Patents

Literature

35results about How to "Curb dumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

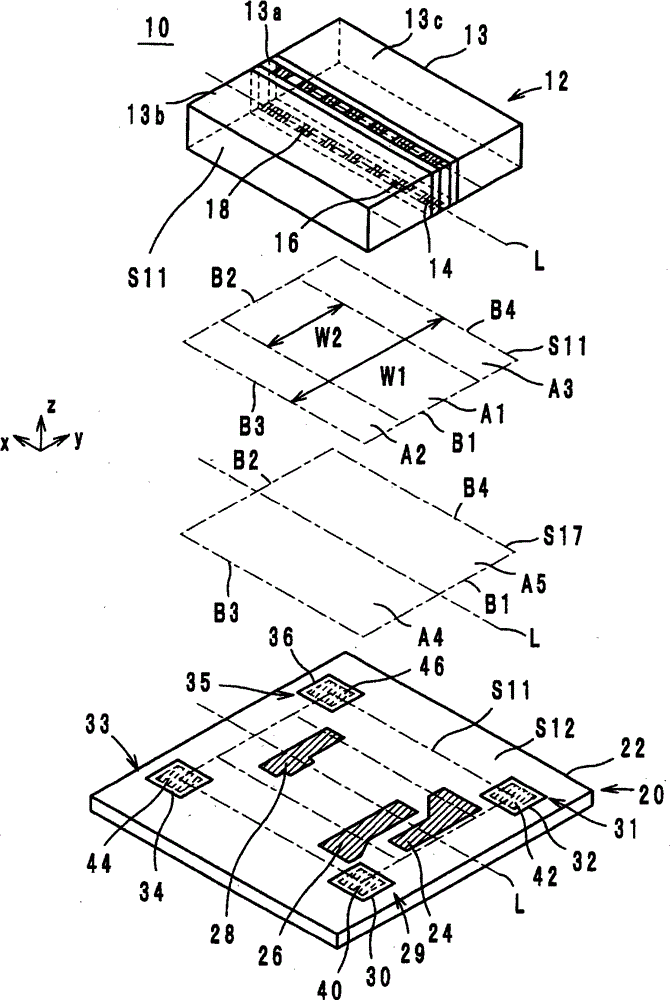

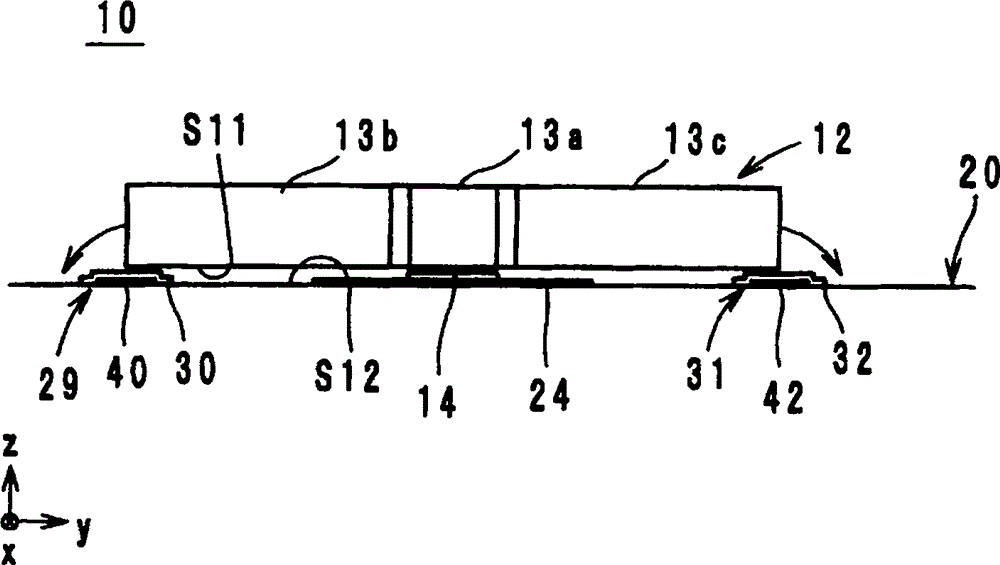

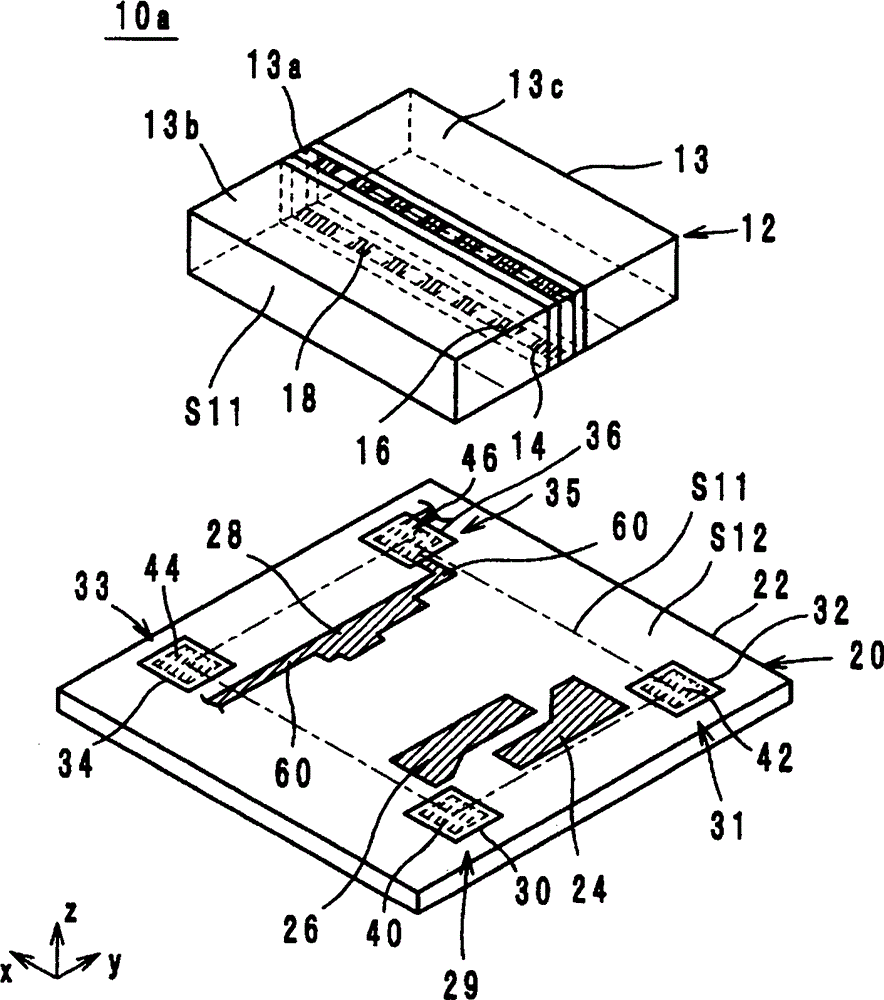

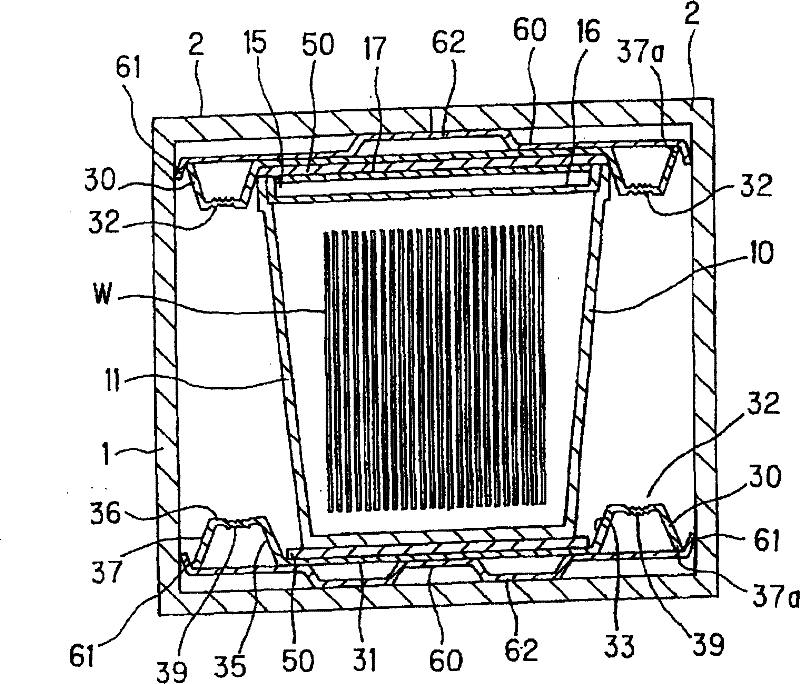

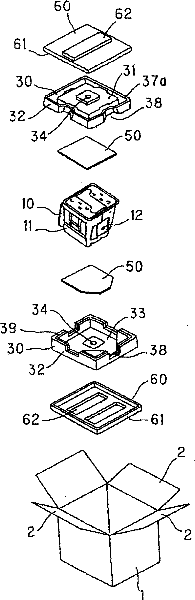

Packaging body

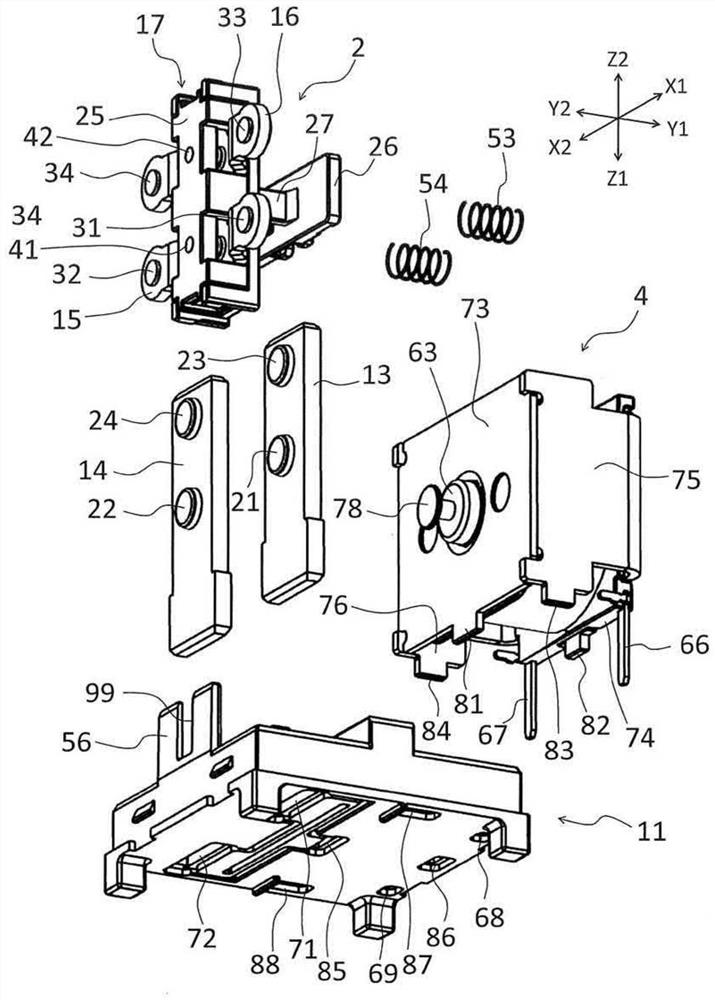

InactiveCN101309842AAvoid shockAvoid damageSemiconductor/solid-state device manufacturingPackagingElastomerEngineering

