Thermal-sensing type valve mechanism

A valve mechanism and temperature-sensing technology, applied in the field of temperature-sensing valve mechanisms, can solve problems such as cost increase, and achieve the effects of reducing assembly man-hours, absorbing manufacturing errors, and accurate hydraulic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

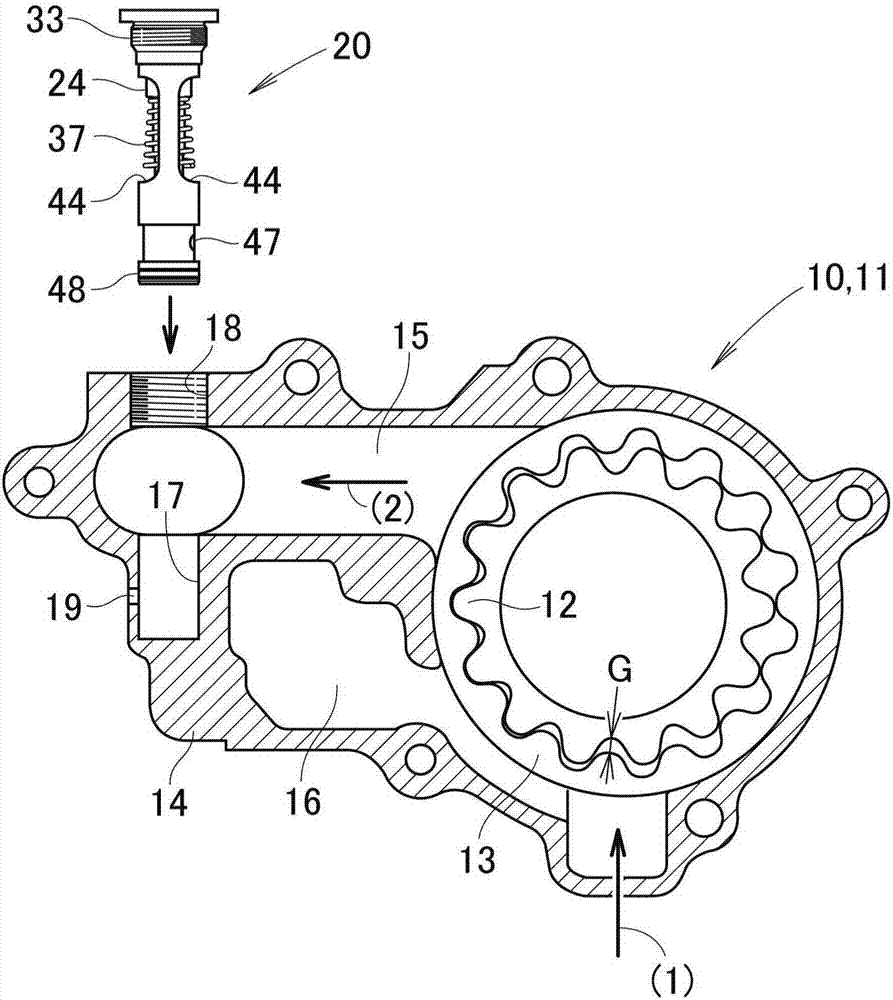

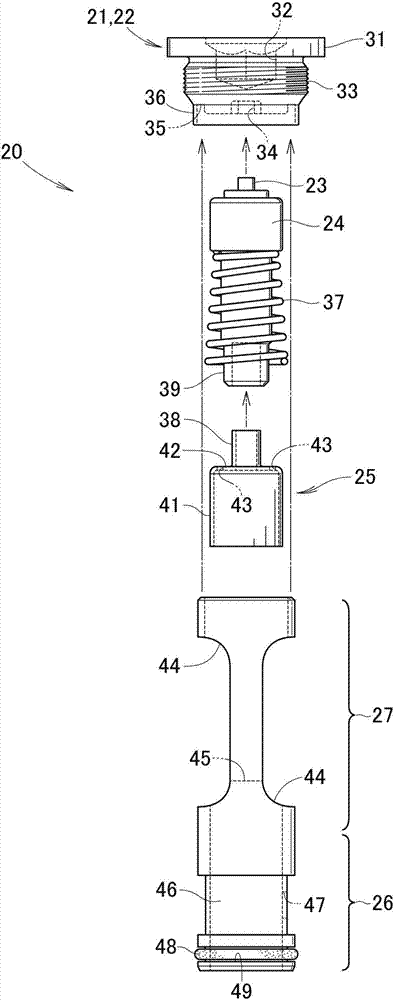

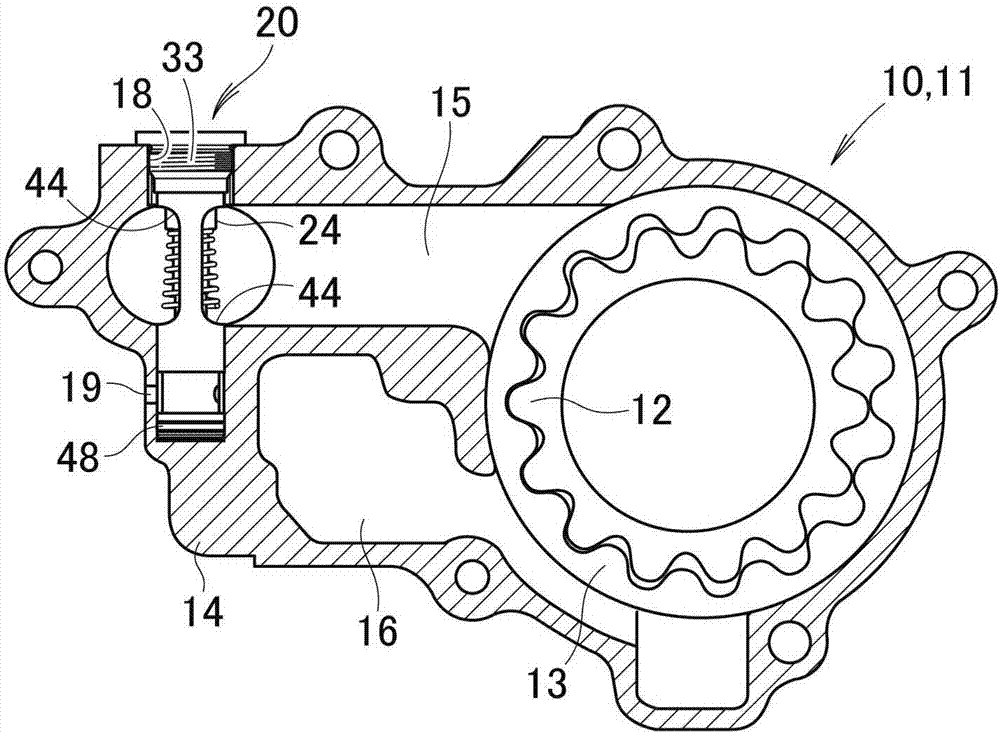

[0062] exist figure 1 Here, an example in which the temperature-sensitive valve mechanism 20 of the present invention is detachably attached to the oil pump 11 as the structure 10 will be described.

[0063] Such as figure 1 As shown, an oil pump 11 as a structure 10 is composed of an internal gear 12 , an external gear 13 , and a pump case 14 that accommodates these gears 12 and 13 . When the internal gear 12 is rotated by a part of the power of the engine, the external gear 13 is rotated interlockingly. During this rotation, the volume of the gap G between the gears 12, 13 changes, and due to this change, lubricating oil is sucked in and pressurized as indicated by the arrow (1), and is compressed as indicated by the arrow (2). was discharged.

[0064] The pump housing 14 is provided with a main oil passage 15 as an oil passage, and a return oil passage 16 is provided substantially parallel to the main oil passage 15 . When the hydraulic pressure in the main oil passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com