and at least one end thereof is communicated with the longitudinal groove 11 or the lateral groove 12. At least one bending point P is provided on the contour line of the shallow groove 20. A sipe 30 extending along the shallow groove 20 is provided on the flat bottom surface of the shallow groove 20. A terminal end portion T terminating in the center block 13c is provided in the center shallow groove 21, of the shallow groove 20, which is formed in the center block 13c.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

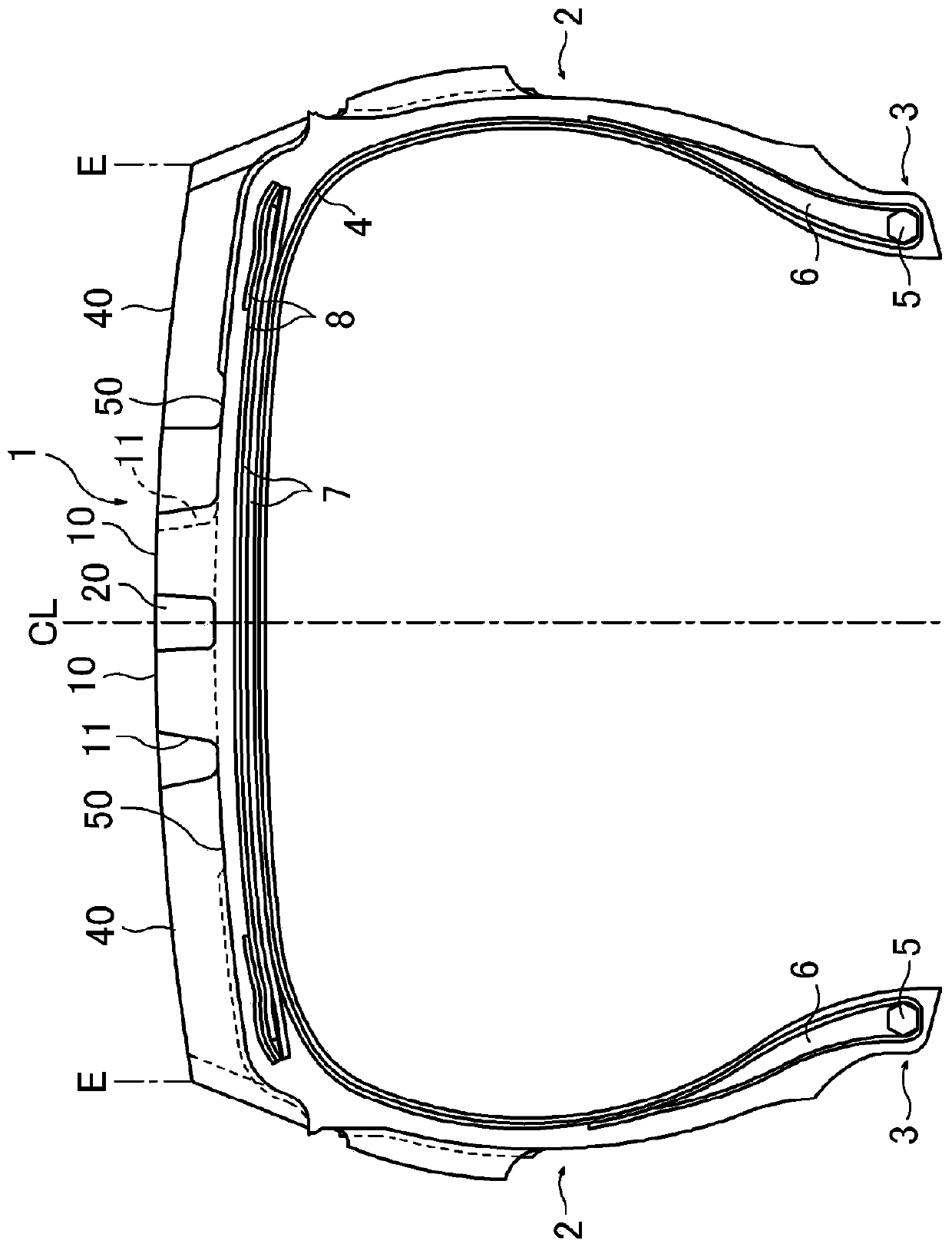

PendingUS20220063349A1Improve balanceEnsure sufficientOff-road vehicle tyresTyre tread bands/patternsControl theoryMechanical engineering

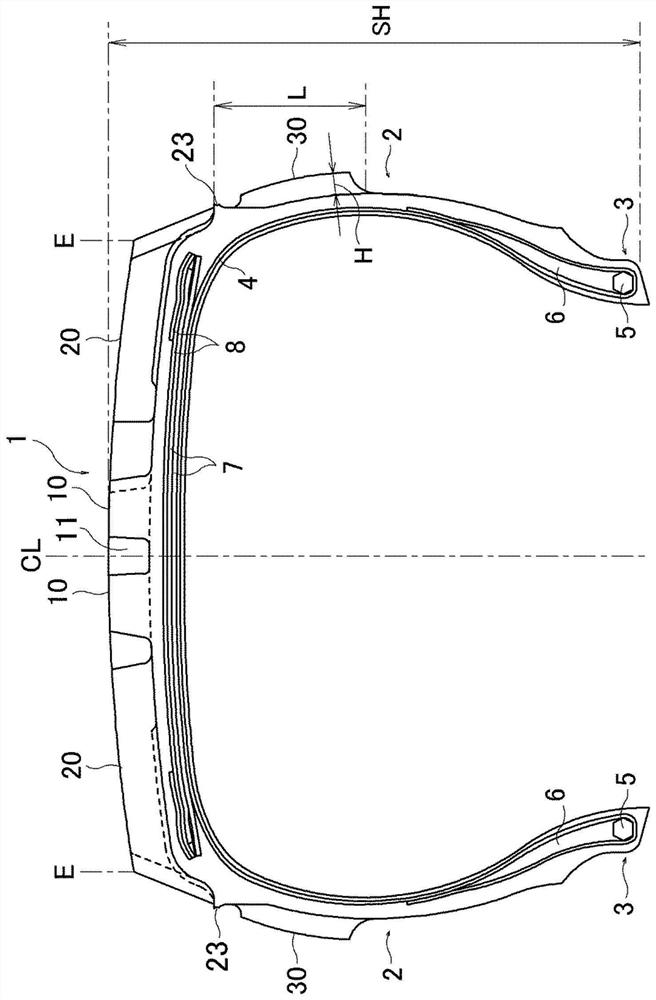

To provide a pneumatic tire that provides improved noise performance and running performance on unpaved roads. A plurality of side blocks rising from an outer surface of a sidewall portion and defined by a segmentation element are provided in each of side regions adjacent to an outer side in a tire width direction of an outermost end portion in the tire width direction of a tread portion. The number Nin of the side blocks provided in an inner side region that is an inner side with respect to a vehicle when a tire is mounted on the vehicle is smaller than the number Nout of the side blocks provided in an outer side region that is an outer side with respect to the vehicle when the tire is mounted on the vehicle.

