Process and equipment for preparing paper-plastic molded high-quality yellow serofluid product

A high-quality, paper-plastic technology, applied in the direction of natural cellulose pulp/paper, non-woody plant/crop pulp, paper, etc., can solve the problems of slow quality decline, short growth cycle, difficult to degrade, etc., and achieve rapid growth and regeneration powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of technique of paper molding fine-quality yellow pulp product of the present embodiment, comprises the following steps:

[0039] S1. beating, concentrating and grinding the original bamboo in boiling water for 3 hours to obtain bamboo fiber, choose 200-400 mesh bamboo fiber, and add water 2 times the weight of bamboo fiber to stir into bamboo fiber slurry;

[0040] S2. Soak the raw bagasse pulp in an alkaline aqueous solution for 24 hours, after beating, concentrate to 10% after beating, and after refining, obtain sugarcane fibers, select 200-400 mesh sugarcane fibers and add water 3 times the weight of sugarcane fibers Stir into a slurry;

[0041] S3. Get 50 parts of the above-mentioned bamboo fiber slurry, 100 parts of sugarcane fiber slurry, add 20 parts of binder, 8 parts of sodium alginate, 3 parts of chitosan, 3 parts of waterproofing agent and anionic emulsification 1 part, mix well;

[0042] Among them, the adhesive selected in this embodiment is prepa...

Embodiment 2

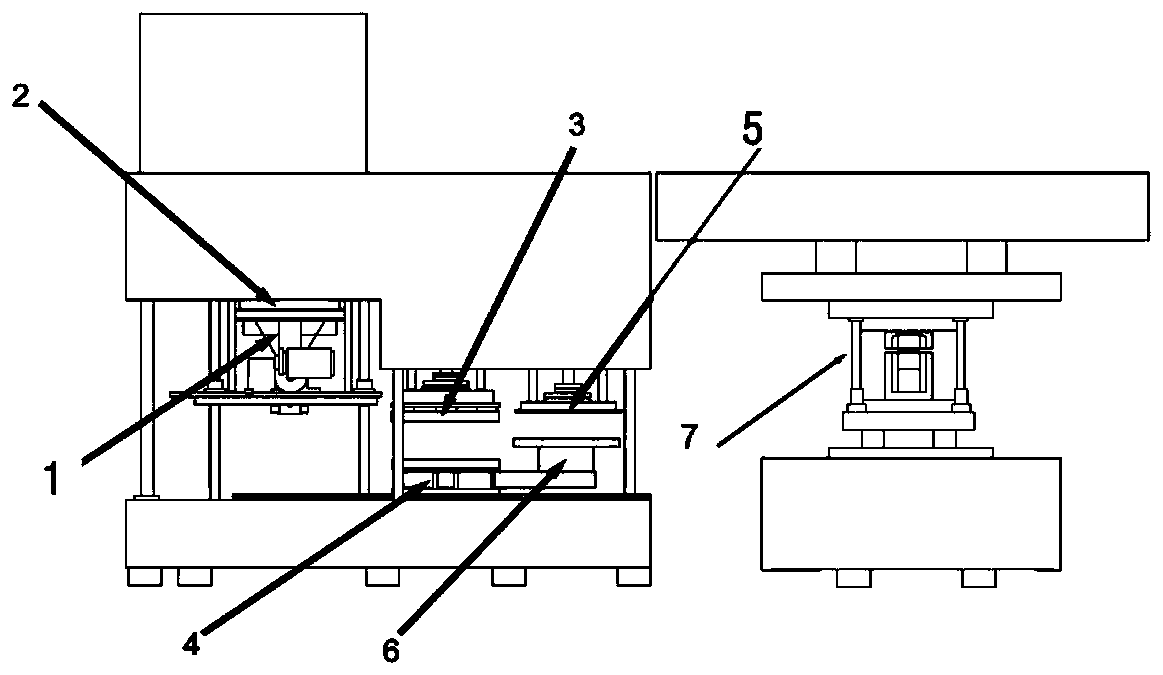

[0045] This embodiment provides a kind of equipment that implements the above-mentioned embodiment 1 process, see figure 1 As shown, it includes: slurry suction mold 1 forms a wet embryo after sucking slurry from the slurry pool; extrusion mold 2 is set above the slurry suction mold 1, and after slurry suction mold 1 is reversed upwards with the wet embryo, it is aligned with extrusion mold 2 The wet embryo is extruded for the first time; the hot-press upper die 3 can move up and down in the vertical direction; pressure treatment; the hot-pressing upper die 3 is provided with an air suction device, and the hot-pressing lower die 4 is provided with an air-blowing device; the hot-pressing lower die 4 and the transfer die 5 placed on the downstream side of the hot-pressing lower die 4 are fixed on a horizontal On the sliding plate, the lower part of the transfer mold is provided with an air blowing structure, which blows the product on the workbench 6; manually transfers the once...

Embodiment 3

[0048] A kind of technique of paper molding high-quality yellow pulp product of the present embodiment, comprises the following steps:

[0049] S1. beating, concentrating and grinding the original bamboo in boiling water for 5 hours to obtain bamboo fiber, choose 200-400 mesh bamboo fiber, and add water 3 times the weight of bamboo fiber to stir into bamboo fiber slurry;

[0050] S2. Soak the raw bagasse pulp in alkaline aqueous solution for 24 hours, after beating, concentrate to 10% after beating, and after refining, obtain sugarcane fiber, select 200-400 mesh sugarcane fiber and add water twice the weight of sugarcane fiber Stir into a slurry;

[0051] S3. Get 80 parts of the above-mentioned bamboo fiber slurry, 50 parts of sugarcane fiber slurry, add 40 parts of binder, 5 parts of sodium alginate, 5 parts of chitosan, 1 part of waterproofing agent and anionic emulsification 3 parts, mix well;

[0052] Among them, the adhesive selected in this embodiment is prepared by mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com