Packaging body

A packaging body and packaging box technology, applied in packaging, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of large packaging body size, large storage space, and obstacles to reuse or recycling, and achieve storage space expansion, The effect of improving strength or rigidity and suppressing surrounding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 6 approach

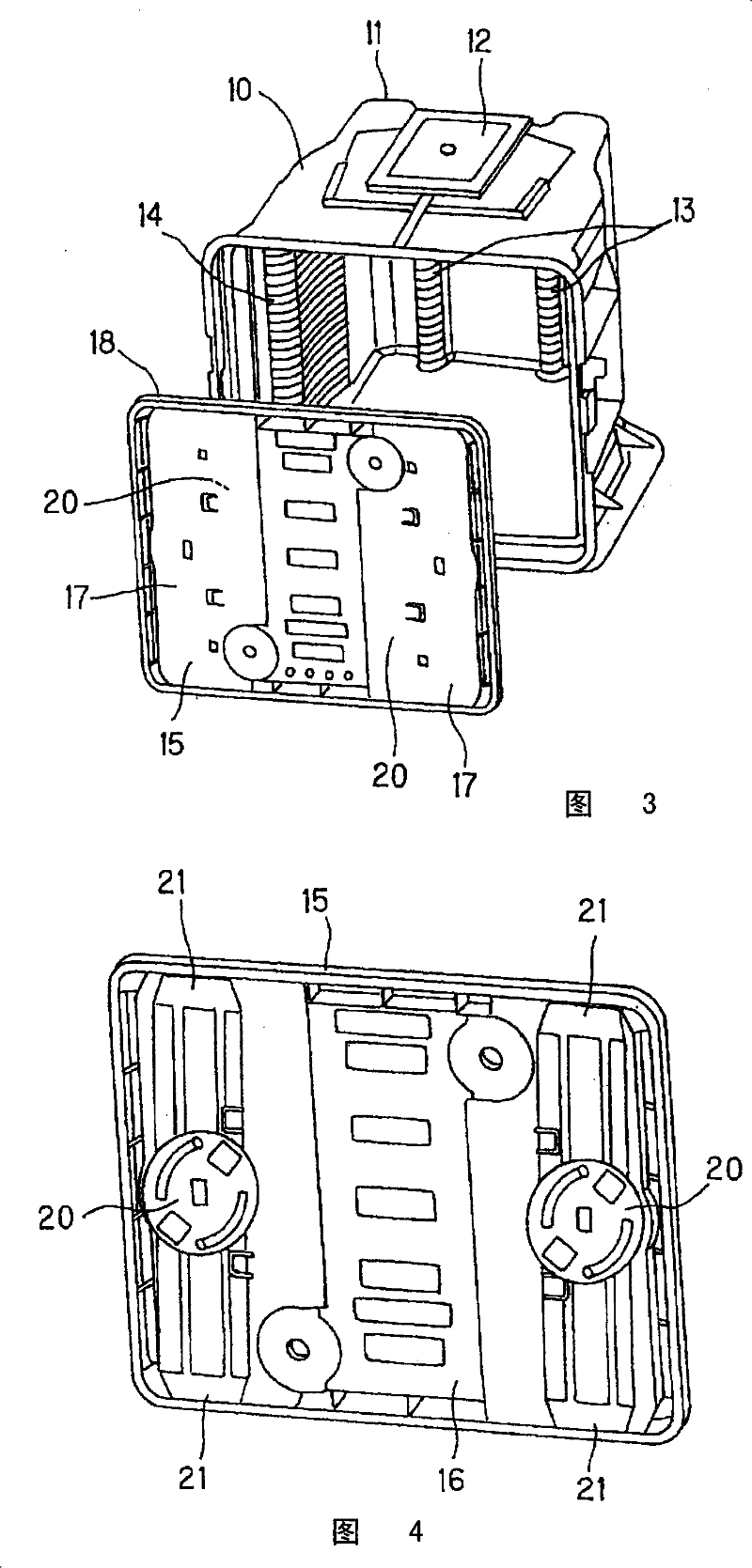

[0093] then, Figure 12 The sixth embodiment of the present invention is shown. In this case, the substrate storage container 10 is not a front-opening cassette type in which semiconductor wafers W with a diameter of 300 mm are arranged in a row, but a top-opening cassette type in which semiconductor wafers W with a diameter of 200 mm are arranged in a row. type.

[0094] The substrate storage container 10 of this type includes: a substantially rectangular cylindrical container body 11A; an inner box 26 that is detachably accommodated in the container body 11A from above, and accommodates a plurality of semiconductor wafers W in an array via an array groove; The lid body 15A at the upper portion of the opening of the container body 11A is opened and closed via the annular gasket 27 . Inside the lid body 15A, an elastic pressure plate 28 that holds the upper peripheral edge of each semiconductor wafer W contained therein is attached. About other parts, since it is the same as...

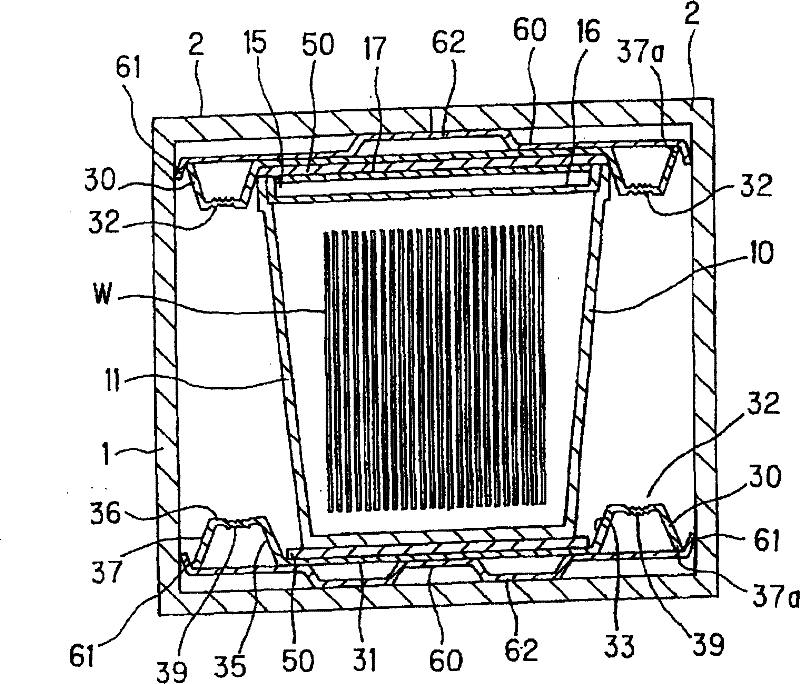

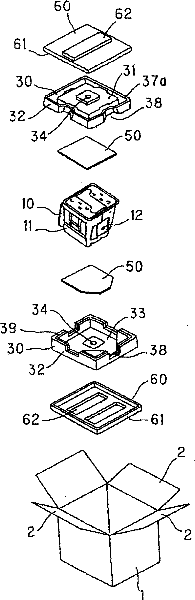

Embodiment 1

[0102]The package of Example 1 is of the type of the first embodiment. The substrate storage container was of a front opening cassette type that accommodated 25 silicon wafers with a diameter of 300 mm, and was packaged with the lid facing upward. In addition, the package of Example 2 is of the type of the second embodiment, and the substrate storage container is the same as that of Example 1. In addition, the package of Example 3 is of the type of the third embodiment, and the substrate storage container is the same as that of Example 1.

[0103] On the other hand, the package of the comparative example is a type in which a pair of reinforcements are removed from the type of the third embodiment, and the substrate storage container is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com