Pneumatic tire

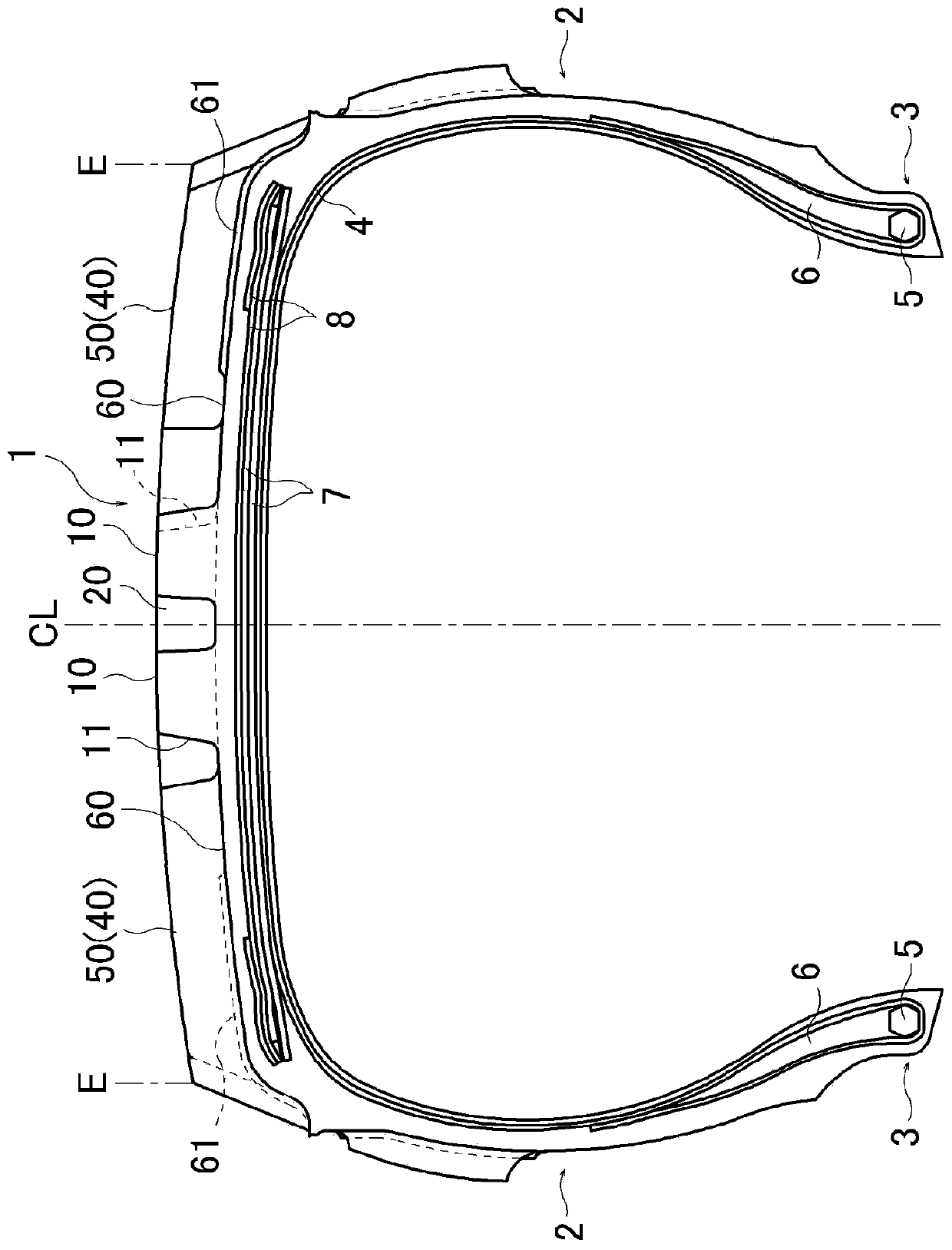

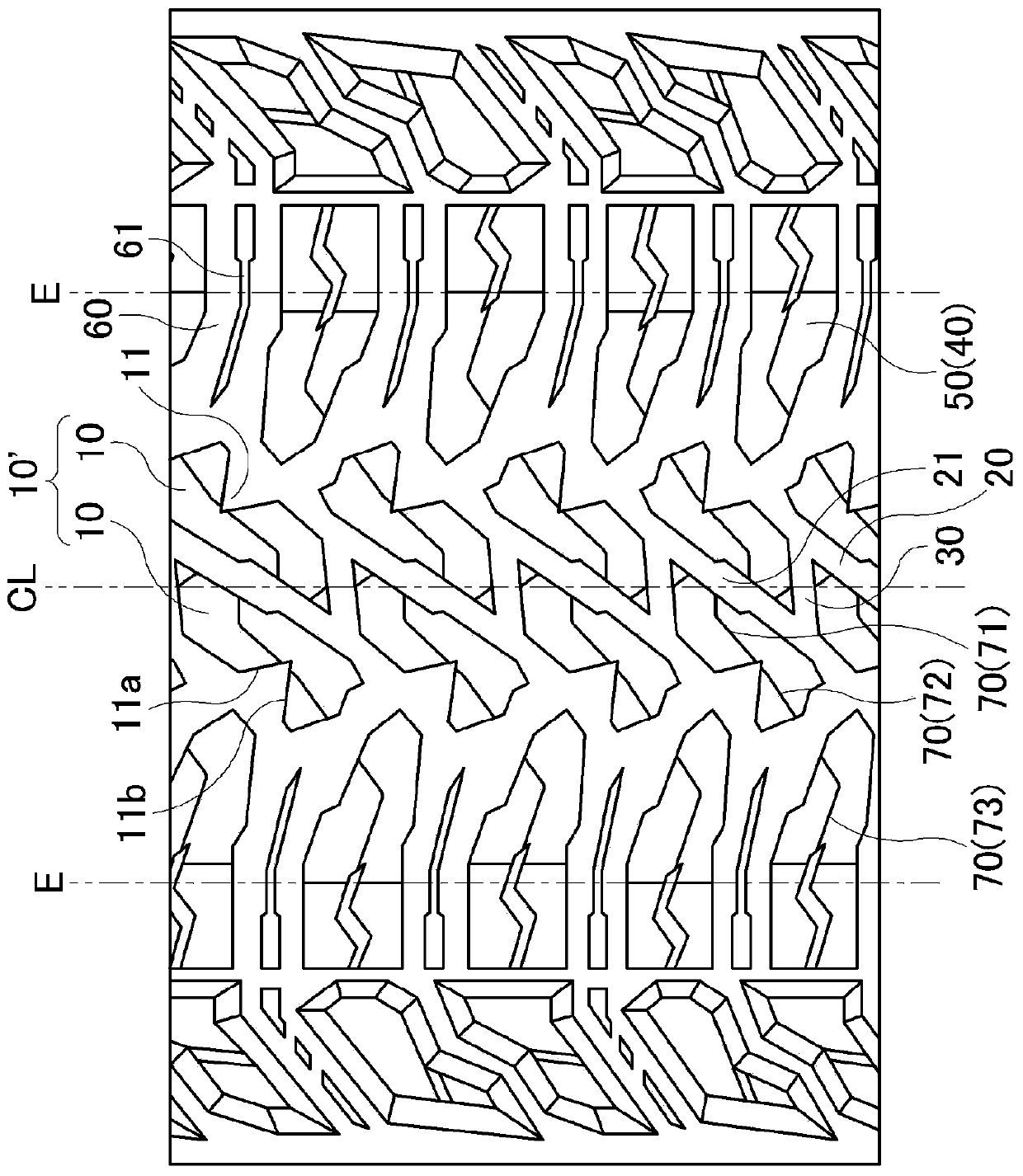

A technology for pneumatic tires and tires, which is applied to heavy-duty tires, off-road vehicle tires, tire parts, etc. It can solve the problems of easy damage to the middle block, large groove area, and difficulty in ensuring block rigidity, so as to maintain block rigidity and improve durability. Damage resistance, the effect of improving traction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