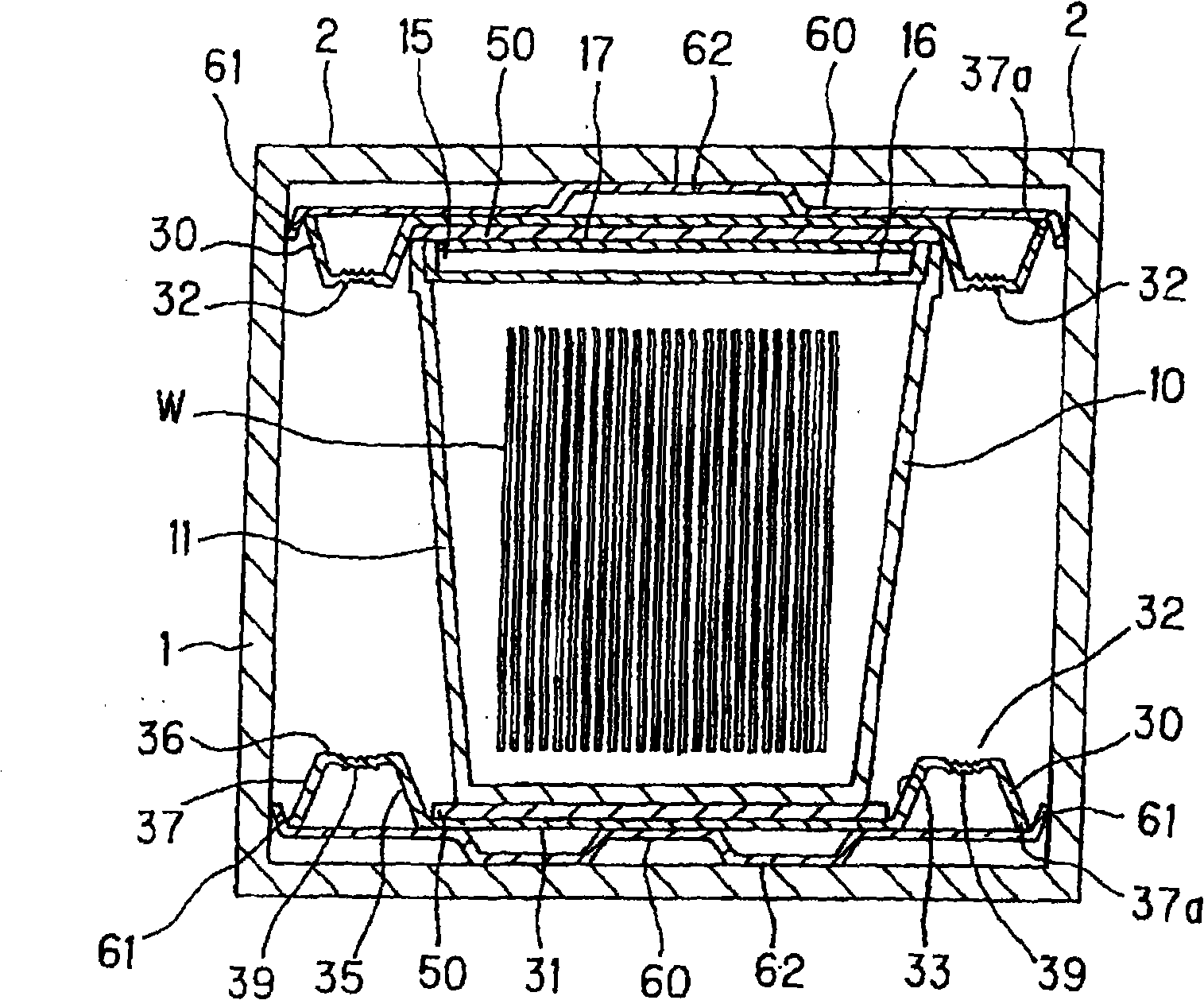

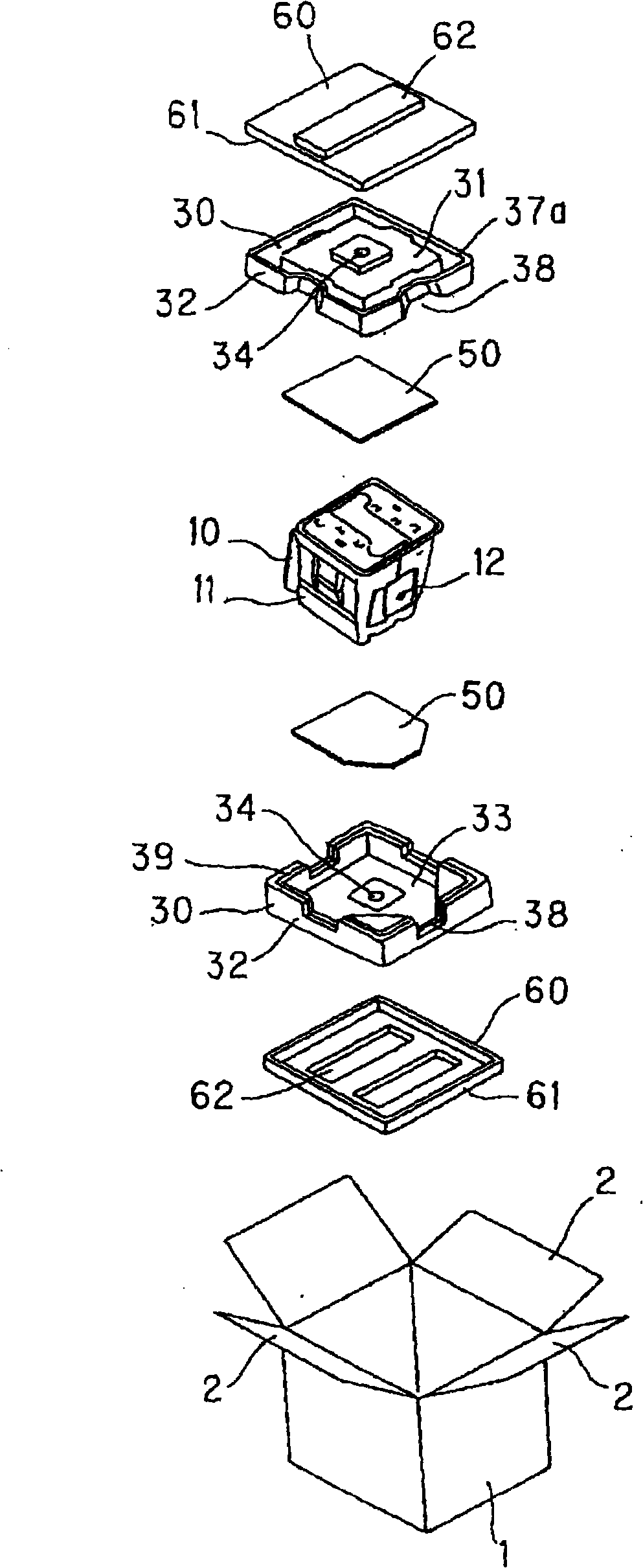

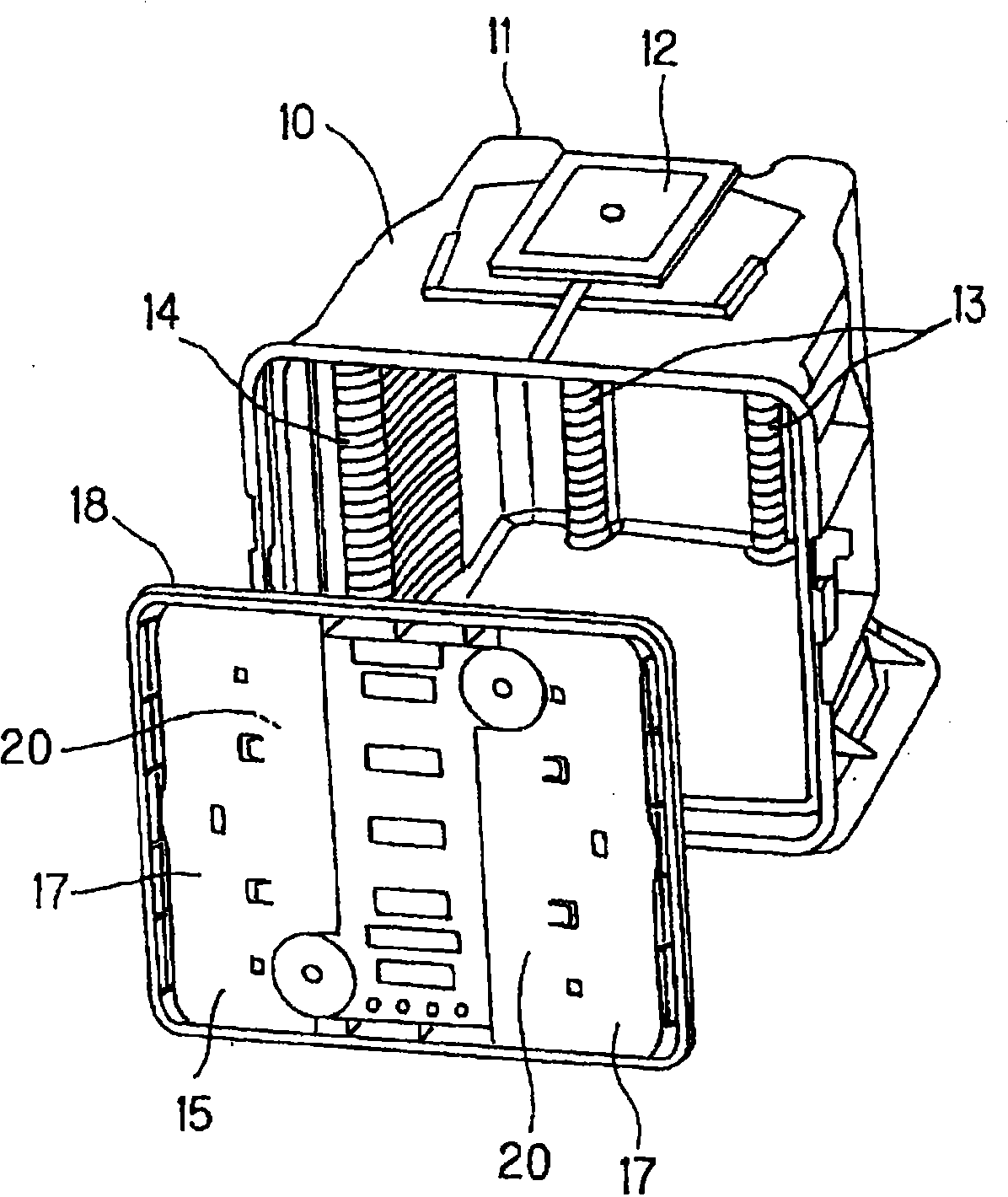

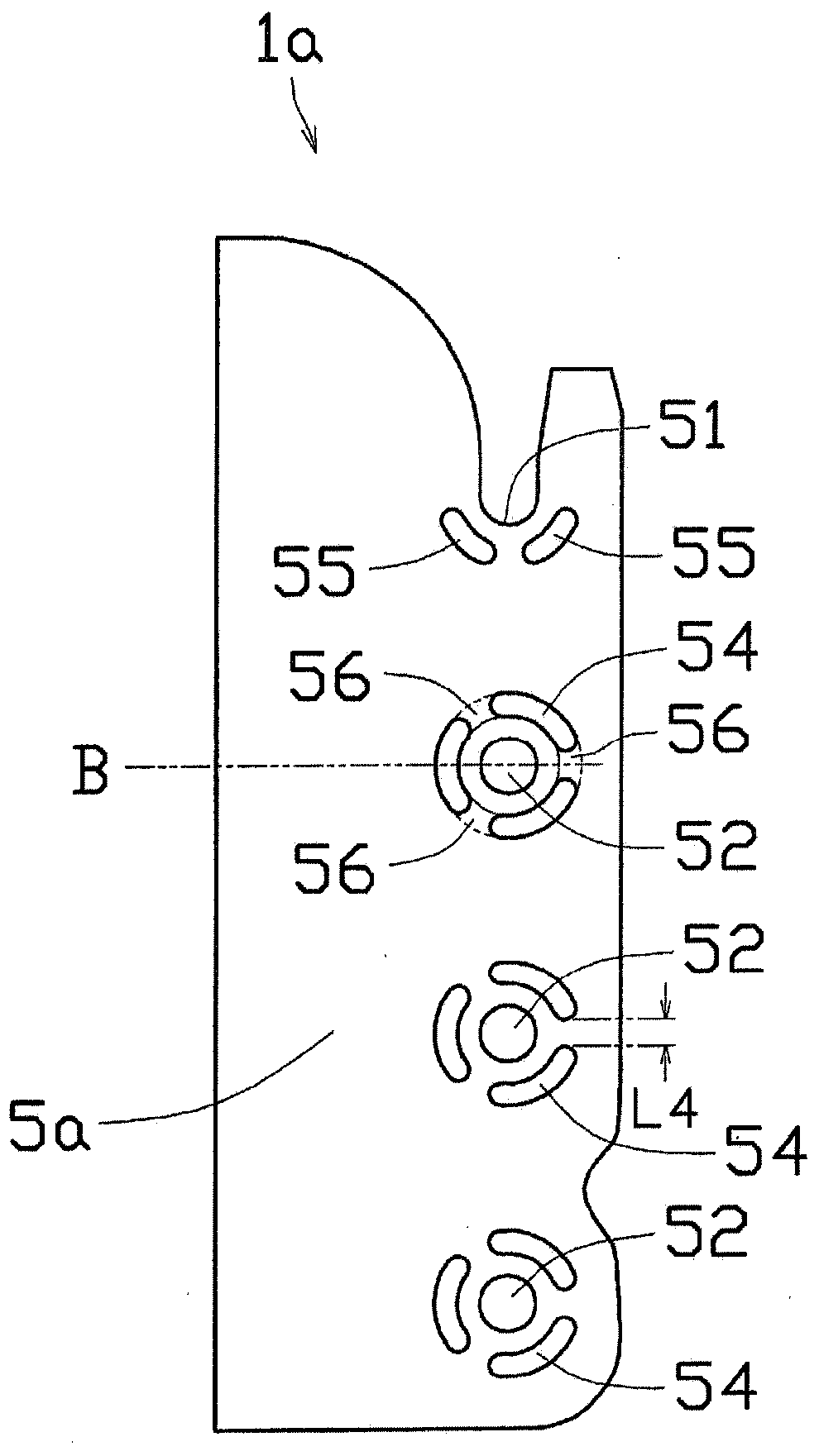

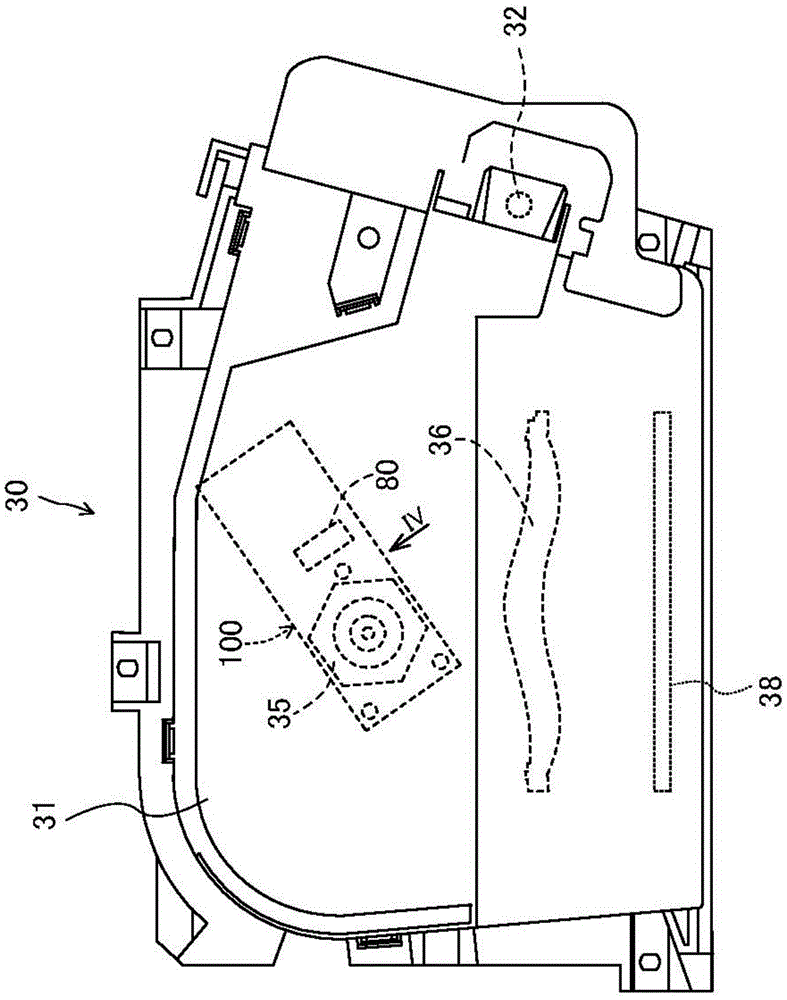

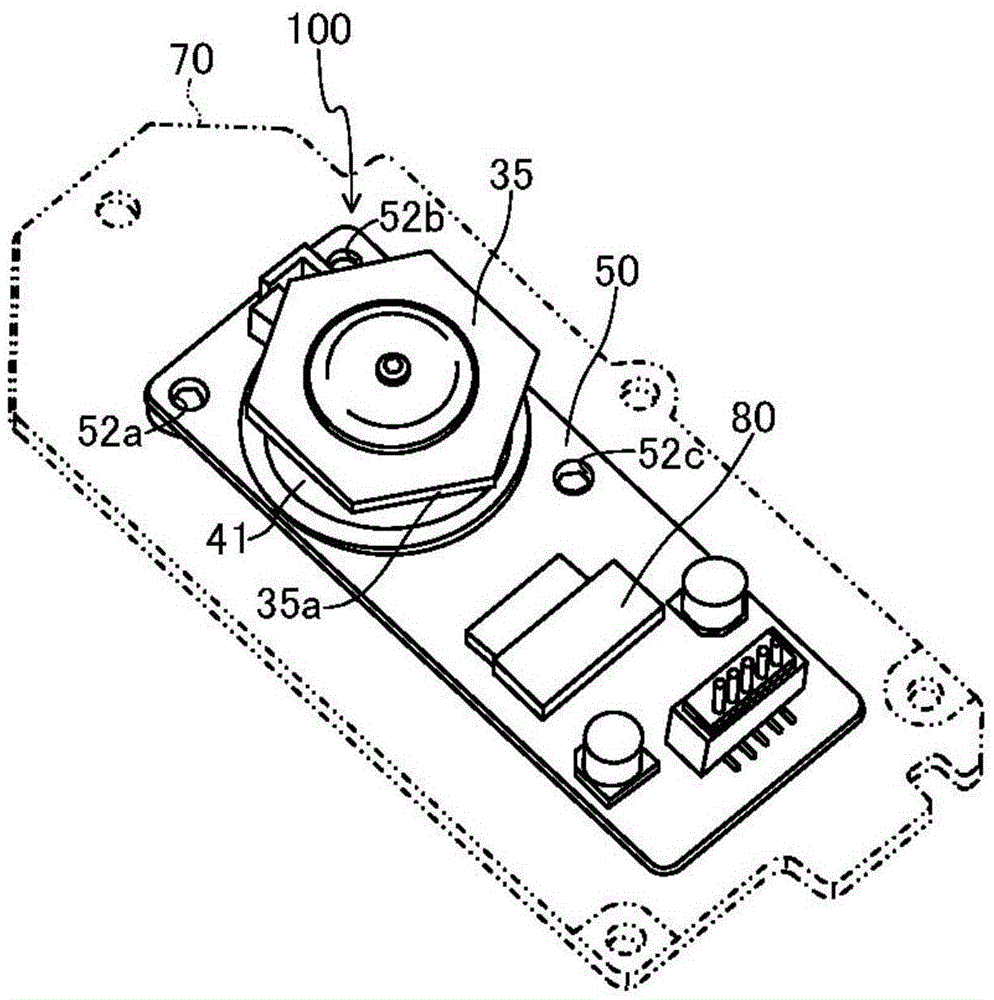

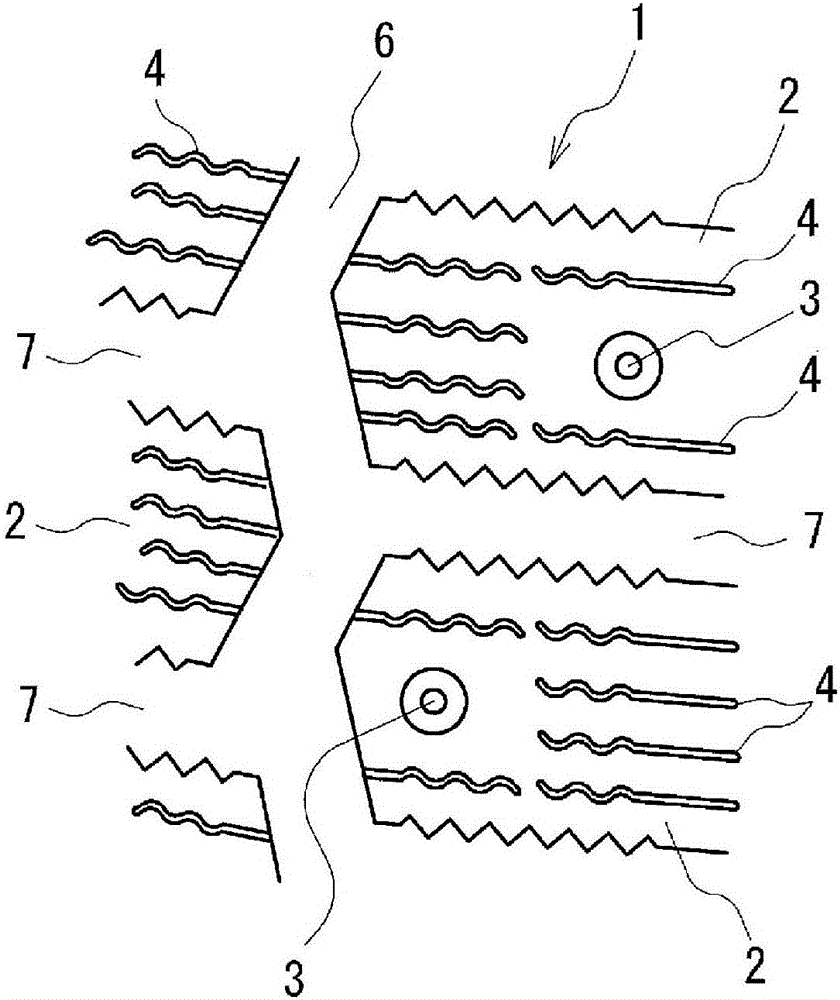

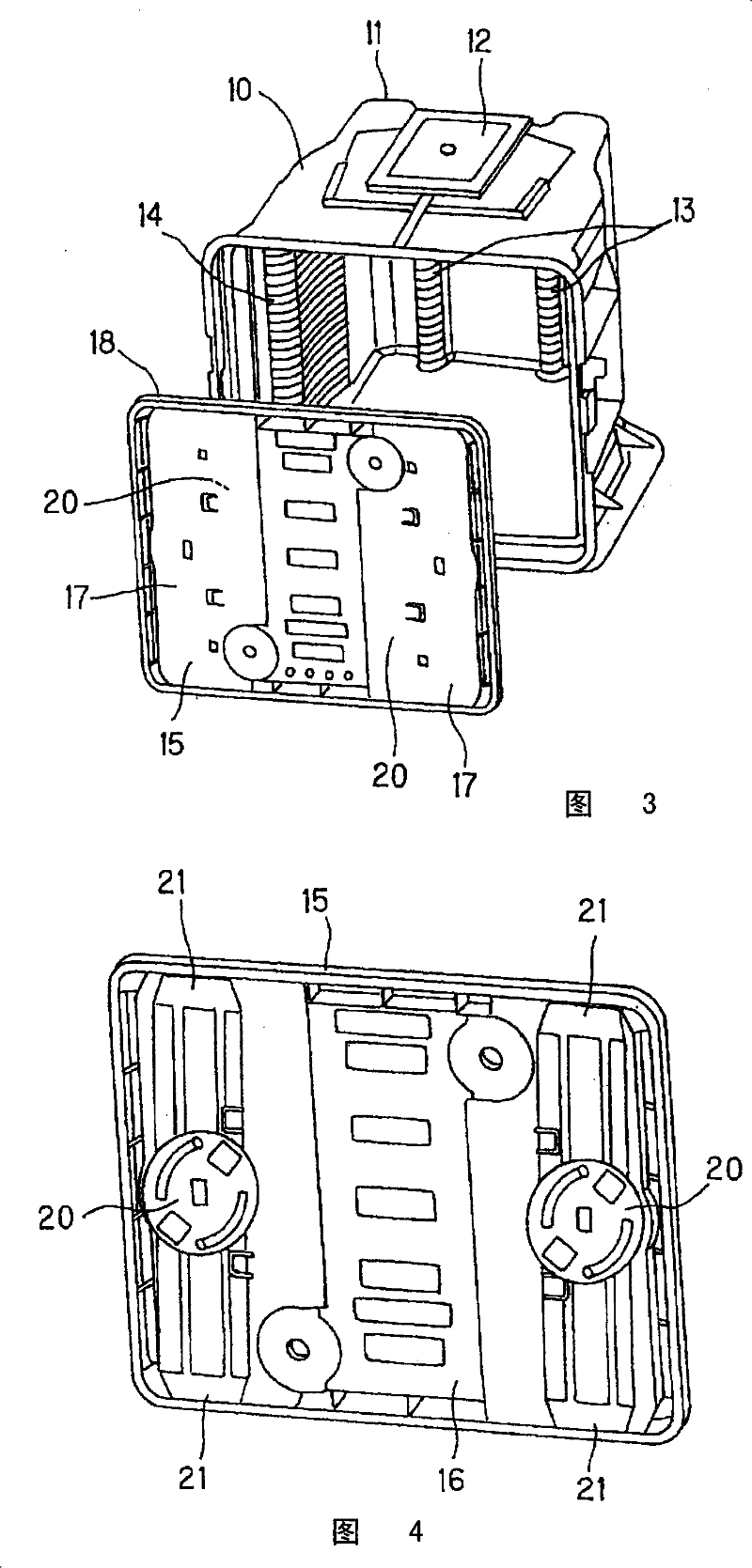

A packaging body that is suitable for transporting contents such as a substrate receiving container, that is not large in size, that has less possibility of contaminating the surroundings, that does not require an increased storage space, and that is less likely to cause problems when reused or recycled. The packaging body has a rectangular tube-like packaging box (1) with the bottom; an upper and lower pair of shock absorbing bodies (30) received in the packaging box (1) while holding the substrate receiving container (10); an elastic body (50) interposed between the substrate receiving container (10) and each shock absorbing body (30); and a reinforcement body (60) for reinforcing each shock absorbing body (30). The shock absorbing body (30) is prepared as a shock absorbing member (31) fitted to the substrate receiving container (10), and a peripheral wall (32) of the shock absorbing member (31) is constructed from an inner wall (35) formed in a bent manner at the peripheral edge of the shock absorbing member (31), a projection (36) formed at and projecting from the inner wall (35), and an outer wall (37) formed at the projection (36) and facing the inner wall (35) of the shock absorbing member (31) with a spacing in between. The reinforcement body (60) is formed to have a substantially dish-shaped cross-section, and a bent peripheral edge section (61) of the reinforcement body is fitted and engaged from the outside to an outer wall end section (37a) of the shock absorbing member (31).

Owner:SHIN-ETSU POLYMER CO LTD

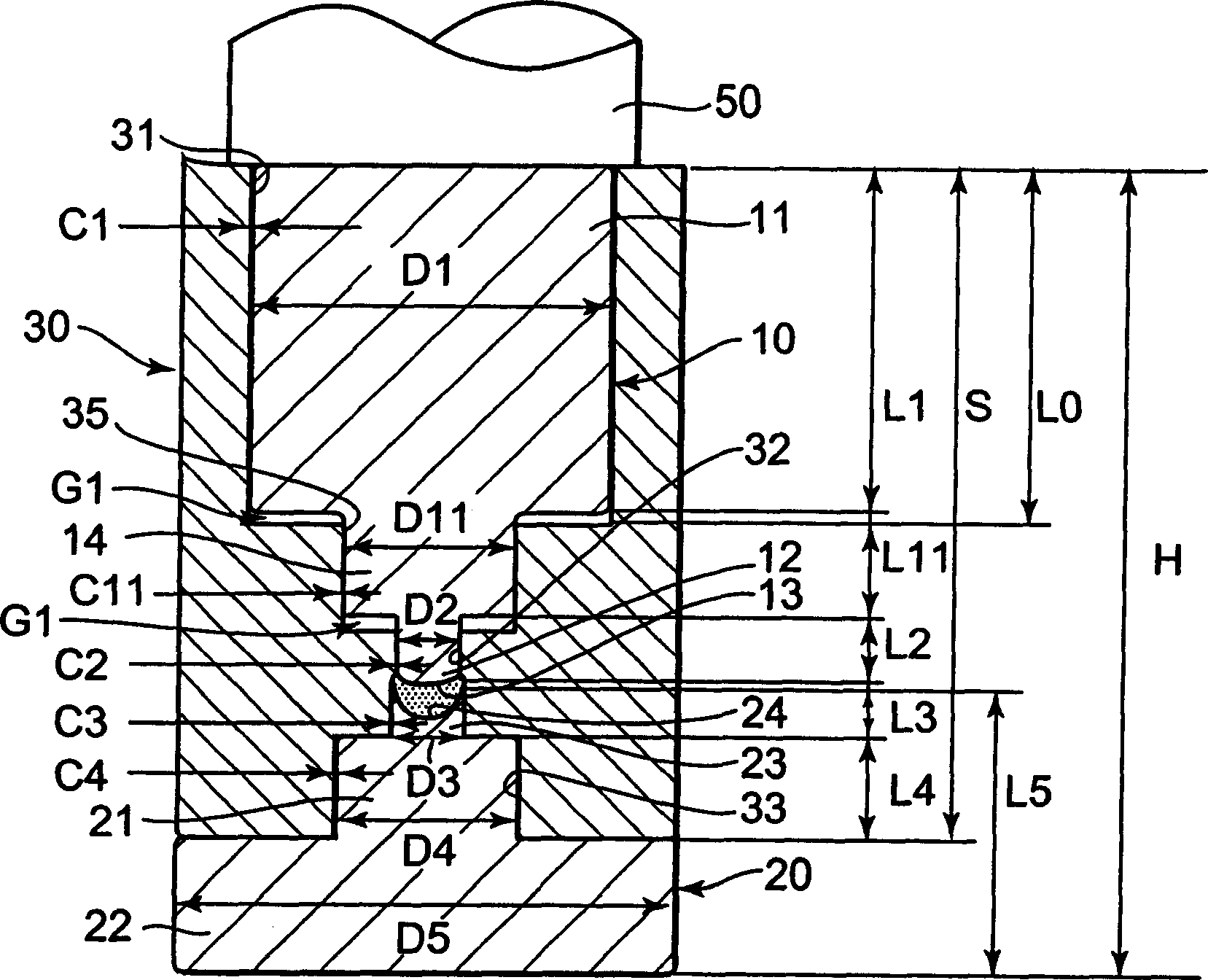

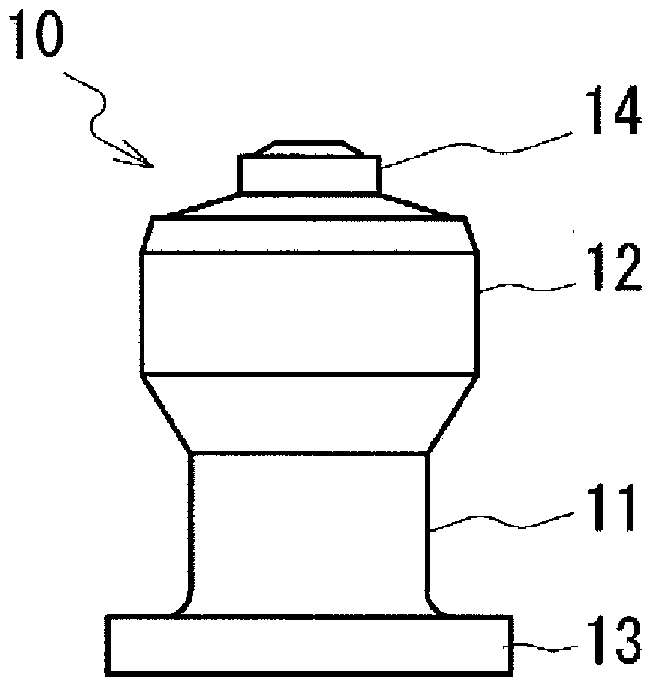

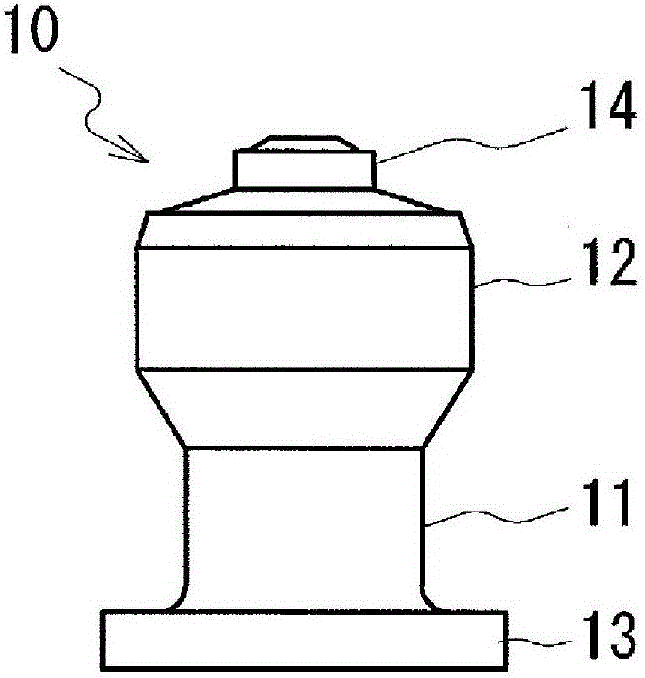

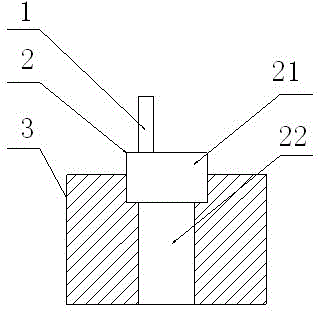

Manufacturing method of model forming module and optical component

ActiveCN1792906AAvoid breakingSmall sliding gapGlass pressing apparatusGlass press-moulding apparatusFlangeElectrical and Electronics engineering

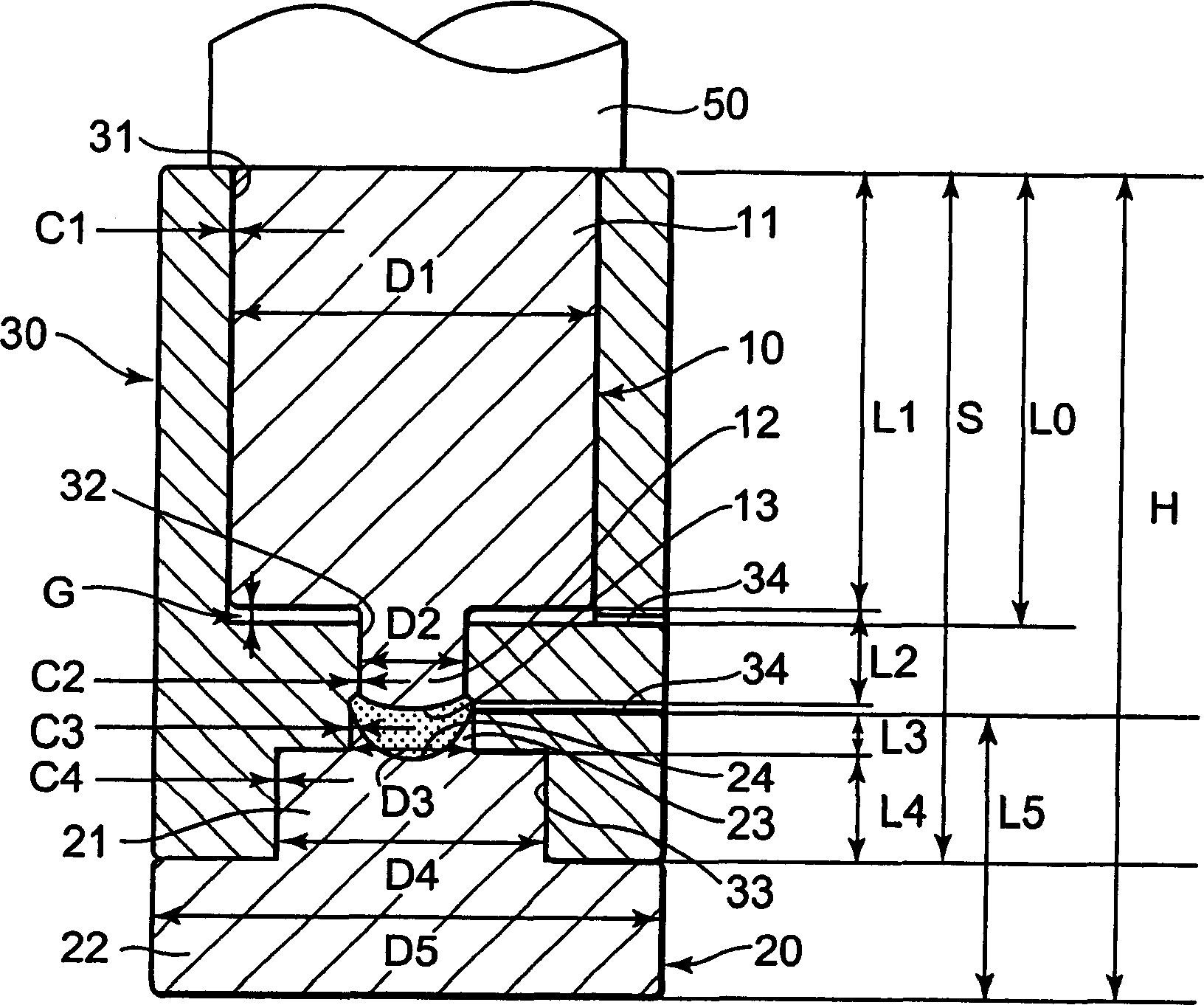

When the axial length of the large-diameter portion 11 of the upper die (sliding die) (10) is defined as (L1), and the axial length of the small-diameter portion (12) of the upper die (10) is defined as (L2), L1>L2 is established, when the large diameter portion (21) of the lower mold (stationary mold) (20) is accommodated in the (2) inner peripheral large diameter portion (33) of the main body mold (30), when passing through the main mold (30) ) is docked with the flange portion (22) of the lower mold (20), the mutual position of the lower mold (20) and the main mold (30) is specified, and the upper mold (10) is slidably guided to the main mold ( When the length in the axial direction of the portion in 30) is (L), and the overall length in the axial direction of the main body (30) is (S), L≥0.5S holds.

