Metal joint and building structure

A technology for joining metals and components, applied in building structures, buildings, etc., can solve the problems of increasing yield tolerance deviation, damage to joints, strength differences, etc., and achieve the effect of suppressing tolerance deviation, suppressing fracture, and high yield tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

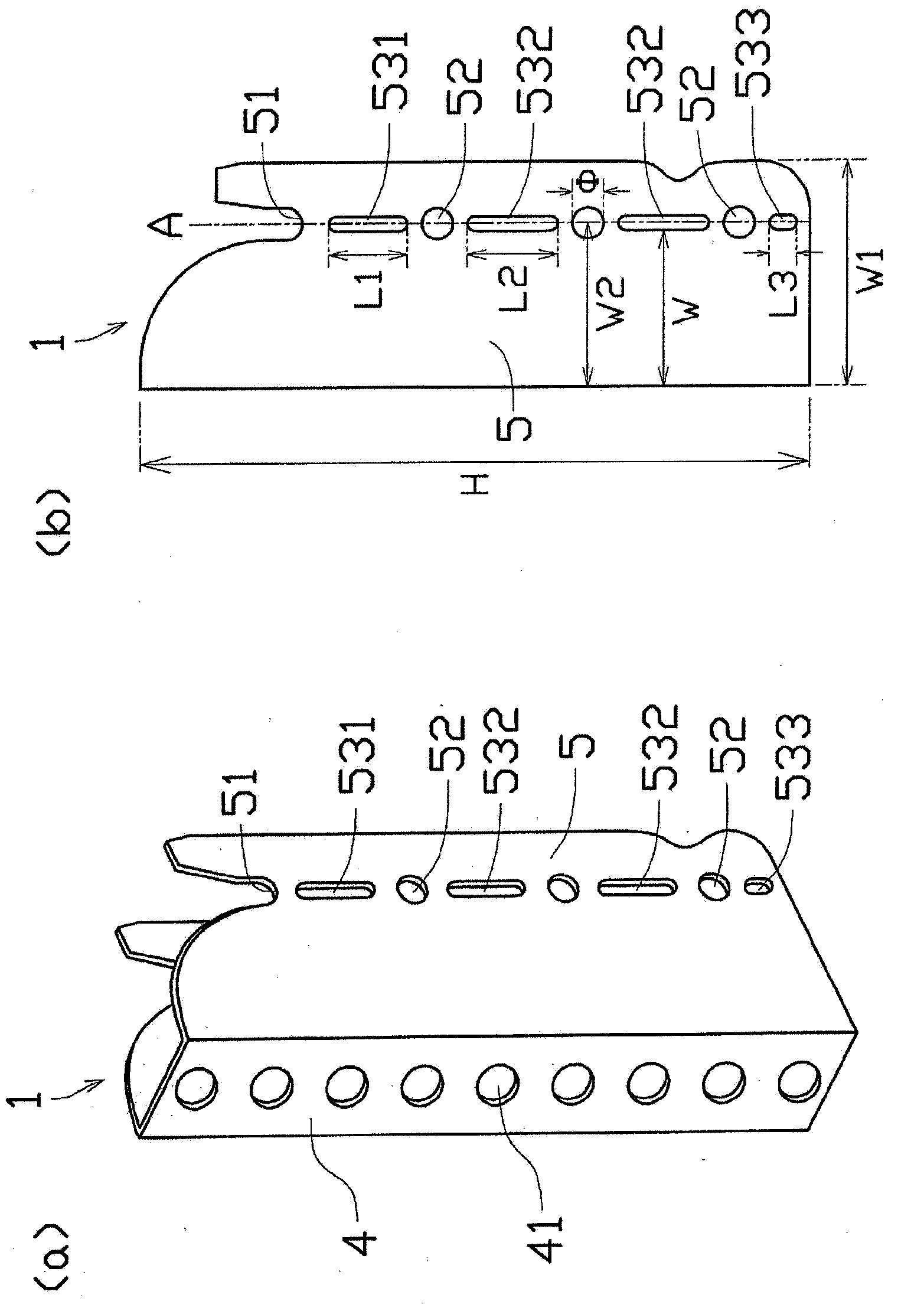

[0098] Example 1 uses figure 1 The illustrated joint metal fitting 1 has a longitudinally long slit-shaped sixth missing portion 531 and second missing portions 532 , 533 formed in the connecting plate 5 . In this metal joint 1, the height H: 266mm, the width W1: 90mm, the diameter Φ of the connecting hole 52: 12.5mm, and the distance W2 from the base end of the connecting plate 5 to the center of the connecting hole 52: 65mm, these values are in The same applies to other Examples 2 and 3 and Comparative Examples 1 and 2. In addition, in the sixth missing part 531 and the second missing part 532, 533, the length L1 of the longitudinal direction of the sixth missing part 531: 31 mm, the length L2 of the longitudinal direction of the second missing part 532: 36 mm, the second missing part The length L3 of the longitudinal direction of 533: 11 mm, and the widths of the sixth missing portion 531 and the second missing portions 532 and 533 are all 6 mm.