Owner:THE YOKOHAMA RUBBER CO LTD

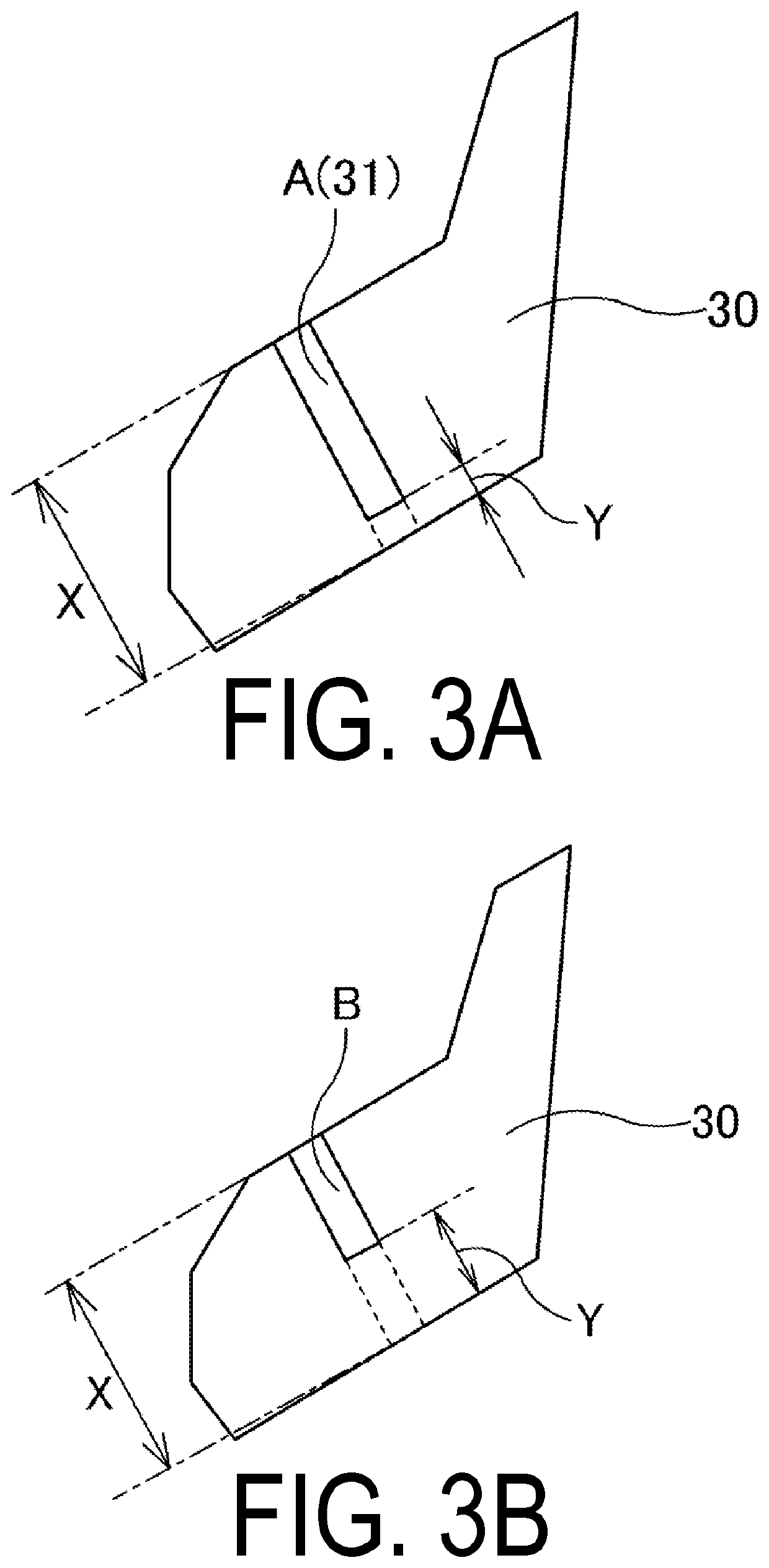

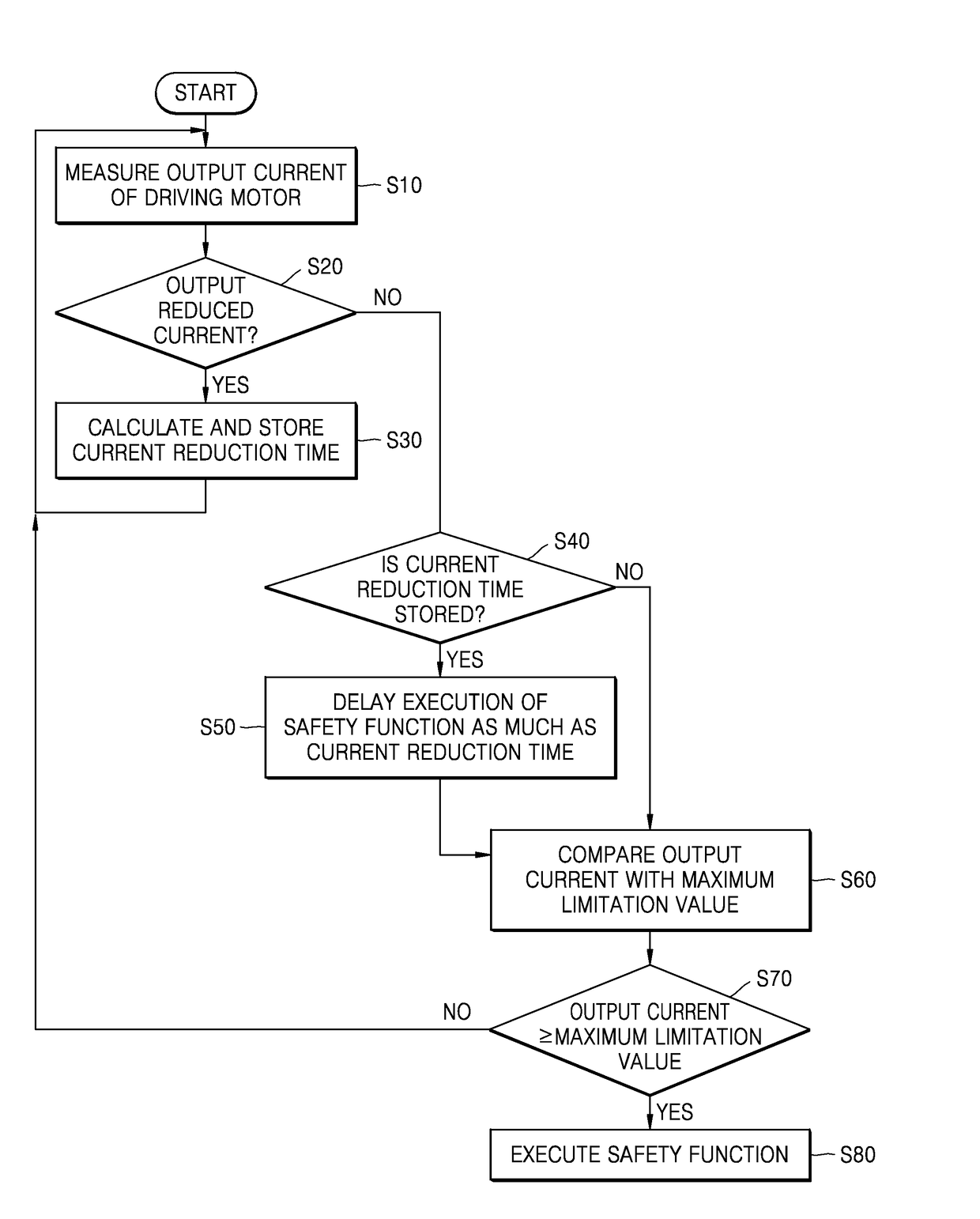

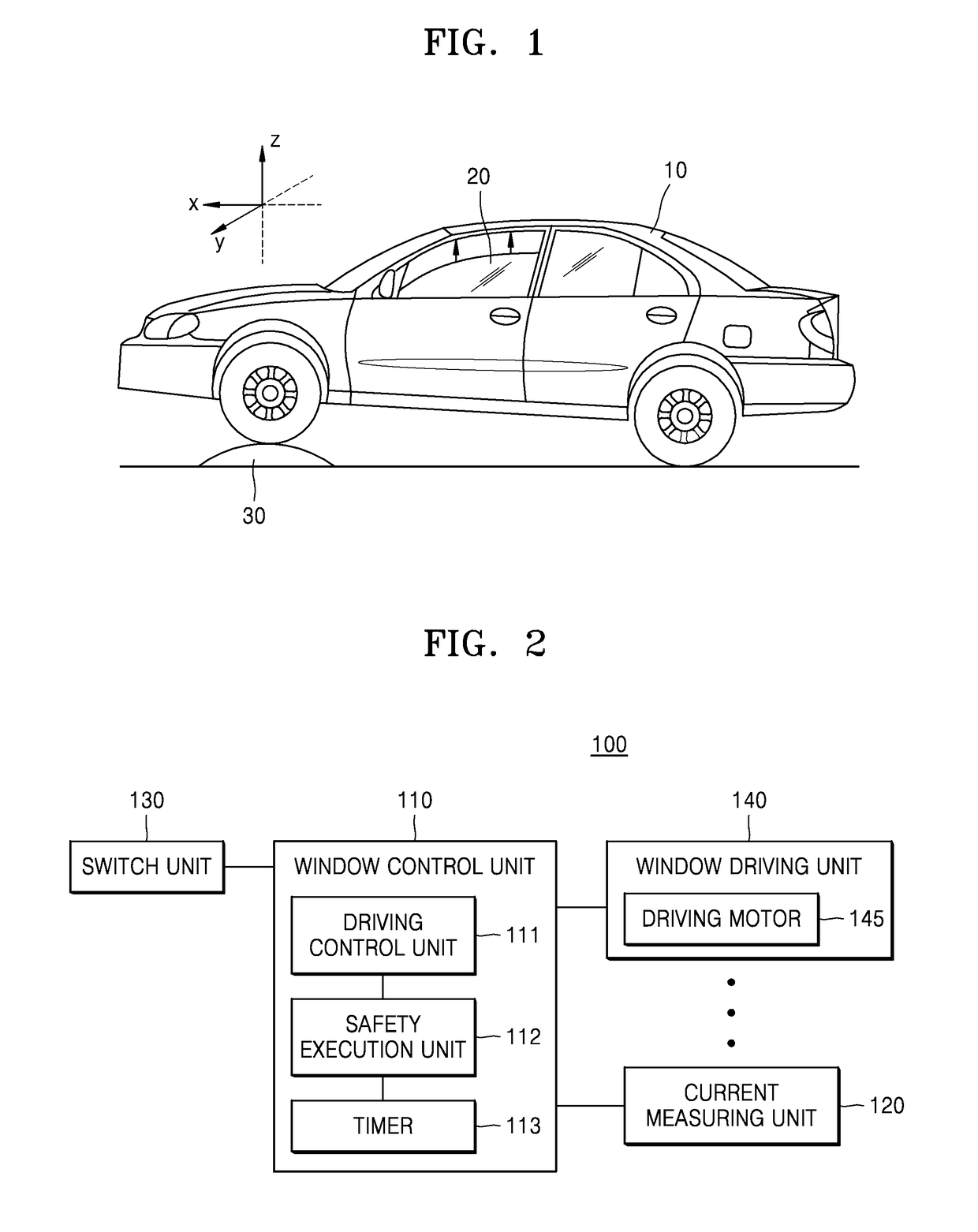

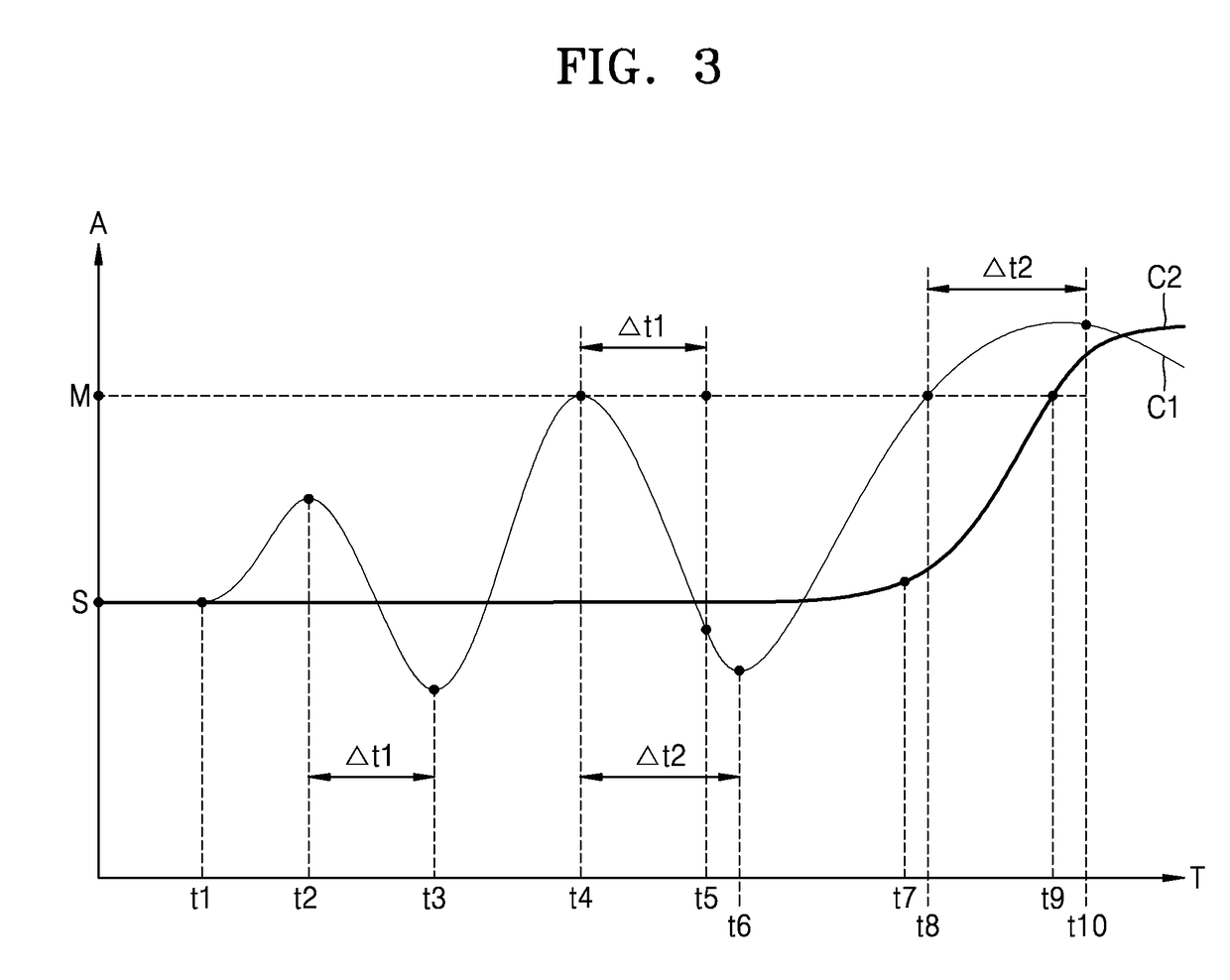

Apparatus for and method of controlling power window by using output current of motor

An apparatus and method of controlling a power window by using an output current of a driving motor. The output current is measured to calculate and store a current reduction time, and then, execution of a safety function is delayed when an interruption in ascending of the window glass is sensed, so that interruption caused by noise generated when a car moves over an unpaved road or road bumps may be distinguished from interruption caused by an actual obstacle. Then, the safety function is prevented from being executed if the interruption in the ascending of the window glass is caused by the noise. Therefore, the interruption of the ascending of window glass due to the noise generated when the car moves on the unpaved road or road bumps may be distinguished without using an additional sensor.