Owner:HOYA CORP

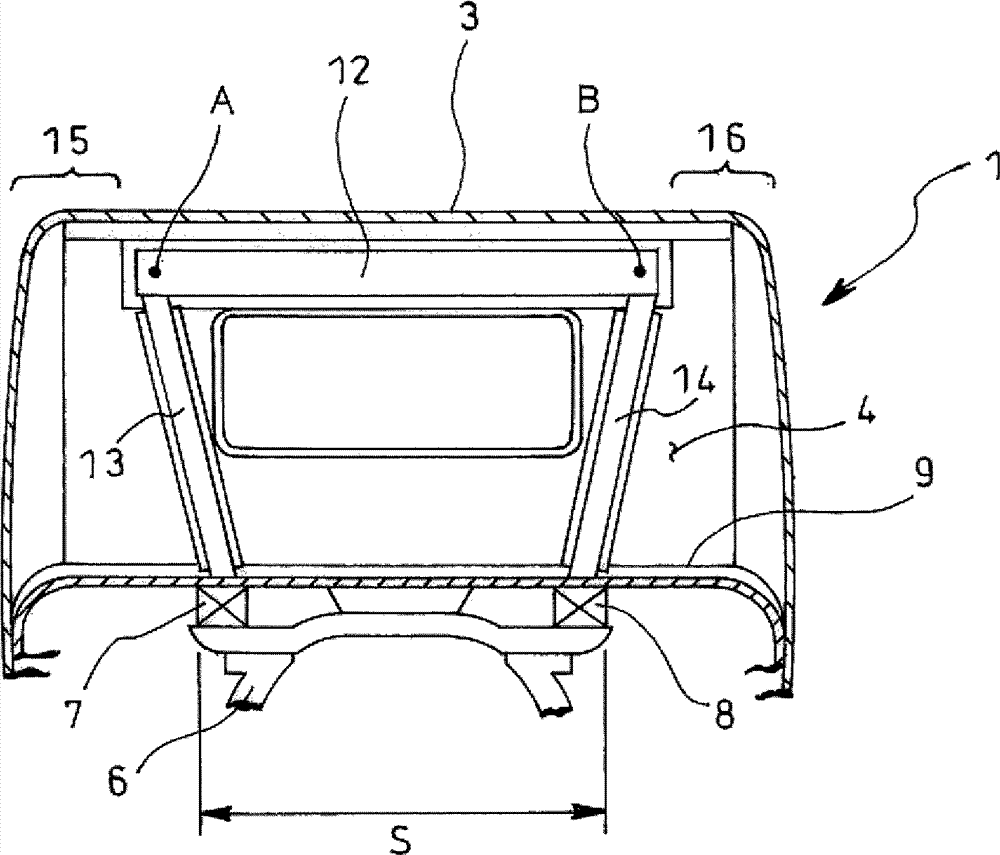

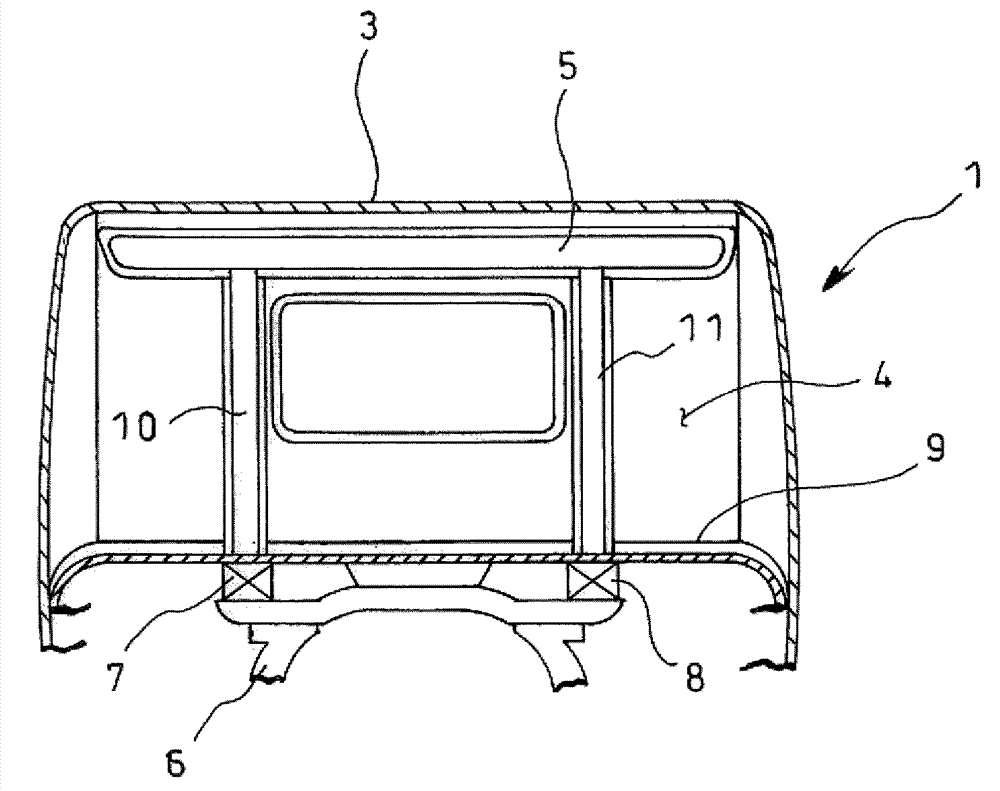

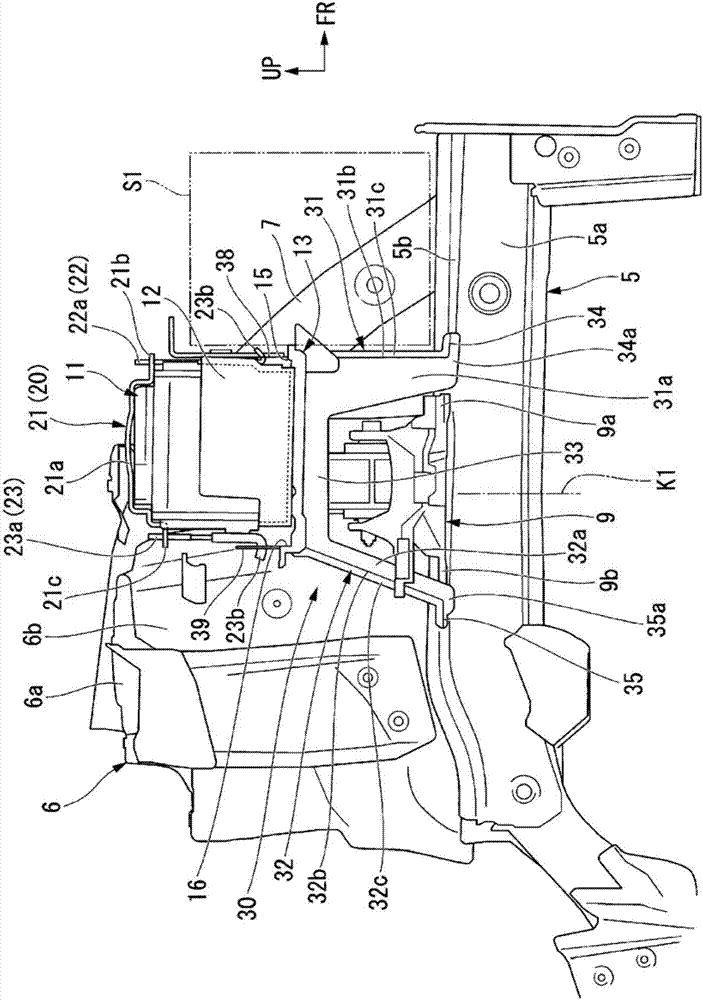

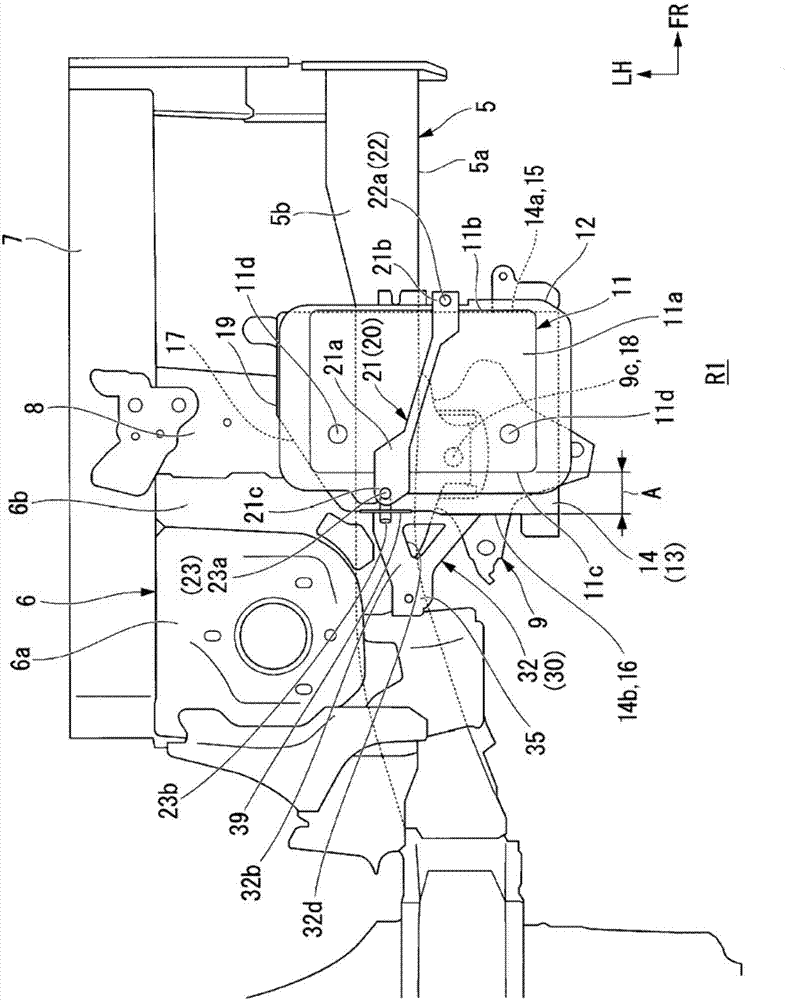

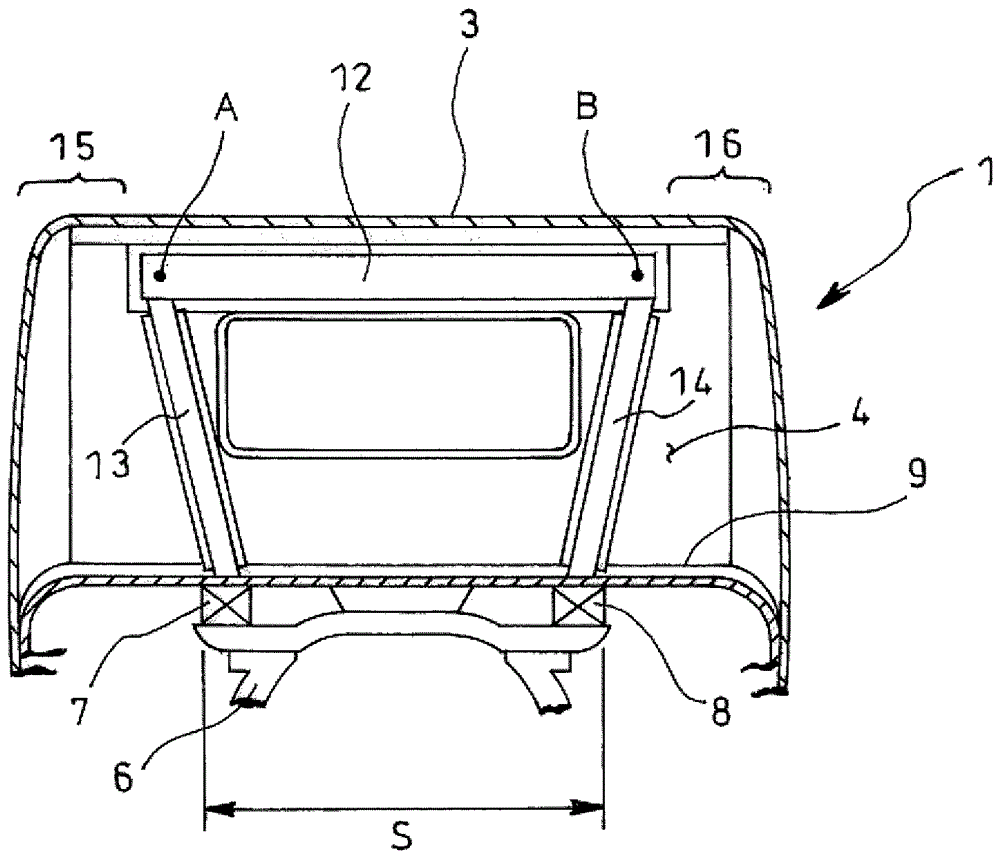

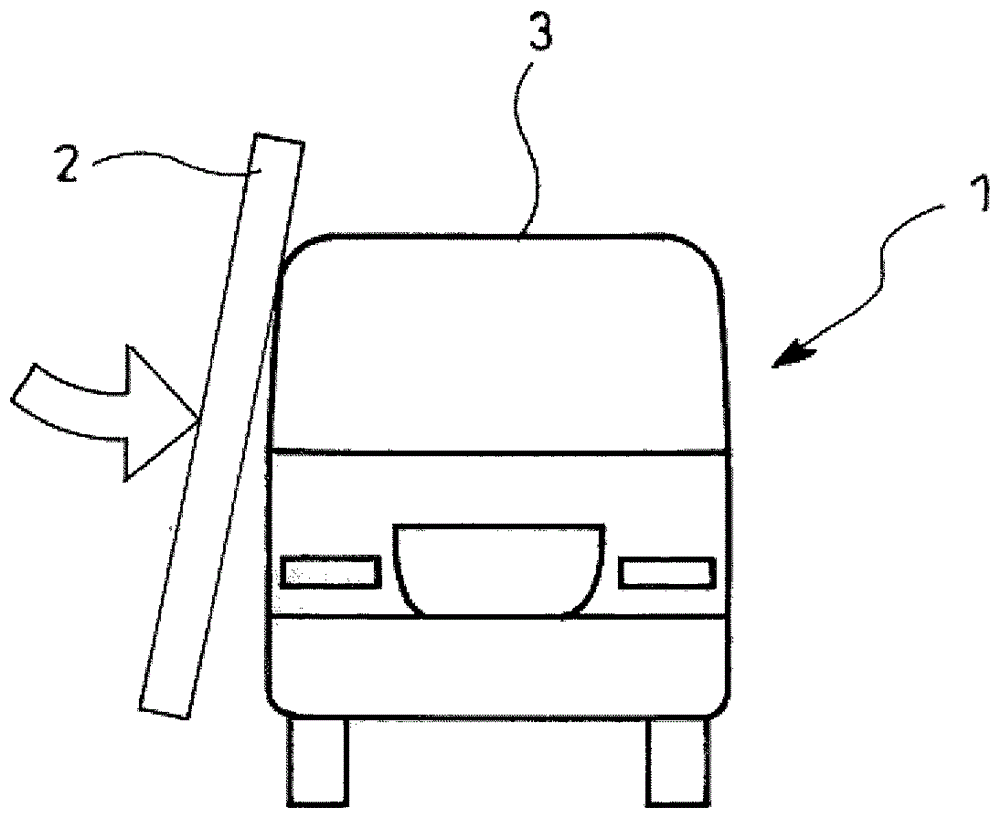

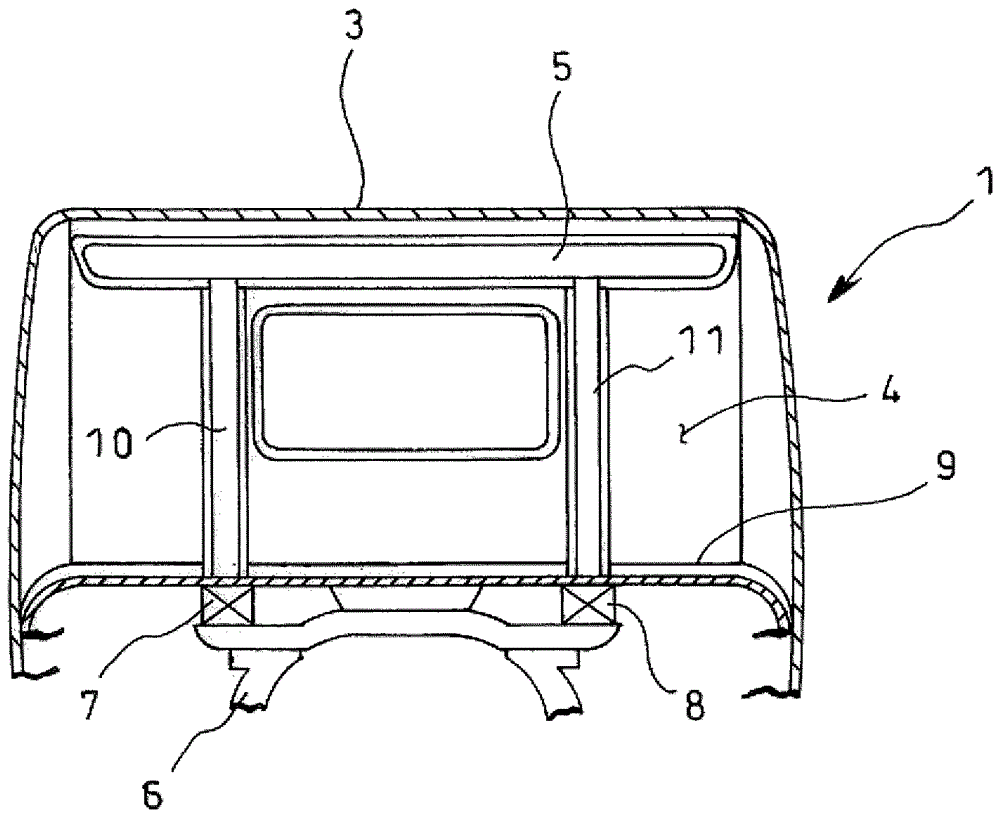

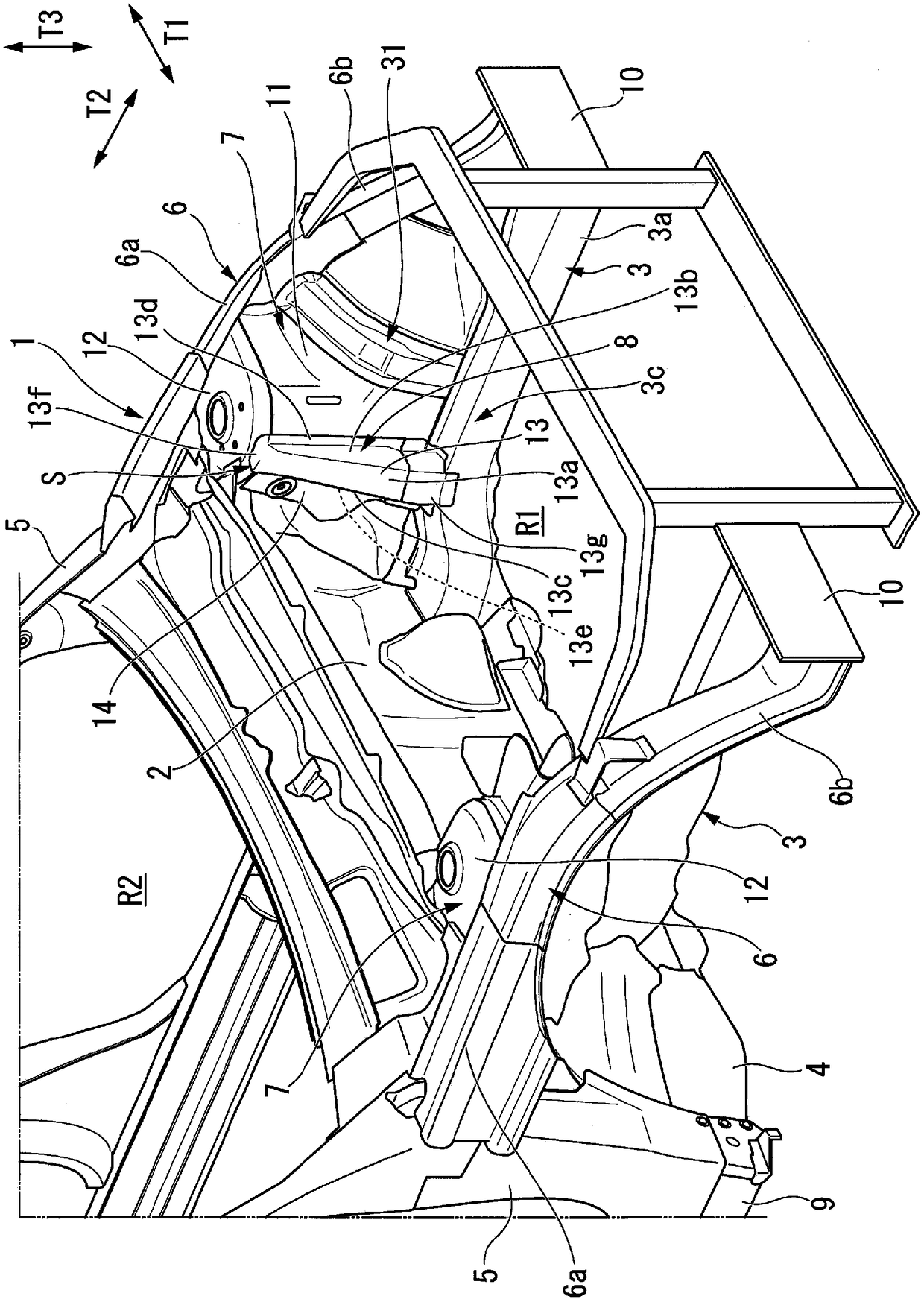

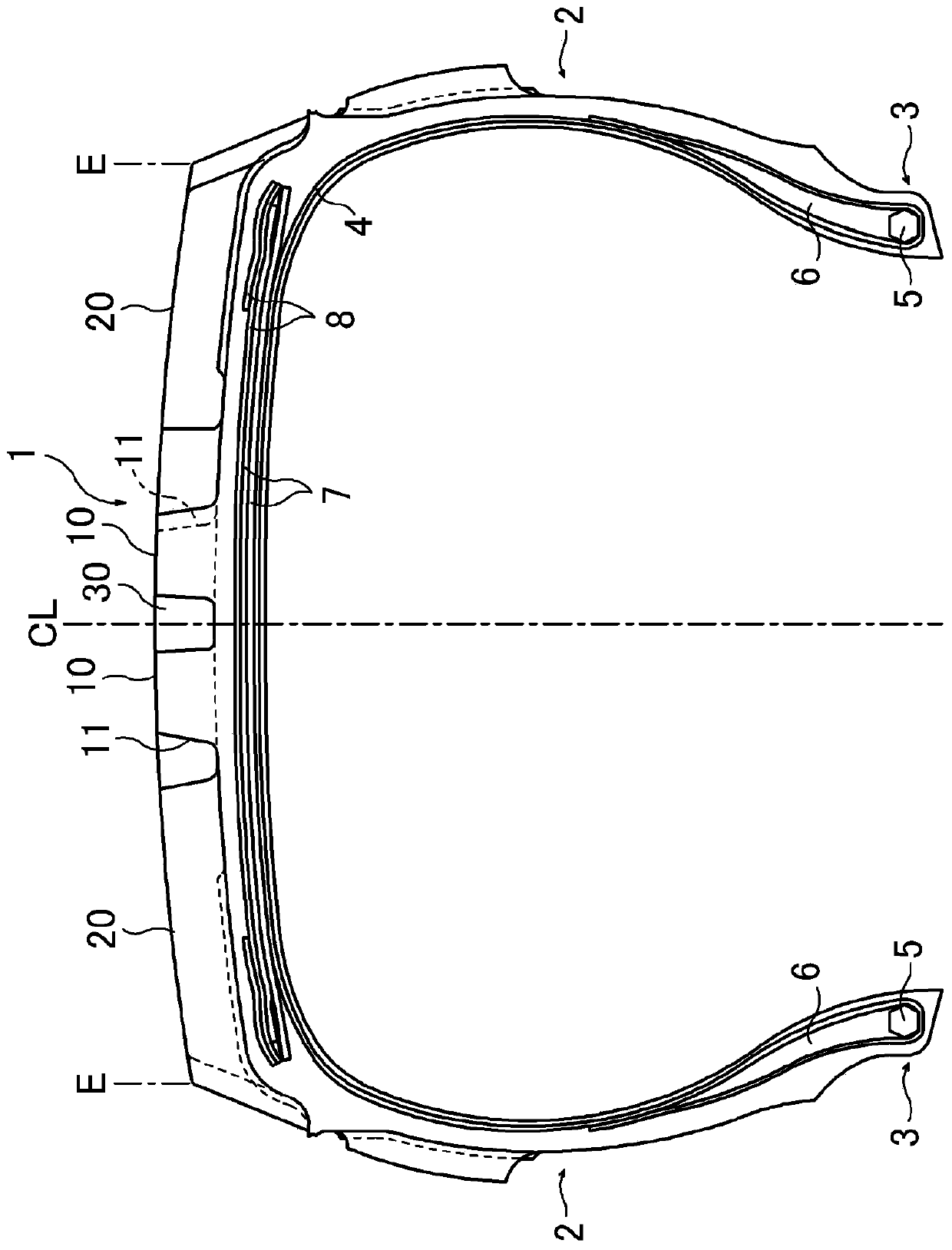

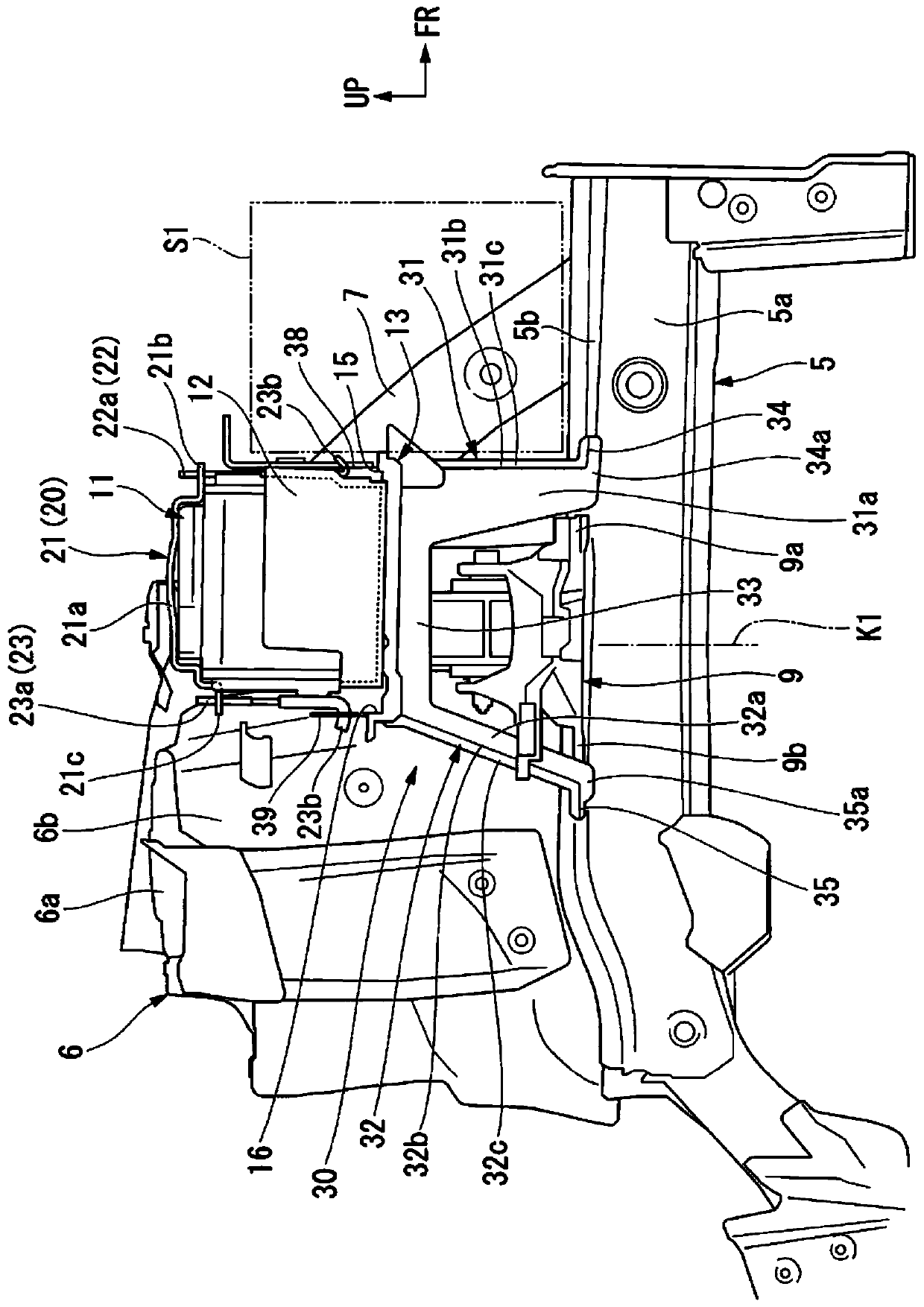

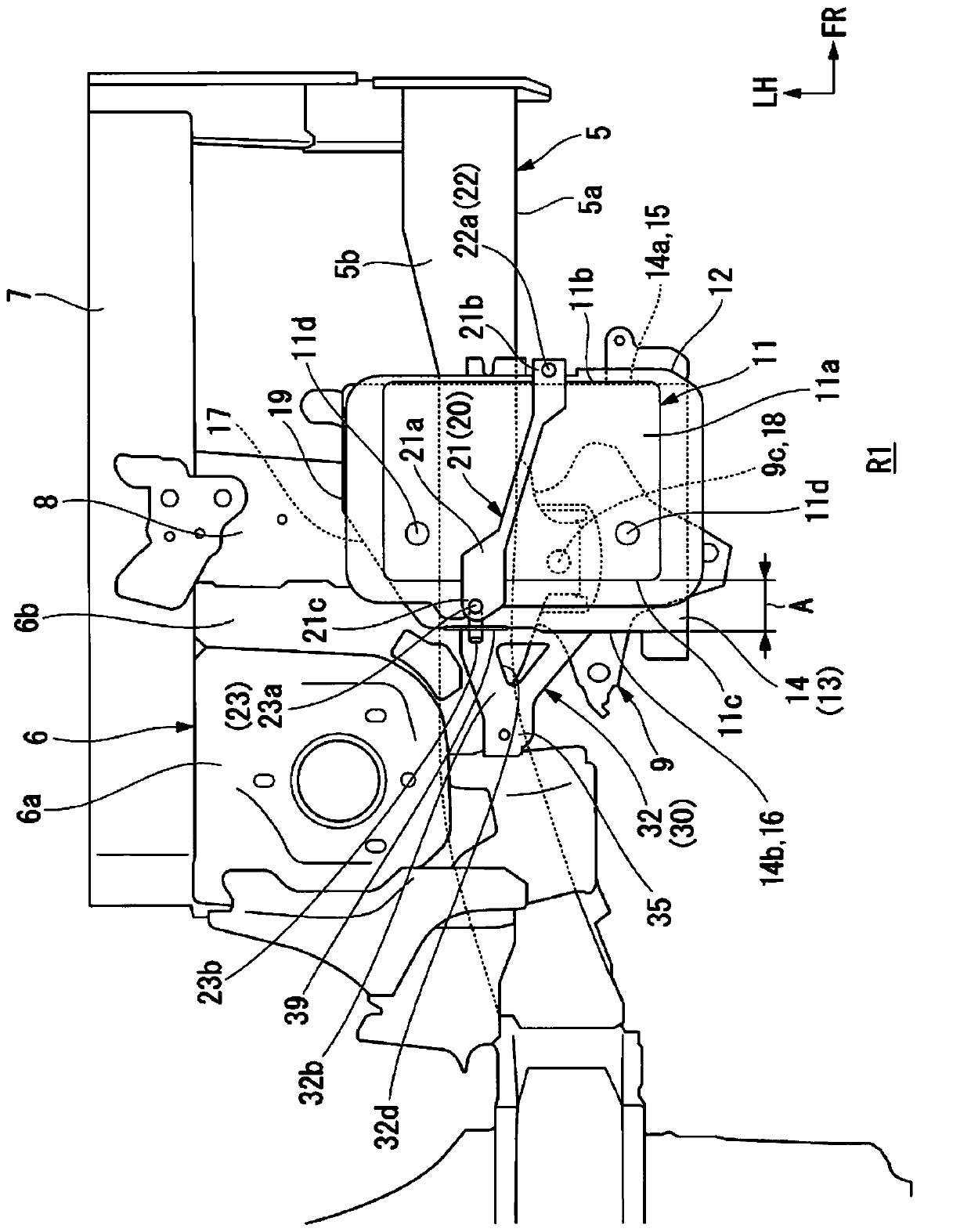

Cab reinforcing structure

InactiveCN104755362APrevent dumpingSuppression of flattening deformationPedestrian/occupant safety arrangementUnderstructuresSupport point

Two locations drawn inward from vehicle-widthwise outside ends in the top part of a back panel (4) of a cab (1) are designated as load support points (A, B), a pair of reinforcing studs (13, 14) are attached to the back panel (4) so as to connect the load support points (A, B) and a floor (9) directly above a pair of rear-side cab mountings (7, 8) supporting the rear part of the cab (1) from a frame (6) side, a reinforcing beam (12) is attached to the back panel (4) so as to connect the top ends of the reinforcing studs (13, 14) together, and the unreinforced parts on the vehicle-widthwise sides of the reinforcing beam (12) remain as impact-absorbing parts (15, 16).

Owner:HINO MOTORS LTD

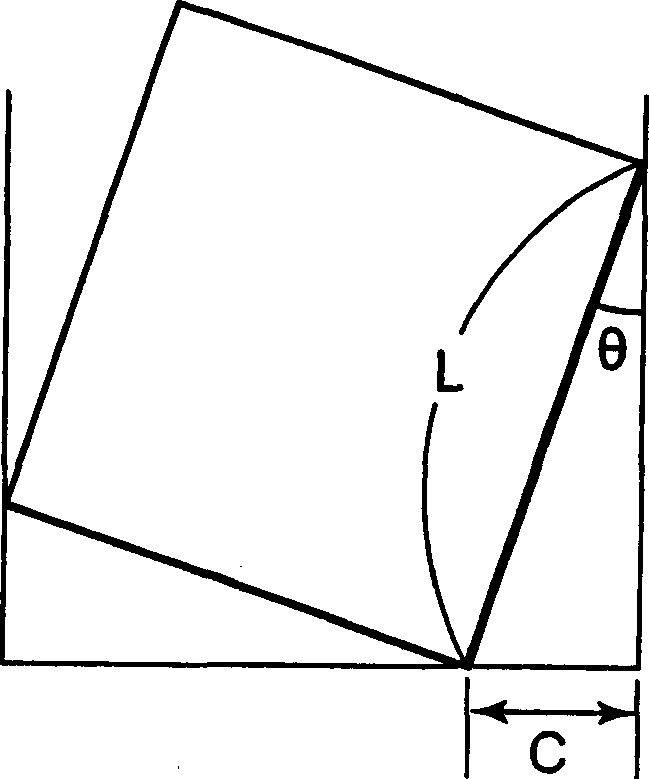

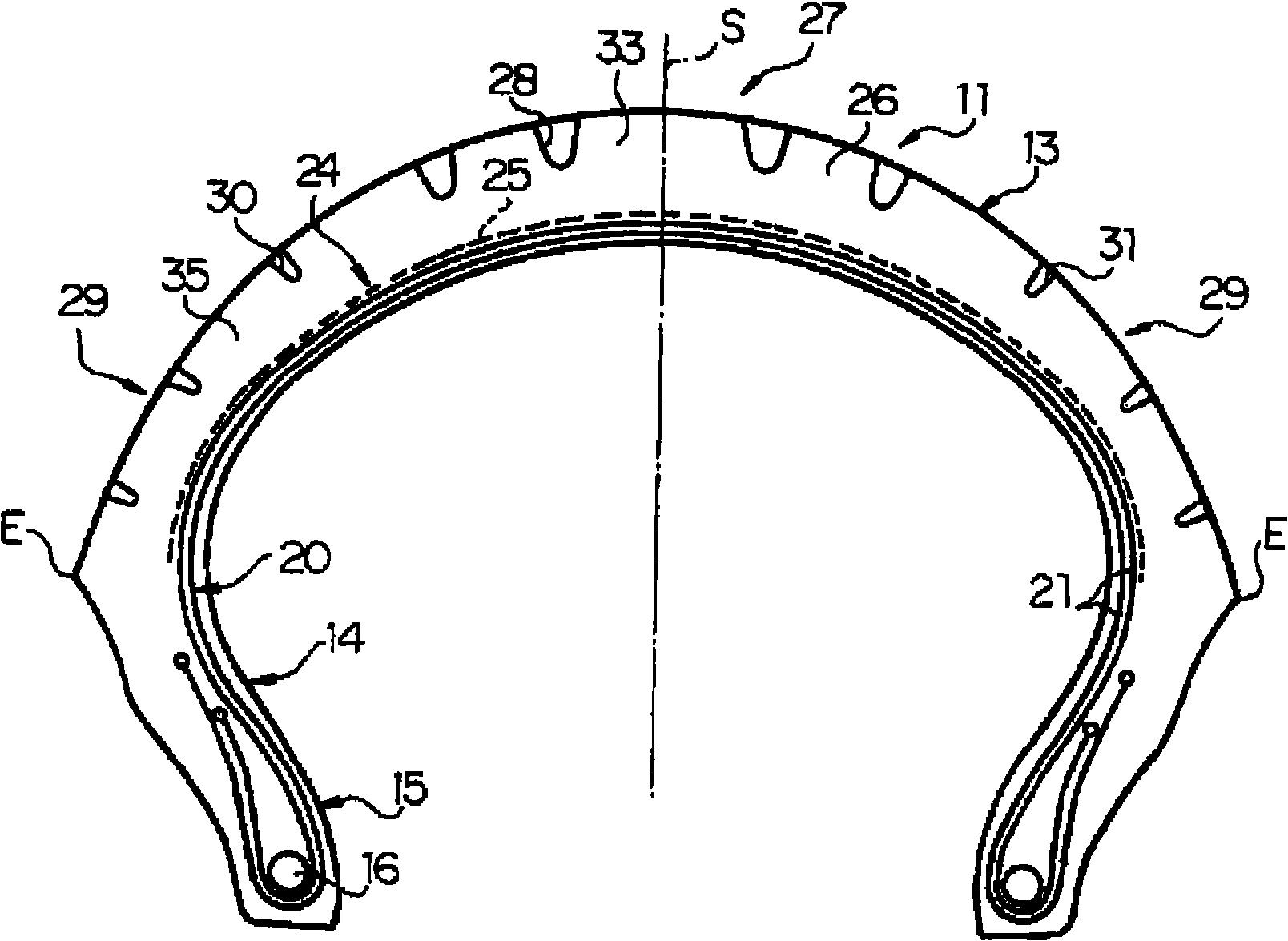

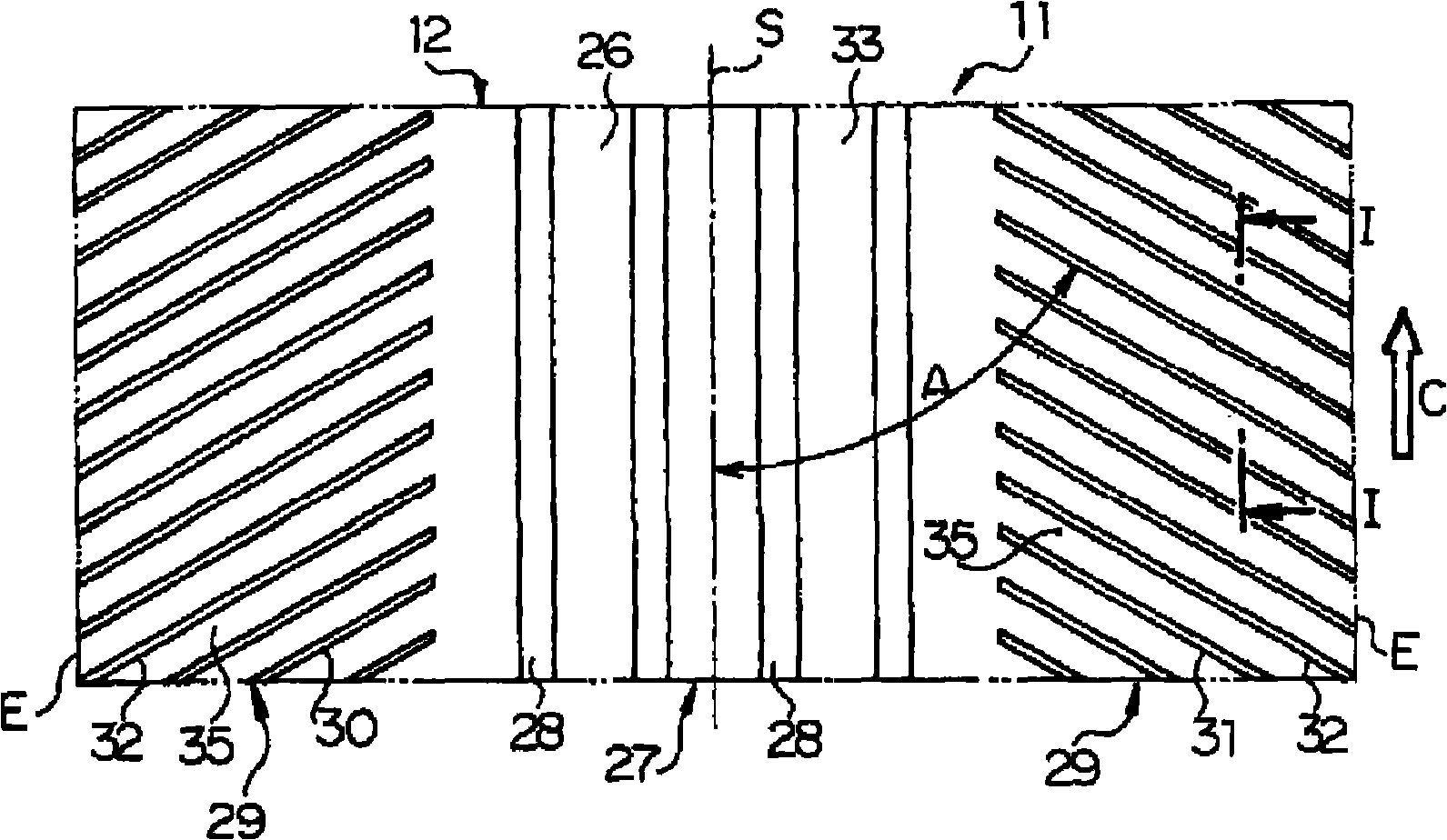

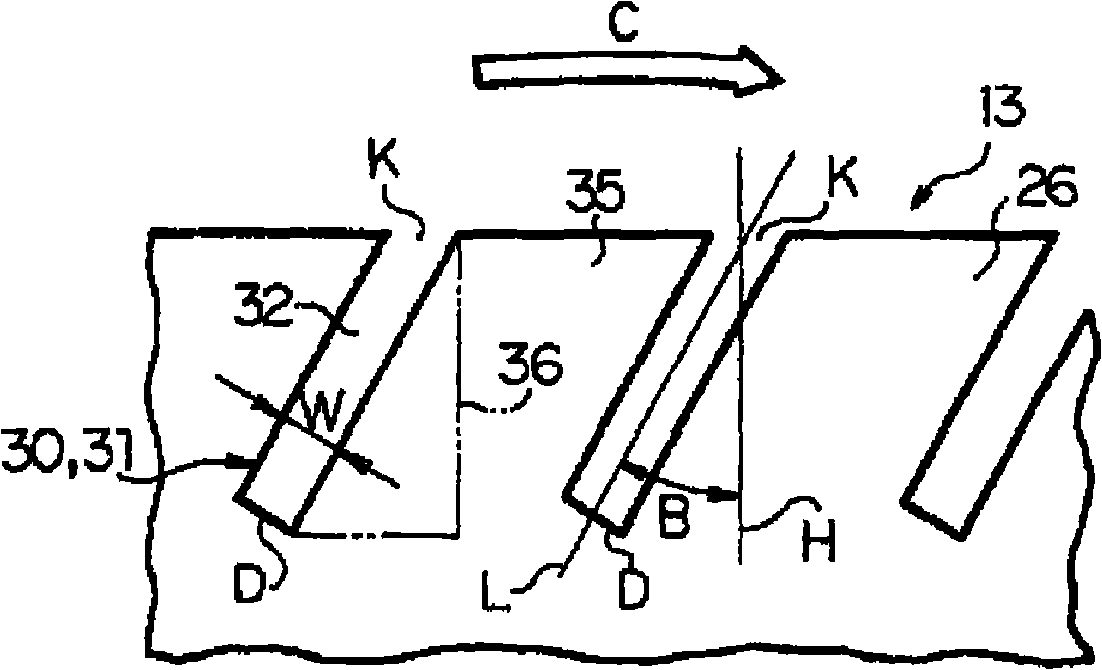

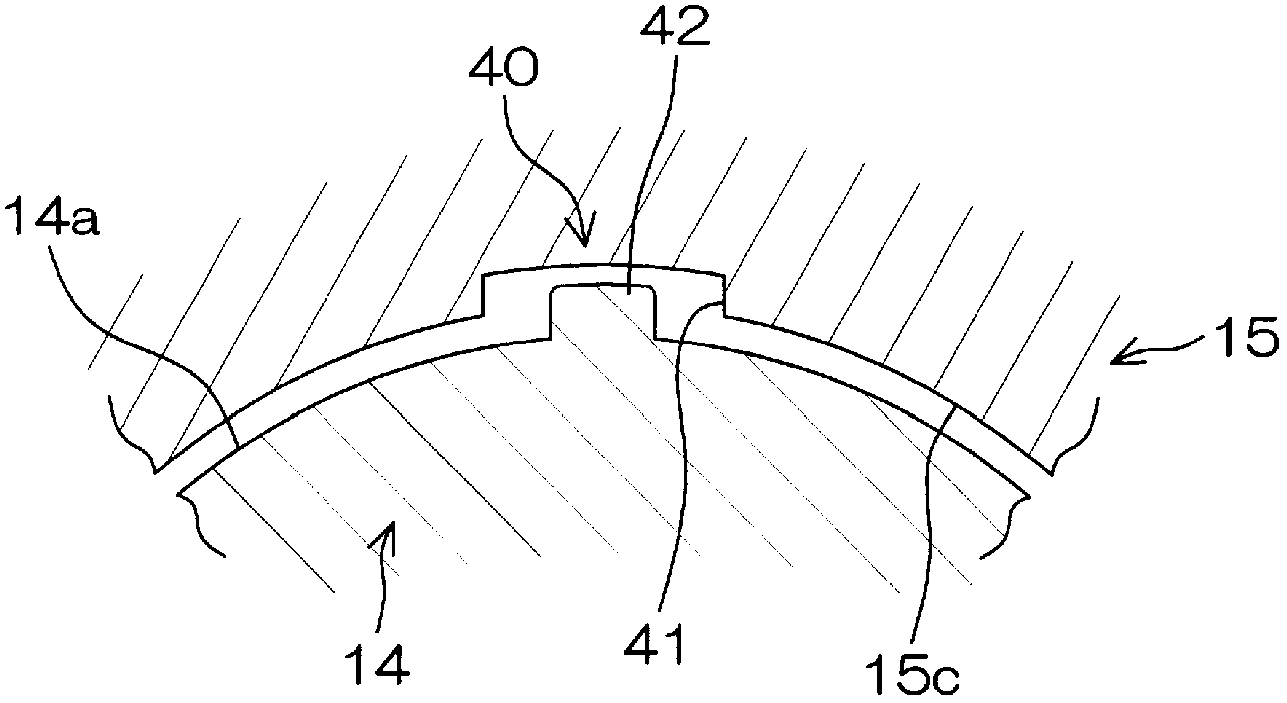

Pneumatic tire for bicycle

In a pneumatic tire for a bicycle having grooves (30, 31) (inclining portion (32)) formed in the outer surface of a tread (13) to extend substantially in the width direction, and having its rotational direction specified, driving performance or braking performance is enhanced. Since driving force acts on a tire for a rear wheel during acceleration traveling, the entire land (35) between the inclining portions (32) begins to tilt rearward in the rotational direction; since the inclining portions (32) are inclining forward in the rotational direction, as a whole, from a deepest portion (D) toward the end (K) of an opening, a substantially triangular brace (36) formed at the rear end of each land (35) in the rotational direction resists powerfully thus suppressing tilt at each land (35) effectively. Consequently, drive performance is enhanced by enhancement in grip force during driving, and occurrence of uneven wear is suppressed by a uniformed ground-contacting pressure.

