Pneumatic tire

A technology for pneumatic tires and treads, applied in tire parts, treads, transportation and packaging, etc., to improve durability, suppress the impact of quality and production costs, and suppress dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

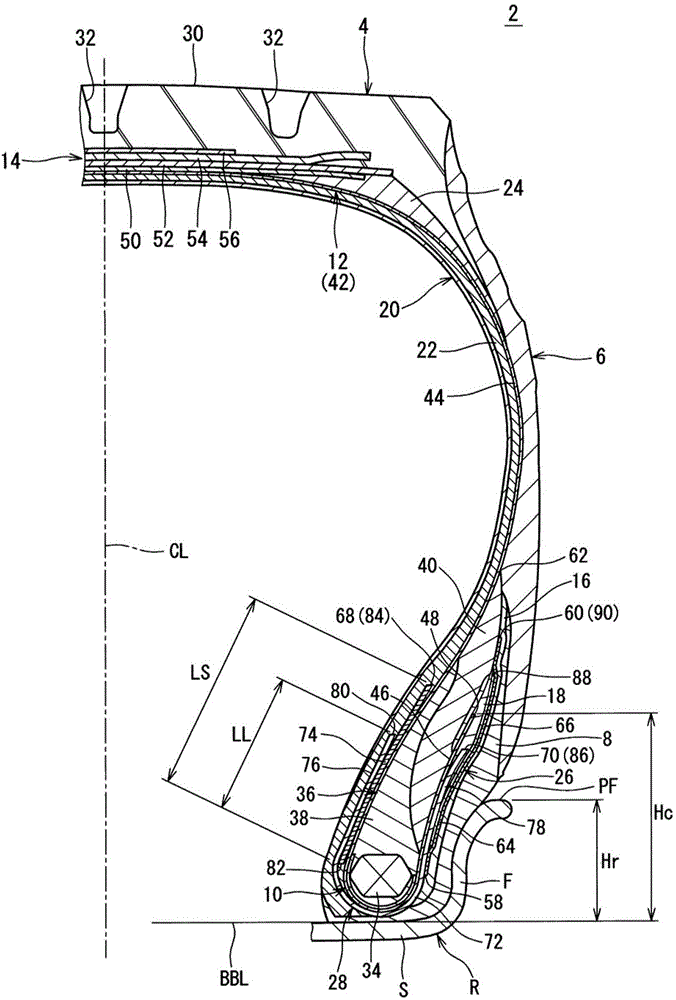

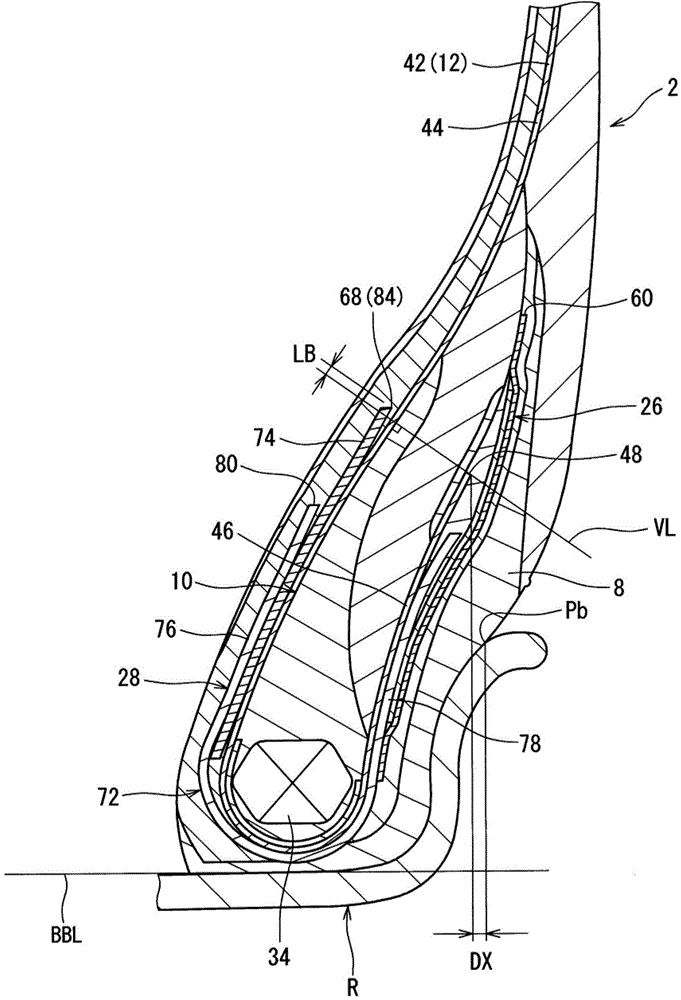

[0099] Obtained the possession of embodiment 1 figure 1 The basic structure shown is a heavy-duty pneumatic tire having the specifications shown in Table 1 below. The tire size is 12.00R20. Therefore, the size of the rim on which this tire is assembled is 8.8×20, and the height Hr of the flange of the rim is 45 mm.