Owner:DYAUTO

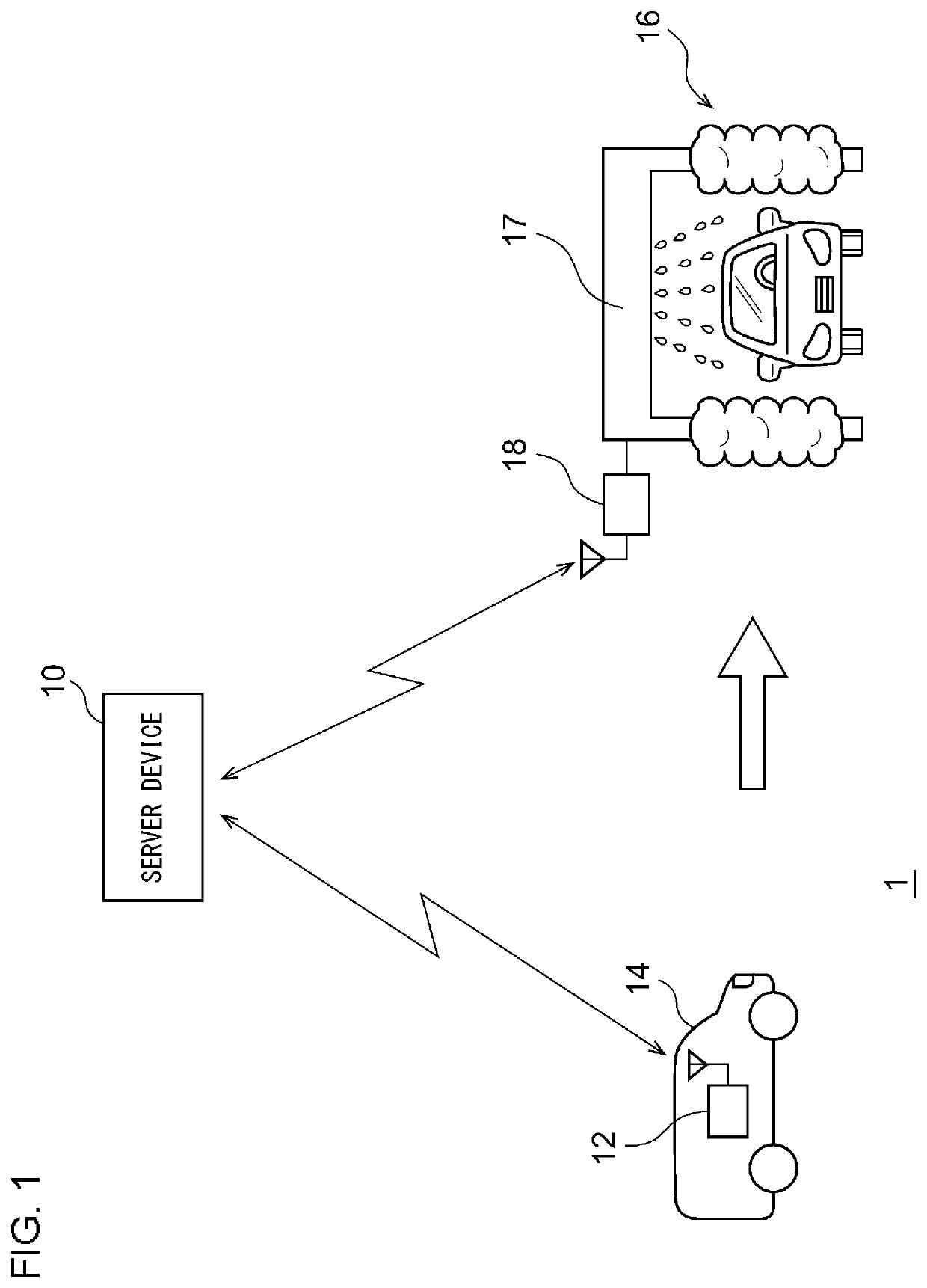

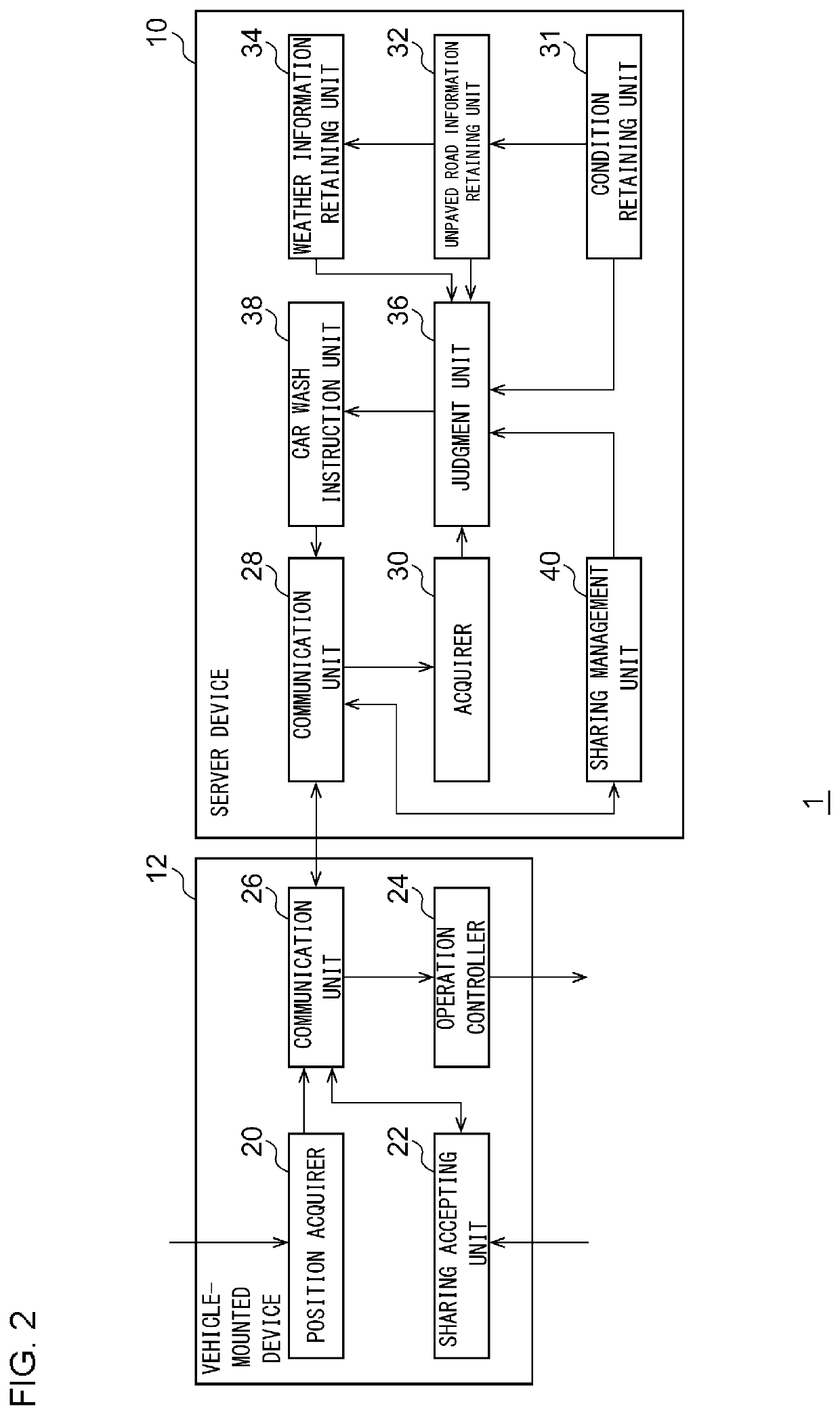

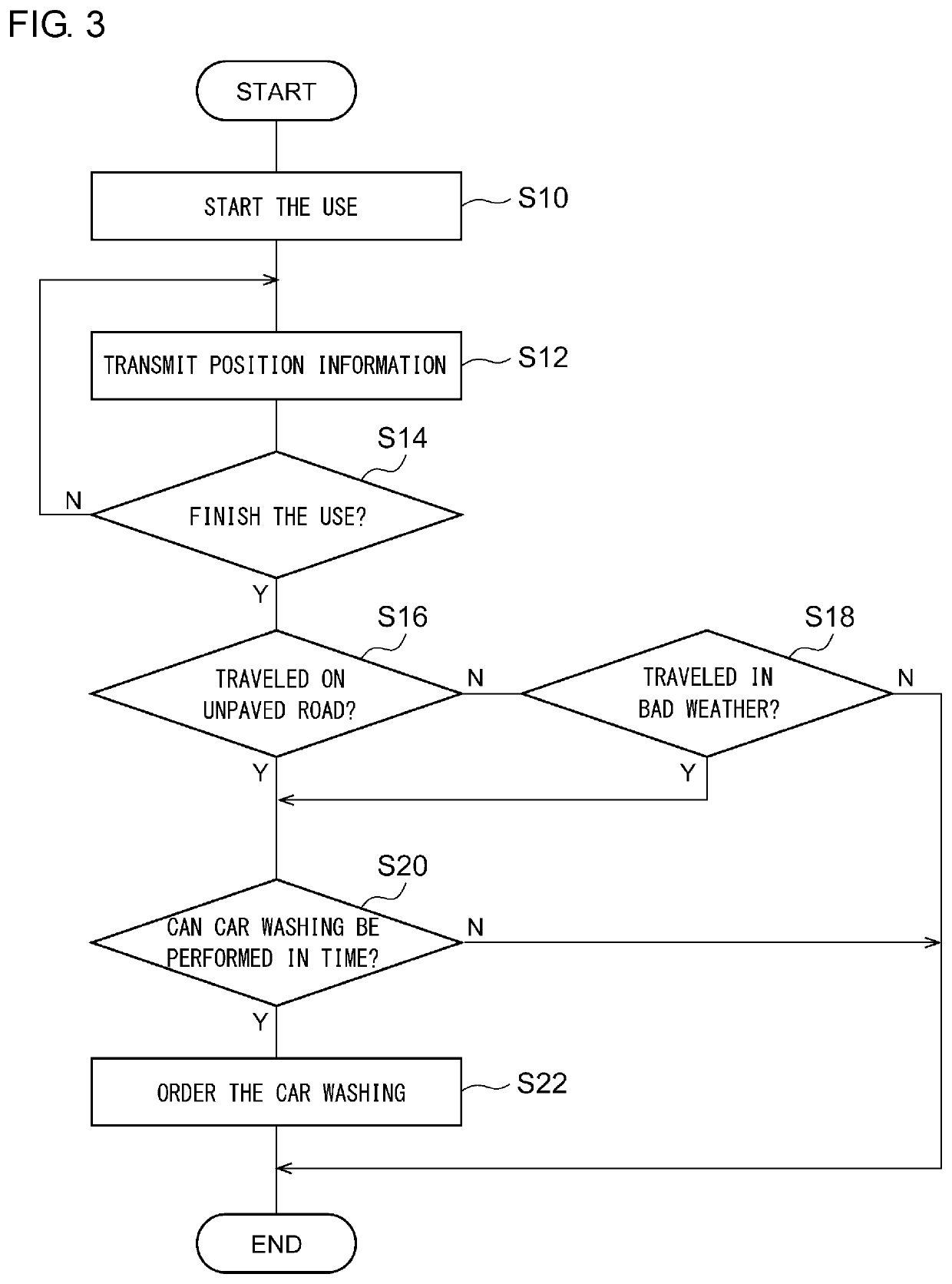

Car wash judgment system and car wash judgment method

InactiveUS20200401159A1Easy to judgeInstruments for road network navigationData processing applicationsTransport engineeringReal-time computing

In a car wash judgment system, an acquirer acquires traveling information of a vehicle. A condition retaining unit retains a certain car wash condition. A judgment unit judges whether or not traveling information acquired at the acquirer satisfies the certain car wash condition. An unpaved road information retaining unit retains unpaved road information indicating the position of an unpaved road. The certain car wash condition includes traveling on an unpaved road by the vehicle. When a vehicle that has transmitted traveling information is an automated driving vehicle capable of performing automated driving and when the traveling information of the automated driving vehicle satisfies the certain car wash condition, a car wash instruction unit transmits an instruction signal for moving the automated driving vehicle to a car wash station.