Owner:BRIDGESTONE CORP

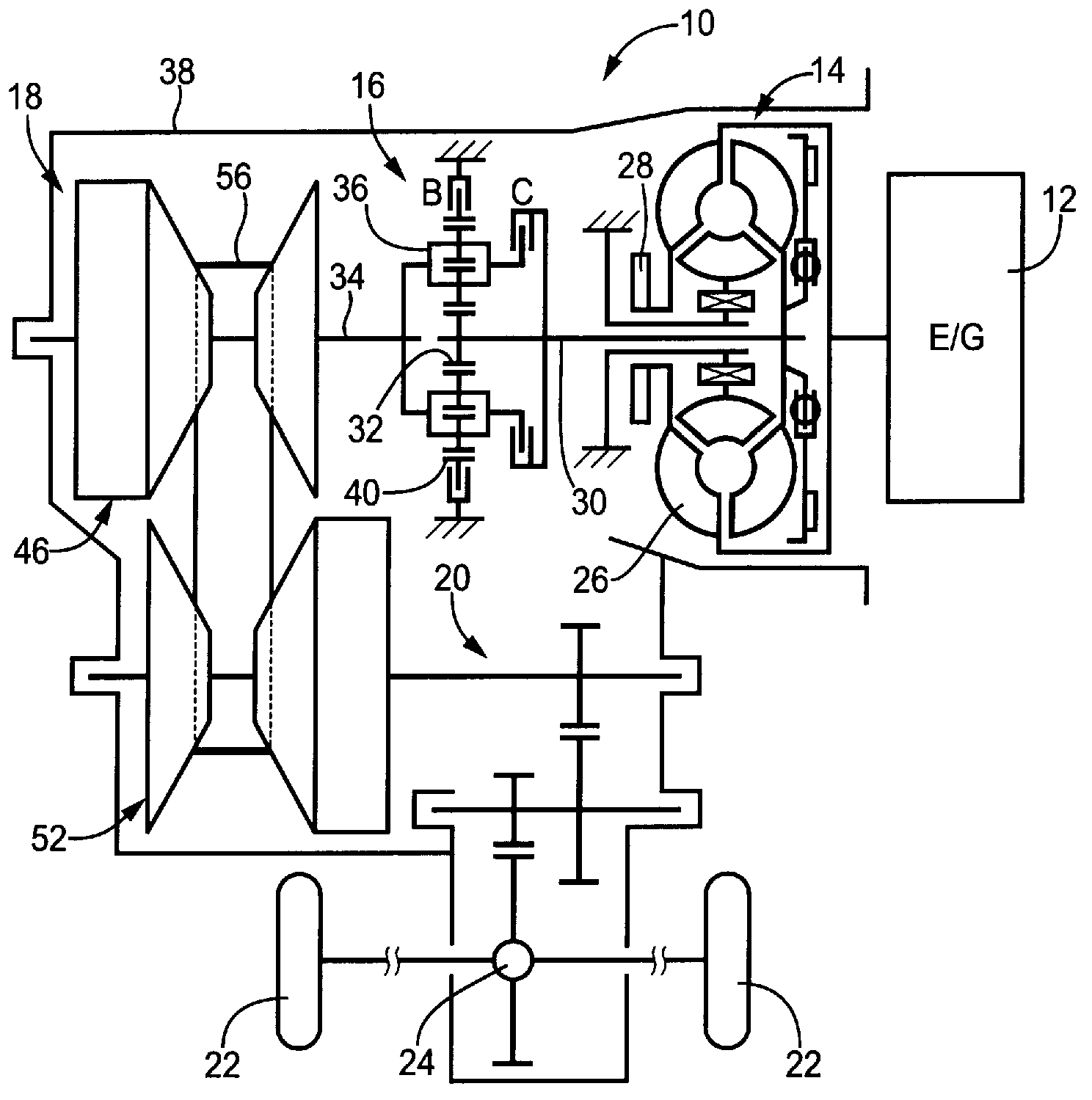

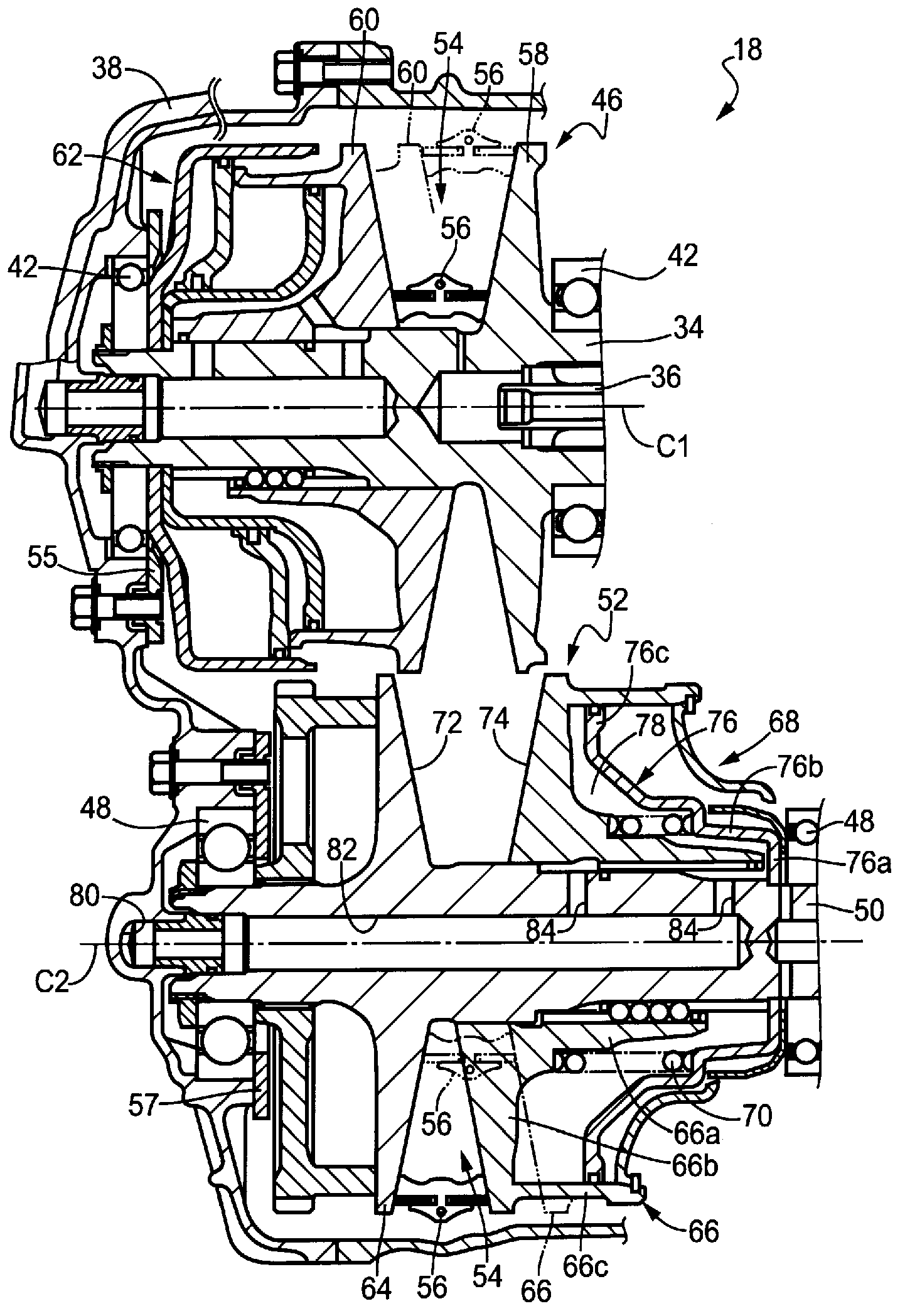

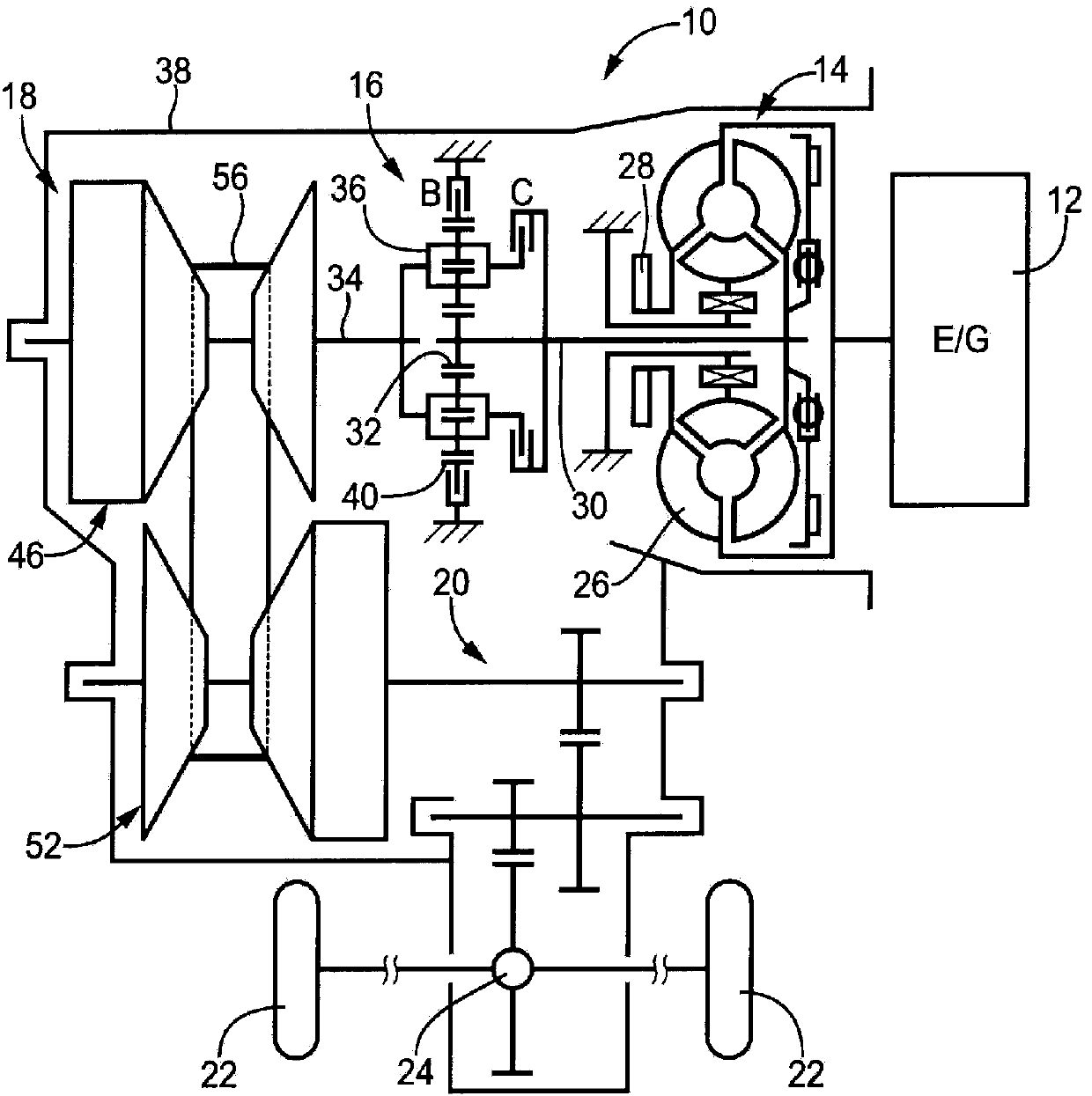

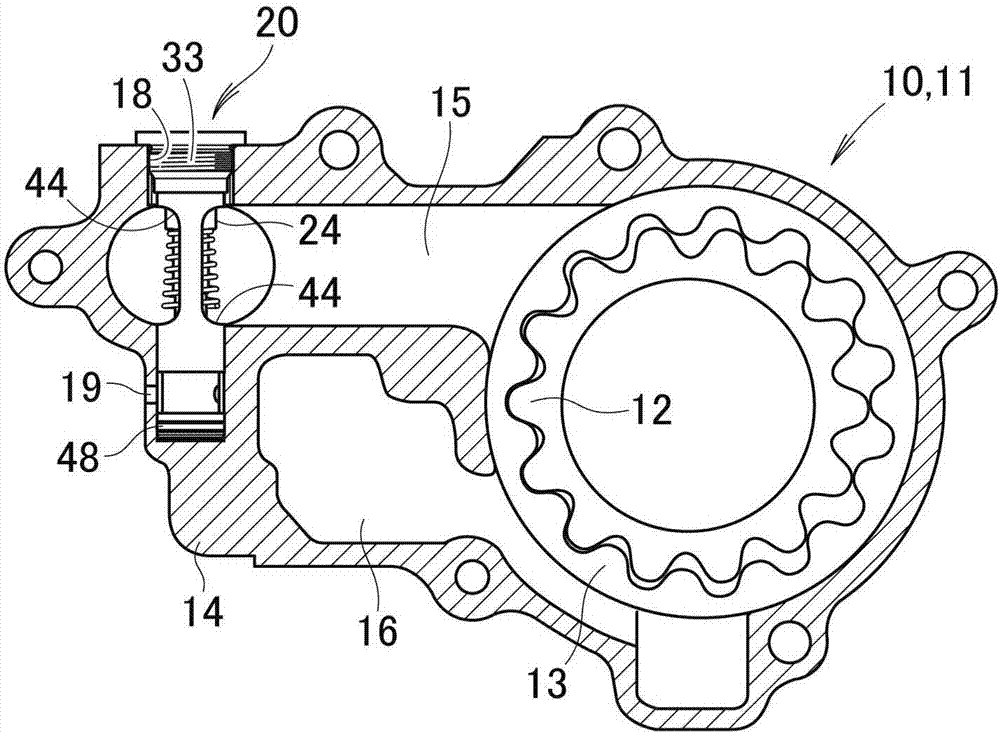

Belt Type Continuously Variable Transmission For Vehicle

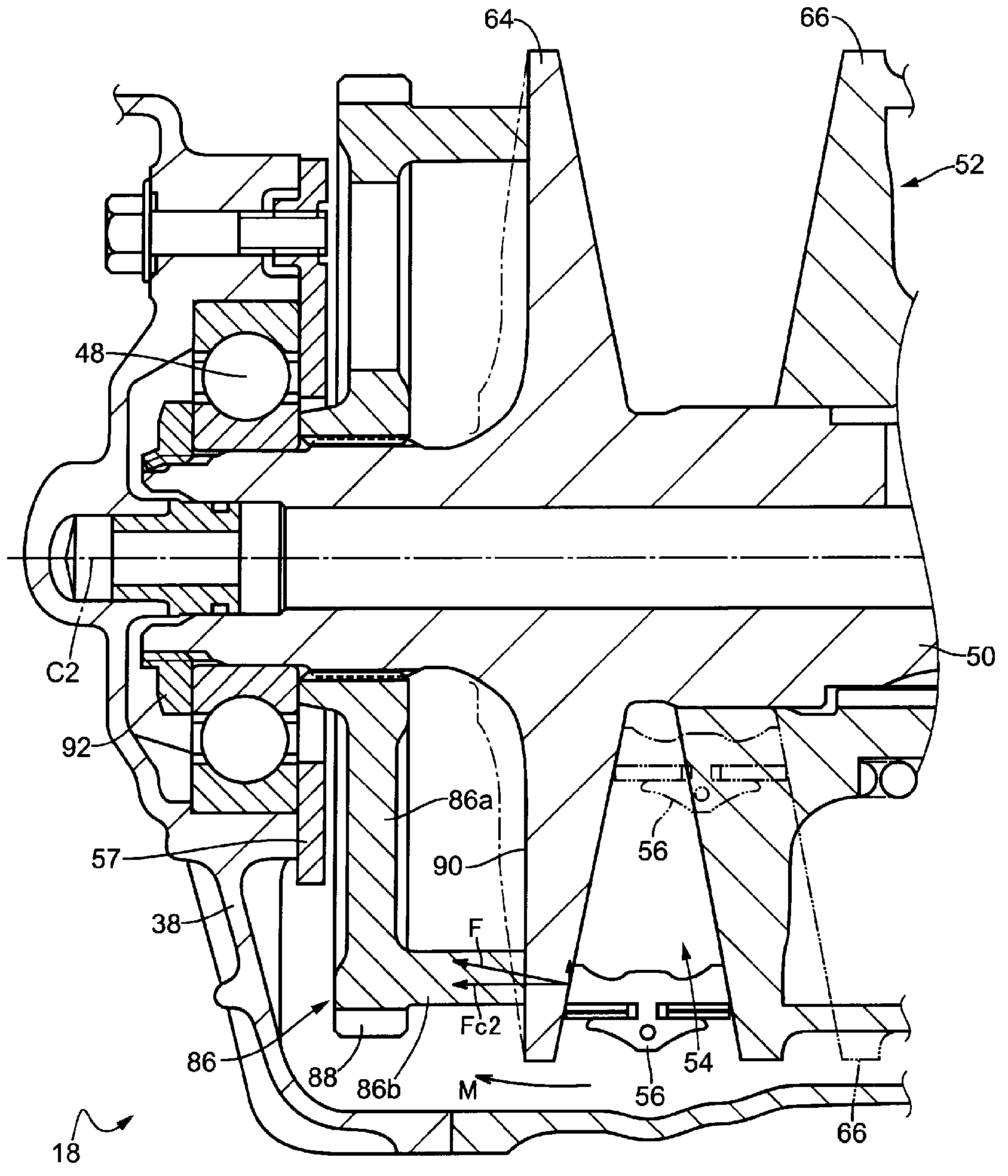

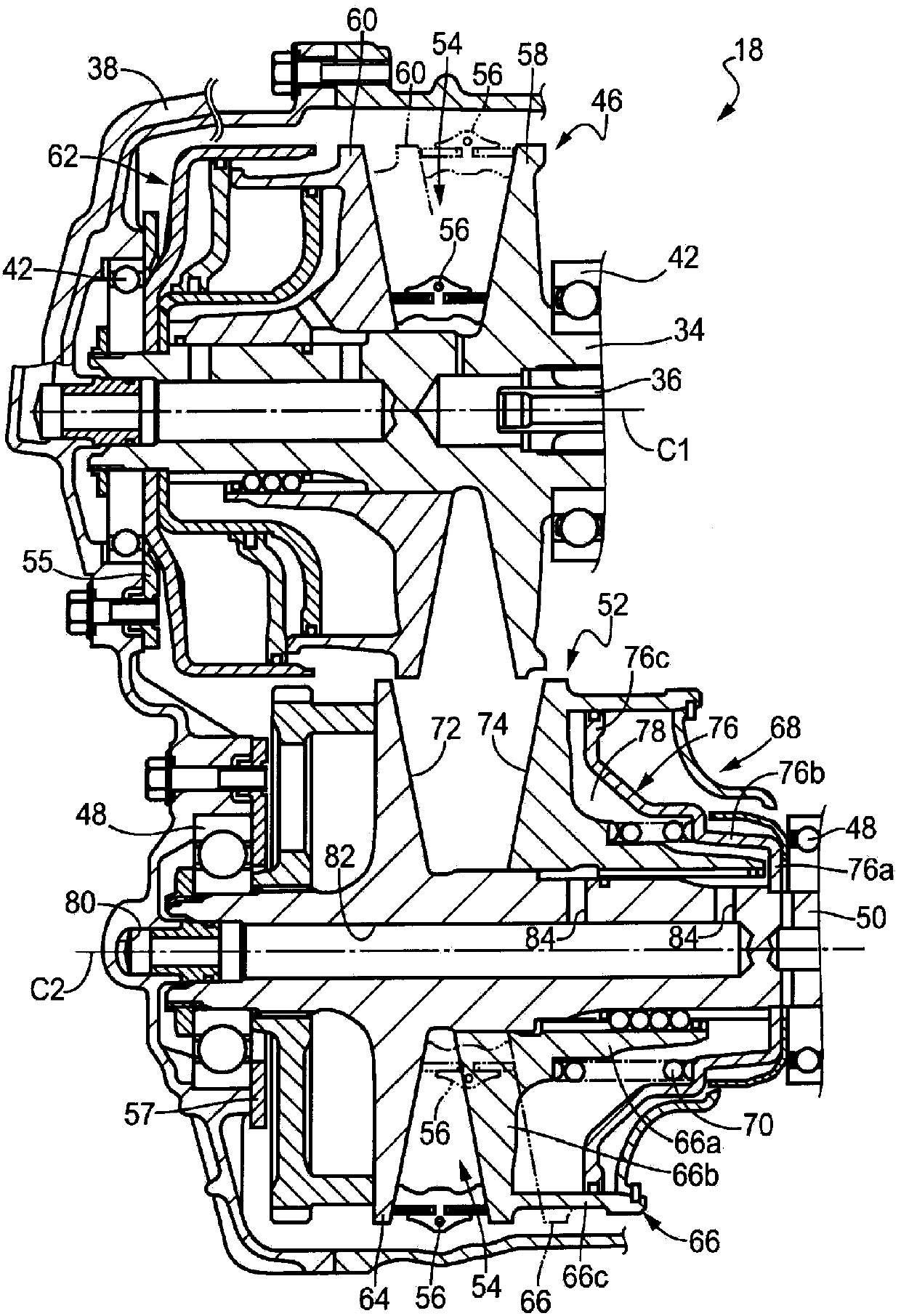

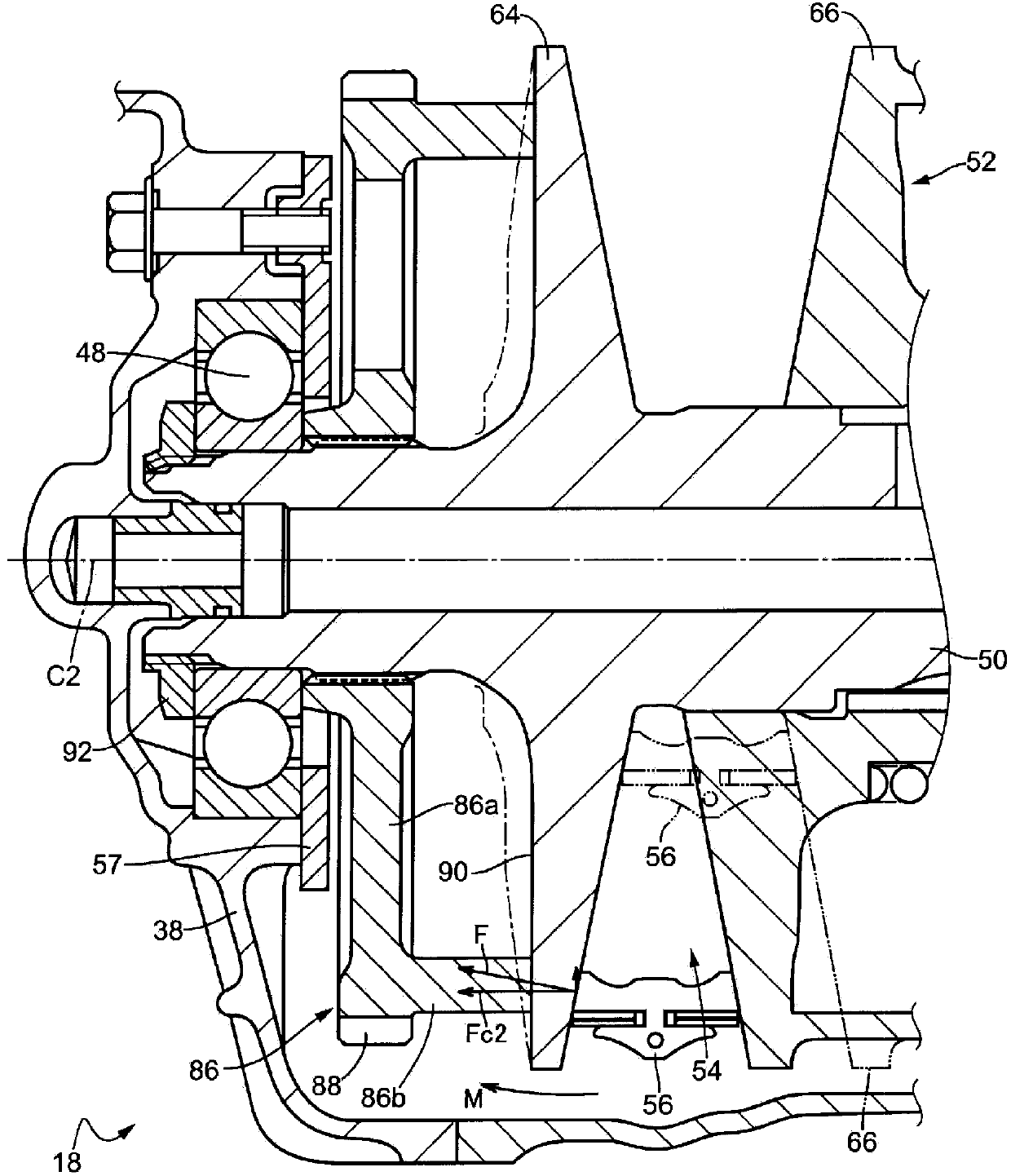

InactiveCN102812267ACurb dumpingEasy to changeGearingGearing controlTransmission beltRadial position

Provided is a belt type continuously variable transmission for a vehicle such that the bending-over of a fixed sheave can be restricted. A parking gear (86) comprising a disk-shaped main body section (86a) and an annular protrusion (86b) is provided on that side of the fixed sheave (64) which is other than the side facing a movable sheave (66), said disk-shaped main body section (86a) being fixed to an output shaft (50), for example, by being splined together therewith, and said annular protrusion (86b) protruding from the main body section (86a) toward that wall surface of the fixed sheave (64) which is other than the side facing the movable sheave (66), that is, toward a back surface (90), and abutting the back surface (90) at that radial position which corresponds to the maximum engagement radius of a transmission belt (56). Therefore, even if the fixed sheave (64) is subjected to an axial reaction force (Fc2) in an axial direction (C2) by the transmission belt (56), that area of the back surface (90) of the fixed sheave (64) which is outward of the minimum engagement radius of the transmission belt (56) is supported by the parking gear (86), which is formed by adding only relatively simple changes to a conventional one. Consequently, the bending-over of the fixed sheave (64) can be restricted.

Owner:TOYOTA JIDOSHA KK

Belt type continuously variable transmission for vehicle

A belt type continuously variable transmission for a vehicle includes: an input shaft and an output shaft disposed in parallel with each other; a pair of groove width variable pulleys disposed on the outer circumferential sides of the input shaft and the output shaft; and a transmission belt wound around each of V-grooves of the pair of the groove width variable pulleys, the belt type continuously variable transmission for a vehicle changing a winding diameter of the transmission belt by changing the groove widths of the V-grooves so as to continuously vary a gear ratio, wherein the groove width variable pulley includes a fixed sheave fixed to an outer circumferential surface of one of the input shaft and the output shaft, and a movable sheave disposed relatively non-rotatably on the one shaft and relatively movably in the direction of the shaft center of the one shaft so as to form the V-groove with the fixed sheave, wherein the belt type continuously variable transmission for a vehicle is disposed with a parking gear having a disc-shaped main body portion fixed to the one shaft on the side opposite to the movable sheave relative to the fixed sheave, and an annular projecting portion projecting from the main body portion toward a wall surface of the fixed sheave on the side opposite to the movable sheave and abutting on the wall surface of the opposite side on the outer circumferential side than the minimum winding diameter of the transmission belt, and wherein the annular projecting portion of the parking gear abuts on the wall surface of the fixed sheave on the side opposite to the movable sheave at a radial position corresponding to the maximum winding diameter of the transmission belt.

Owner:TOYOTA JIDOSHA KK

Construction solution for reinforcing joints on load bearing wall and precast slabs of brick-concrete structure

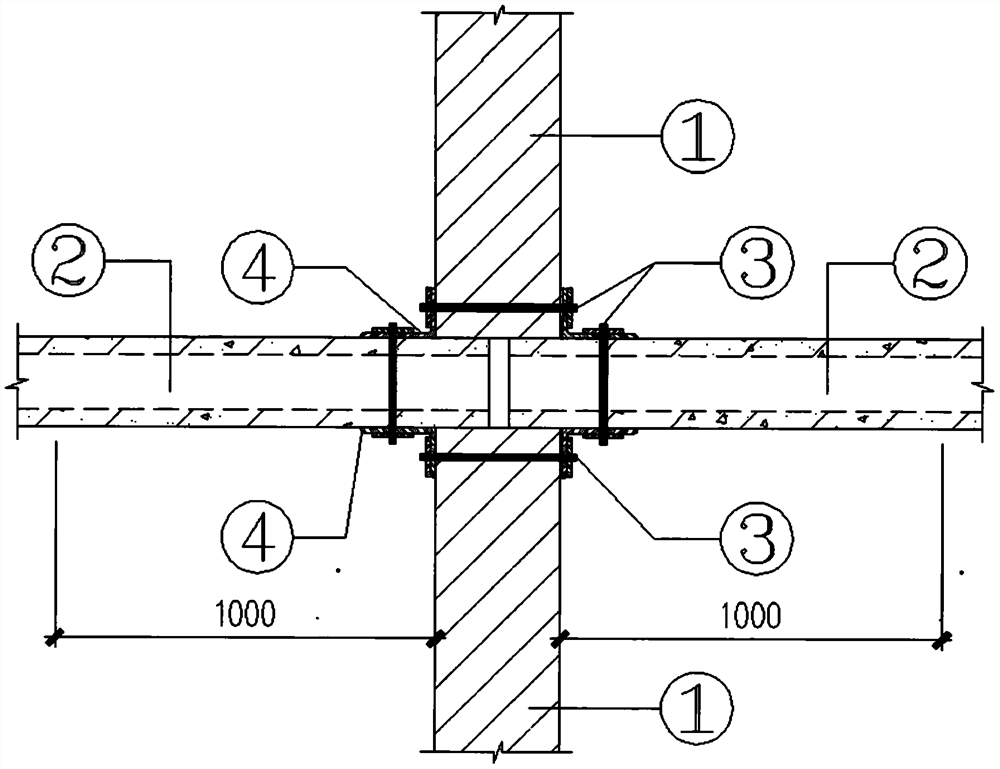

InactiveCN112854795AHigh strengthImprove integrityBuilding repairsProtective buildings/sheltersEarthquake resistantWall plate

The invention discloses a construction solution for reinforcing joints on a load bearing wall and and precast slabs of a brick-concrete structure. The reinforcing solution only relates to a brick-concrete structure house provided with the load bearing wall and the precast slabs. The joint construction method comprises the following steps that holes of the prefabricated slabs are filled with glue in the 1000 millimeters range of the end parts of the left and right prefabricated slabs placed at the upper part of the load bearing wall, reversely four pieces of full-length angle steel are installed at four internal corners at the upper and lower parts of the joint of wallboards, and oppositely pulling and anchoring are conducted on the four pieces of angle steel in pairs by using opposite-penetrating bolts. The construction solution has the advantages that the integrity of the brick-concrete structure house is enhanced, the anti-seismic capacity is higher, falling of the prefabricated slabs and falling of the load bearing wall caused by the transverse horizontal effect are more effectively restrained during an earthquake, and the escape time of people is prolonged.

