Pneumatic tire

A technology for pneumatic tires and tires, which is applied to off-road vehicle tires, tire parts, tire treads/tread patterns, etc., can solve the problems of low driving performance, low performance noise performance, etc., to improve driving performance and increase the width direction. Effects of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

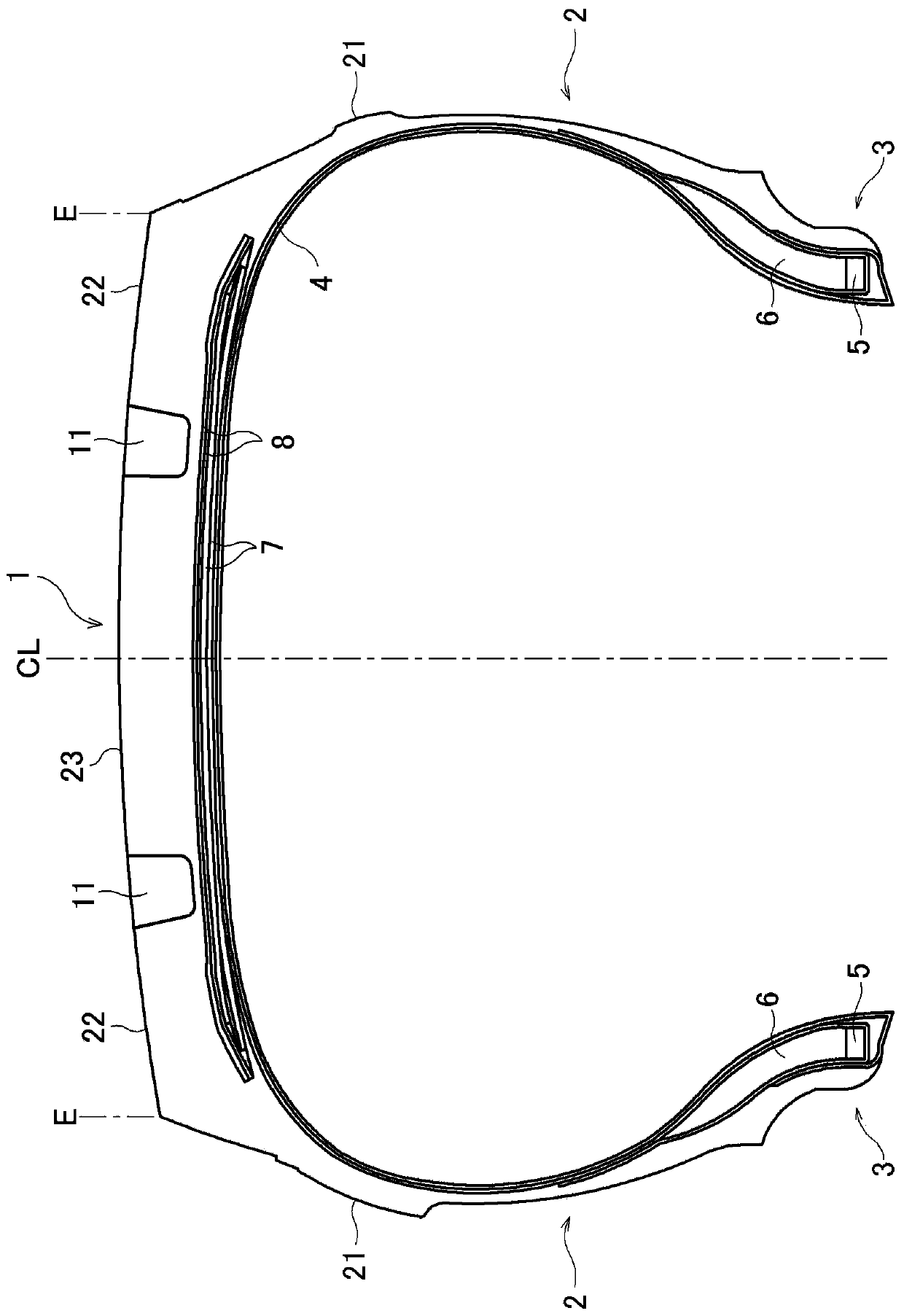

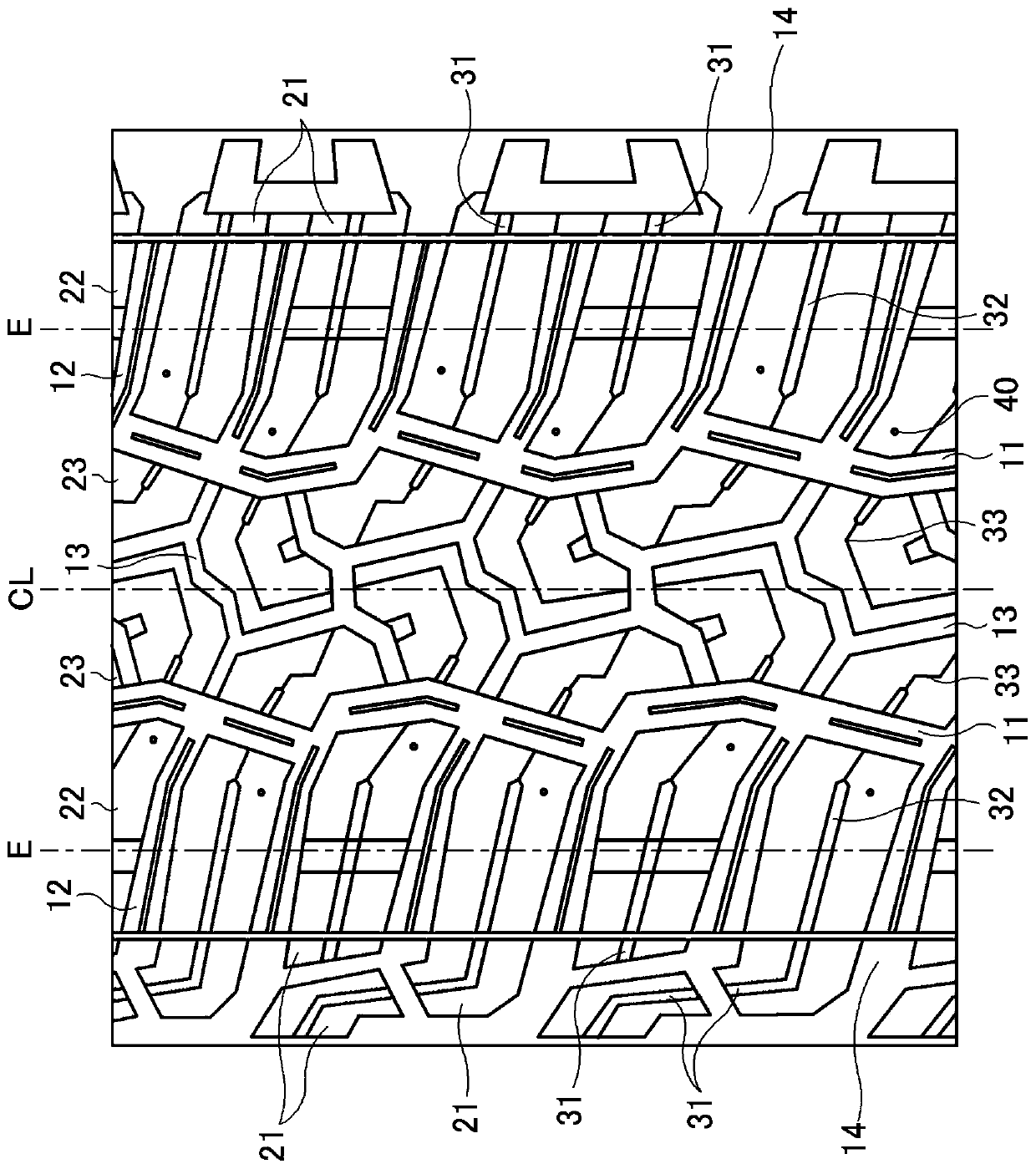

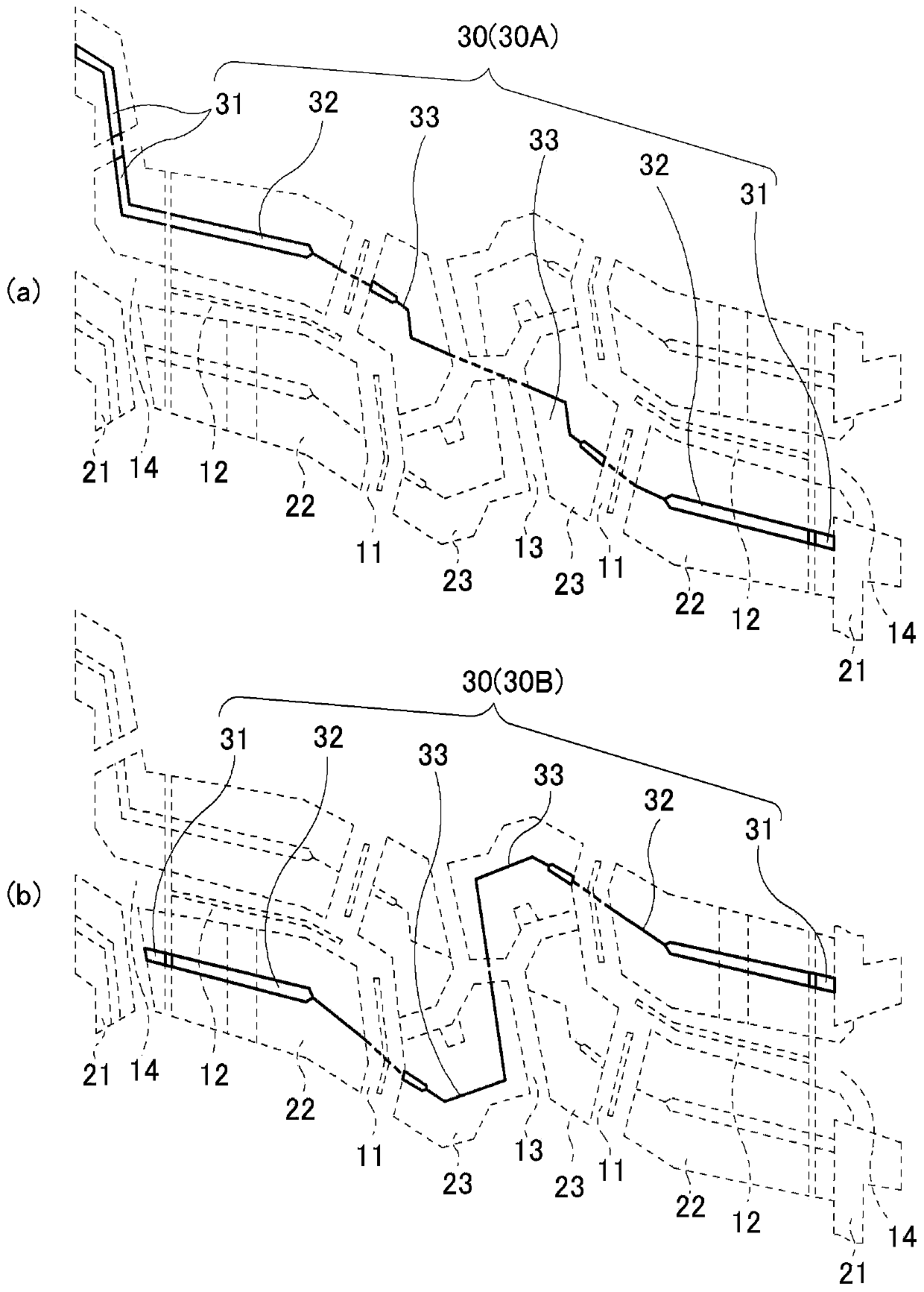

[0047] The tire size is LT265 / 70R17 121Q, with figure 1 The illustrated basic configuration and the figure 2 The tread pattern is the keynote and will be the continuous existence of the transverse groove group, the shape of the first to third groove elements, the type of the transverse groove group, the presence or absence of the intersection of the transverse groove group, the presence or absence of the side block pair, The presence or absence of shoulder block pairs was set as in Table 1 for the 11 pneumatic tires of Comparative Examples 1 to 4 and Examples 1 to 7, respectively.

[0048] Regarding the presence or absence of continuity of the transverse groove group, describe the first groove element and the second groove element on one side in the "First / Second (one side)" column of "Continuity of the transverse groove group" in Table 1 Whether it is continuous or discontinuous, in the "second / third (one side)" column of "continuity of transverse groove group" in Table 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com