Aluminum oxide loaded PtCu monatomic alloy catalyst and preparation method and application thereof

A technology of alumina-loaded and alloy catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of slow deactivation rate of catalytic dehydrogenation and the amount of precious metals Large and low precious metal content, etc., to achieve the effect of improving atom utilization, high specific surface area, and high dehydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 0.0021g mass parts of H 2 PtCl 6 and 0.3802g mass parts of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 0.5 mL deionized water;

[0033] (2) 1.0000g Al 2 o 3 Soak in the above solution, ultrasonic for 0.5h, dry at room temperature for 12h, and completely dry at 100°C;

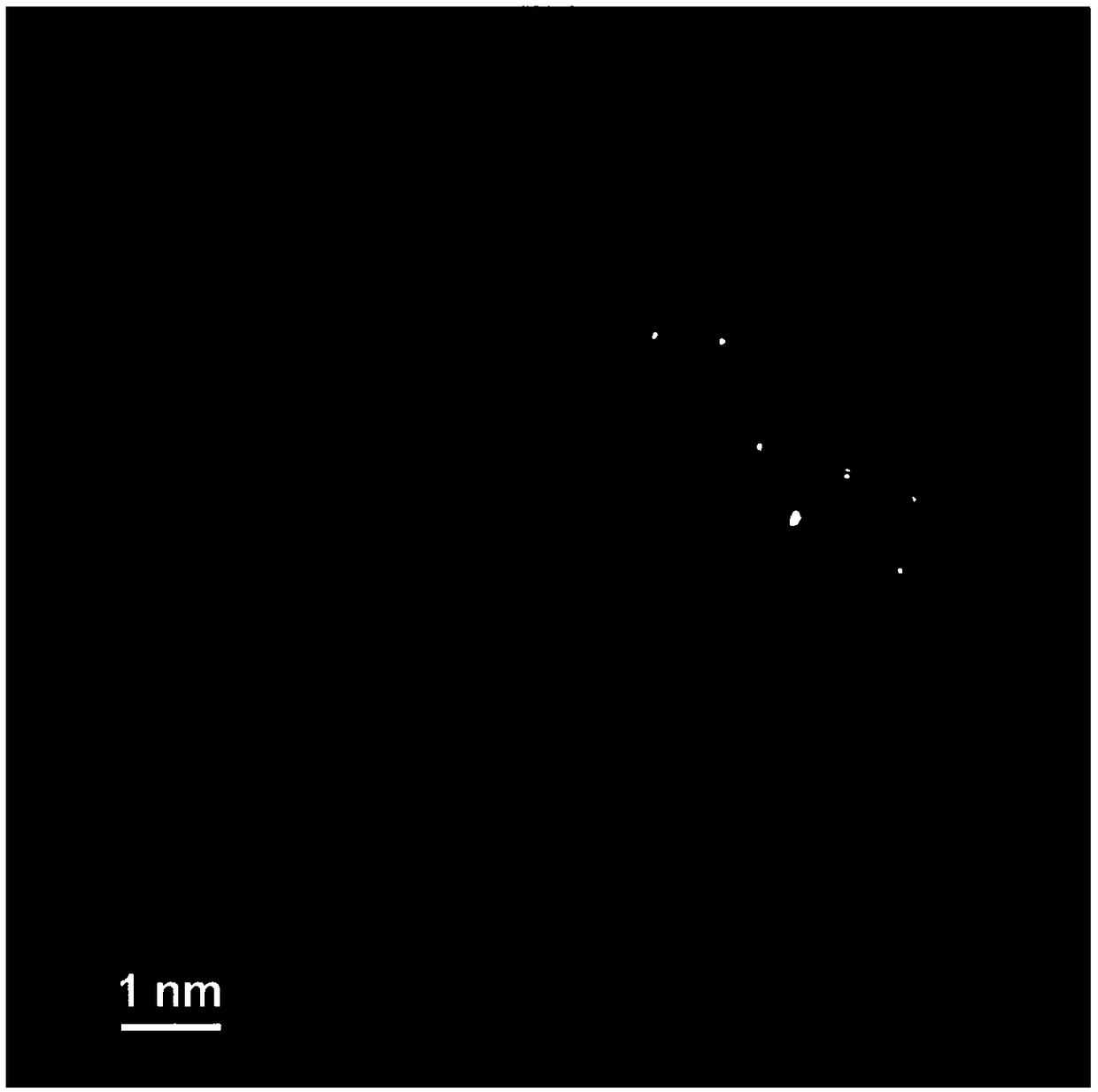

[0034] (3) Calcinate the solid obtained in (2) at 600°C for 2h, and then reduce at 600°C for 1h to obtain Pt-Cu / Al 2 o 3 Catalyst, the catalyst is based on the mass of the carrier, the mass percentage of Pt is 0.1%, and the mass percentage of Cu is 10%;

