Electric bicycle center shaft force moment sensing device

A technology of electric bicycles and sensing devices, which is applied to vehicle components, rider driving, transportation and packaging, etc. It can solve the problems of non-zero start, poor measurement accuracy, inaccurate output of induced potential signals, etc., and achieve stable driving performance , high sensitivity and high precision, stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

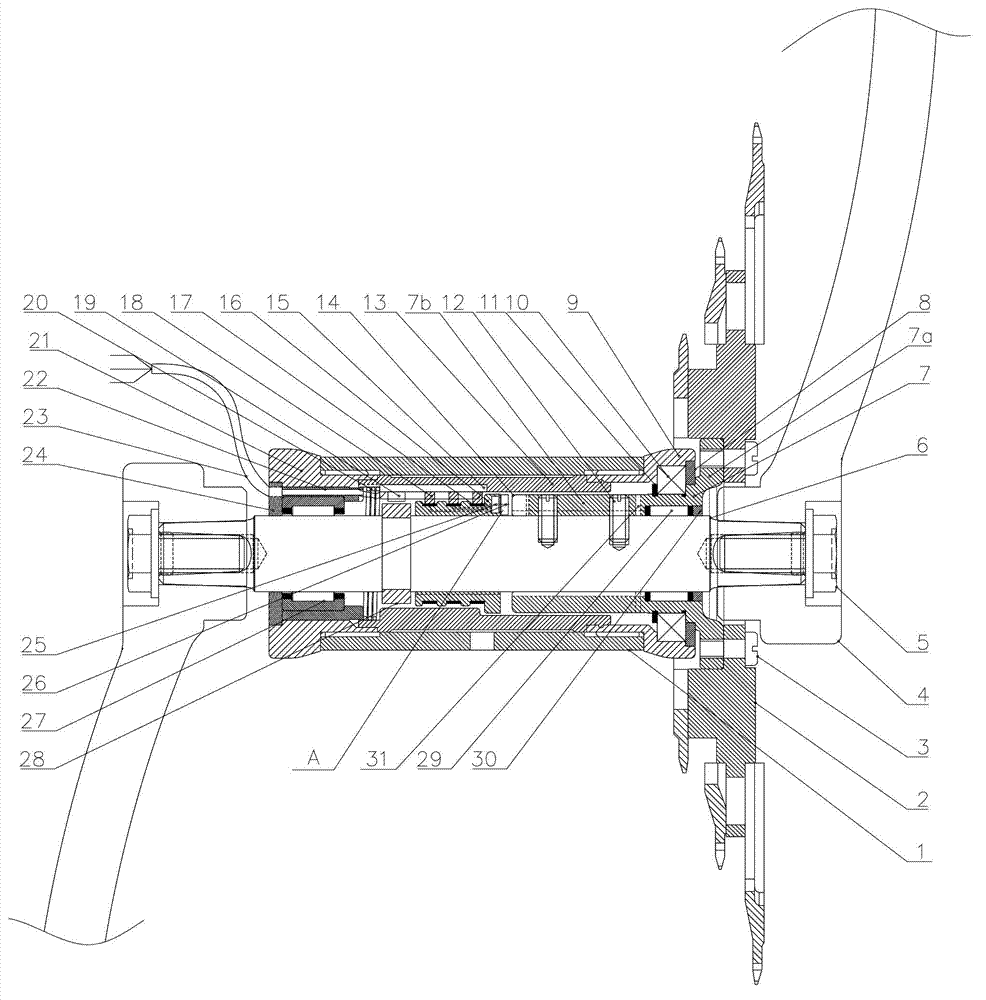

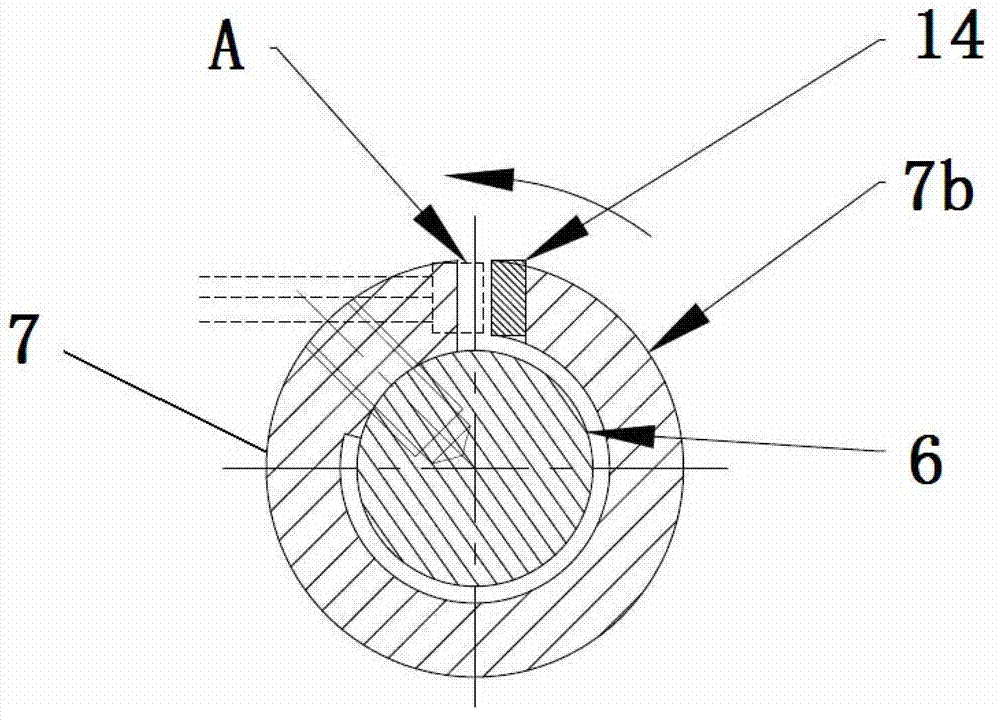

[0024] Example: Combine Figure 1 ~ Figure 2 As shown, the specific embodiment of the torque sensing device for the center shaft of this electric bicycle provided by the present invention is specifically composed of a bottom bracket 1, a tooth plate 2, a tooth plate fixing screw 3, a crank 4, a bolt 5, and a center shaft 6 , elastic torsion member 7, dust-proof retaining ring 8, right wrist guard 9, deep groove ball bearing 10, circlip for shaft 11, center shaft fixing screw 12, positioning bushing for outgoing circuit board 13, torque sensing magnet 14, Outlet circuit board 15, collector ring bracket 16, collector ring 17, conductive brush 18, speed sensing Hall body 19, adjustment spring 20, left wrist guard 21, outlet bushing 22, outlet wire 23, outlet retainer 24, The torque sensing Hall element A, the left needle roller bearing 27, the speed induction magnetic steel 28, the right needle roller bearing 29 and the sealing ring 30 are composed of these parts.

[0025] Same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com