Owner:TOYOTA JIDOSHA KK

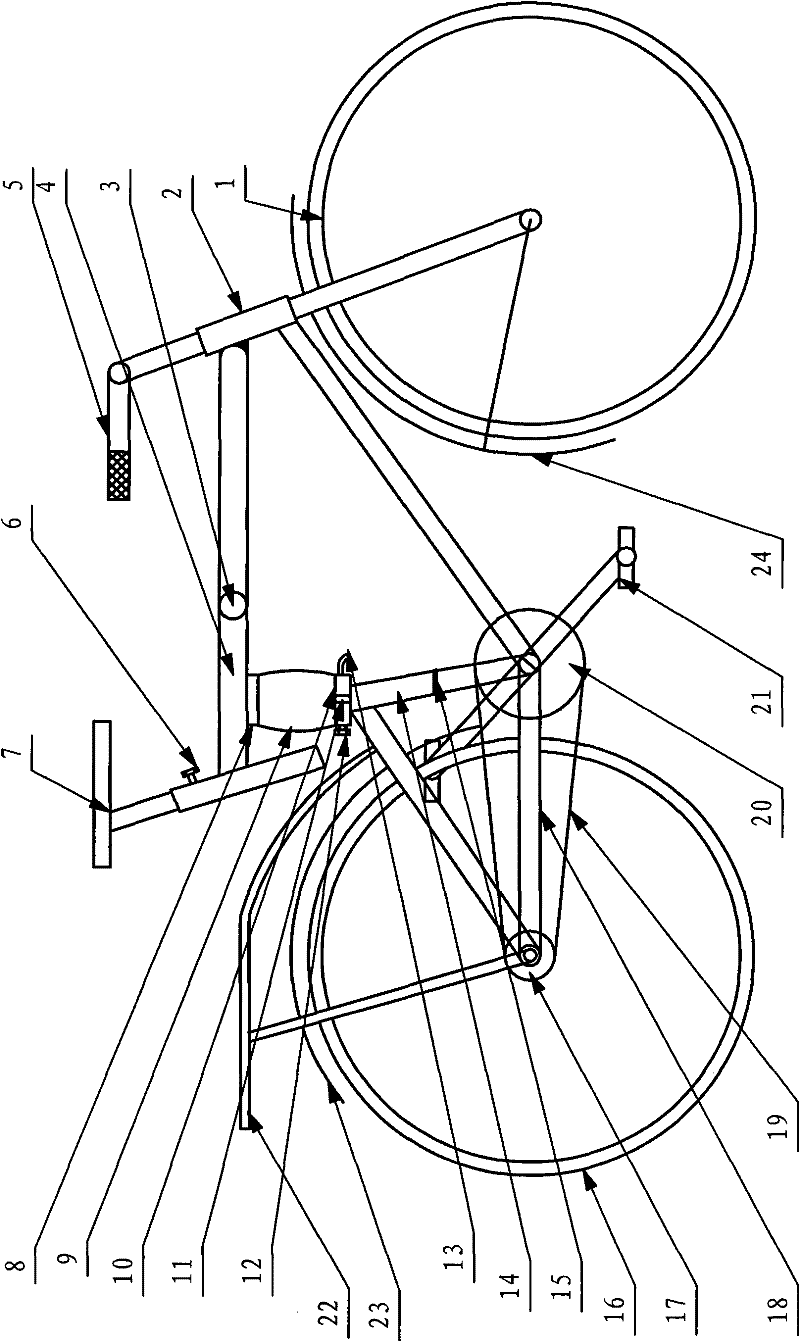

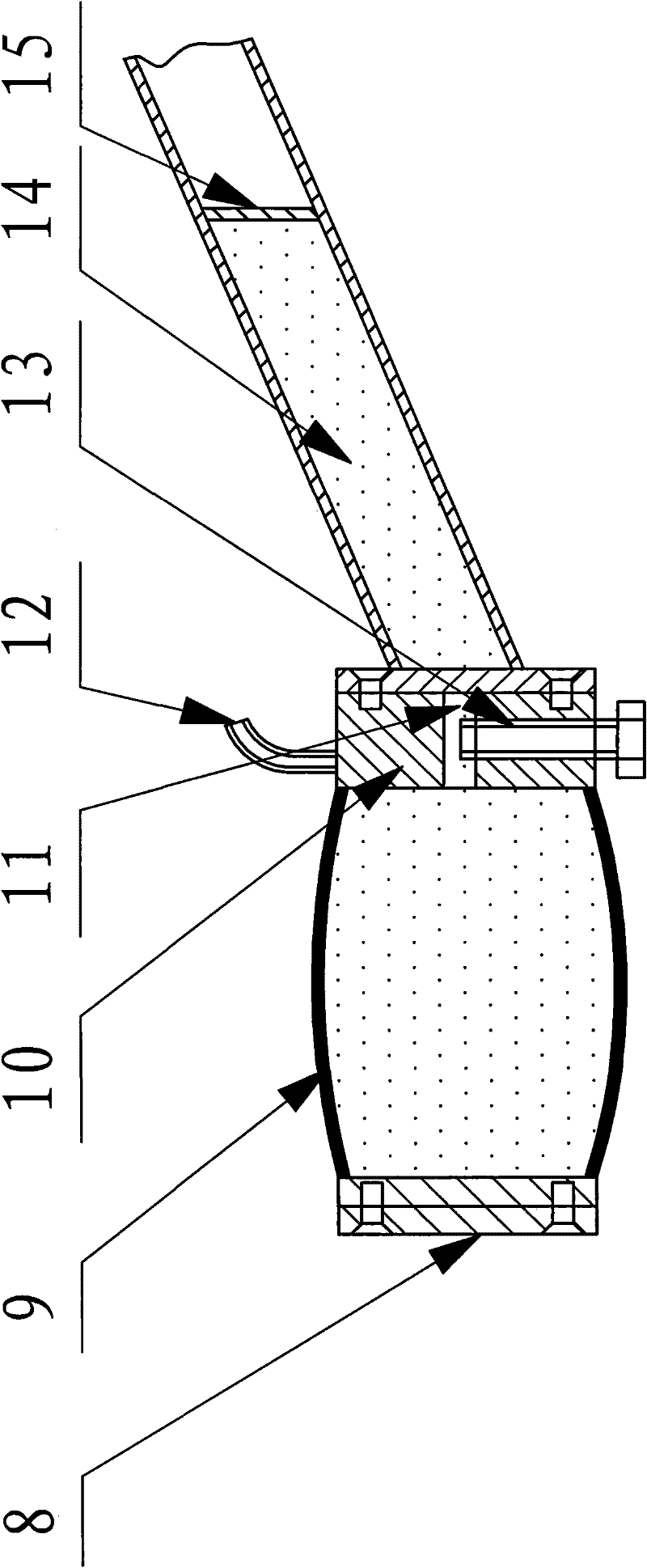

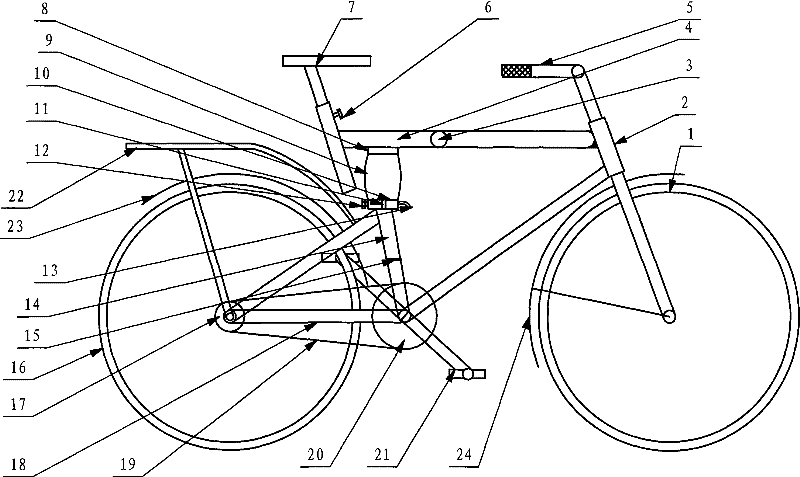

Air spring bicycle vibration damping method with additional air chamber and bicycle

InactiveCN102285309AReduce vibrationGood vibration dampingWindowsWindscreensVariable stiffnessVehicle frame

Owner:NANJING AGRICULTURAL UNIVERSITY

Method and apparatus for anticipatory all wheel and four wheel drive engagement

A system includes a processor configured to automatically engage all wheel drive (AWD) when a vehicle reaches areas along a route that were previously flagged as slippery, in a memory in communication with the processor. The flagging may have occurred, for example, based on existence of unpaved roads or precipitation at those areas.

Owner:FORD GLOBAL TECH LLC

Pneumatic tire

ActiveCN110234519AIncrease the edgeEffective controlOff-road vehicle tyresTyre tread bands/patternsClassical mechanicsMechanical engineering

Provided is a pneumatic tire that is suitable for use as a tire for traveling on unpaved roads and that improves traveling performance on unpaved roads. Center blocks 10, which are provided in a center region of a tread section 1, are arrayed so as to form a pair of center blocks 10 between which there are interposed inclined grooves 30 that extend in an inclined direction with respect to a tire circumferential direction. The center blocks 10 are made to extend so as to straddle a tire equator CL from one side to the other side of the tire equator CL. Notches 11, which are each composed of a first wall 11a and a second wall 11b connected to each other in a V shape, are provided in treads in each center block CL. The first walls 11a are made to extend at an angle within + / -20 degrees with respect to the tire circumferential direction; the second walls 11b are made to extend at an angle of + / -10 degrees with respect to a tire width direction; and third walls 21 that each face a notch 11of a shoulder block 20 provided in a shoulder region of the tread section 1 are made to extend at an angle within + / -5 degrees with respect to a straight line A that connects an end point P1 of the first wall 11a on the shoulder block 20 side and an end point P2 of the second wall 11b on the shoulder block 20 side.