[0035] (4) The prepared Pt-Cu / Al 2 o 3 Catalyst pellets are 20-40 mesh granular catalysts;

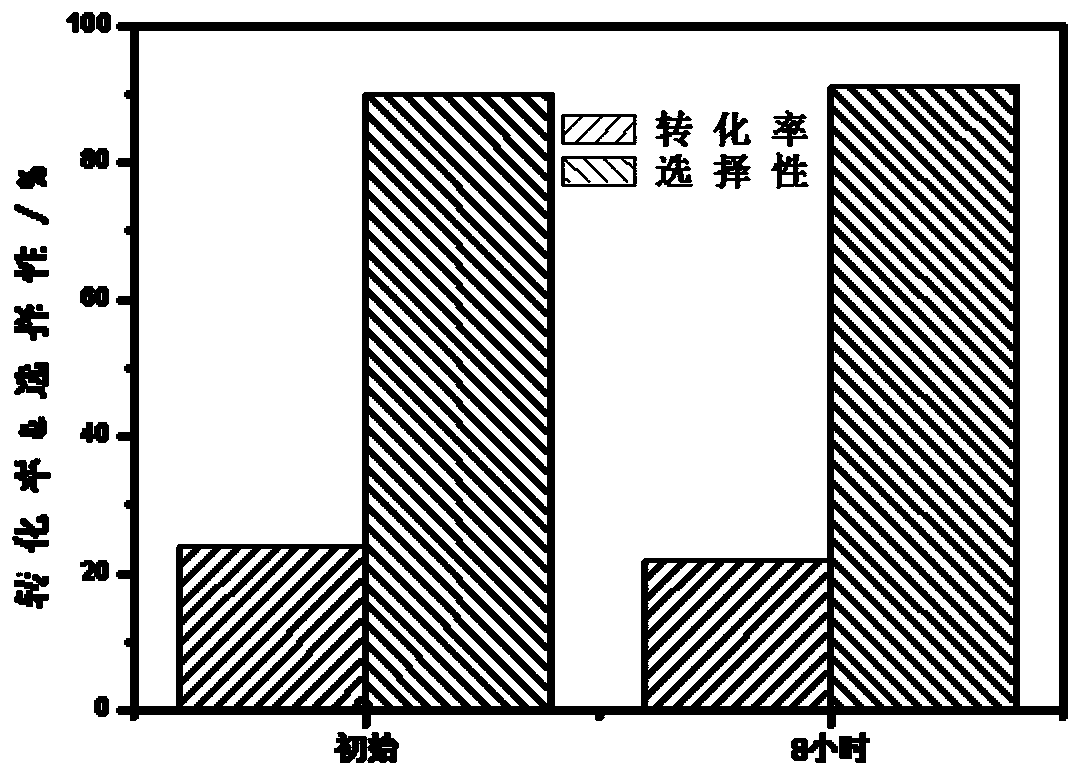

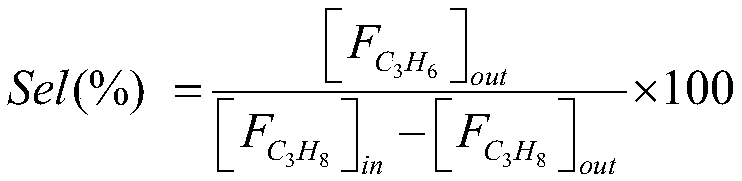

[0036] (5) Pt-Cu / Al after tableting 2 o 3 Put the granular catalyst into the fixed bed reactor, feed nitrogen, and raise the temperature to a pretreatment temperature of 600°C; feed hydrogen for pretreatment, and maintain it at 600°C for 1 hour; cool down to the reaction temperature of 550°C, and the mass space velocity of propane is 4 hours -1 Switch ...

Embodiment 2

[0048] Prepare and react with embodiment 1 method, its difference is only in step (1) copper nitrate (Cu(NO 3 ) 2 ·3H 2 The mass of O) is 0.1902g; The obtained catalyst is based on the carrier mass, and the mass percentage of Cu is 5%.

Embodiment 3

[0050] Prepare and react with embodiment 1 method, its difference is only in step (1) copper nitrate (Cu(NO 3 ) 2 ·3H 2 The mass of O) is 0.7603g; The obtained catalyst is based on the carrier mass, and the mass percentage of Cu is 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com