Owner:HANGZHOU GULI CONSTR ENG

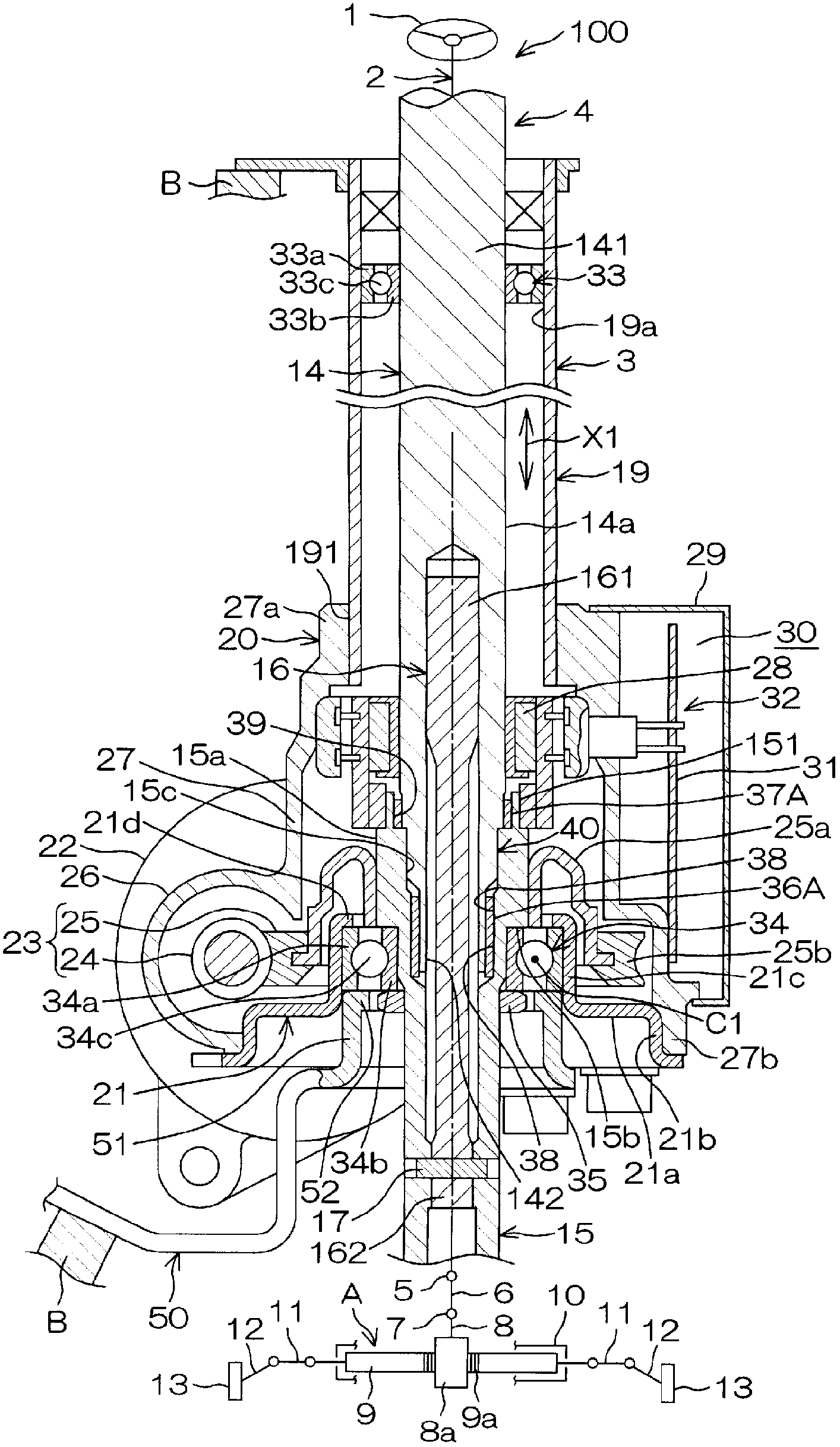

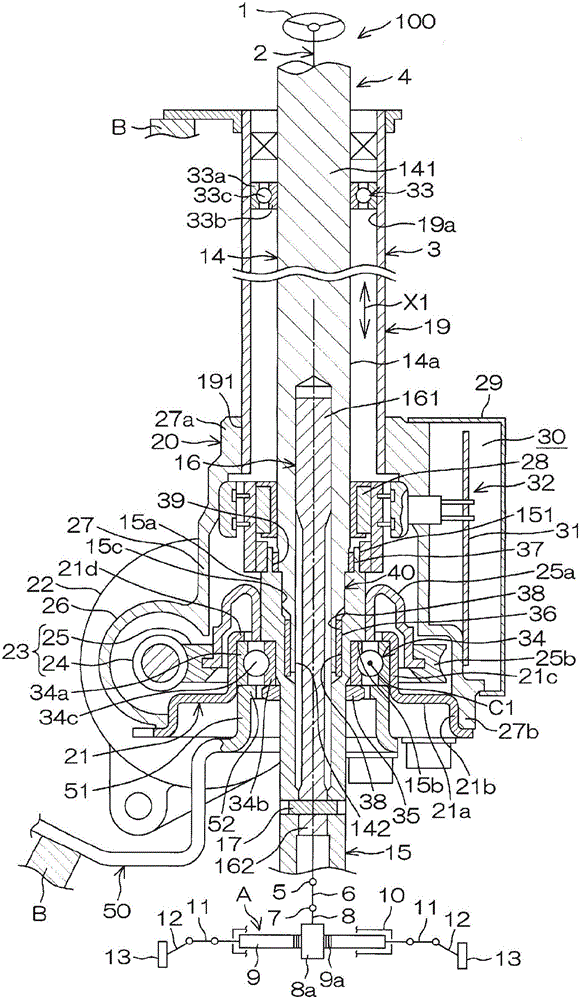

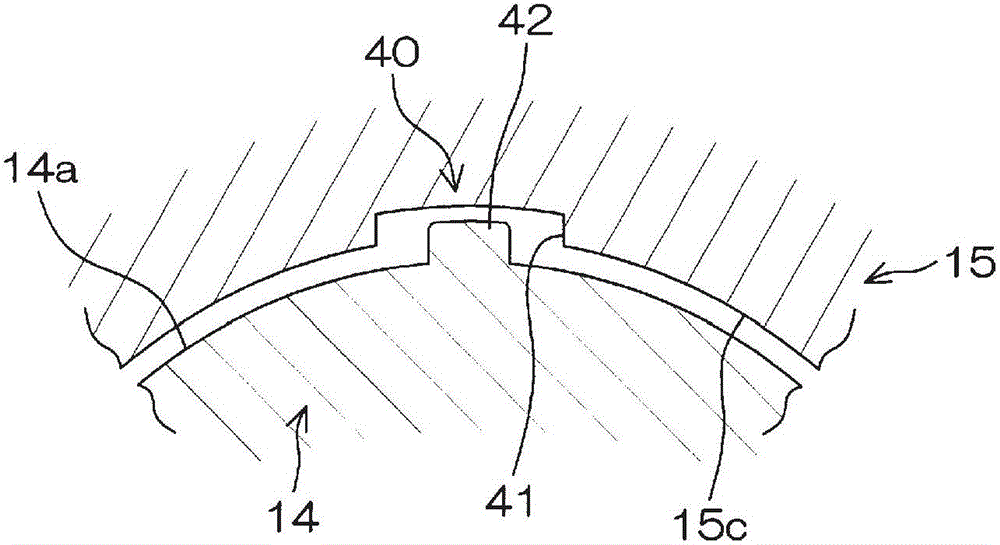

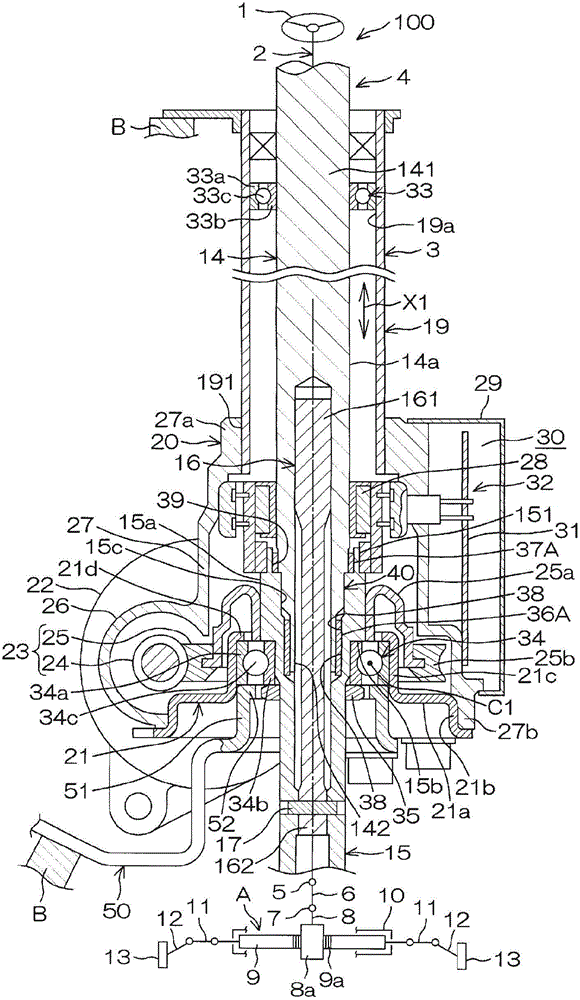

Steering device for vehicle

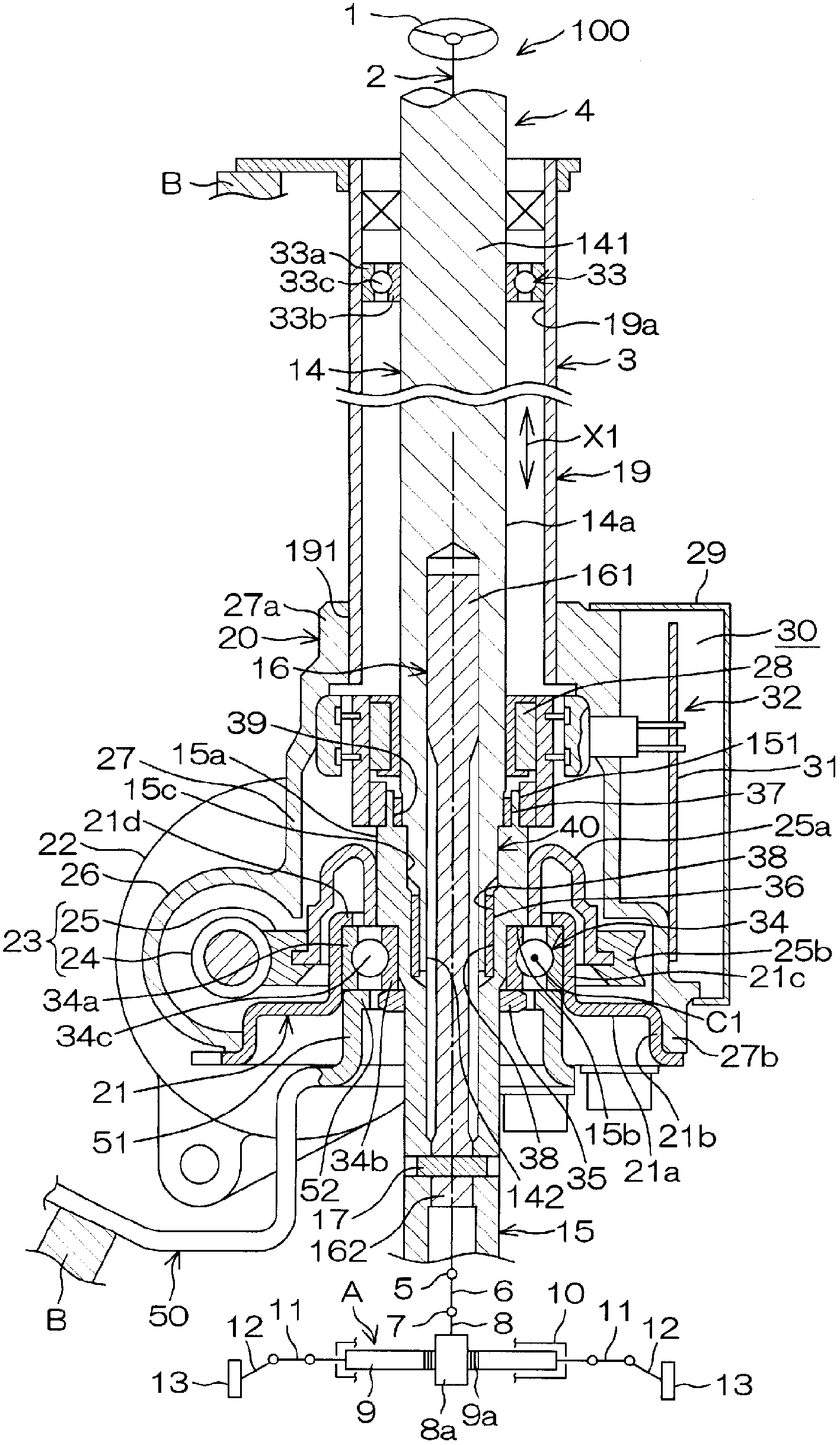

InactiveCN103269939ASave spaceReduce dumpingAutomatic steering controlElectrical steeringEngineeringMechanical engineering

A steering shaft (2) penetrating through a hollow support member (3) includes an upper shaft (14) and a lower shaft (15) which are coaxially connected through a torsion bar (16). A first ball bearing (33) retained by the support member (3) rotatably supports the upper end (141) of the upper shaft. A second ball bearing (34) retained by the support member (3) rotatably supports the lower shaft (15). A first inter-shaft bearing (36; 36A) retained by the lower shaft (15) rotatably supports the lower end (142) of the upper shaft (14). A second inter-shaft bearing (37; 37A) retained by the upper shaft (14) rotatably supports the upper end (151) of the lower shaft (15). The first inter-shaft bearing (36; 36A) includes a portion disposed inward radially of the bearing center (C1) of the second ball bearing (34). The first and second inter-shaft bearings (36, 37; 36A, 37A) are separated from each other in the direction (X1) of the axis of the steering shaft (2).

Owner:JTEKT CORP

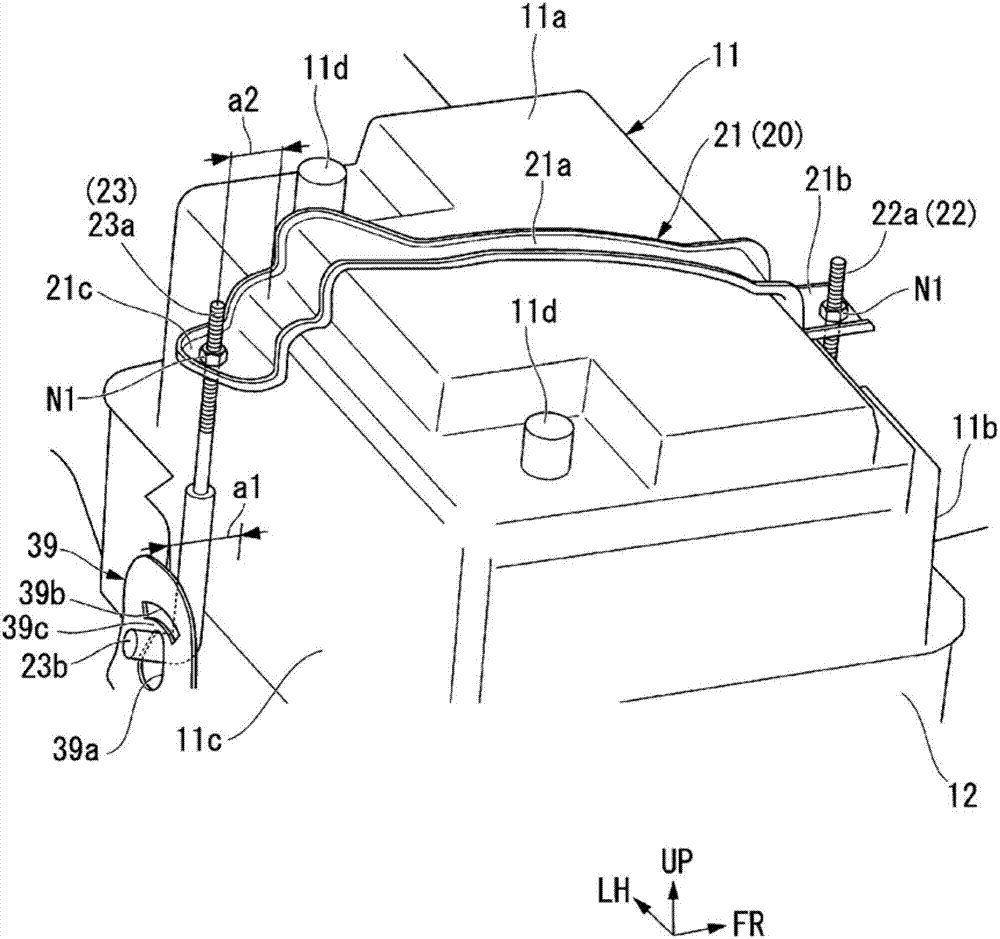

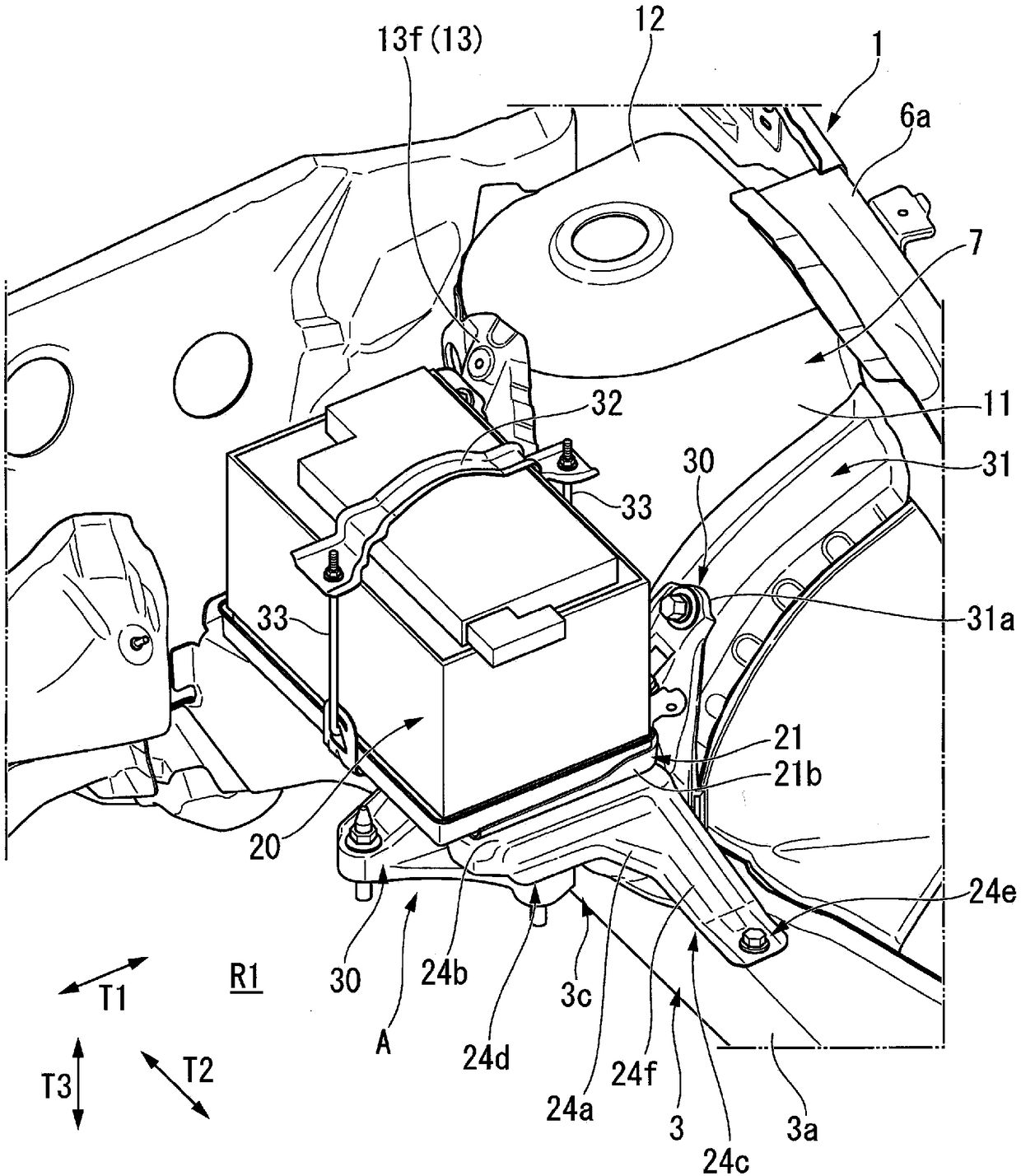

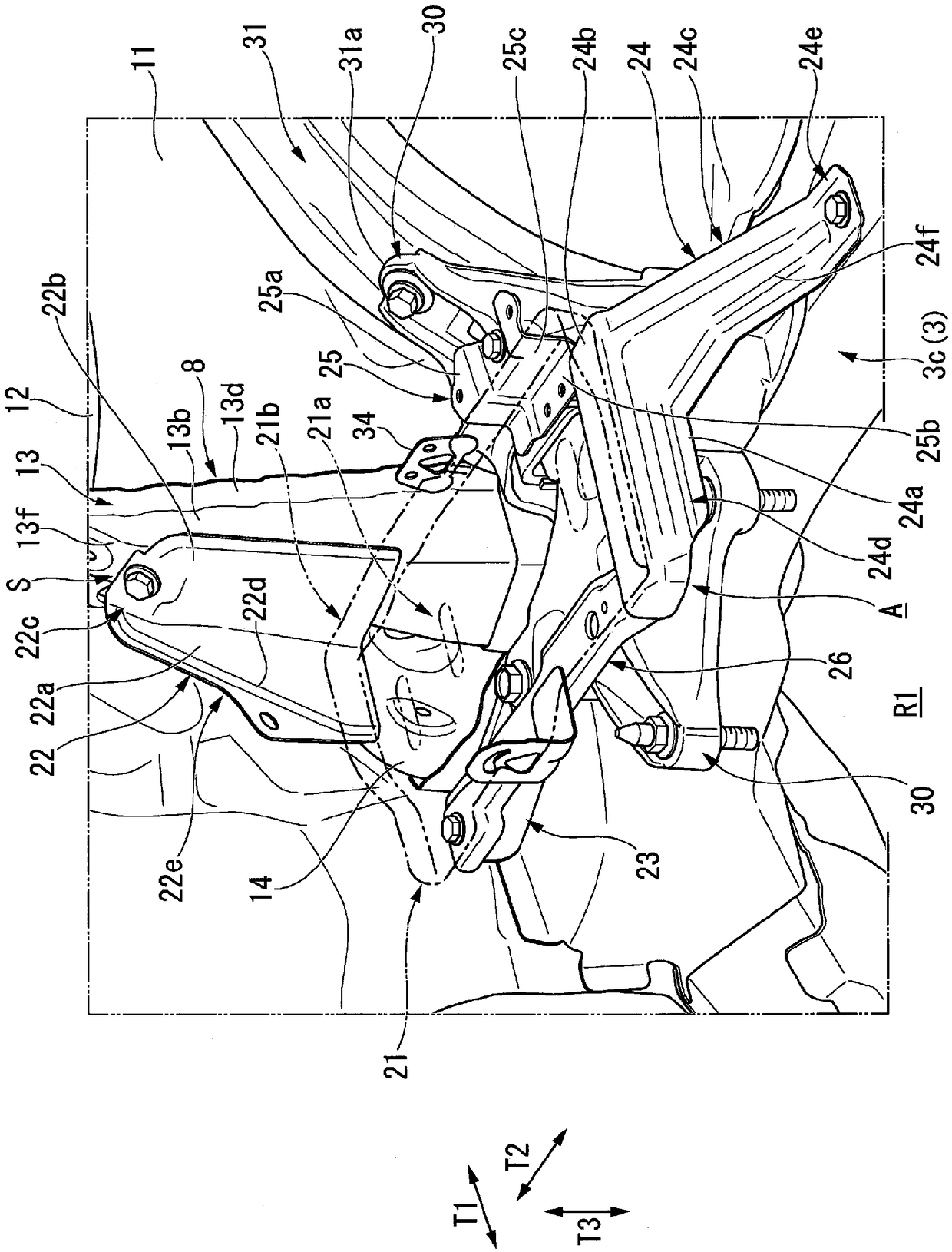

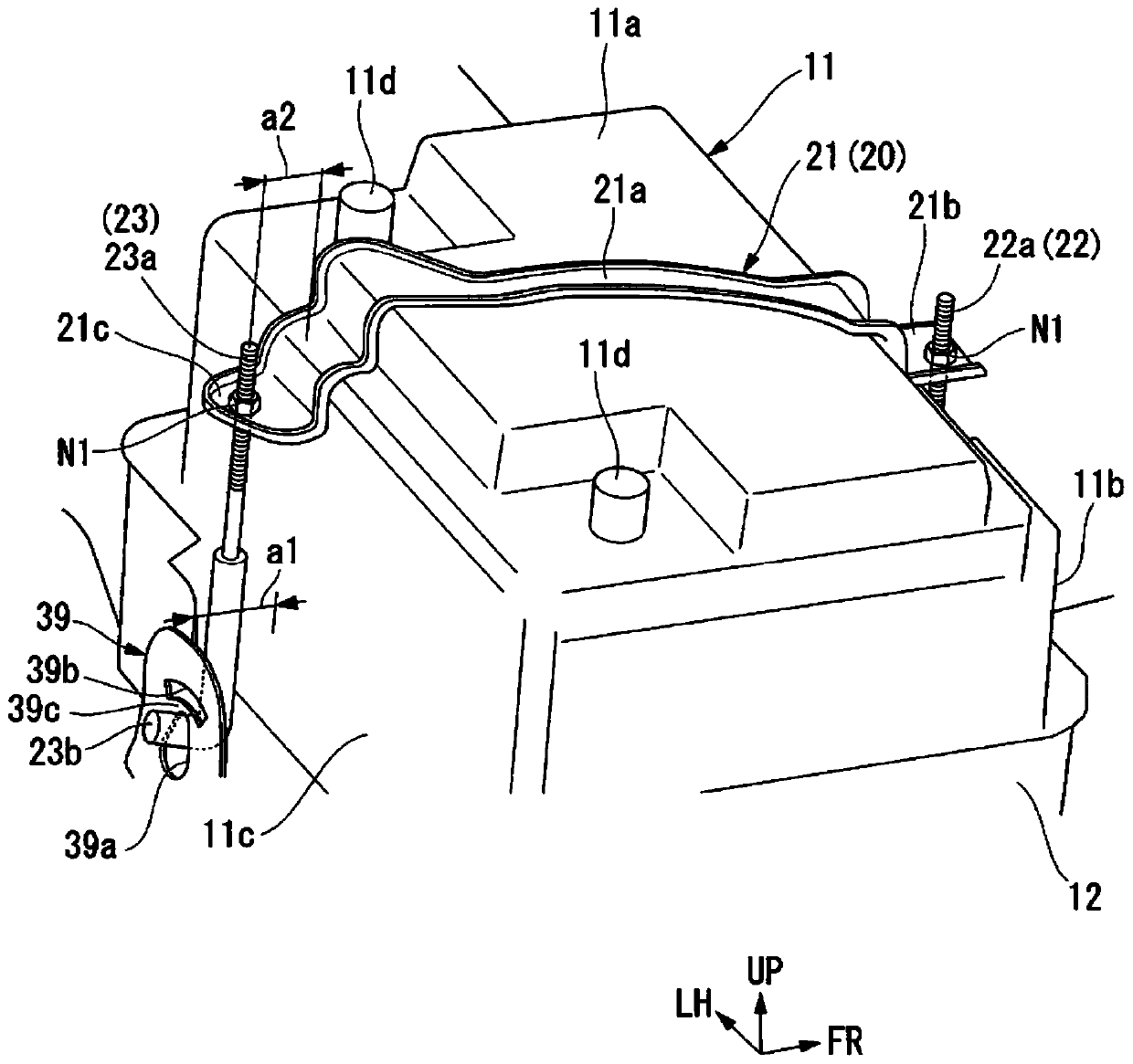

Automobile battery mounting structure

ActiveCN107031542AAvoid deformationStay stuckSuperstructure subunitsElectric/fluid circuitVehicle frameElectrical battery

According to the present invention, there is provided an automobile battery mounting structure in which a leg (30) of a battery base (13) is formed of a metal plate intersecting a vehicle front-rear direction, and the width of the vehicle is larger, (34, 35) is provided at the lower end of the leg (30), and the lower bent portion (34, 35) is fixed to the front side frame (5), and the lower end (38b) is provided at the upper end of the leg portion (30), and the upper end engaging portion (38, 39) is locked to the upper end of the opening (31d, 32d) Battery clamping parts. Accordingly, it is possible to maintain the engagement of the hook portion of the battery gripping bolt with respect to the battery base locking member when the vehicle collides with the front side.

Owner:HONDA MOTOR CO LTD

Steering devices for vehicles

InactiveCN103269939BCurb dumpingStable supportAutomatic steering controlSteering columnsBall bearingEngineering

Owner:JTEKT CORP

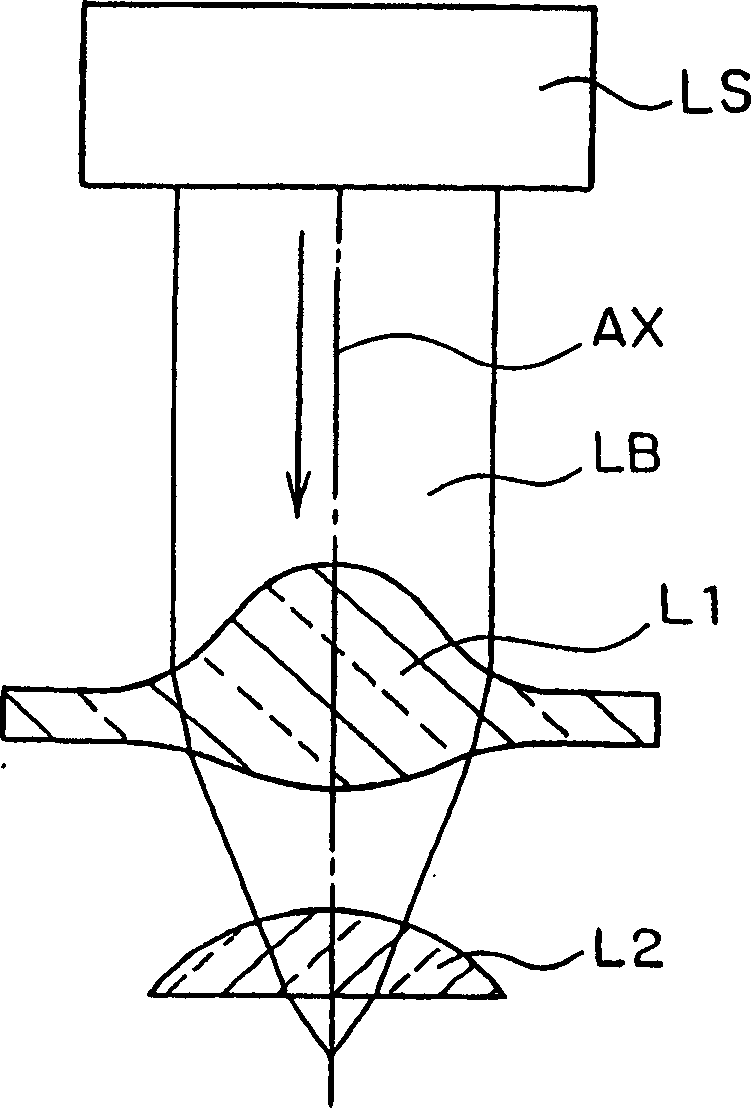

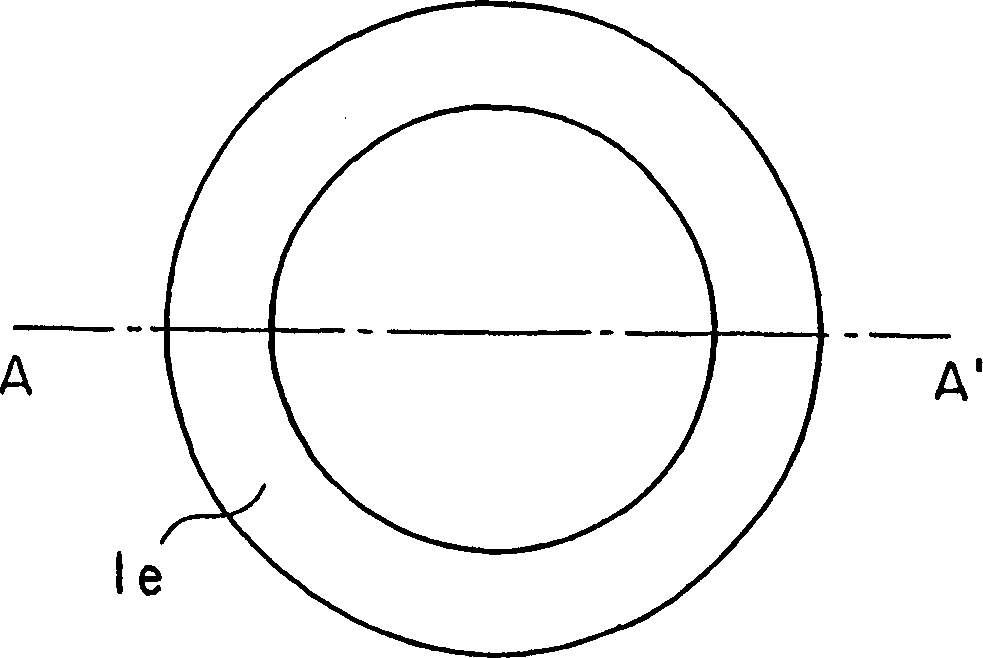

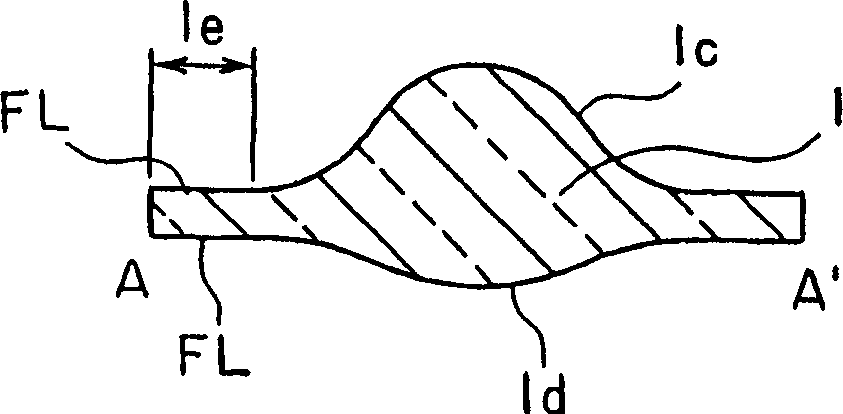

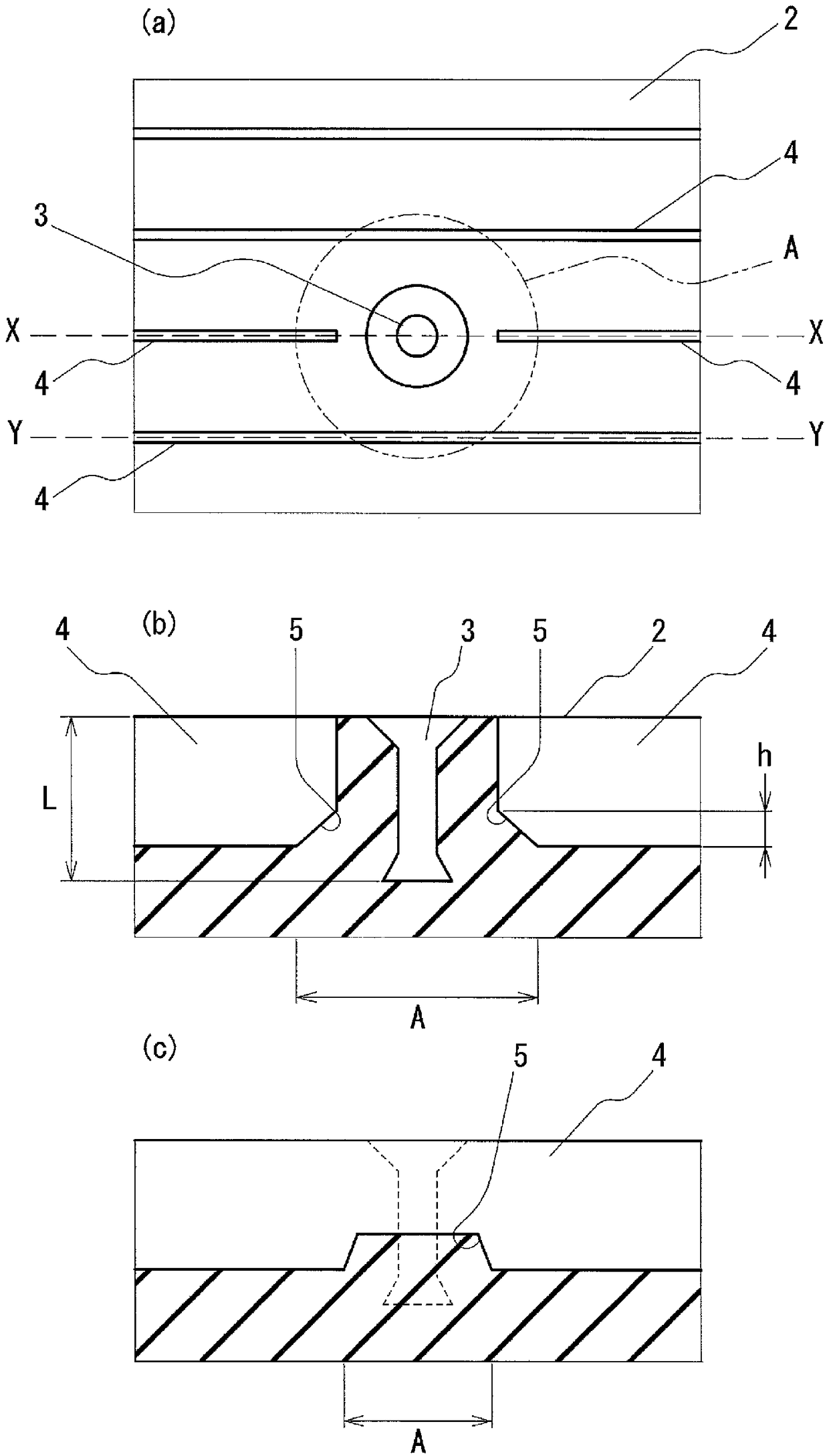

Lens, combination lens and its mfg. method, optical pickup

A lens and combination lens able to suppress deviation of an optical axis of a lens occurring at the time of combination and able to be adjusted at a high precision, a method of producing the combination lens, and an optical pickup device and an optical disk drive mounting the combination lens thereon are provided. A first lens L1 comprising a lens body 1 where one surface on an incident side or an emitting side of light is a flat surface and the other surface parallel to the surface formed as the flat surface is a structural element and a second lens L2 comprising a lens body 2 where one surface on an incident side or an emitting side of light is a flat surface and the other surface parallel to the surface formed as the flat surface is a structural element are adhered together. The combination lens is used as the object lens for an optical pickup device and an optical disk drive.