Owner:THE YOKOHAMA RUBBER CO LTD

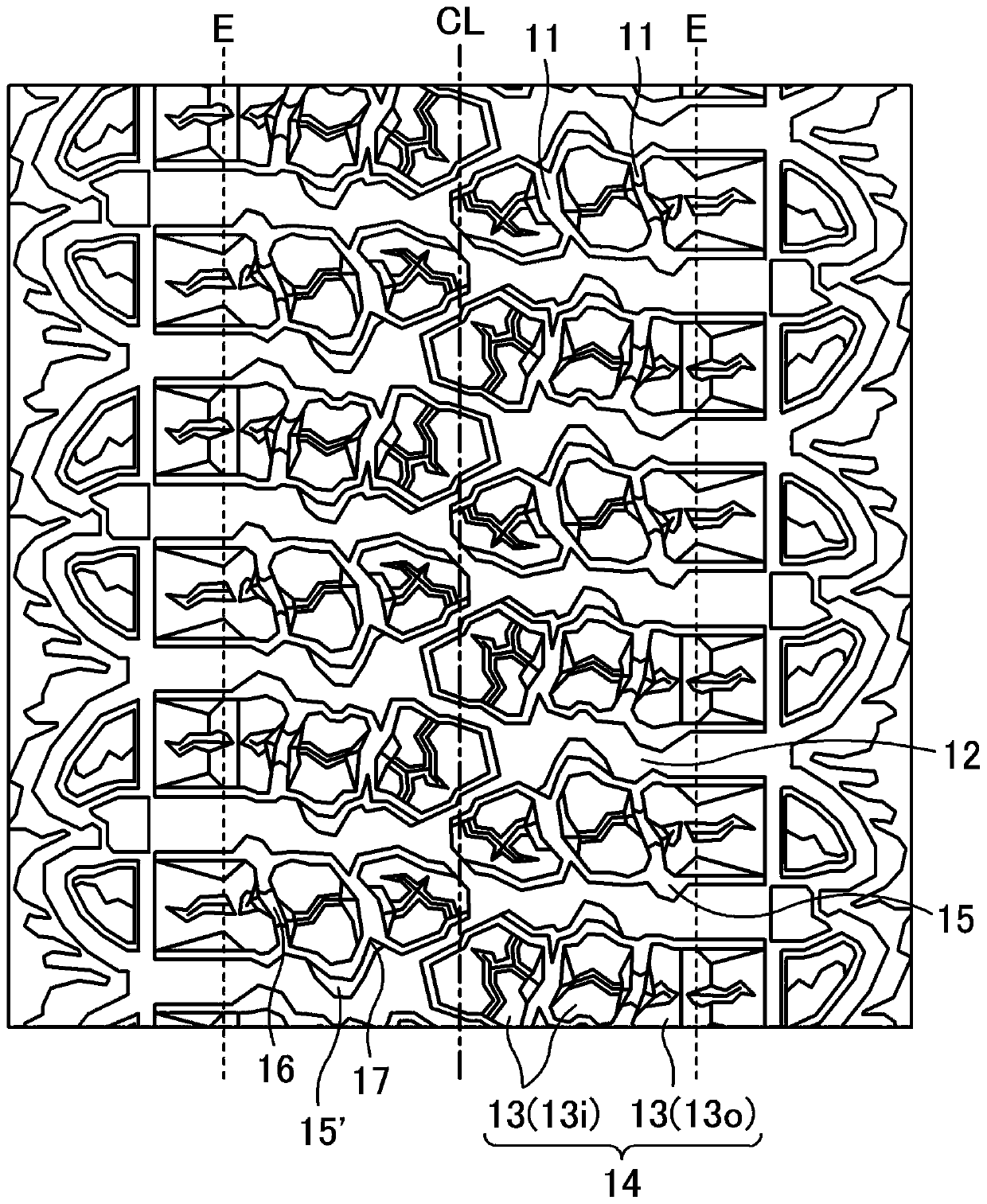

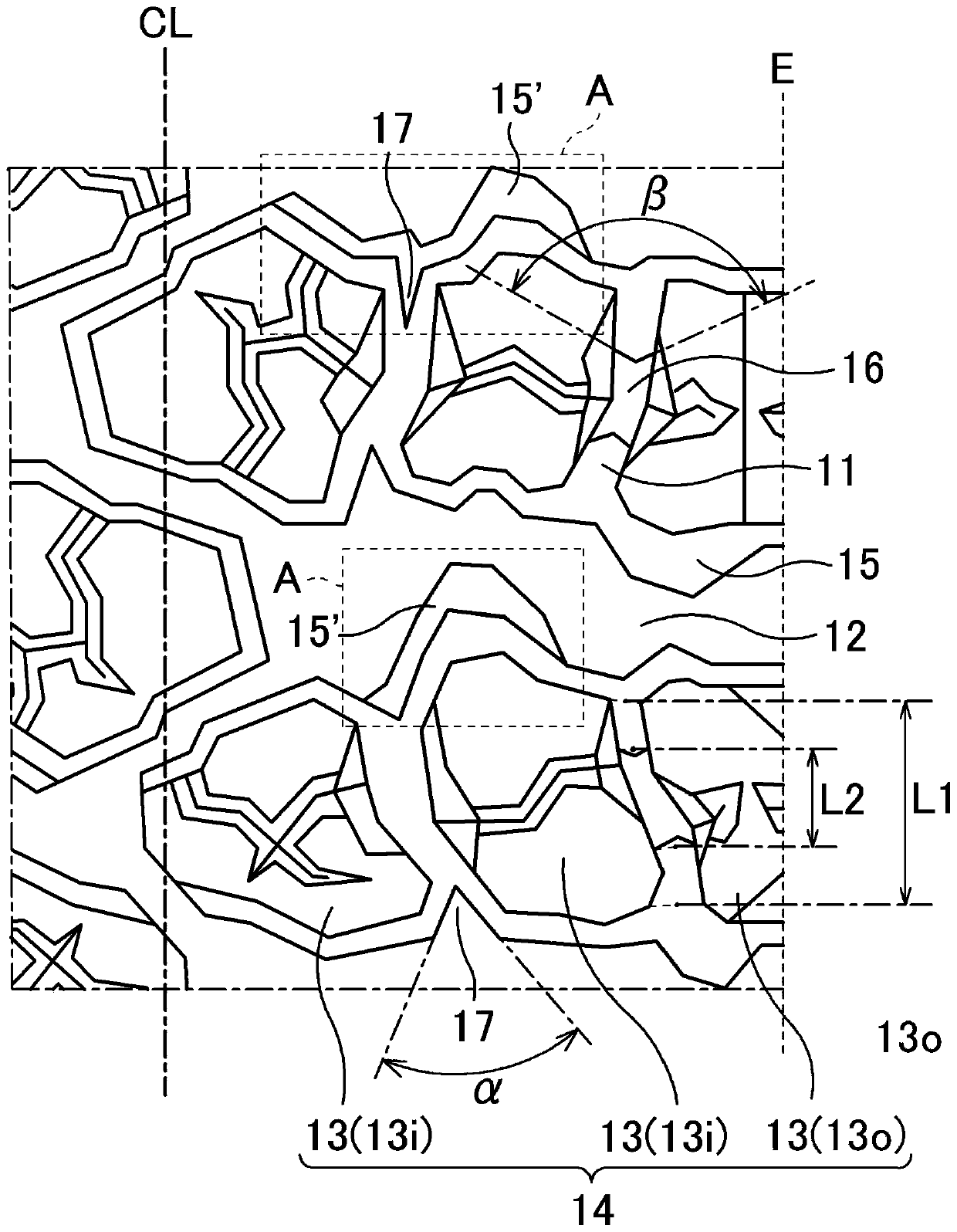

Pneumatic tire

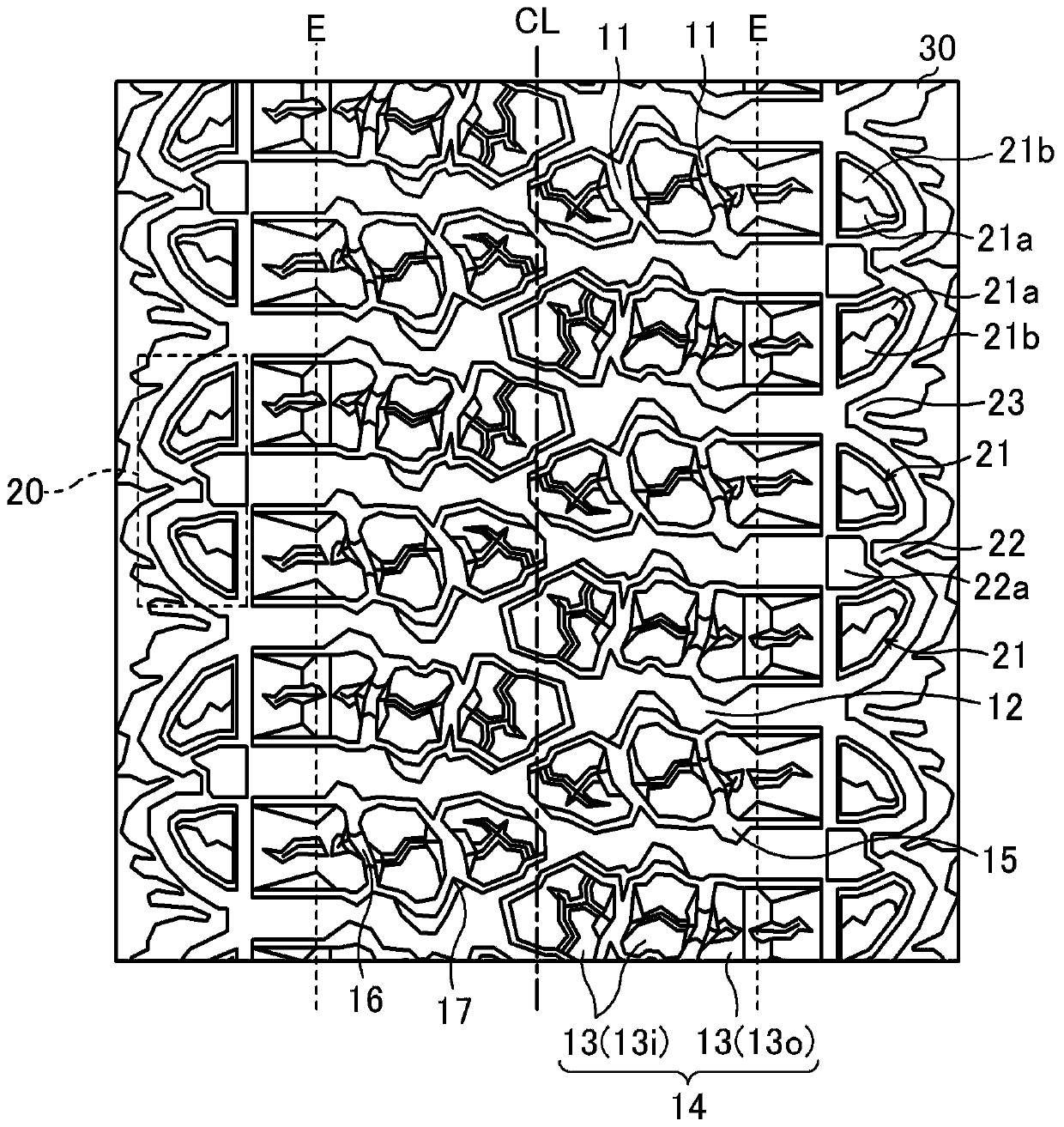

ActiveCN110914073AImprove rigidityImprove discharge effectOff-road vehicle tyresTyre tread bands/patternsMechanical engineeringTread

Provided is a pneumatic tire that is favorable for traveling on an unpaved road and shows improved traveling performance and anti-wear performance on an unpaved road. Of a plurality of blocks 13 formed in a tread portion, at least three blocks 13 that include an outermost block 13o located outermost in a tire width direction and are adjacent to each other in the tire width direction, and at leasttwo vertical grooves 11 located between these blocks 13, are arranged on a platform 15 that protrudes from a groove bottom of a horizontal groove 12, has a flat top surface, and projects to either side in a tire circumferential direction with respect to the at least three blocks 13, and a bottom raising portion 16 protruding from a groove bottom of the vertical groove 11 adjacent to the outermostblock 13o is provided on the groove bottom of the vertical groove 11, to connect the outermost block 13o to the block 13 adjacent to the outermost block 13o.

Owner:THE YOKOHAMA RUBBER CO LTD

Road surface matting

Owner:安东尼·安森

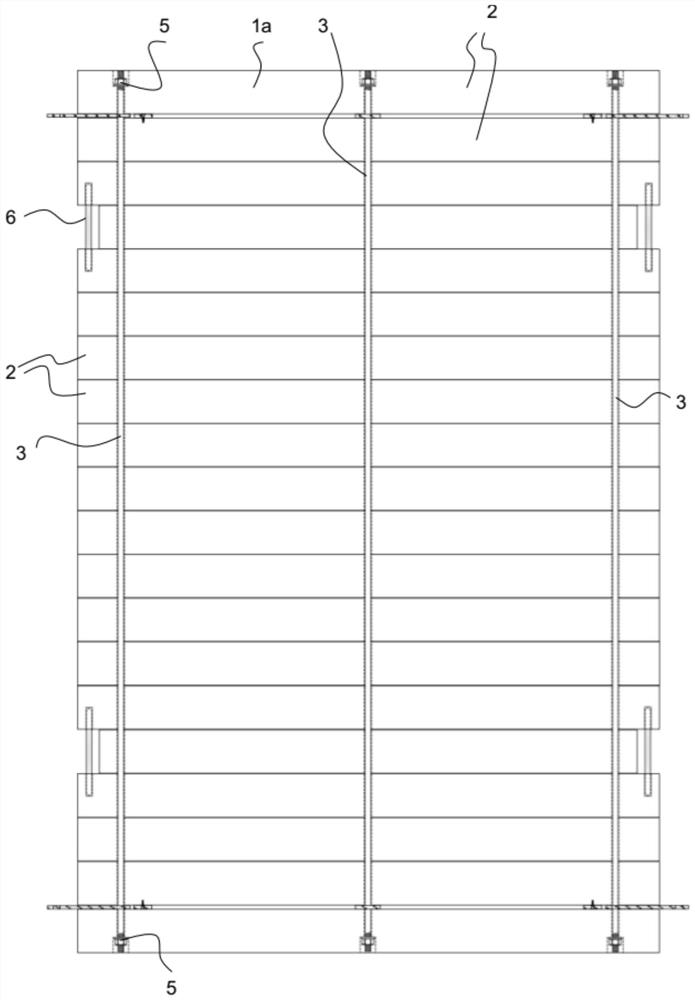

Road Surface Matting

PendingUS20220162809A1Single unit pavingsTemporary pavingsArchitectural engineeringStructural engineering

