Construction solution for reinforcing joints on load bearing wall and precast slabs of brick-concrete structure

A technology of brick-concrete structure and construction scheme, applied in building structure, building maintenance, building type, etc., can solve problems such as falling off, wall collapse, limited reinforcement effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

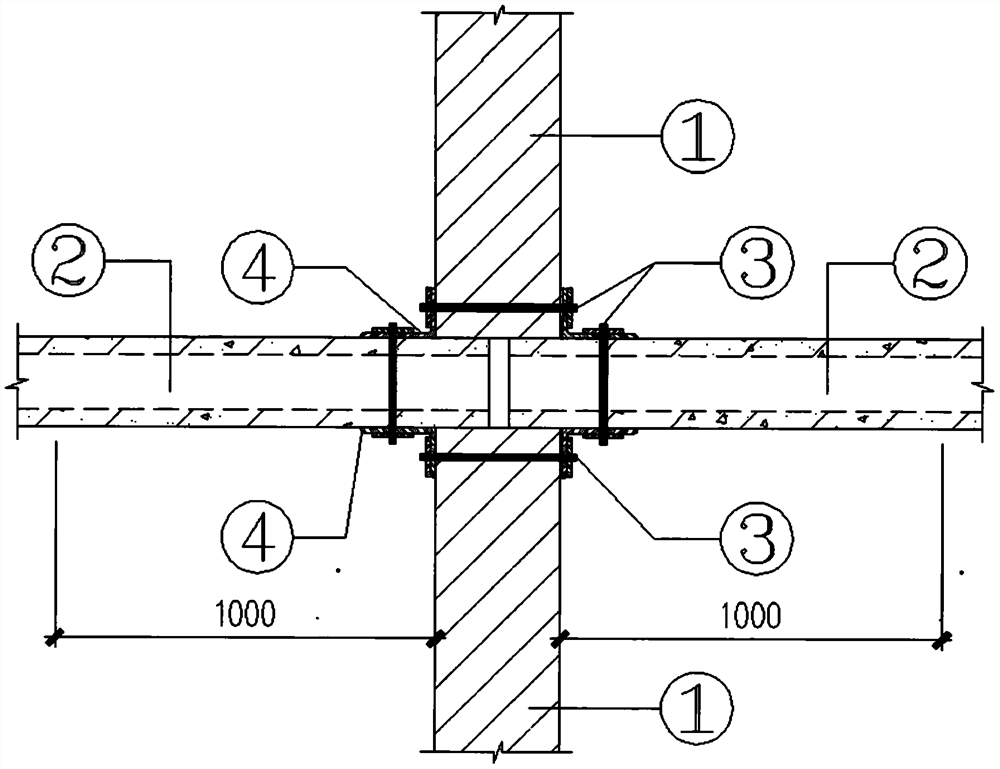

[0024] A construction scheme for reinforcing joints of prefabricated slabs in a load-bearing wall of a brick-concrete structure, characterized in that:

[0025] The first step: base treatment: setting out wire positioning, grinding and smoothing the plate and wall base where the angle steel is installed, cleaning it up and opening the bolt holes at the corresponding positions;

[0026] The second step: angle steel blanking processing: cut the corresponding length of angle steel according to the length of the load-bearing wall and open the bolt holes at the corresponding positions;

[0027] Step 3: Hole filling of the prefabricated panel: within 1000mm of the end of the prefabricated panel, the holes shall be filled with pouring glue, etc.;

[0028] Step 4: Angle steel installation: Install the finished angle steel on the upper, lower, left, and right corners at the junction of the board and wall, and tighten the bolts;

[0029] Step 5: Angle steel injection: fill the gap betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com