Owner:SONY CORP

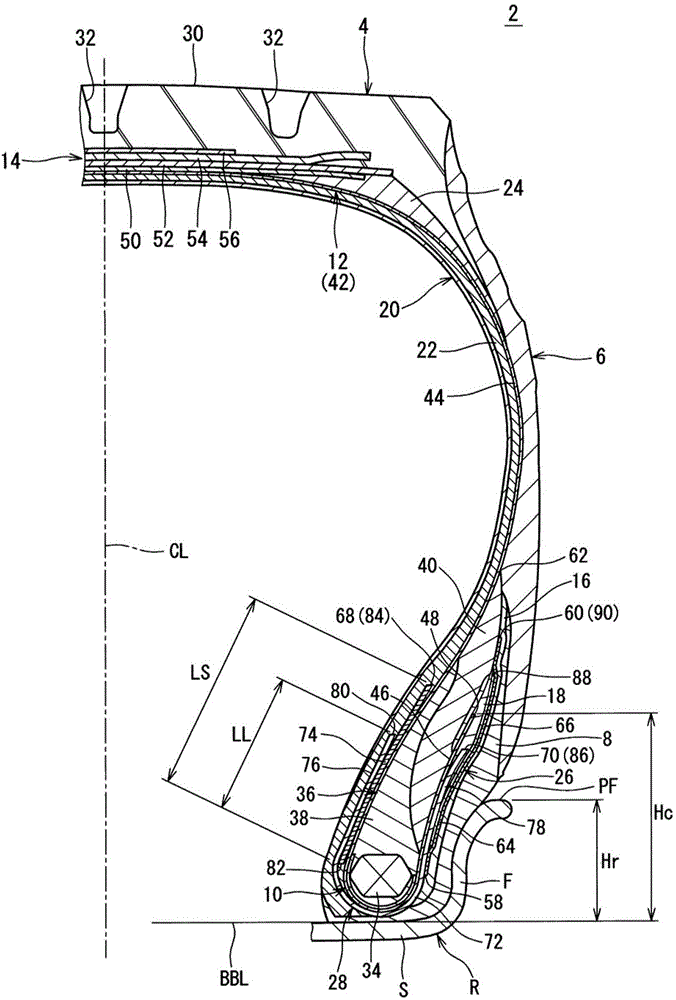

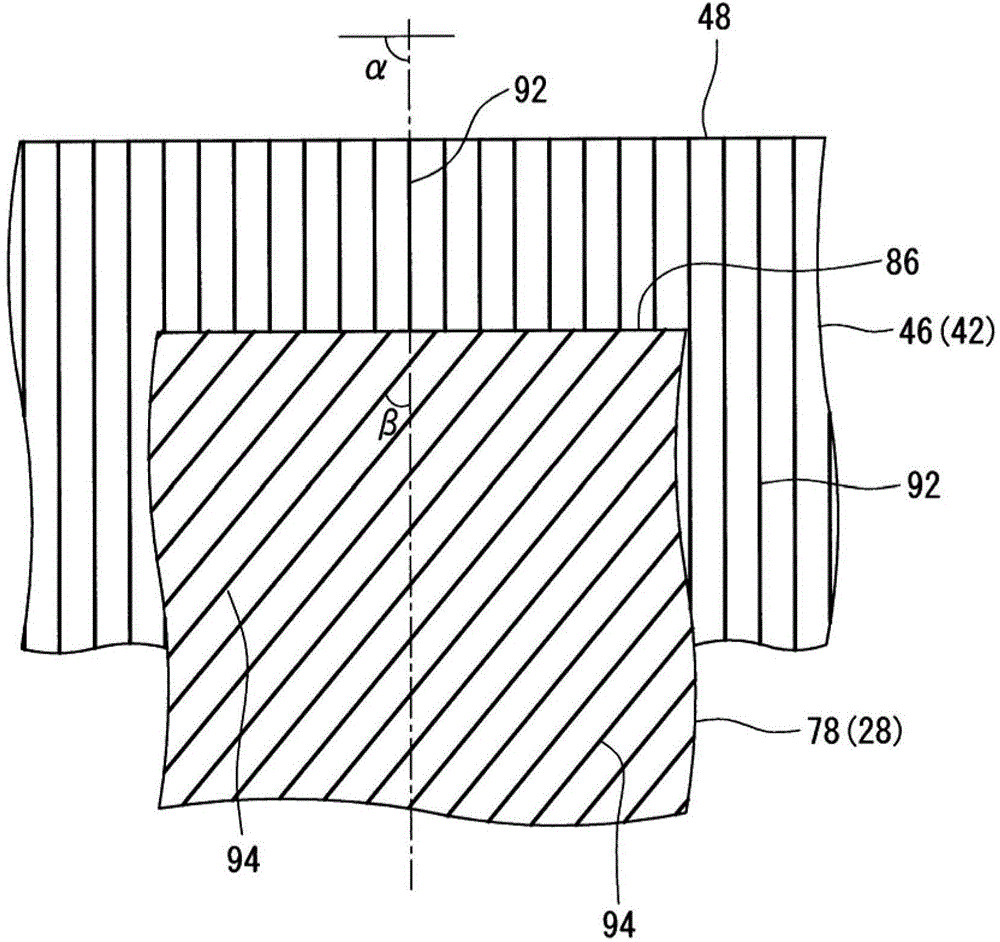

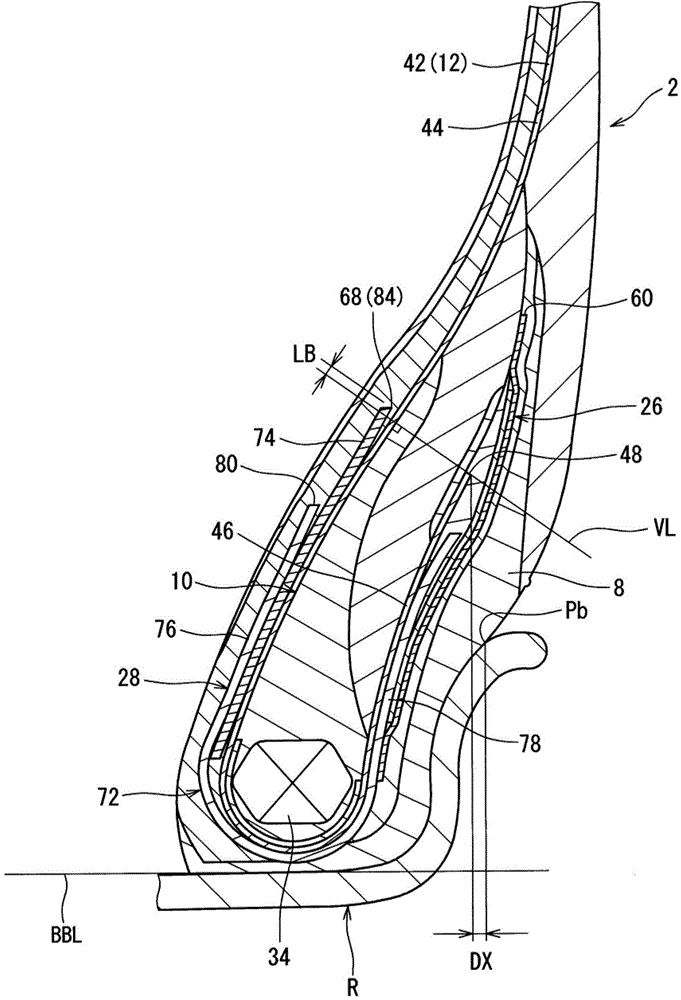

Pneumatic tire

The invention provides a pneumatic tire (2) capable of improving durability, wherein, in the pneumatic tire (2), a first filling member (26) is closer to the outer side than a tire bead (10) at axial direction; an end portion (48) of a return portion (46) of a tire body cord fabric layer (42) is closer to the inner side than an outer side end (60) of the first filling member (26) at radial direction; a second cord thread (94) of a second filling member (28) is crossed with a tire body cord thread (92) of the tire body cord fabric layer (42); the absolute value of the crossed angle is between 35 degree to 45 degree; with the height of a flange (F) of a wheel ring (R) as a benchmark height, the ratio between the height of the return portion (46) and the benchmark height is between 1.58 to 1.75; with an end portion on the contact surface of the wheel ring (R) as a benchmark position, the end portion (48) of the return portion (46) and the benchmark position are the same at the axial direction, or the end portion (48) of the return portion (46) is closer to the inner side than the benchmark position at the axial direction; and axial direction distance (DX) from the benchmark position to the end portion (48) of the return portion (46) is less than 3 mm.

Owner:SUMITOMO RUBBER IND LTD

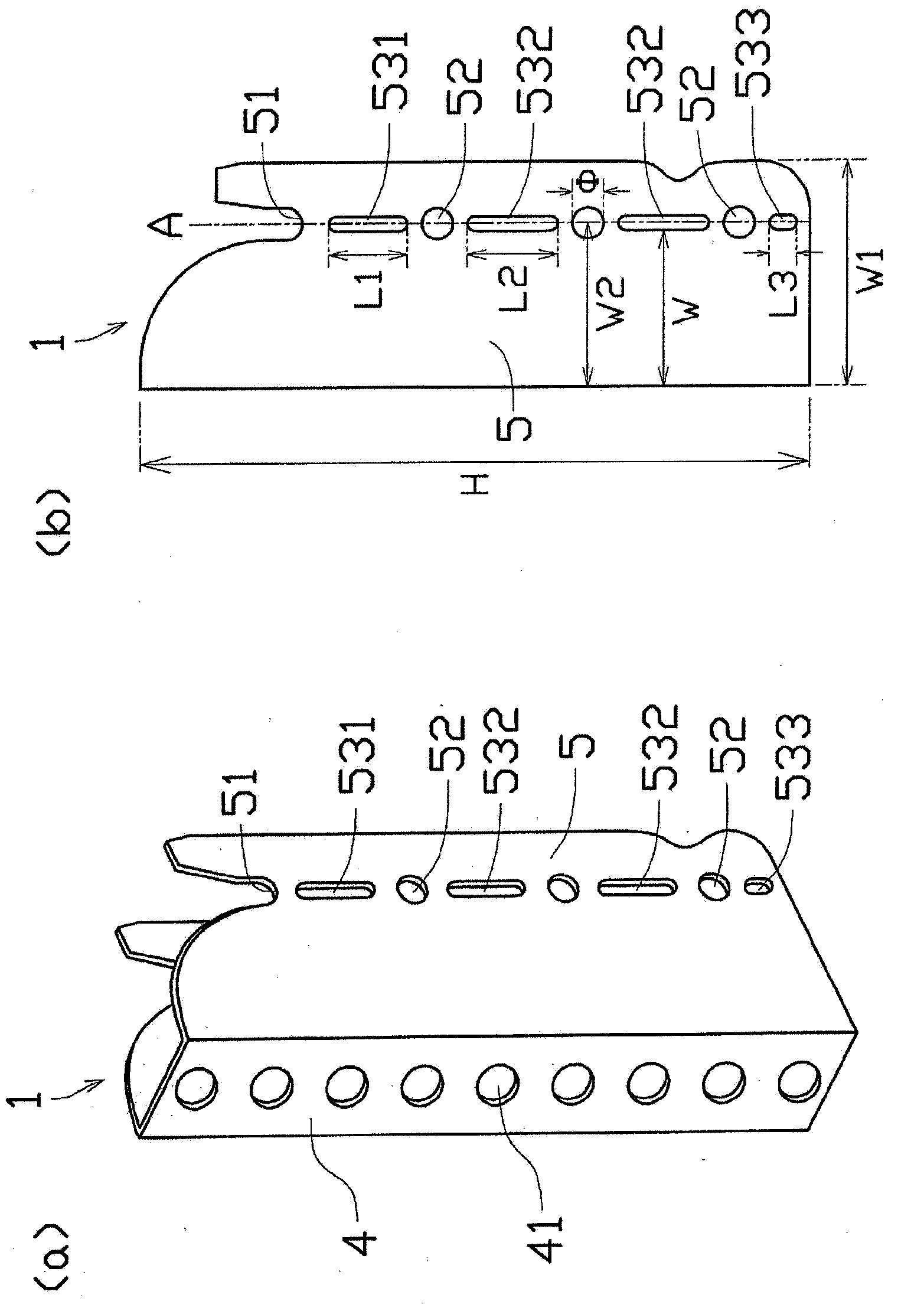

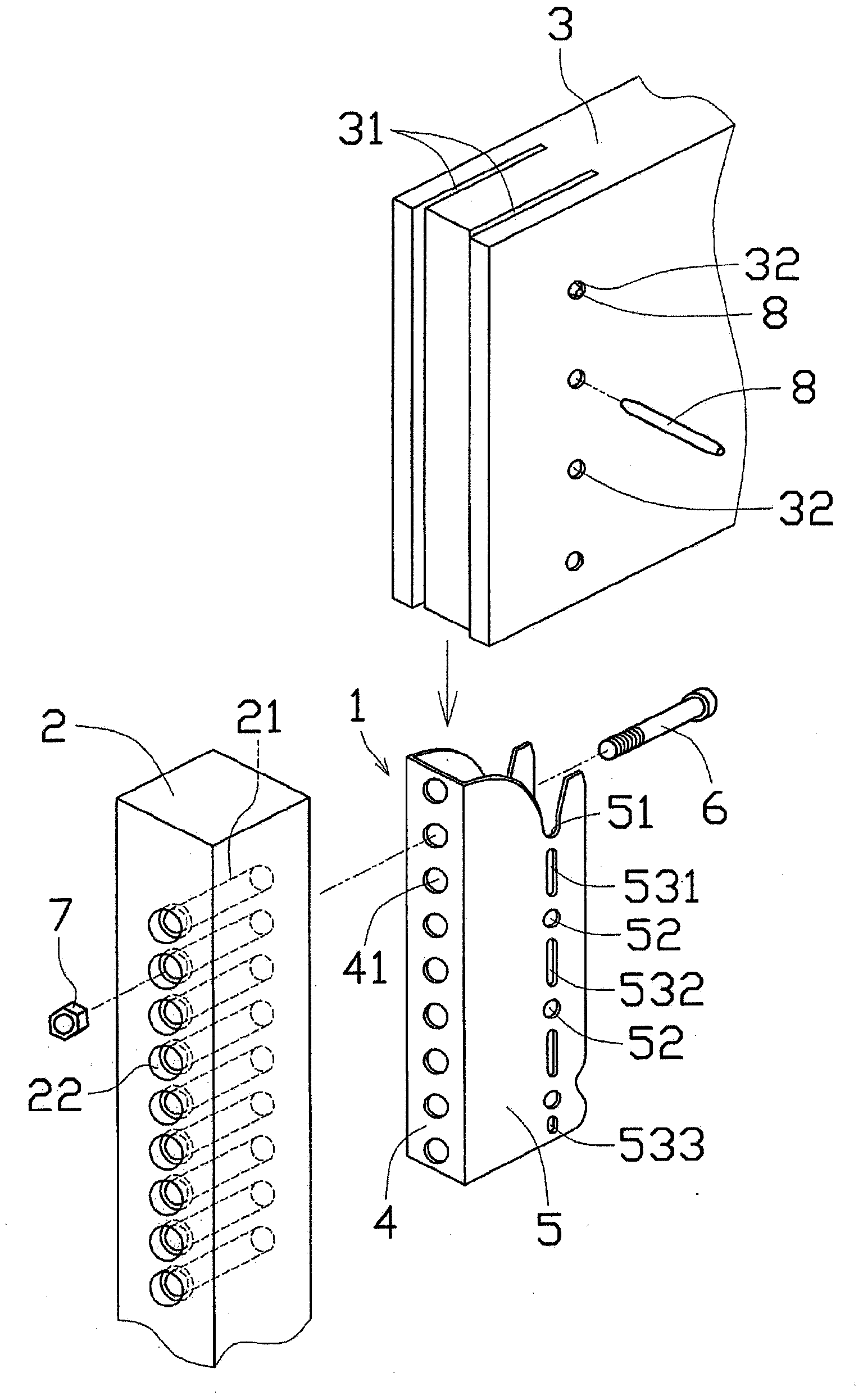

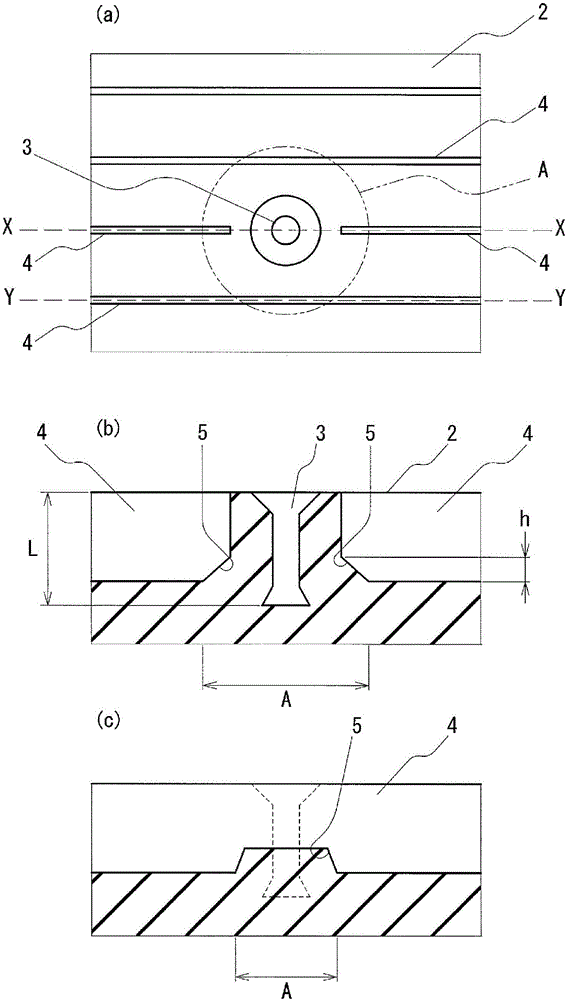

Metal joint and building structure

ActiveCN104136693AInhibition of fractureControl overall deformationBuilding constructionsEnergy absorptionMetal

[Problem] To provide a metal joint and building structure that is very reliable and has excellent stability as a junction and that does not lose yield resistance, initial stiffness, energy absorption capacity or the like in the junction when an excessive load is applied at the junction of a support member and horizontal member. [Solution] A metal joint (1) comprising a stationary plate (4) affixed to a side face of a support member (2), and a coupling plate (5), which is provided protruding from the stationary plate (4) toward the side of a horizontal member (3) and which is connected so as to be inserted into grooves (31) formed across the end face of the horizontal member (3) in the vertical direction, wherein the coupling plate (5) is provided with a plurality of coupling holes (52), into which cylindrical coupling instruments (8) are inserted into the grooves (31) so as to pass through the horizontal member (3), and a first cut portion (54) formed by cutting around the coupling holes (52). The first cut portion (54) is formed to be in an arc-shape centered on the coupling hole (52).

Owner:SEKISUI HOUSE KK

pneumatic tire

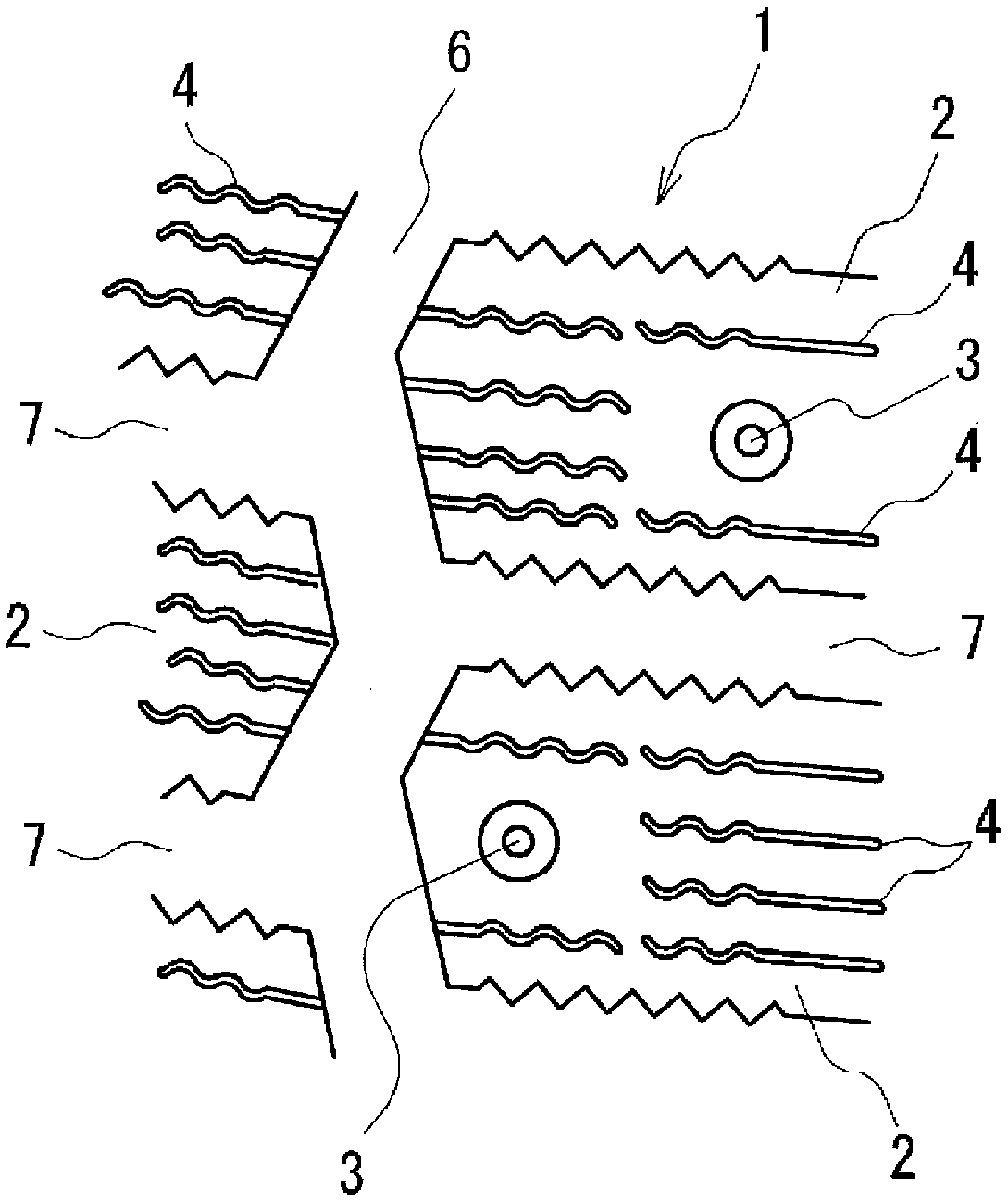

The present invention provides a pneumatic tire in which the studs are suppressed from coming off when the studs are driven into the stud holes, and the performance on ice and snow is improved above the conventional level. The pneumatic tire has a tread (1) with a plurality of blocks (2) divided by grooves (6) extending in the tire circumferential direction and grooves (7) extending in the tire width direction. There are a plurality of sipe (4) and stud holes (3), characterized in that at least a part of the bottom of the sipe (4) located in the peripheral area A of the stud holes (3) is raised.

Owner:THE YOKOHAMA RUBBER CO LTD

circuit module

InactiveCN102024800BCurb dumpingFinal product manufacturePrinted circuit aspectsEngineeringElectronic component

An electronic component includes a component body including a mounting surface facing a circuit substrate, and a plurality of first external electrodes arranged on the mounting surface so as to extend between a first side and a second side of the mounting surface substantially parallel with each other and so as to be within a first region having a width that is substantially equal to half a length of the first side in a direction in which the first side extends. A circuit substrate includes a substrate body, a plurality of second external electrodes, arranged on a main surface of the substrate body, respectively connected to the plurality of the first external electrodes, and support units arranged to protrude from the main surface of the substrate body and such that the electronic component overlaps the support units outside the first region.

Owner:MURATA MFG CO LTD

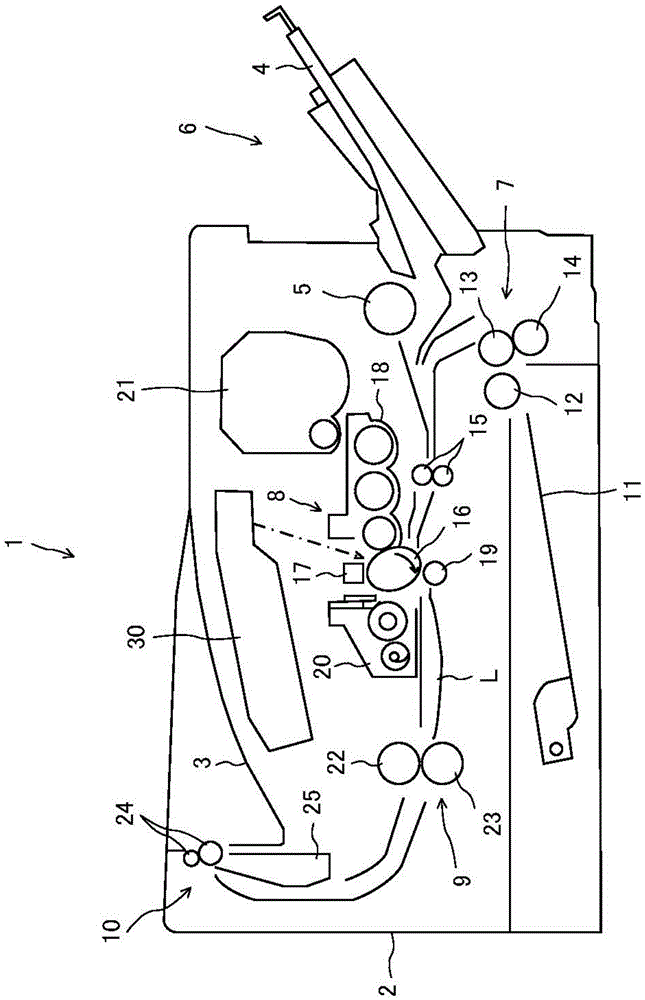

Optical scanning device and image forming device including optical scanning device

InactiveCN104076651BEffective coolingCurb dumpingElectrographic process apparatusPrintingImage formationOptoelectronics

An optical scanning device includes a rotating polygon mirror, a motor, a substrate, a heat releasing member and a heat transfer member. The rotating polygon mirror deflection scans light emitting by a light source. The motor rotatively drives the rotating polygon mirror. The substrate has a drive circuit part for controlling the motor. The heat releasing member releases heat generated from the substrate. The heat transfer member is sandwiched between the substrate and the heat releasing member to be compressively deformed. A receiving portion that part of the heat transfer member compressively deformed enters is formed in a first part of the heat releasing member in which the heat transfer member is provided.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

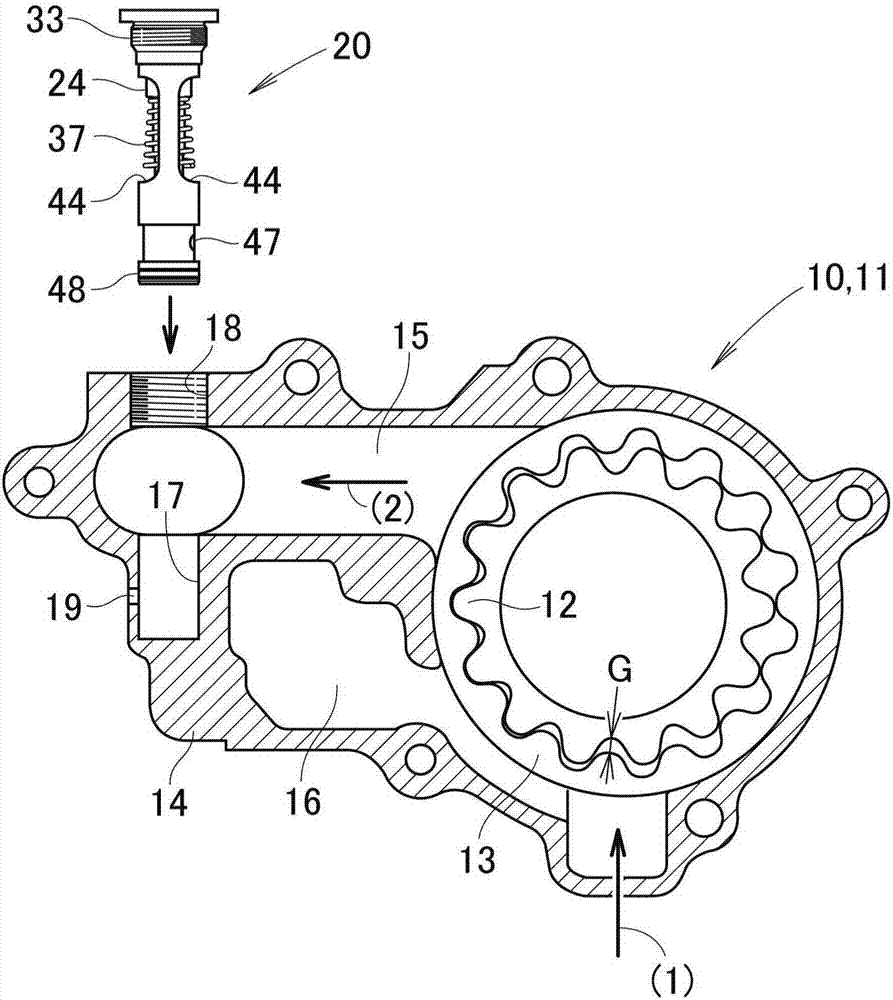

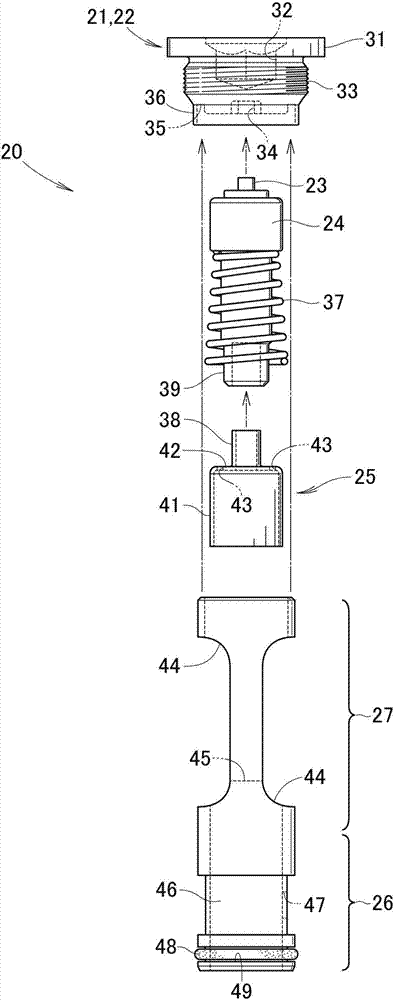

Thermal-sensing type valve mechanism

ActiveCN107269522AConfirm thermal performanceReduce assembly man-hoursOperating means/releasing devices for valvesMachines/enginesEngineeringLiquid tank

The invention provides a thermal-sensing type valve mechanism which can confirm thermal performance with low cost. A pump shell (14) is provided with a main oil path (15), and a return oil path (16) parallel to the main oil path (15) substantially is arranged. The pump shell (14) is provided with a valve insertion hole (17) which transecting the main oil path (15), with the tail end reaching the vicinity of the return oil path (16). The valve insertion hole (17) is provided with an internal thread (18) at the hole opening and is provided with a through hole (19) leading to the outside of the pump shell (14) at the tail end. The thermal-sensing type valve mechanism (20) can be inserted in the valve insertion hole (17) any time. In the prior art, a thermal-sensing type valve mechanism and a pump shell need to be carried to a liquid tank or constant temperature tank together. The invention solves the problem. People only need to carry the small and light thermal-sensing type valve mechanism to the liquid tank or constant temperature tank. The thermal-sensing type valve mechanism can determine thermal performance with low cost.