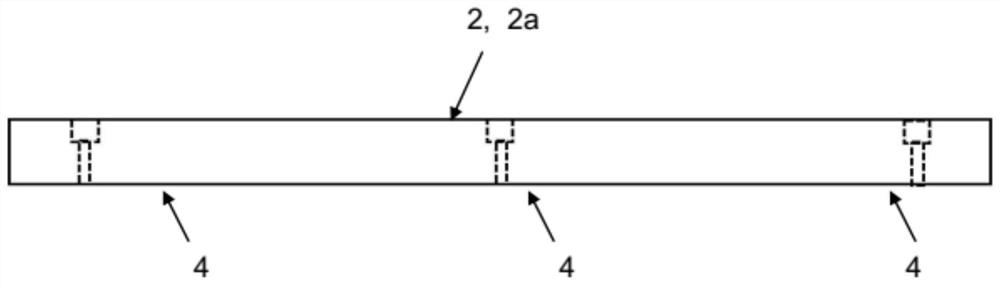

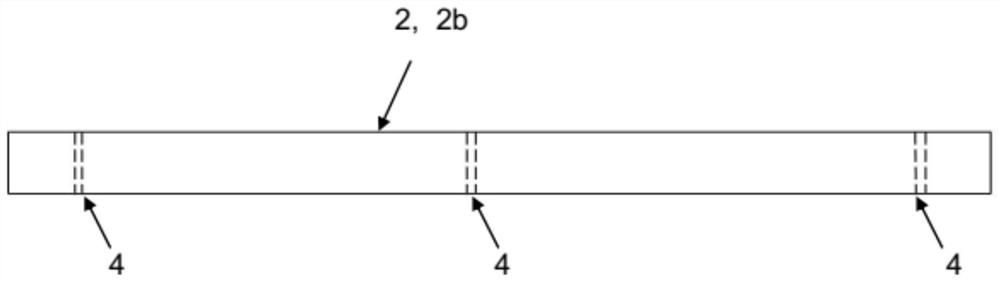

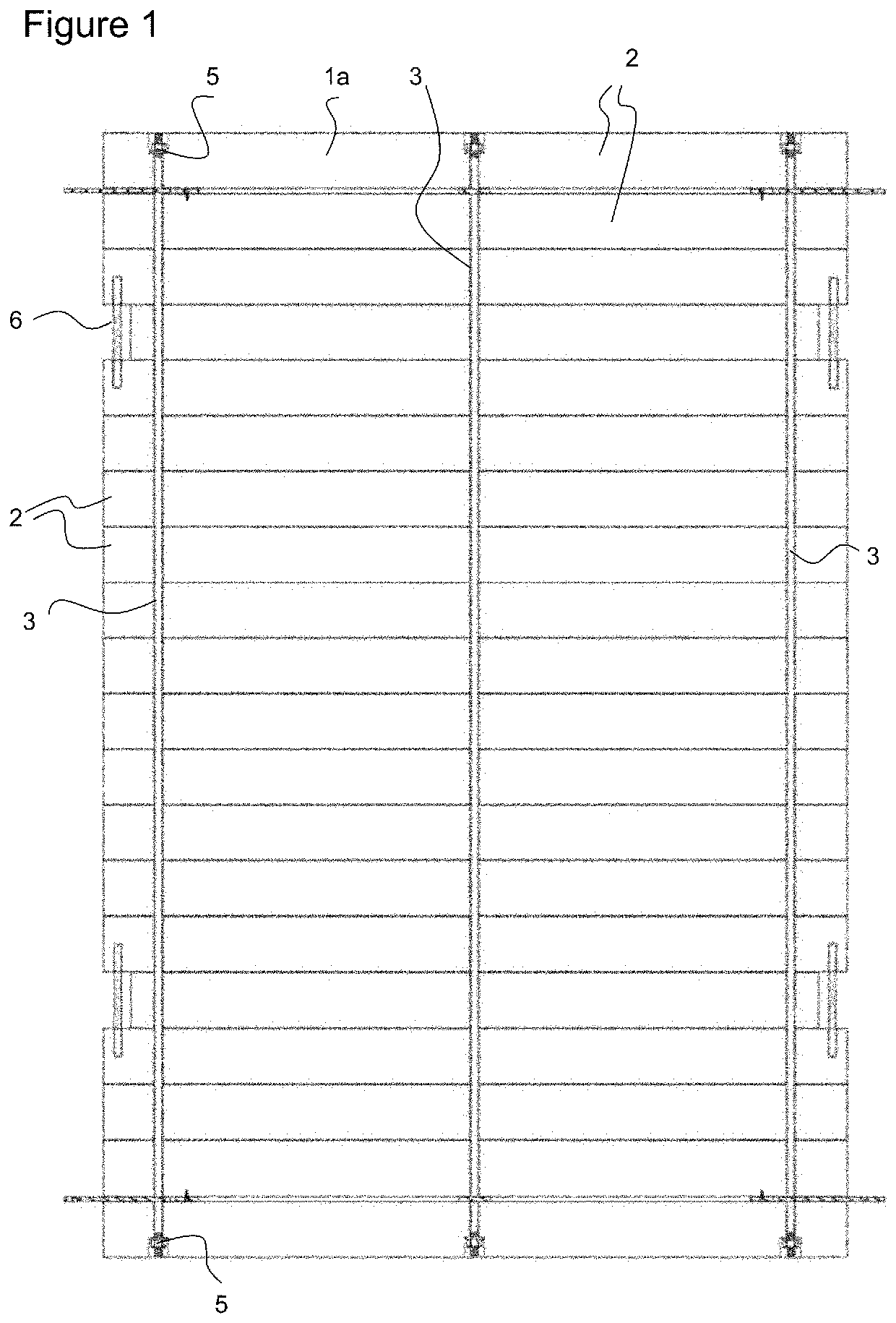

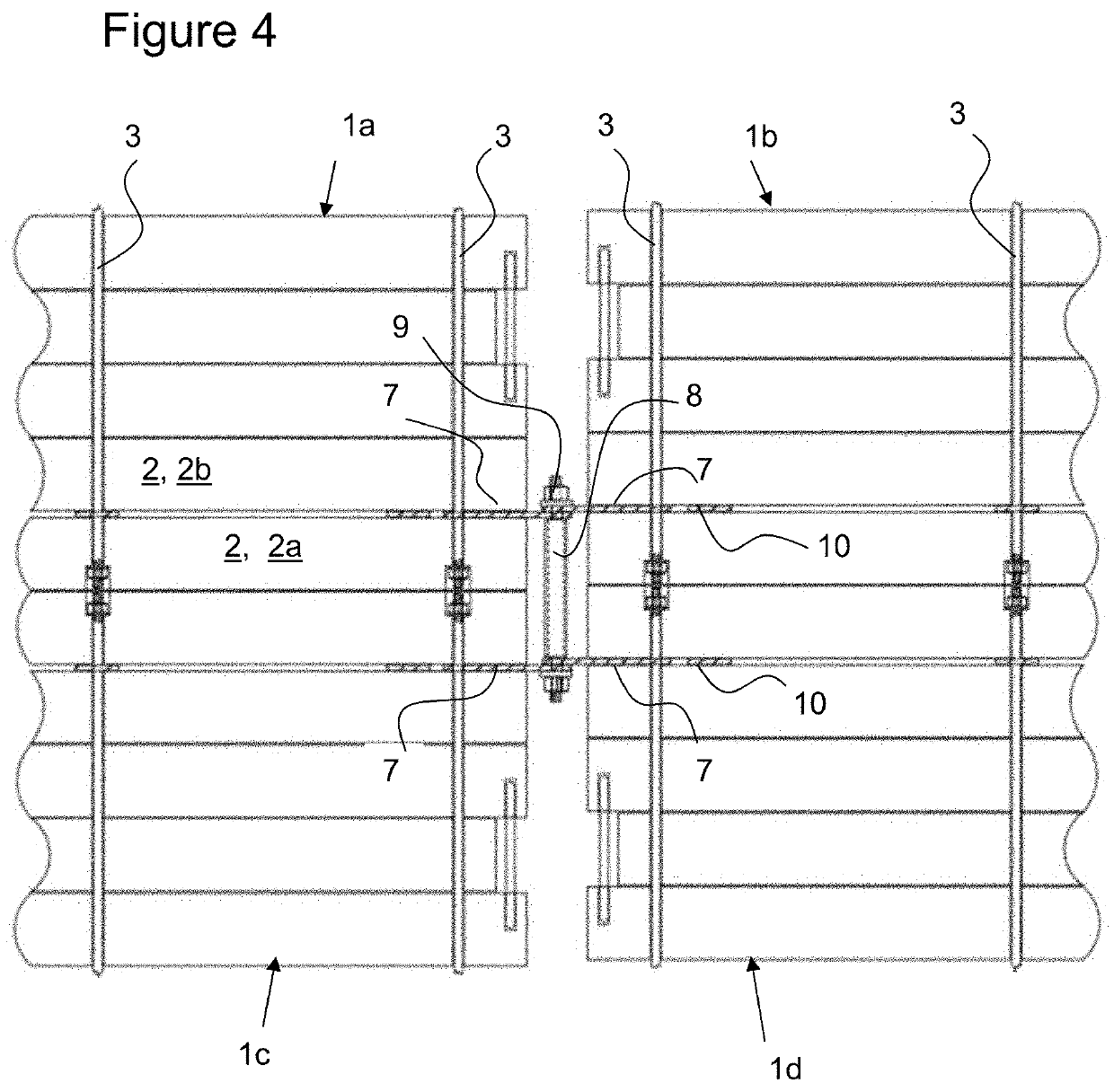

A problem with unpaved roads is that they can be prone to damage when driven on. The road surface matting includes a first mat 1a and a second mat 1b, each mat having a series of substantially parallel beams 2, a plurality of spine rods 3 that run substantially perpendicular to and through the beams and connect the beams to one another. Each mat also has a joiner 7 adjacent an edge of the mat, arranged so that one of the spine rods passes through the joiner. The matting is such that the first and second mats are connected to one another by way of a connecting rod 8 that passes through and joiner 8 of one mat and the joiner 8 of the other mat.

