Supported PtZn intermetallic alloy catalyst as well as preparation method and application thereof

一种金属间合金、催化剂的技术,应用在催化剂活化/制备、金属/金属氧化物/金属氢氧化物催化剂、碳化合物催化剂等方向,能够解决Pt系催化剂易积碳失活、催化脱氢失活速率慢、贵金属用量大等问题,达到提高原子利用率、重复性高、高比表面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) 0.0021g mass parts of H 2 PtCl 6 and 0.078g mass parts of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 4 mL deionized water;

[0039] (2) 1.0000gSiO 2 (or Al 2 o 3 ) soaked in the above solution, ultrasonicated for 0.5h, dried at room temperature for 12h, and completely dried at 100°C;

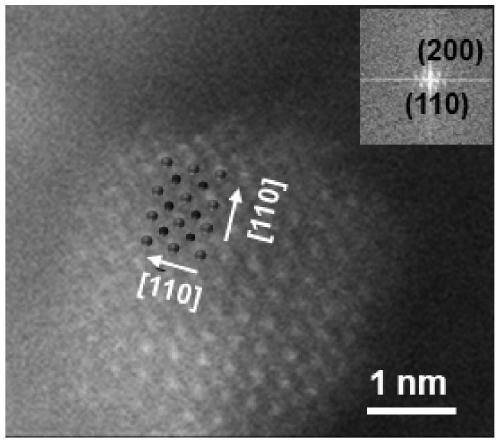

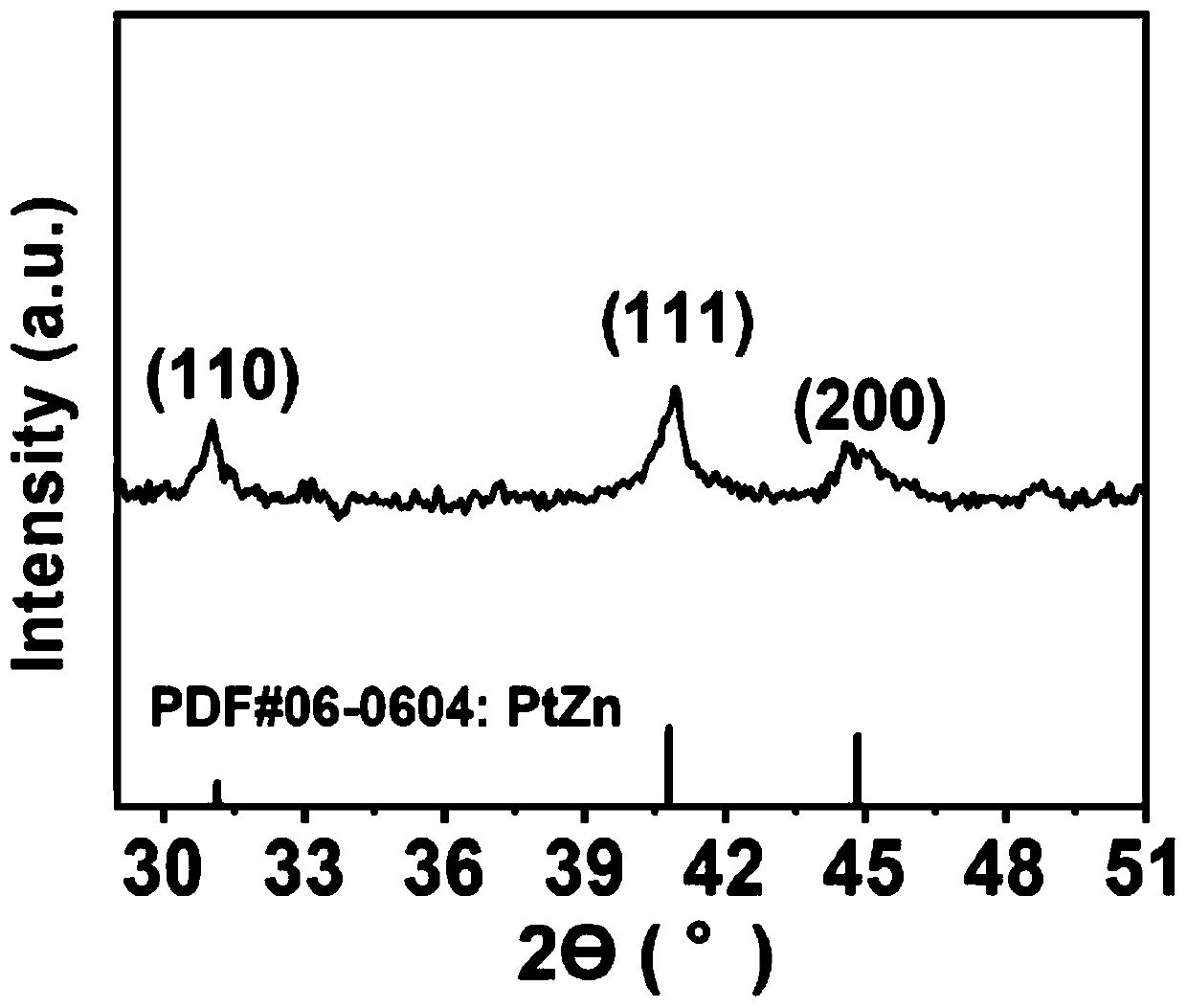

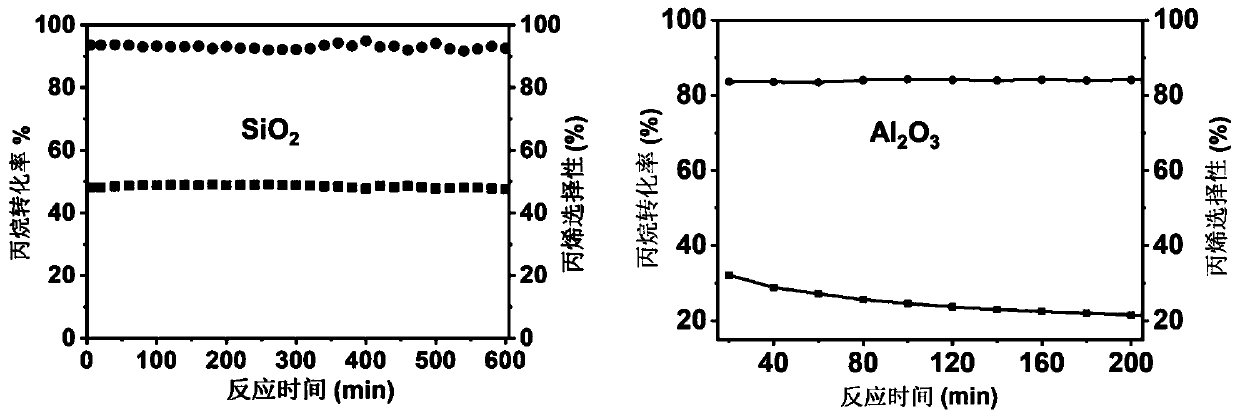

[0040] (3) Reduce the solid obtained in (2) at 600°C for 1 h to obtain PtZn / SiO 2 (or PtZn / Al 2 o 3 ) catalyst, the catalyst is based on the mass of the carrier, the mass percentage of Pt is 0.1%, and the mass percentage of Zn is 0.17%;

[0041] (4) the prepared SiO 2 (or Al 2 o 3 ) the supported PtZn intermetallic catalyst tablet is 20-40 purpose granular catalyst;

[0042] (5) SiO after tableting 2 (or Al 2 o 3 ) loaded PtZn intermetallic granular catalyst into a fixed-bed reactor, feed nitrogen, and heat up to a pretreatment temperature of 600°C; feed hydrogen for pretreatment, and maintain it at 600°C for 1 hour; cool down to a reaction temperature of 550°C, Propane ma...

Embodiment 2

[0054] Prepare and react with embodiment 1 method, its difference is only in step (1) zinc nitrate (Zn(NO 3 ) 2 ·6H 2 The quality of O) is 0.026g; The obtained catalyst is based on the carrier quality, and the mass percentage of Zn is 0.06%.

Embodiment 3

[0056] Prepare and react with embodiment 1 method, its difference is only in step (1) zinc nitrate (Zn(NO 3 ) 2 ·6H 2 The quality of O) is 0.234g; The obtained catalyst is based on the carrier quality, and the mass percentage of Zn is 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mesh size | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com