Owner:YAMADA SEISAKUSHO KK

Cab Reinforcement Structure

InactiveCN104755362BGood effectConvenient and quick escapePedestrian/occupant safety arrangementUnderstructuresSupport pointBackplane

The reinforcement structure of the present invention is based on the two parts of the upper part of the back panel (4) of the cab (1) entering from the outside end in the vehicle width direction to the inside as load support points (A, B), and a pair of reinforcement columns ( 13, 13) Install on the aforementioned back panel (4) so as to be directly above the pair of rear cab brackets (7, 8) that support the rear of the aforementioned cab (1) from one side of the frame (6) Between the bottom plate (9) of the aforementioned load support points (A, B), and at the same time, the reinforcing beam (12) is installed on the aforementioned back plate (4) so that the upper ends of the aforementioned reinforcing columns (13, 14) are connected to each other. For connection, non-reinforced portions are left as impact absorbing portions (15, 16) on both sides of the reinforcing beam (12) in the vehicle width direction.

Owner:HINO MOTORS LTD

A battery support structure

The present invention provides a battery support structure that can stably support / hold a battery while achieving space saving and weight reduction. The battery supporting structure (A) is used for supporting a battery carried by a battery carrying portion (21), disposed on the front side frame (3) and at a side inside the vehicle width direction (T1) of a damper housing (11). The battery supporting structure is provided with a suspension supporting portion (22), as a first supporting component (22), for suspending and supporting the battery carrying portion (21). The suspension supporting portion (22) is configured in a manner that one wall portion (22a) and another wall portion (22b) extending in the axis direction along the vertical direction (T3) form a substantially L shape, the upperend is fixed to a position near a damper seat (12) at the upper end side of the damper housing (11), and the battery carrying portion (21) is fixed to the lower end, thus supporting the battery carrying portion (21).

Owner:HONDA MOTOR CO LTD

Pneumatic tire

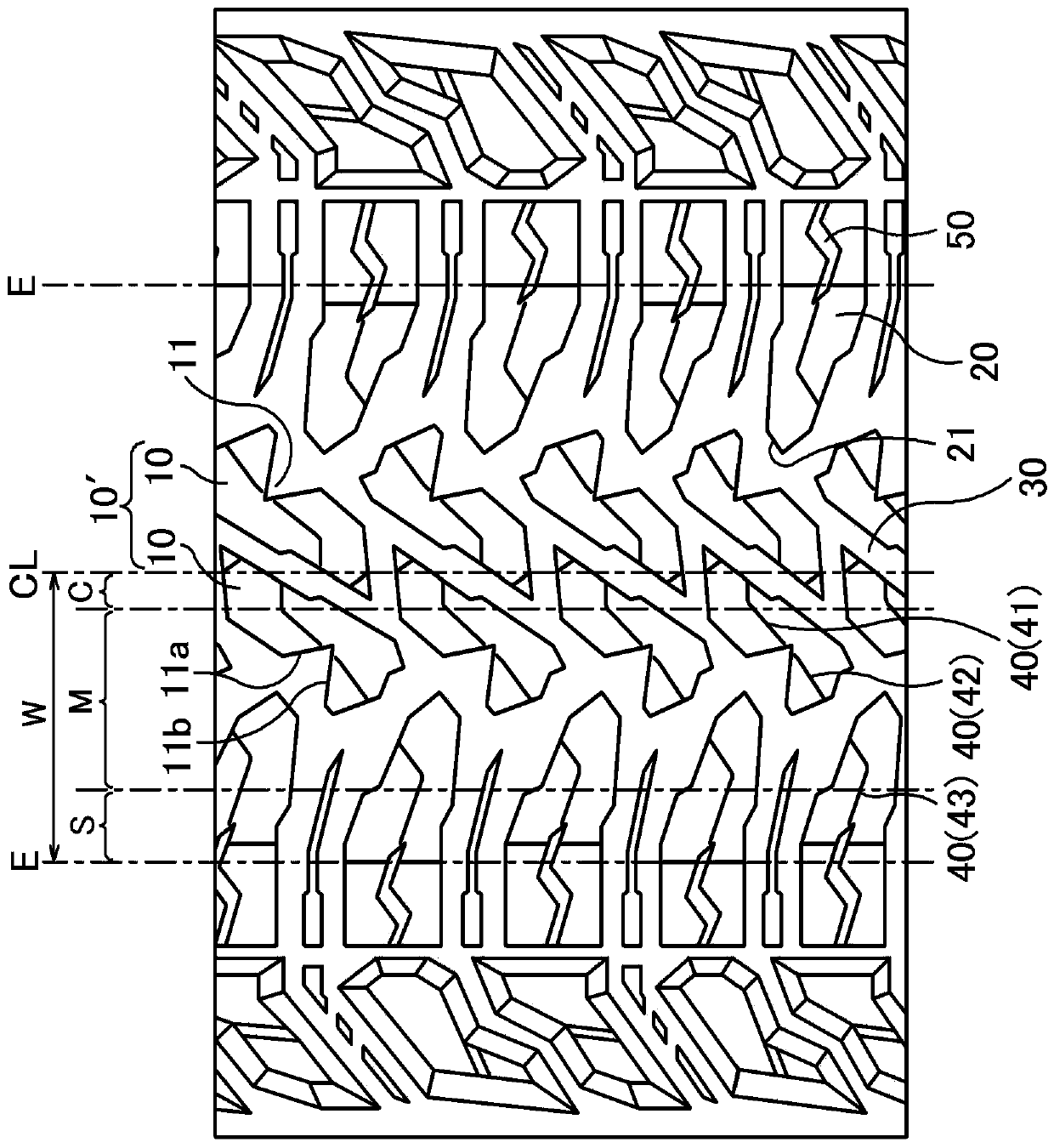

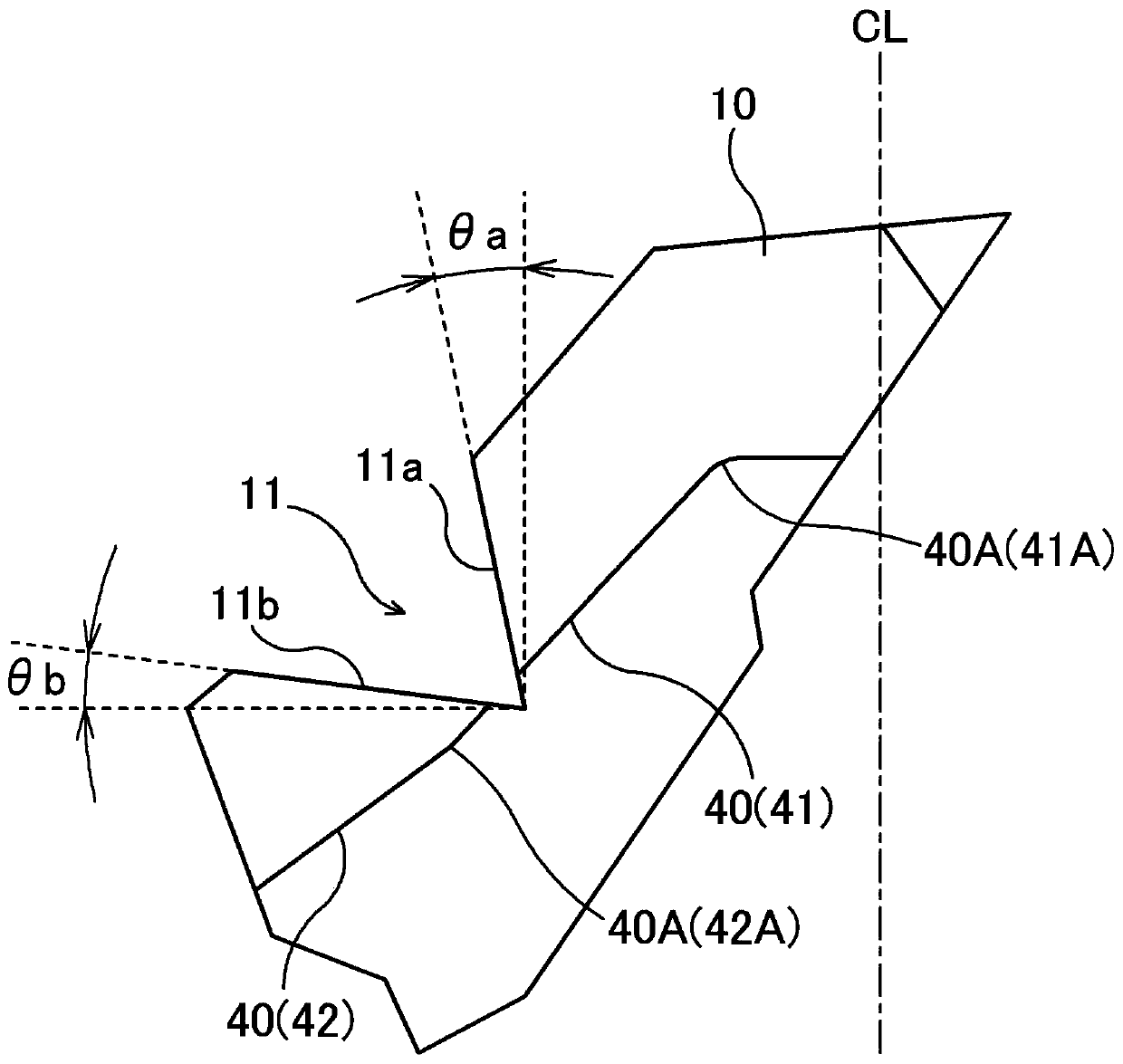

ActiveCN110198848ACurb dumpingEffective controlOff-road vehicle tyresTyre tread bands/patternsMechanical engineeringTread

The present invention provides a pneumatic tire that is suitable for use as a tire for traveling on unpaved roads, and that improves traveling performance and damage resistance on unpaved roads. Center blocks 10, which are provided in a center region of a tread section 1, are arrayed so as to form a pair of center blocks 10 between which there are interposed inclined grooves 30 that extend in an inclined direction with respect to a tire circumferential direction. The center blocks 10 are made to extend so as to straddle a tire equator CL from one side to the other side of the tire equator CL.Notches 11, which are each composed of a first wall 11a and a second wall 11b connected to each other in a V shape, are provided in treads in each center block CL. The first walls 11a are made to extend at an angle within + / -20 degrees with respect to the tire circumferential direction; the second walls 11b are made to extend at an angle of + / -10 degrees with respect to a tire width direction; andthe average angle of sipes, which are respectively formed in the center blocks 10 and shoulder blocks 20, lies within 90 degrees + / -10 degrees in a first region C, lies within 130 degrees + / -10 degrees in a second region M, and lies within 70 degrees + / -10 degrees in a third region S with respect to the tire equator CL. Each sipe is configured to have at least one curved portion.

Owner:THE YOKOHAMA RUBBER CO LTD

Relay

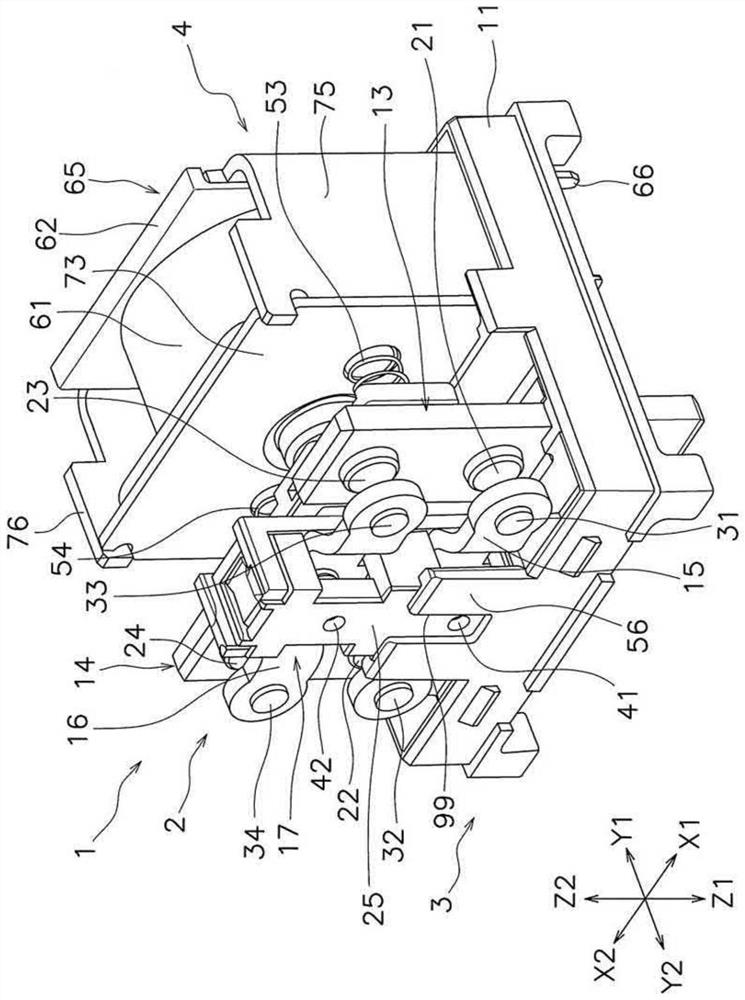

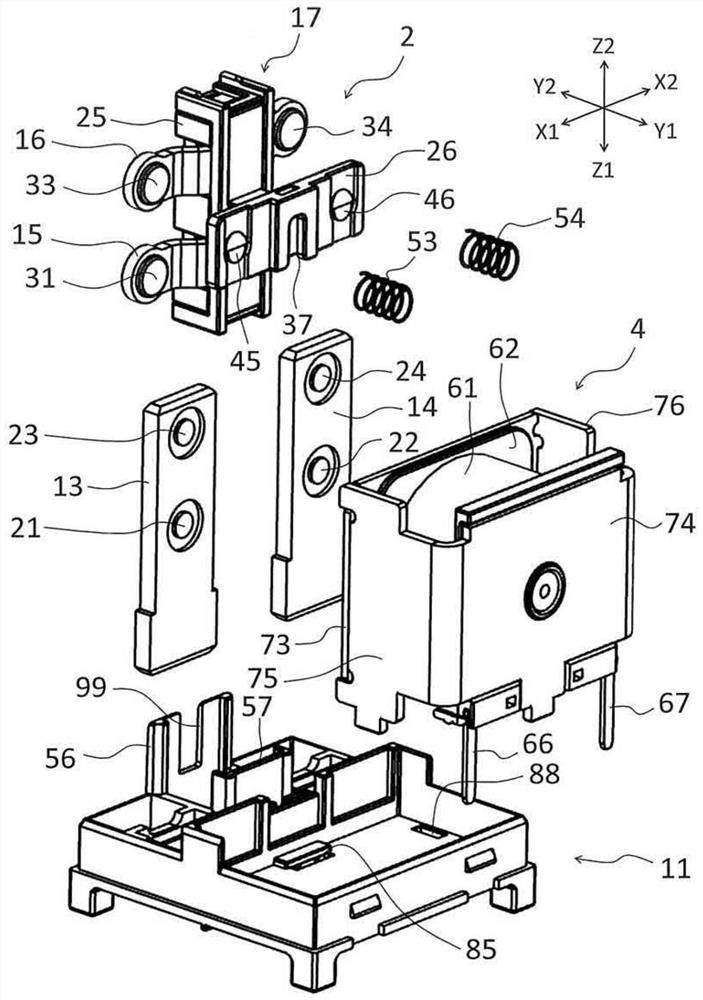

PendingCN112582219ACurb dumpingAvoid interferenceContact testing/inspectionElectromagnetic relay detailsEngineeringComputer science

In a relay according to the present invention, a moving member includes a support portion that holds a movable contact piece. A base includes a bottom surface and a first wall portion. The first wallportion extends from the bottom surface in the supporting direction and faces the moving member in the moving direction. At least a part of the first wall portion overlaps with the movable iron core when viewed from the moving direction.

Owner:ORMON CORP

Car battery installation structure

ActiveCN107031542BAvoid deformationStay stuckSuperstructure subunitsElectric/fluid circuitVehicle frameElectrical battery

According to the present invention, there is provided an automobile battery mounting structure in which a leg (30) of a battery base (13) is formed of a metal plate intersecting a vehicle front-rear direction, and the width of the vehicle is larger, (34, 35) is provided at the lower end of the leg (30), and the lower bent portion (34, 35) is fixed to the front side frame (5), and the lower end (38b) is provided at the upper end of the leg portion (30), and the upper end engaging portion (38, 39) is locked to the upper end of the opening (31d, 32d) Battery clamping parts. Accordingly, it is possible to maintain the engagement of the hook portion of the battery gripping bolt with respect to the battery base locking member when the vehicle collides with the front side.

Owner:HONDA MOTOR CO LTD

Pneumatic tire

InactiveCN106573507ARestricted activitiesInhibit sheddingTyre tread bands/patternsEngineeringMechanical engineering

Provided is a pneumatic tire configured so that, when a stud pin is pushed into a stud pin hole, the stud pin is prevented from falling out, and performance on snow and ice is improved so as to be greater than conventional levels. In the pneumatic tire, a tread 1 has a plurality of blocks 2 partitioned by a groove 6 extending in the circumferential direction of the tire and grooves 7 extending in the width direction of the tire, and each block 2 is provided with a plurality of sipes 4 and a stud pin hole 3. The pneumatic tire is characterized in that at least a portion of the sipes 4 present in a peripheral region A of the stud pin hole 3 has a raised bottom.

Owner:THE YOKOHAMA RUBBER CO LTD

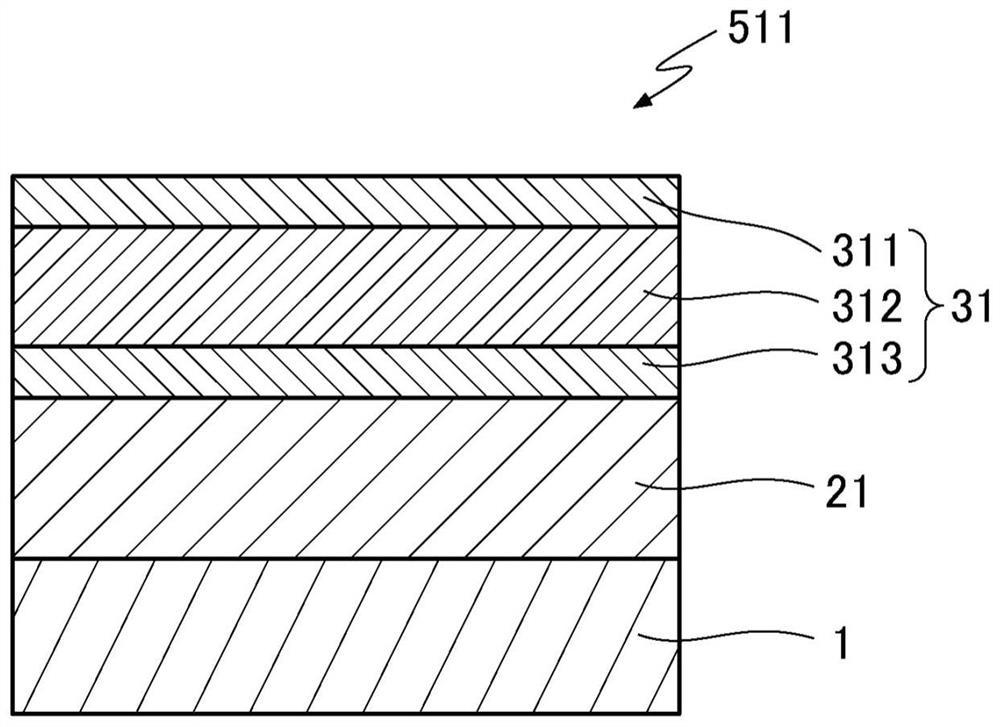

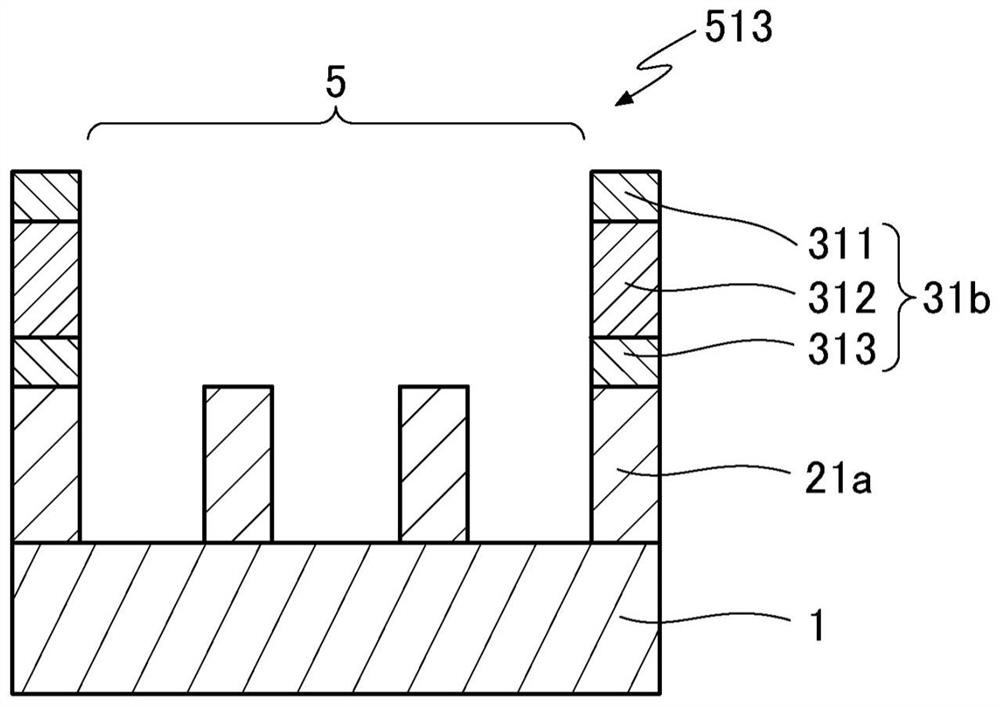

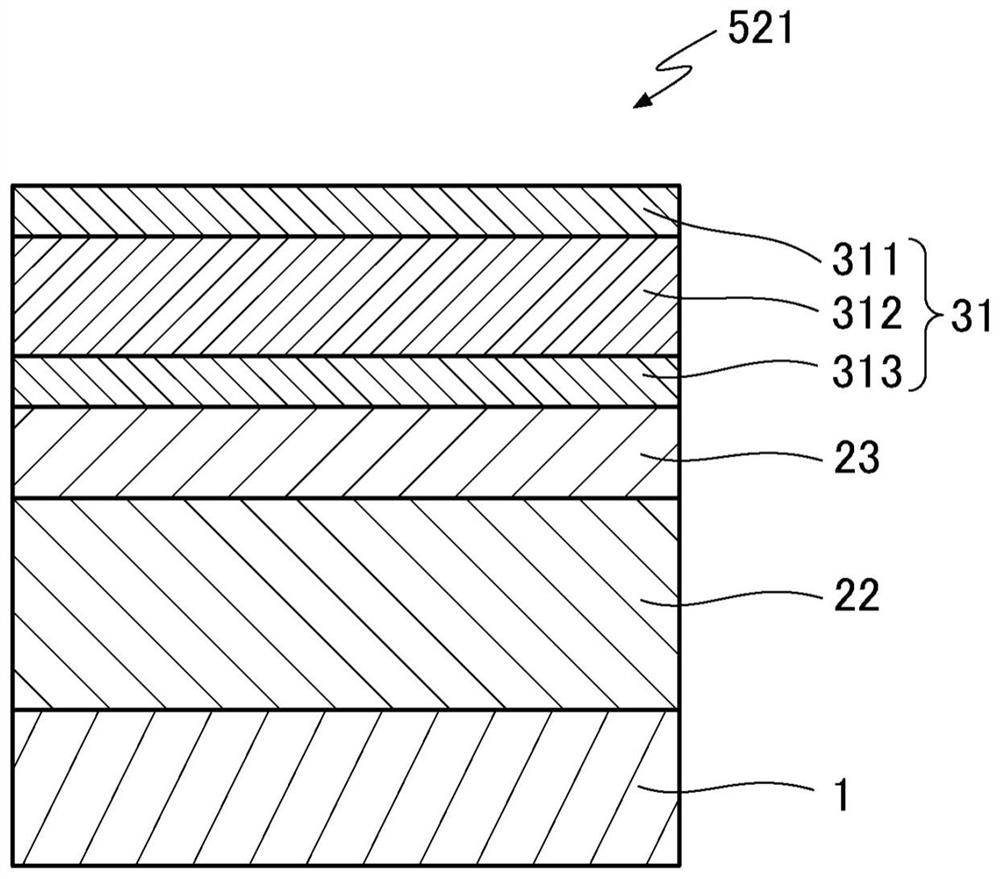

Photomask blank, method for producing photomask, and photomask

PendingCN113874784AExcellent adhesionAdhesion does not deteriorateOriginals for photomechanical treatmentImage resolutionPhysical chemistry

The present invention provides a photomask blank which exhibits high adhesion of a resist film to a film containing chromium, and which is capable of achieving good resolution limit and good CD linearity during the formation of an assist pattern of a line pattern, said assist pattern supplementing the resolution of the main pattern of a photomask. A photomask blank (511) according to the present invention is provided, on a substrate, with: a film (21) to be processed; and, sequentially from the far side from the substrate, a first layer (311) which contains oxygen and nitrogen, while having a chromium content of 40% by atom or less, an oxygen content of 50% by atom or more, a nitrogen content of 10% by atom or less and a thickness of 6 nm or less, a second layer (312) which contains oxygen, nitrogen and carbon, while having a chromium content of 40% by atom or less, an oxygen content of 30% by atom or more, a nitrogen content of 17% by atom or more, a carbon content of 13% by atom or less and a thickness of 46 nm or more, and a third layer (313) which contains oxygen and nitrogen, while having a chromium content of 50% by atom or more, an oxygen content of 20% by atom or less and a nitrogen content of 30% by atom or more.

