A battery support structure

A battery and structure technology, applied in circuits or fluid pipelines, vehicle components, transportation and packaging, etc., can solve the problems of increased torque of the battery bearing part, deformation of the battery bearing part, restrictions on the shape and size of the battery, etc., to prevent dumping. , The effect of improving shape strength and rigidity, and improving assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

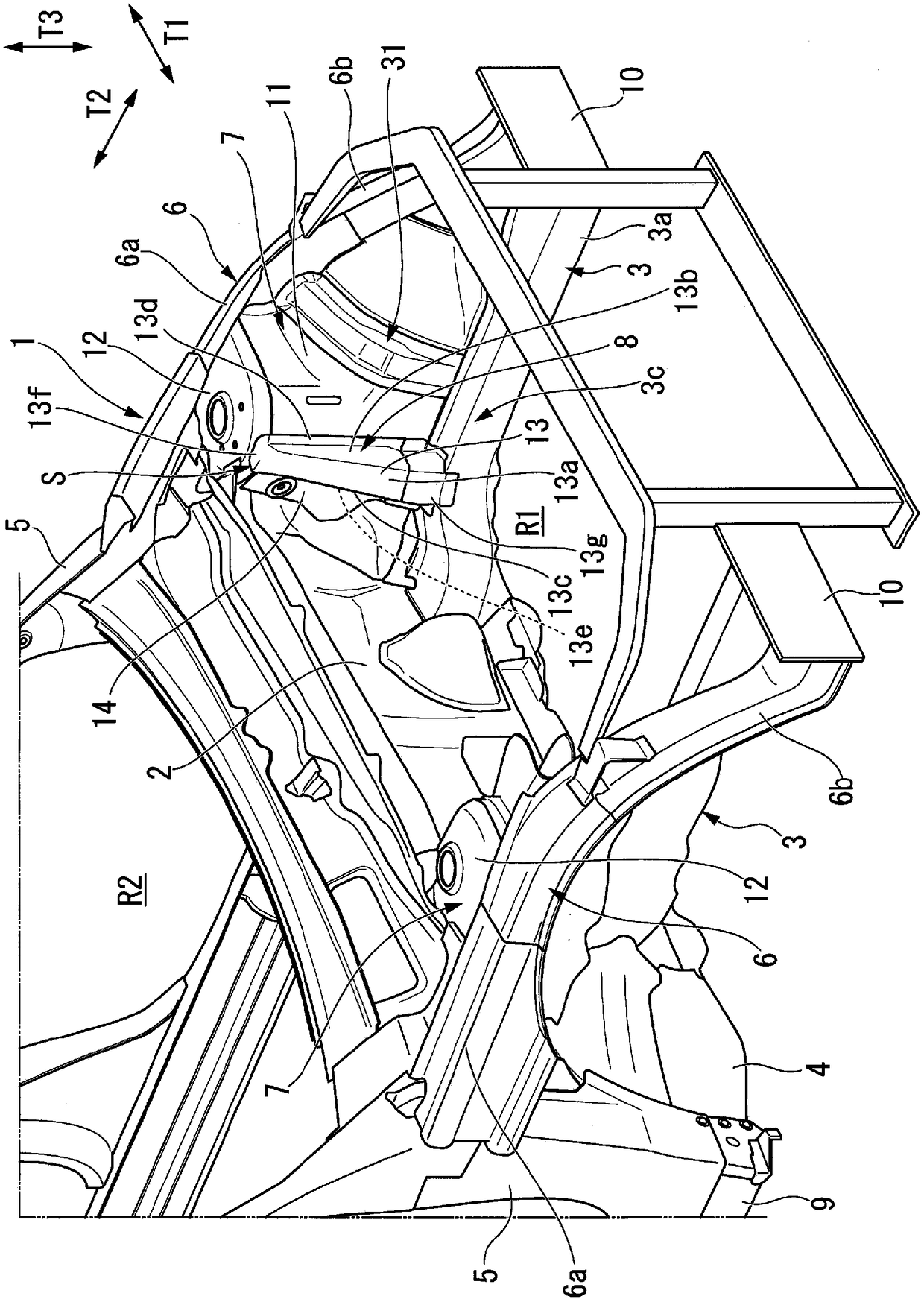

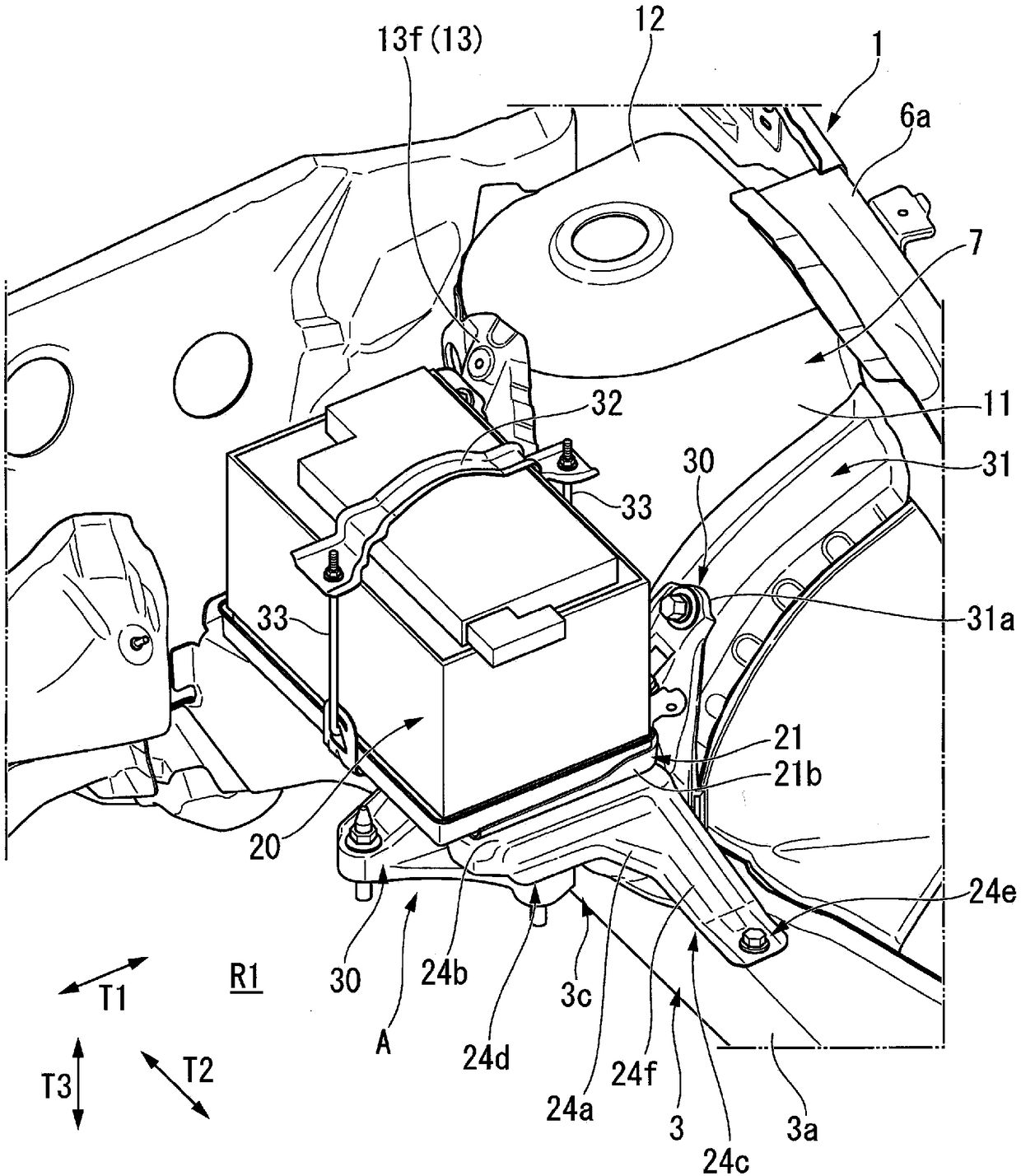