[0100] The carcass ply of this tire employs a cord made of steel as the carcass cord. The absolute value of the angle formed by the carcass cords and the equatorial plane was 90°.

[0101] In this tire, the inner layer and the outer layer of the first filler each use a cord made of nylon fiber as the first cord. A "Y" in the first filler column of the table indicates that the tire has a first filler.

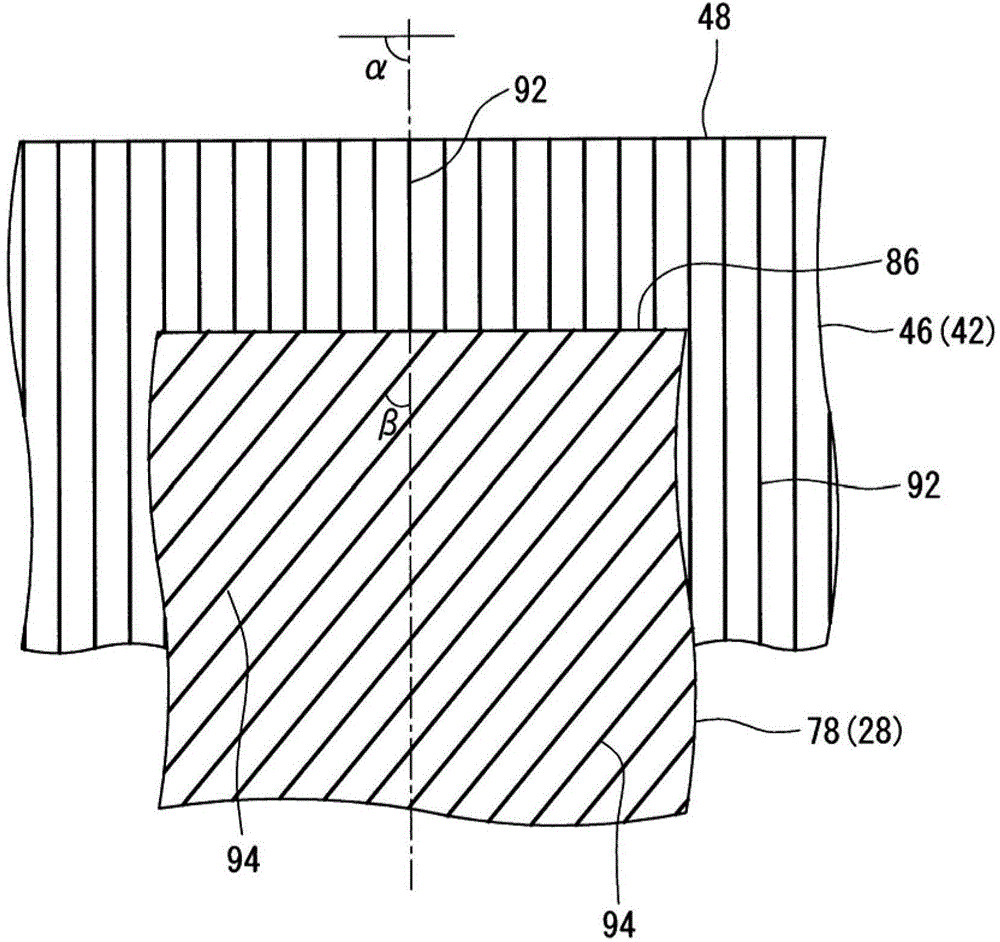

[0102]In this tire, the main layer and the sub-layer of the second filler each employ a cord composed of steel as the second cord.

Embodiment 2~3 and comparative example 2~3

[0106] Tires of Examples 2 to 3 and Comparative Examples 2 to 3 were obtained in the same manner as in Example 1 except that the intersection angle β was shown in Table 1 below.

Embodiment 4~5 and comparative example 4~5

[0108] Tires of Examples 4 to 5 and Comparative Examples 4 to 5 were obtained in the same manner as in Example 1 except that the height Hc of the turned-back portion was adjusted so that the ratio (Hc / Hr) was as shown in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com