Owner:SHIN ETSU CHEM CO LTD

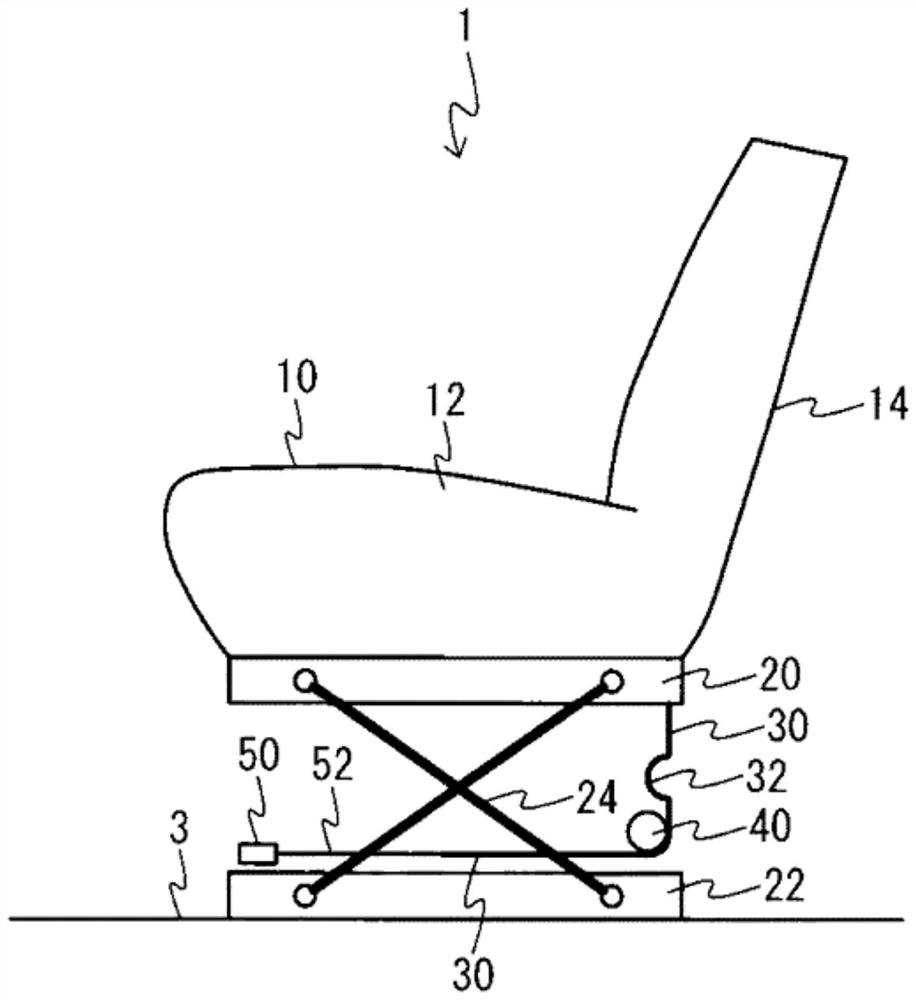

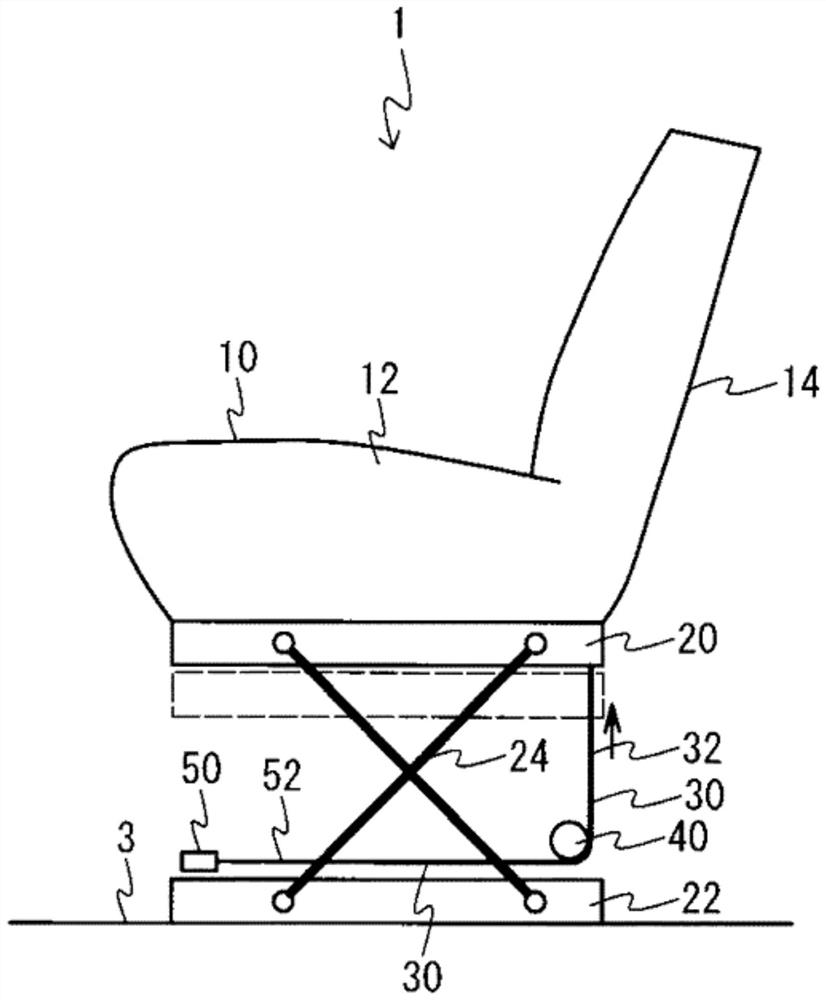

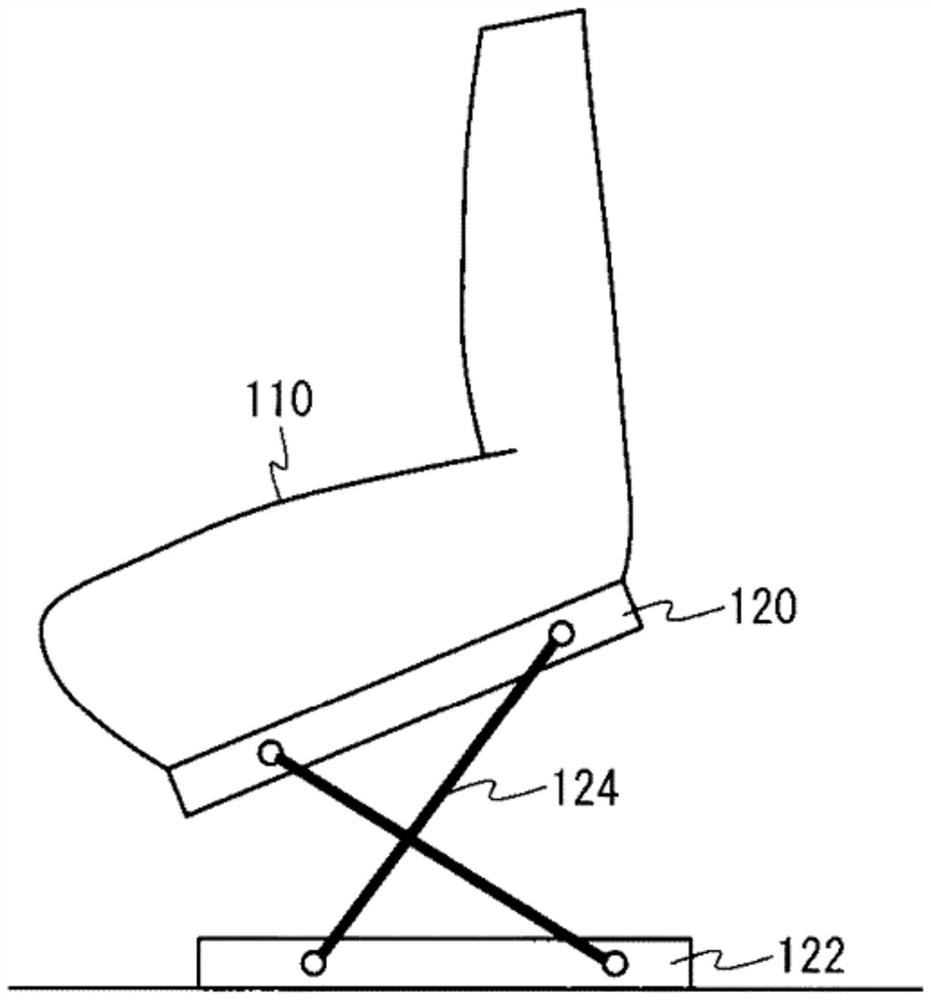

Vehicle seat

Owner:ISUZU MOTORS LTD

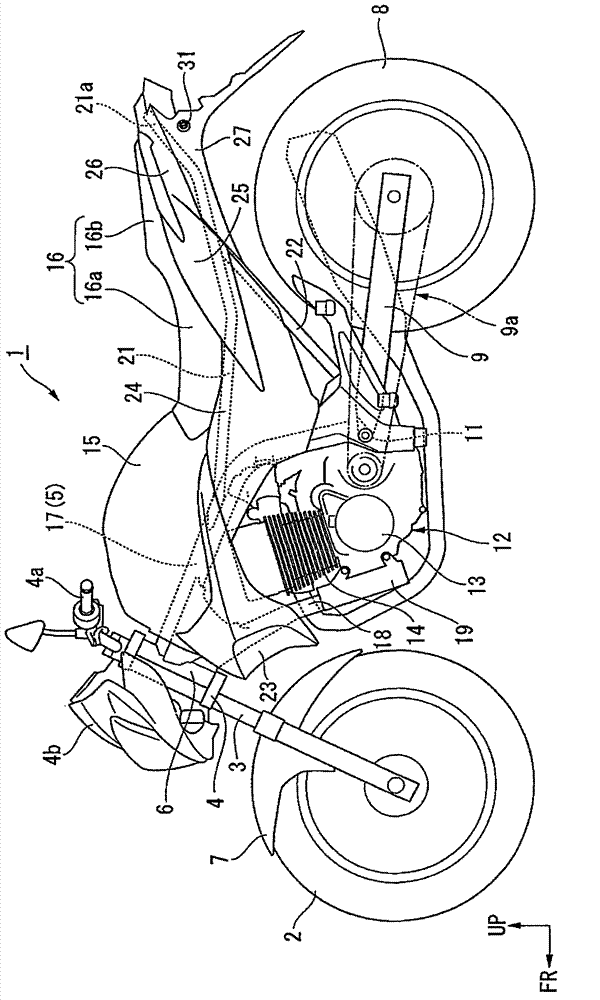

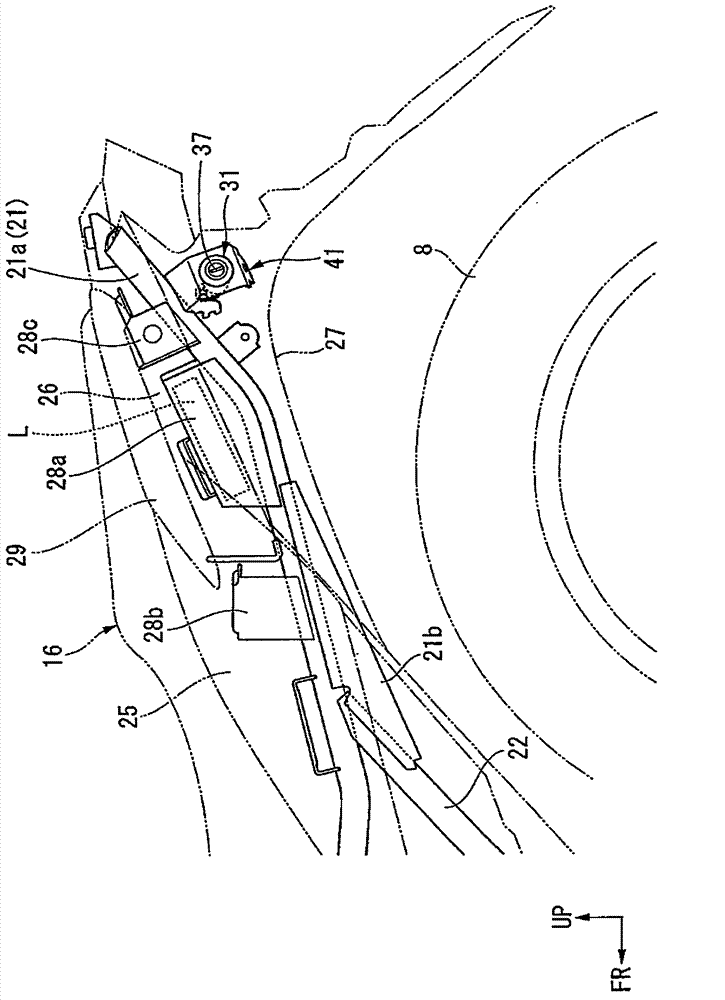

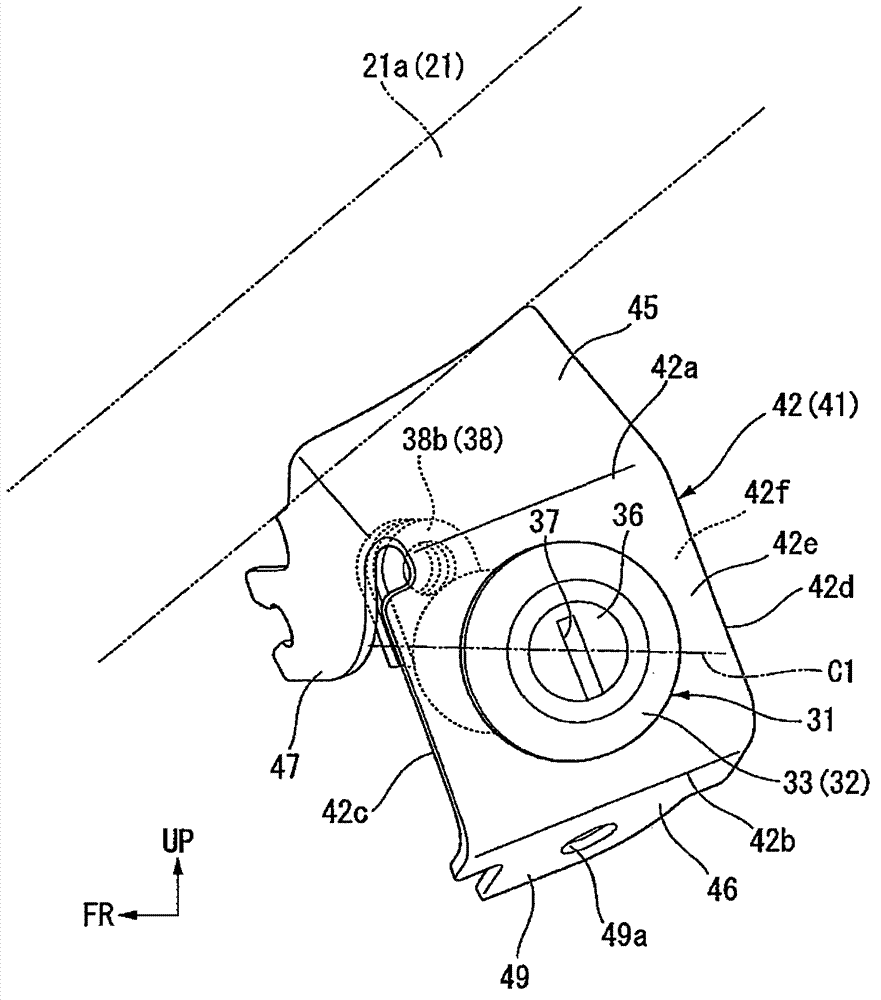

Lock cylinder maintaining structure for bestride type vehicle and method thereof

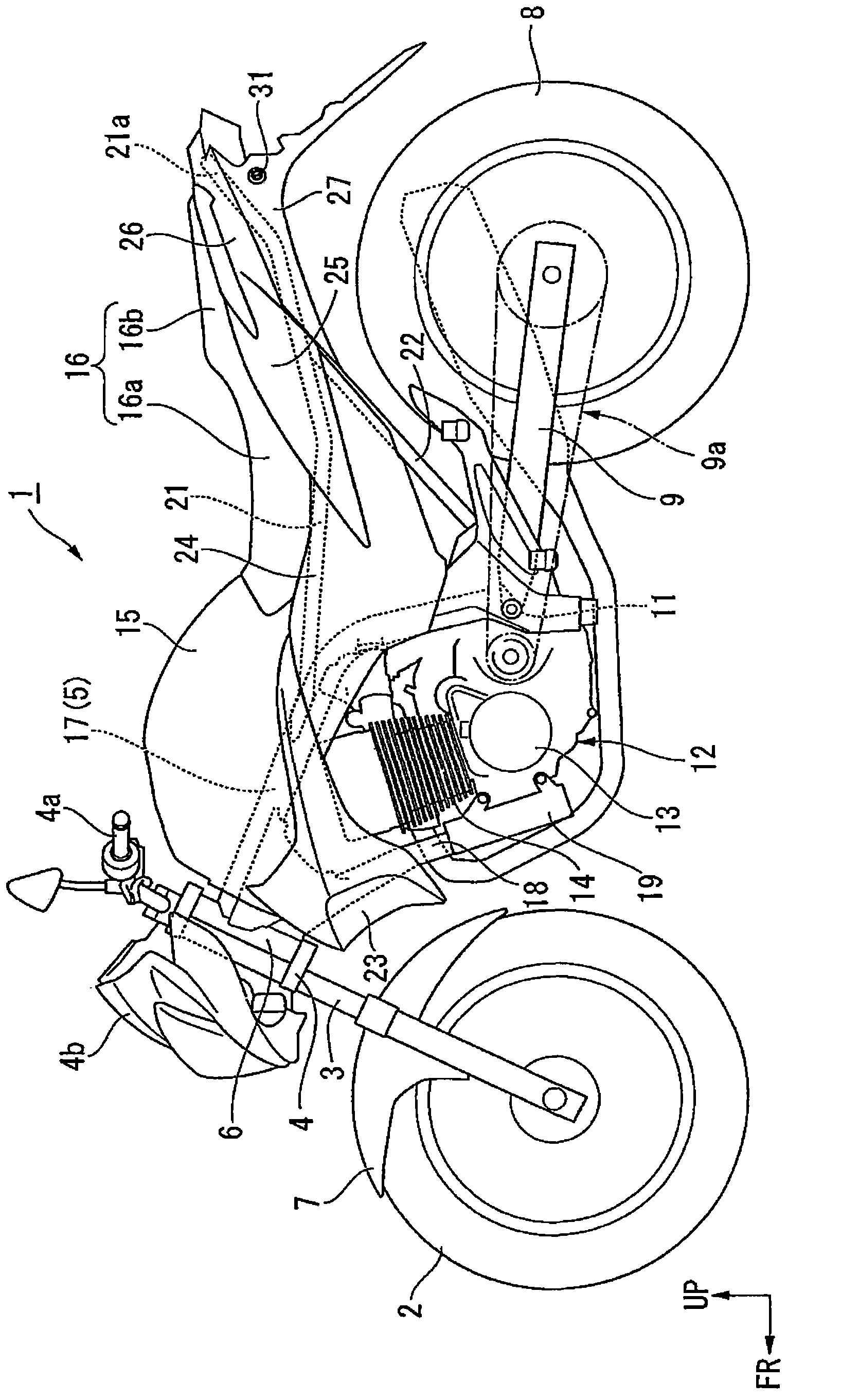

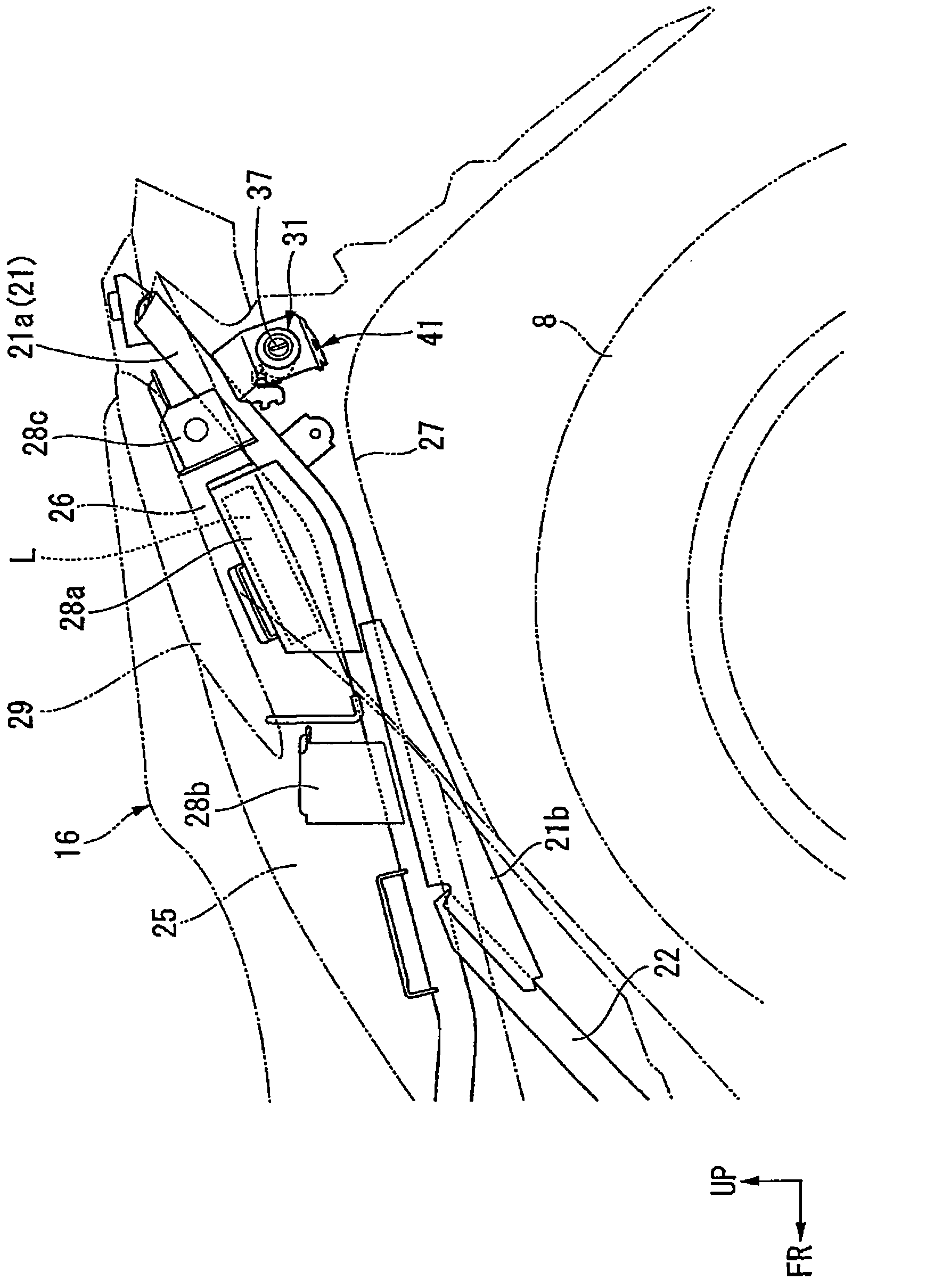

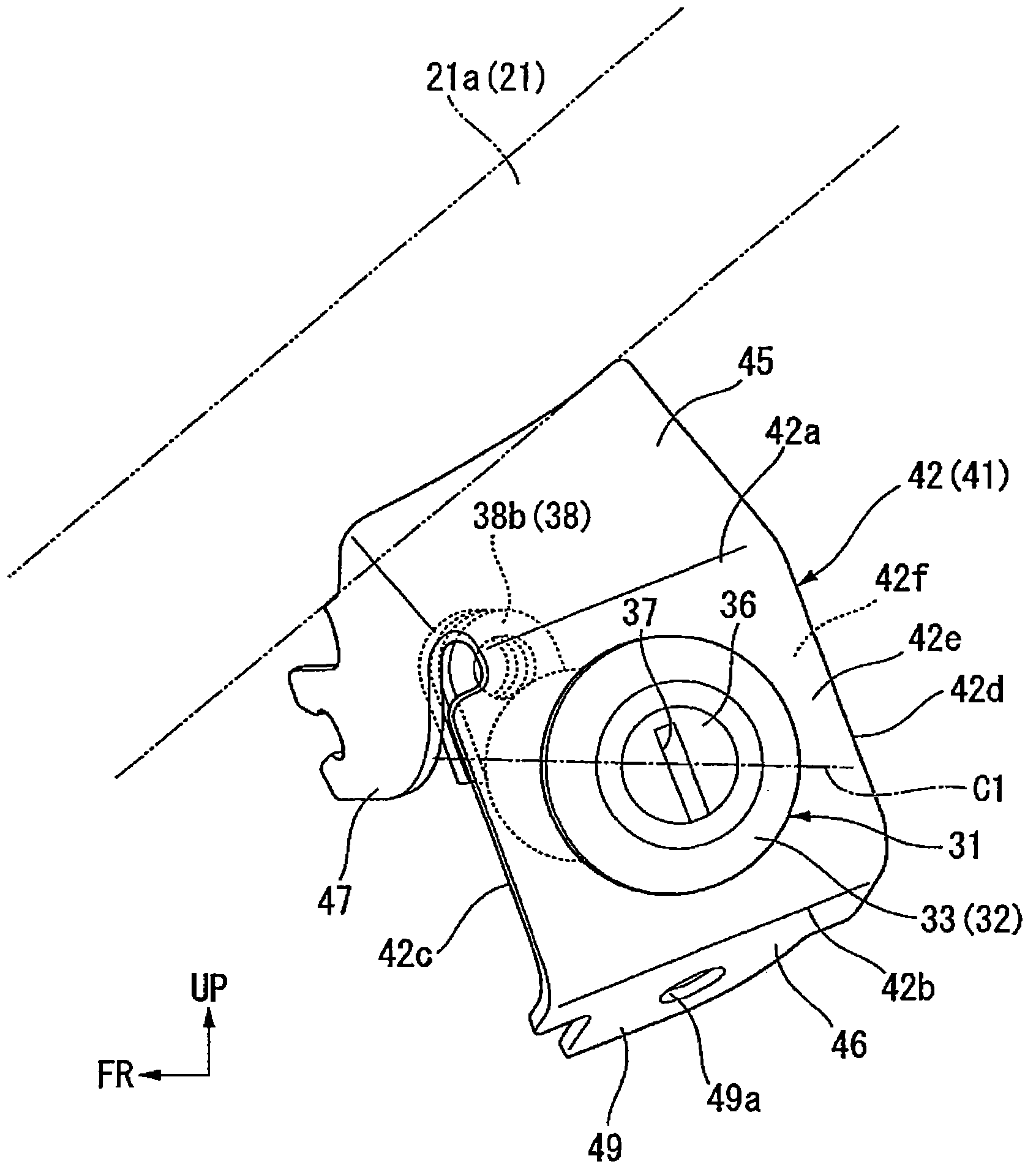

The present invention relates to a lock cylinder maintaining structure for bestride type vehicle and a method thereof, being able to restrain toppling of the lock cylinder so as to perform smooth key operation and to restrain occurence of tricks. A clamping groove (35) is formed on a key part (34) of a lock cylinder (31); the key part (34) is cut along the circumferential direction of the lock cylinder body to form the clamping groove (35); the clamping groove (35) exposed toward the inside of a supporting piece when a flange part (33) is propped to the outer side surface of a supporting plate (42); an inner peripheral part (54) can be clamped on the clamping groove (35), and is embedded on the lock cylinder (31) and avoids the gasket opening part on a gasket component (51) which is propped to the inner side surface (42f) of the supporting plate (42); and the supporting plate (42) is clamped through the gasket component (51) and the flange part (33).

Owner:HONDA MOTOR CO LTD

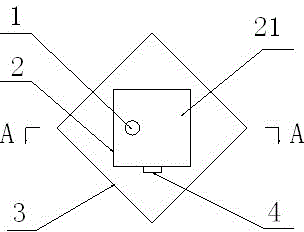

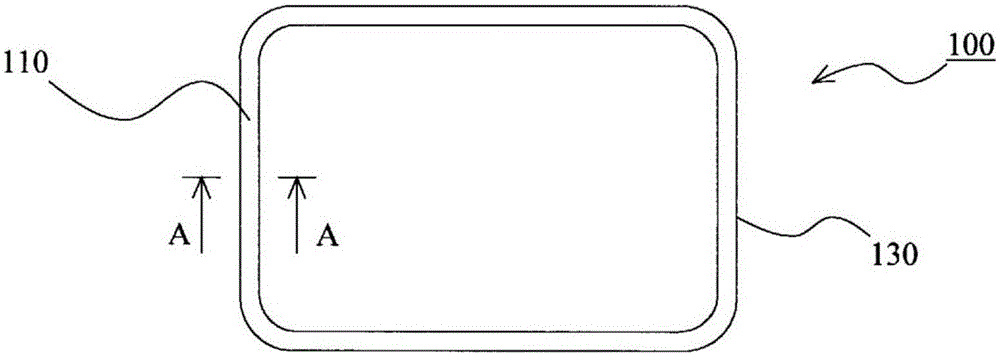

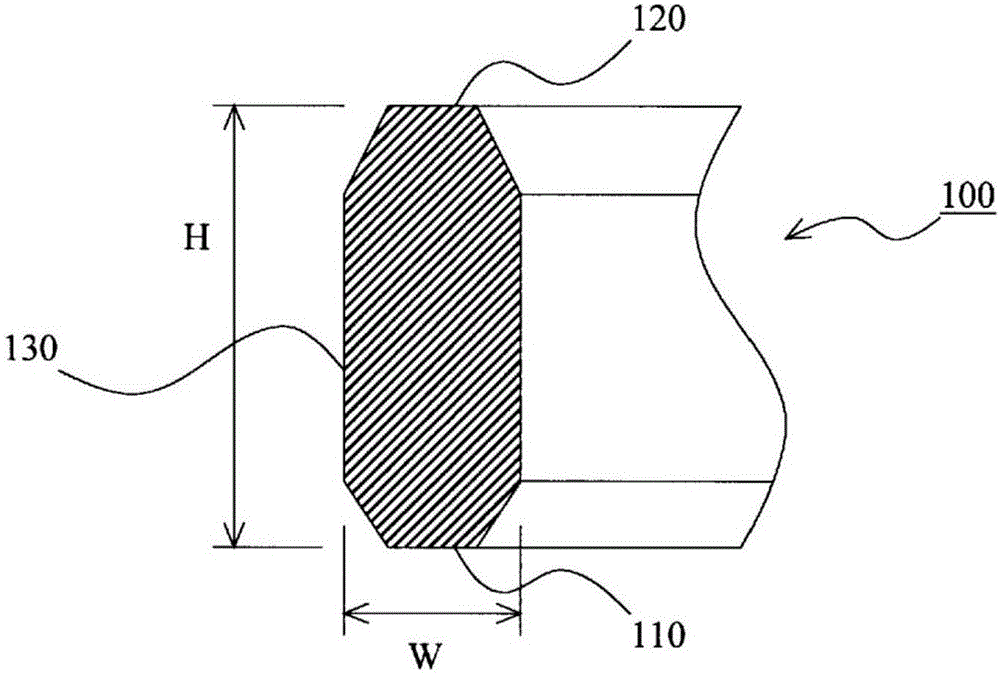

Anti-tip base for light-weight automatic satellite aligning antenna

InactiveCN103337685ACurb dumpingNot easy to dumpAntenna supports/mountingsEngineeringIndustrial engineering

The invention discloses an anti-tip base for a light-weight automatic satellite aligning antenna, which directly takes a motor as an antenna support, adopts a hollow rectangular outer casing of which the upper bottom and the lower bottom are open, the motor can be placed into the outer casing, the center of the motor is superposed with the center of the outer casing, the diagonal direction of the outer casing is vertical to the side length direction of the motor, the diagonal direction of the motor is vertical to the side of the outer casing, the size of the notches on the top surface and the bottom surface of the outer casing is the same with the size of the motor at corresponding positions, and the motor can be clamped in the outer casing firmly. Therefore, the base is stable in various directions of the periphery under the variation of the pitching angle of the antenna.

Owner:SOUTH CHINA UNIV OF TECH

Packaging body

InactiveCN101309842BAvoid shockAvoid damageSemiconductor/solid-state device manufacturingPackagingElastomerEngineering

A packaging body that is suitable for transporting contents such as a substrate receiving container, that is not large in size, that has less possibility of contaminating the surroundings, that does not require an increased storage space, and that is less likely to cause problems when reused or recycled. The packaging body has a rectangular tube-like packaging box (1) with the bottom; an upper and lower pair of shock absorbing bodies (30) received in the packaging box (1) while holding the substrate receiving container (10); an elastic body (50) interposed between the substrate receiving container (10) and each shock absorbing body (30); and a reinforcement body (60) for reinforcing each shock absorbing body (30). The shock absorbing body (30) is prepared as a shock absorbing member (31) fitted to the substrate receiving container (10), and a peripheral wall (32) of the shock absorbing member (31) is constructed from an inner wall (35) formed in a bent manner at the peripheral edge ofthe shock absorbing member (31), a projection (36) formed at and projecting from the inner wall (35), and an outer wall (37) formed at the projection (36) and facing the inner wall (35) of the shock absorbing member (31) with a spacing in between. The reinforcement body (60) is formed to have a substantially dish-shaped cross-section, and a bent peripheral edge section (61) of the reinforcement body is fitted and engaged from the outside to an outer wall end section (37a) of the shock absorbing member (31).

Owner:SHIN-ETSU POLYMER CO LTD

Lock cylinder maintaining structure for bestride type vehicle and method thereof

PROBLEM TO BE SOLVED: To perform smooth key operation and prevent the occurrence of mischievous action by suppressing a key cylinder from falling, in a key cylinder holding structure and method for a saddle-riding type vehicle.SOLUTION: In a key section 34 of a key cylinder 31, an engage groove 35 is formed which is exposed inside of a stay while notching the key section in a circumferential direction of the cylinder and abutting a flange 33 to an outer side surface 42e of a supporting plate 42. To the engage groove 35, an inner edge part 54 can be engaged which is externally fitted to the key cylinder 31 and avoids a washer opening part in a washer member 51 abutted to an inner side surface 42f of the supporting plate 42. The supporting plate 42 is held between the washer member 51 and the flange 33.

Owner:HONDA MOTOR CO LTD

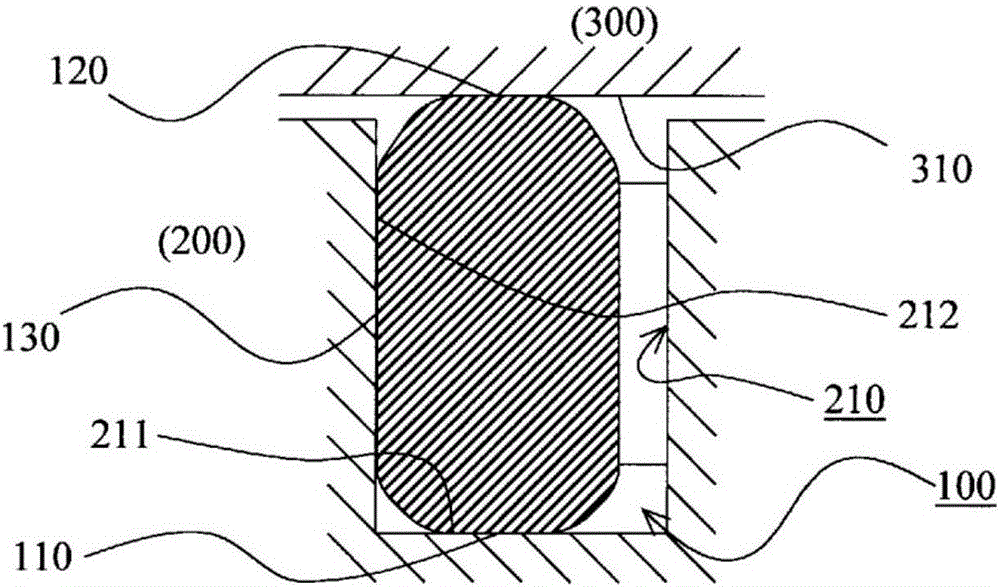

Gasket and sealing structure

ActiveCN106461082ASuppression of serpentine bendsCurb dumpingEngine sealsBiomedical engineeringMaximum temperature

Provided are a gasket and a sealing structure which are capable of exhibiting stable sealing performance, even under conditions in which the temperature of the usage environment is high. This gasket (100) seals a gap between a first member (200) and a second member (300) as a result of being inserted into an annular insertion groove (210) provided in the first member (200), and being disposed in close contact with the groove bottom surface (211) of the insertion groove (210) and an end surface (310) of the second member (300) respectively. The gasket (100) is characterized by being designed such that, under the maximum temperature of the usage environment, the circumference of the outer peripheral surface (130) of the gasket (100) is equal to or less than the circumference of a side-wall surface (212) of the insertion groove (210) at the outer peripheral side.

Owner:NOK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com