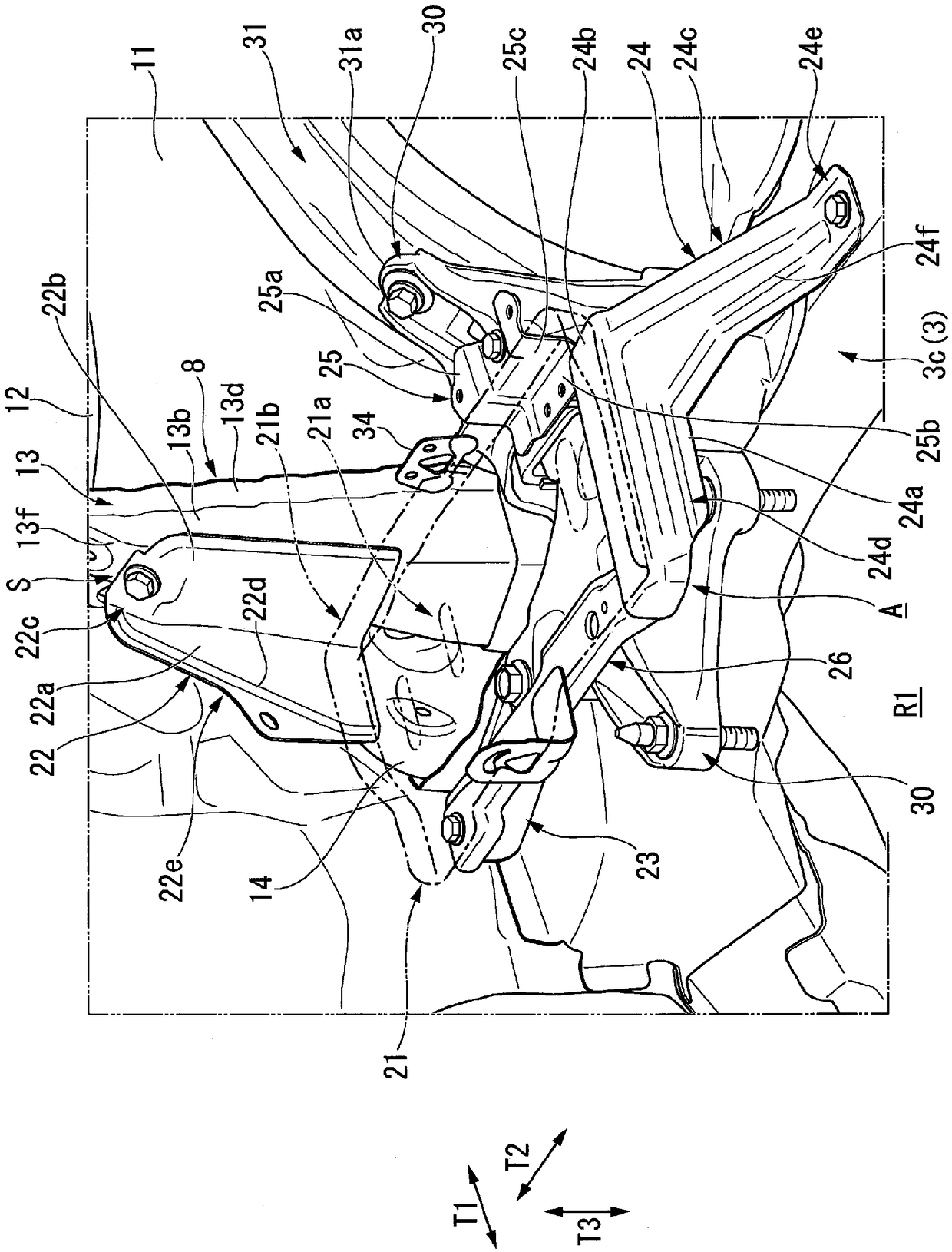

[0118] Below, refer to Figure 1 to Figure 9 A battery support structure according to one embodiment of the present invention will be described. Here, the present embodiment relates to a battery support structure provided in an engine compartment of a front structure of a vehicle to support a battery for supplying electric power to various electrical components.

[0119] First, if figure 1 As shown, the vehicle body 1 of this embodiment is divided into a vehicle compartment R2 and an engine compartment R1 by an instrument panel 2 arranged at its front portion, and consists of a front side frame 3, an outrigger 4, a front pillar 5, an upper The component 6, the shock absorber housing unit 7, the reinforcement unit 8, etc. form the skeleton of the front part.

[0120] The front side frames 3 extend in the front-rear direction T2 of the vehicle body 1 and are respectively disposed at lower portions of the engine room R1 on both sides in the vehicle width direction T1. The fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com