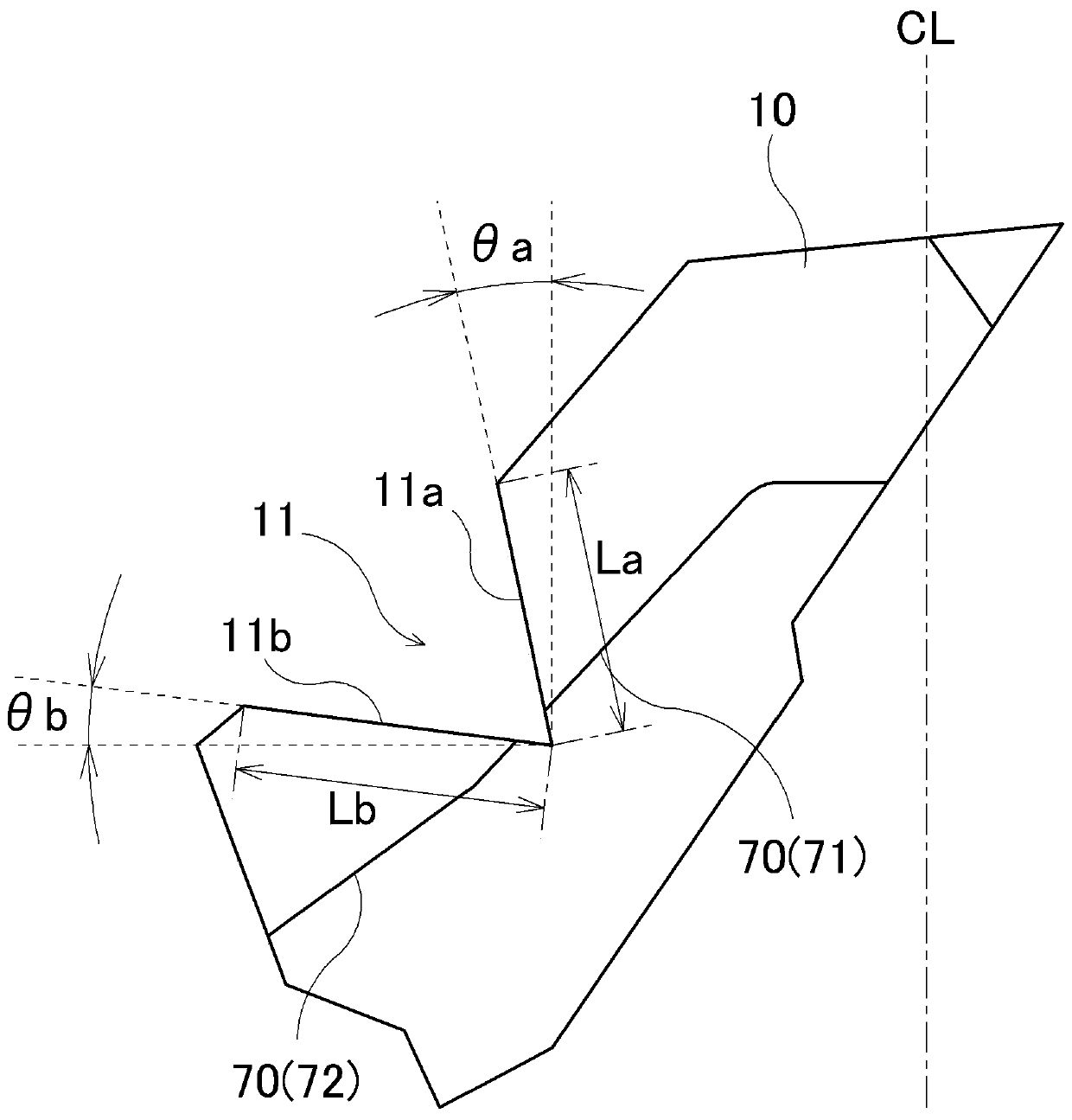

[0049] Made a tire size LT265 / 70R17 with figure 1 The basic structure of the example and the figure 2 The tread pattern is the basic tone, and the angle θa of the first wall relative to the tire circumferential direction, the angle θb of the second wall relative to the tire width direction, the wall surface angles of the first wall and the second wall, and the length La of the first wall The ratio Lb / La to the length Lb of the second wall, the area of the cutout relative to the ground contact area of the central block, the angle of the connecting groove with respect to the tire width direction, the magnitude relationship between the length La of the first wall and the distance Db, the second The relationship between the wall length Lb and the distance Da, the inclination direction of the shoulder inclined groove, the wall angle of the shoulder block, the groove width change of the shoulder inclined groove, the position of the outer end of the groove bottom protrusion, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com