Pneumatic tire

A technology of pneumatic tires and tires, which is applied in the direction of off-road vehicle tires, tire parts, tire treads/tread patterns, etc., can solve the problems of easy damage and cutting resistance of the groove bottom, achieve good configuration, improve driving performance, and improve The effect of locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

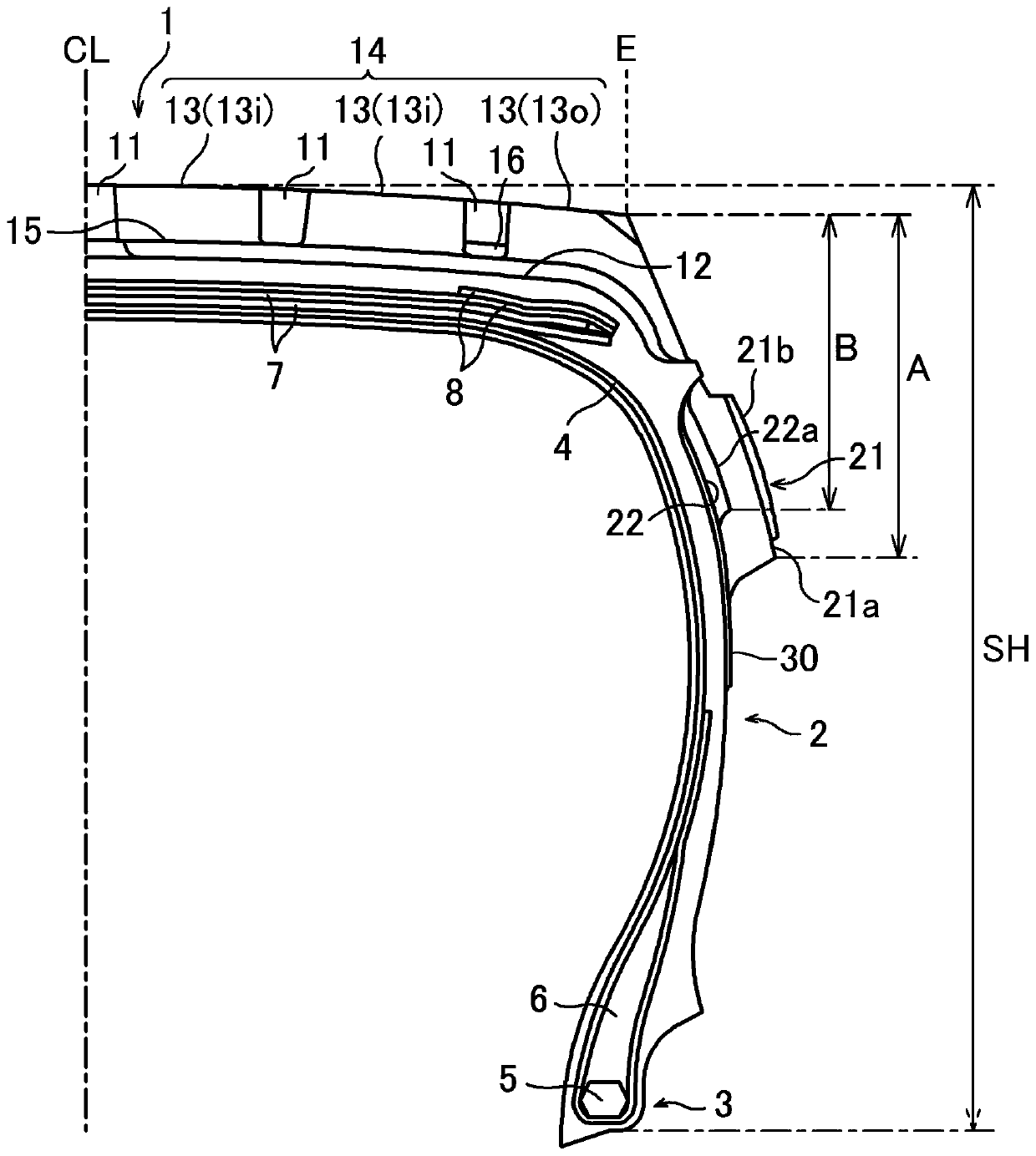

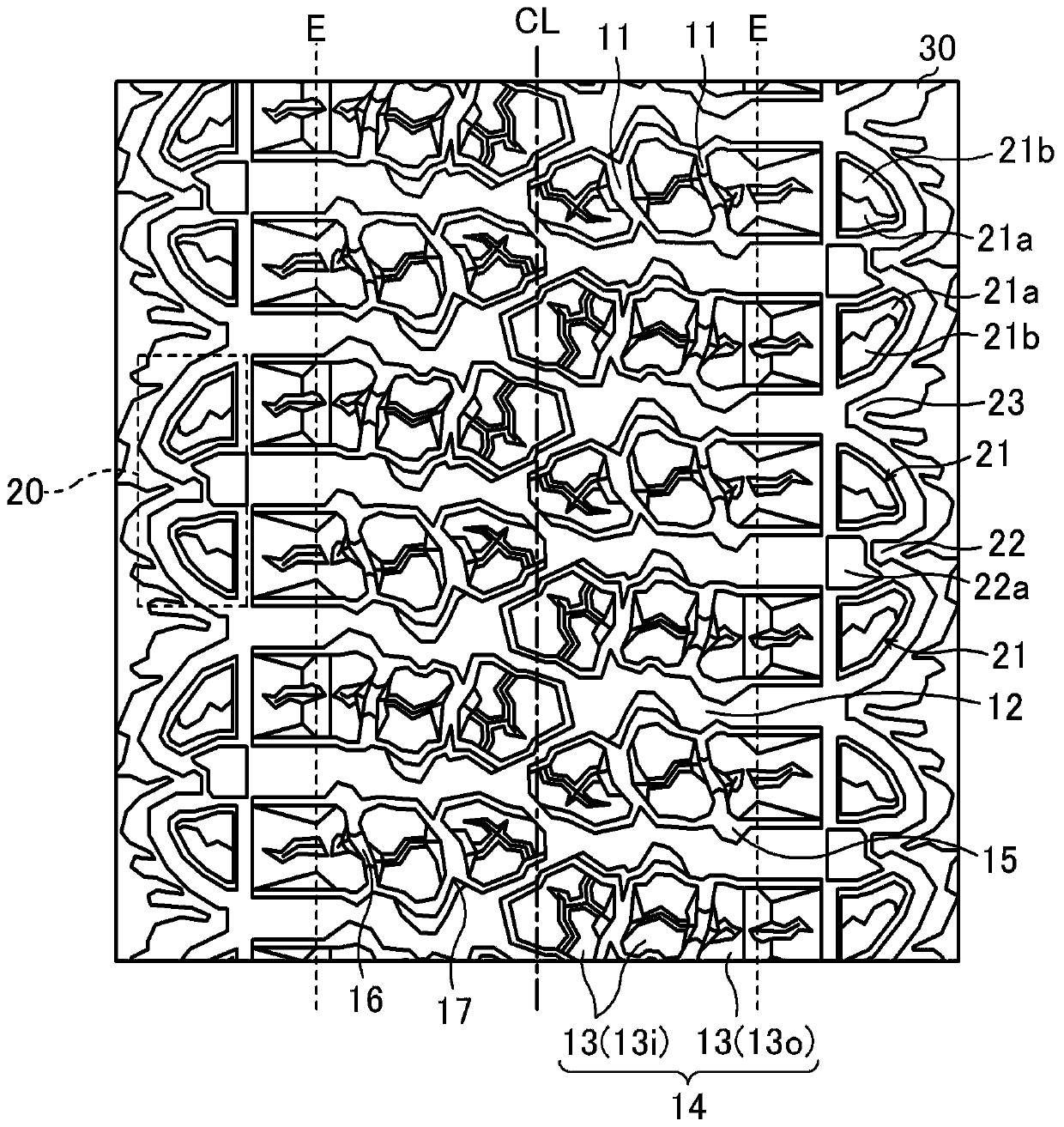

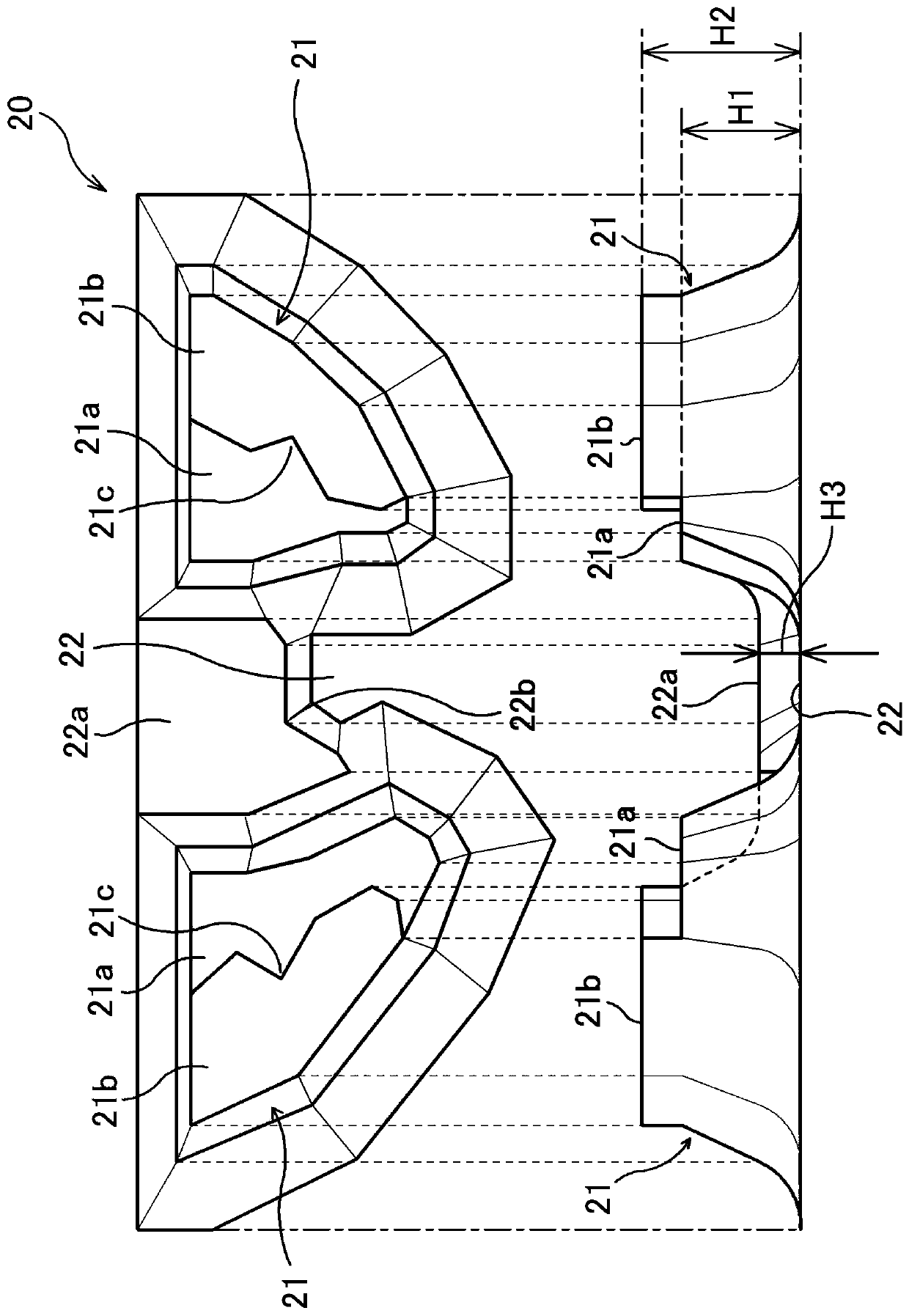

[0049] 23 kinds of pneumatic tires of the following conventional example 1, comparative examples 1-2, and embodiments 1-20 were produced: the tire size was 35×12.50R17 and had figure 1 The basic structure of the example and the figure 2The tread pattern is the basic tone, and, regarding the structure of the sidewall region, the presence or absence of the stepped portion of the sidewall block, the presence or absence of the bottom raised portion in the sidewall groove, and the The ratio A / SH of the vertical distance A measured from the ground contact end position of the tread portion to the radial inner end of the sidewall block to the tire section height SH measured in the radial direction of the tire, and the distance between the reference plane of the sidewall block and the sidewall groove Protrusion amount H1 of the groove bottom, ratio of protrusion amount H2 of the step portion of the sidewall block from the groove bottom of the sidewall groove to the protrusion amount H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com