Owner:ANSON ANTHONY

Pneumatic tire

ActiveCN113573918AImprove traction performanceImprove driving performanceOff-road vehicle tyresTyre tread bands/patternsMechanical engineeringTread

Provided is a pneumatic tire that, even when the tire has an asymmetric pattern, enables uniformity and weight balance of the tire to be satisfactorily maintained while improving traveling performance in a unpaved road. Side blocks 30 are respectively provided to side regions adjacent to the outside in the tire width direction of the outermost end section of a tread part 1 in the tire width direction. The number N1 and the total area SS1 of the side blocks 30 provided to a first side region positioned on one side in the tire width direction, the number N2 and the total area SS2 of the side blocks 30 provided to a second side region positioned on the other side in the tire width direction, the land section area TS1 in a first tread region positioned on the first side region side of the tread part 1, and the land section area TS2 in a second tread region positioned on the second side region side of the tread part 1 satisfy the relationships of N1>N2 and TS1>TS2, and 0.95 <= (SS1xTS1) / (SS2xTS2) <= 1.05.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

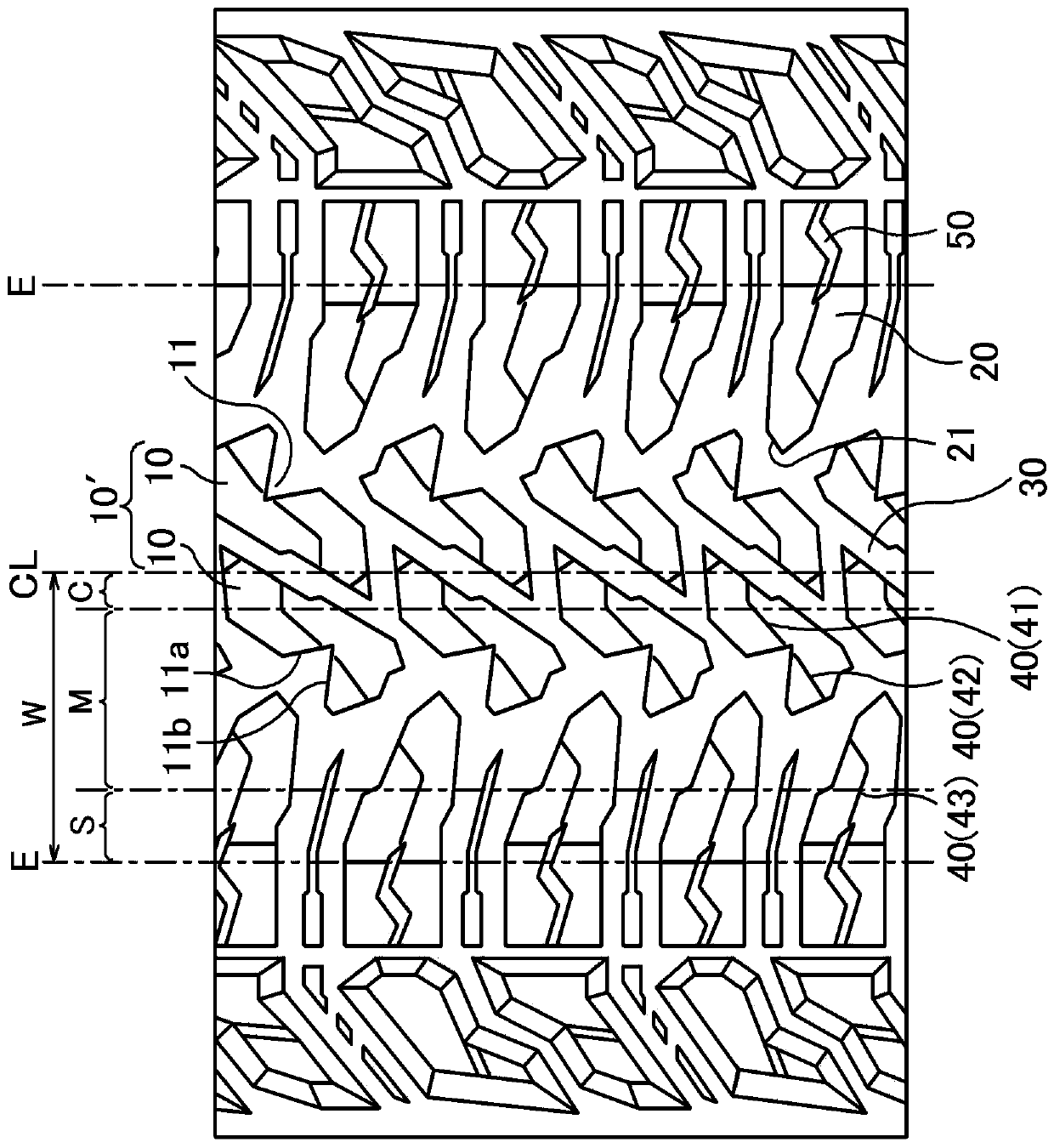

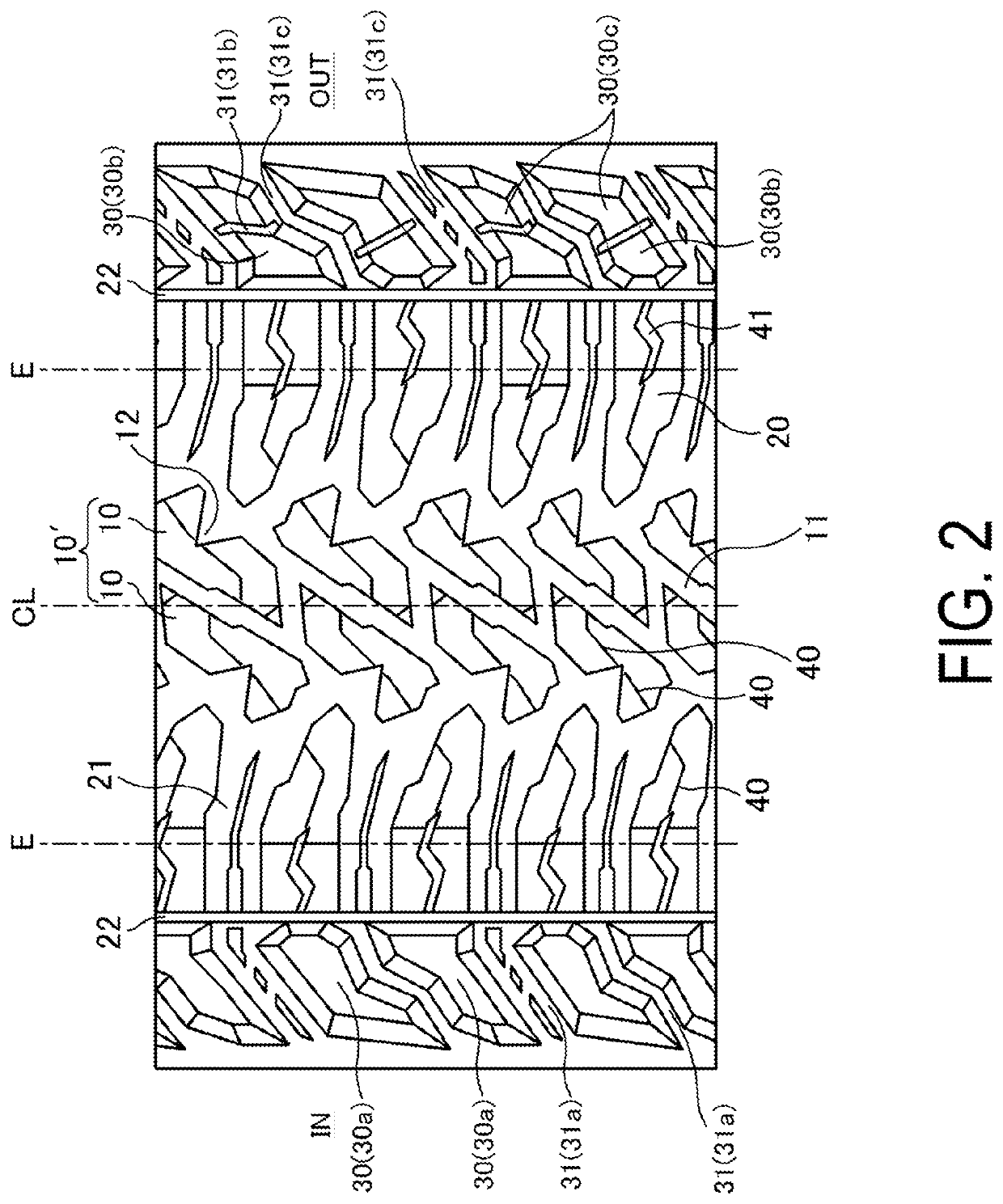

ActiveCN111655513AGreat tractionImprove drainage effectTyre tread bands/patternsEngineeringMechanical engineering

Provided is a pneumatic tire having improved noise performance and improved traveling performance on an unpaved road. The tread section 1 of the pneumatic tire has shoulder land sections 12 and a center land section 12, the shoulder and center land sections being defined on both sides of a tire equator CL by a pair of main grooves 10 extending in a zigzag pattern in a tire circumferential direction. The shoulder land sections 11 have formed therein shoulder lug grooves 20 extending in a tire width direction. The center land section 12 has formed therein: first center lug grooves 31 which continuously extend from the shoulder lug grooves 20 across the main grooves 10, are tilted relative to the tire width direction at an angle in the range of 45 degrees to 70 degrees, inclusive, and reach and terminate at the tire equator CL; and second center lug grooves 32 which terminate without reaching the tire equator CL. The first center lug grooves 31 and the second center lug grooves 32 are alternately arranged in the tire circumferential direction. The center land section 12 has formed therein connection grooves 40 tilted in the direction opposite the direction in which the center lug grooves 30 are tilted, and the connection grooves 40 connect the center lug grooves 30 with each other.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tires

ActiveCN111989229BIncrease the edgeImprove traction performanceHeavy duty tyresHeavy duty vehicleRoad surfaceMechanical engineering

The present invention provides a pneumatic tire capable of improving snow traction performance while maintaining good running performance on an unpaved road surface and uneven wear resistance performance. The lug grooves (20, 30) are alternately arranged, and the lug grooves (20, 30) are composed of: a first groove portion (21, 31) crossing the tire equator CL and extending in the tire width direction; The second groove portion (22, 32) is inclined from one end of the first groove portion (21, 31) at an angle smaller than the angle of the first groove portion (21, 31) relative to the tire circumferential direction and extends to one side of the tire equator The other end of the first groove portion (21, 31) communicates with the second groove portion (32, 22) Arranging the first groove portion (21, 31) at a position closer to the tread side than the end portion of each lug groove (20, 30) on the tread end E side, with the second groove portion (22, 32) The second groove portion (22, 32) is bent or bent in such a manner that the average angle θa in the inner region A is smaller than the average angle θb in the outer region B, and the second grooves to be adjacent in the tire circumferential direction Circumferential thin grooves (40) and lug grooves (20, 30) connecting the portions (22, 32) to each other demarcate the tread of the block (50) forming a shallow groove (60) having at least one inflection point.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com