Embodiment 2

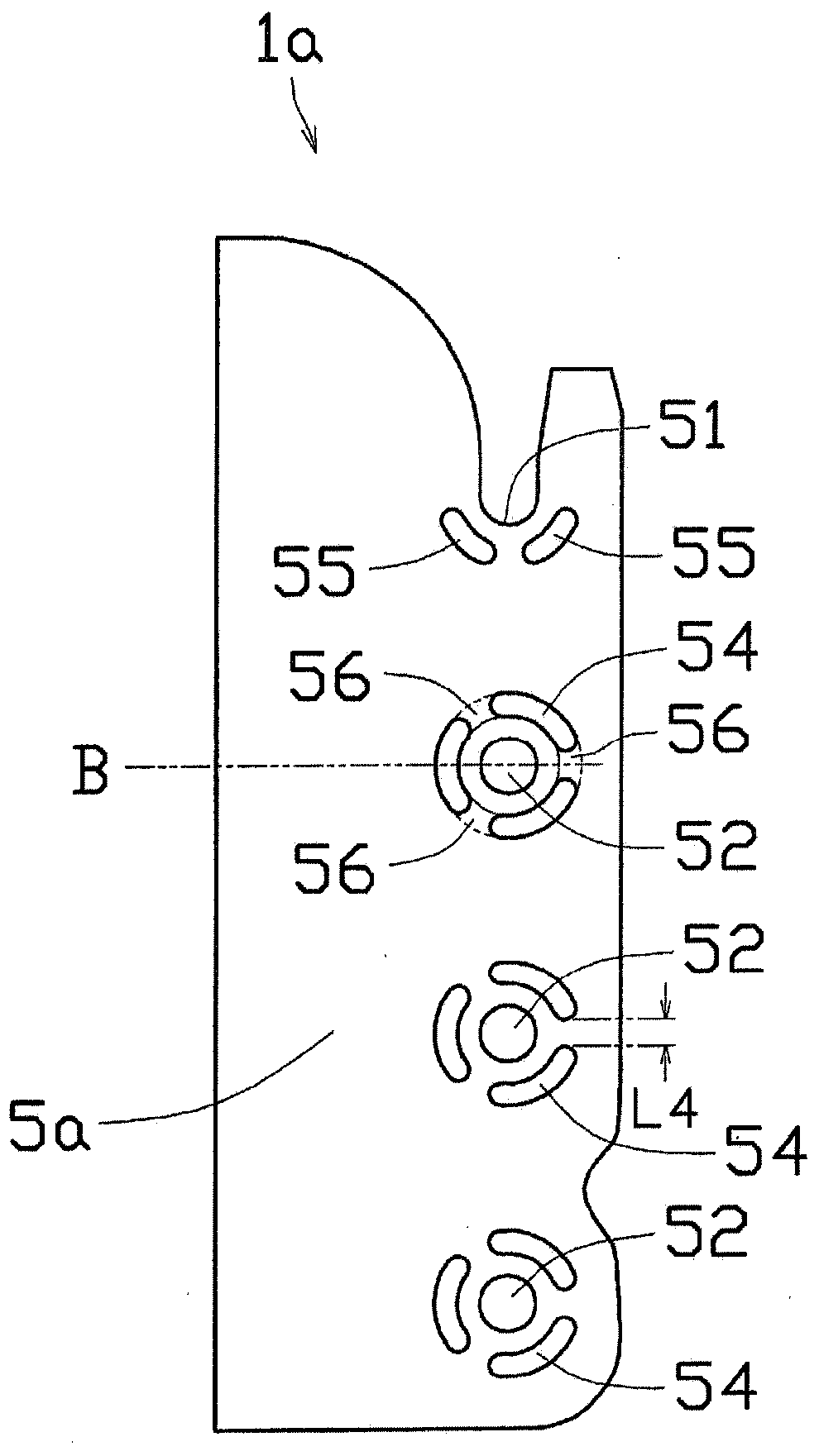

[0100] like image 3 As shown, in Example 2, a joining metal fitting 1a is used in which arc-shaped first missing portion 54 and fifth missing portion 55 are formed in connecting plate 5a. like Figure 4 As shown, in the first missing portion 54 and the fifth missing portion 55 of the metal joint 1a, the radius of curvature of the outer peripheral portion of the arc shape is 16.25 mm, and the radius of curvature of the inner peripheral portion is 11.25 mm. The first missing portion The distance L4 between 54 is 6 mm, and the distance between the fifth missing portion 55 is also 6 mm.

Embodiment 3

[0102] like Figure 9 As shown, in Example 3, a joint metal fitting 1c having a horizontally elongated slit-shaped seventh missing portion 59 formed continuously with the connecting hole 52 is used. In the seventh missing parts 59a, 59b of the joint metal fitting 1c, the length W3 of the seventh missing part 59a in the lateral direction: 26.65 mm, the length W4 of the seventh missing part 59b in the lateral direction: 6.75 mm, and the seventh missing part The vertical width of 59a, 59b is 6.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com