Steering devices for vehicles

A control device and vehicle technology, which is applied to the steering control, steering column, steering mechanism and other directions installed on the vehicle, can solve the problems of torque sensor detection accuracy deterioration, bearing life impact, etc., to reduce dumping, save space, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

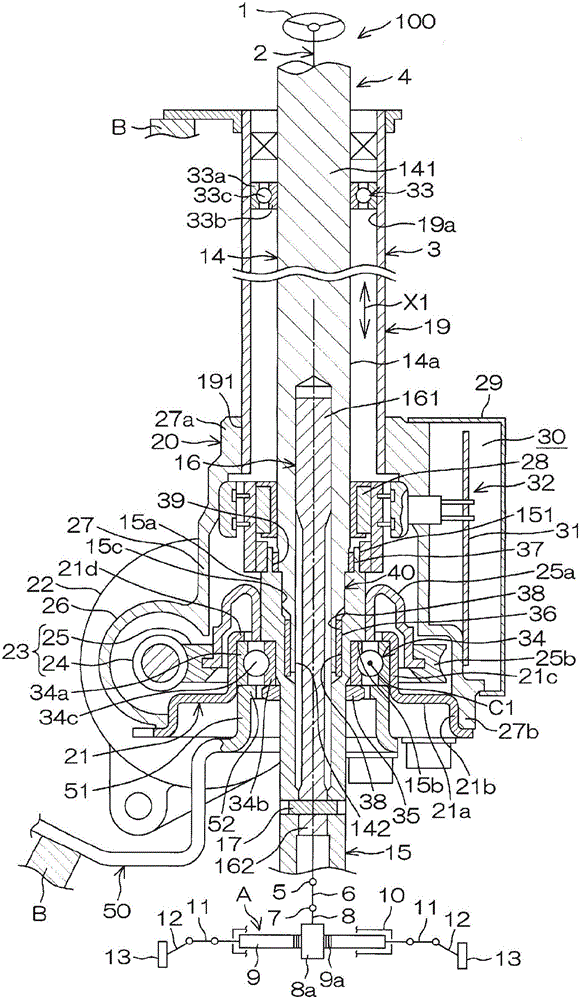

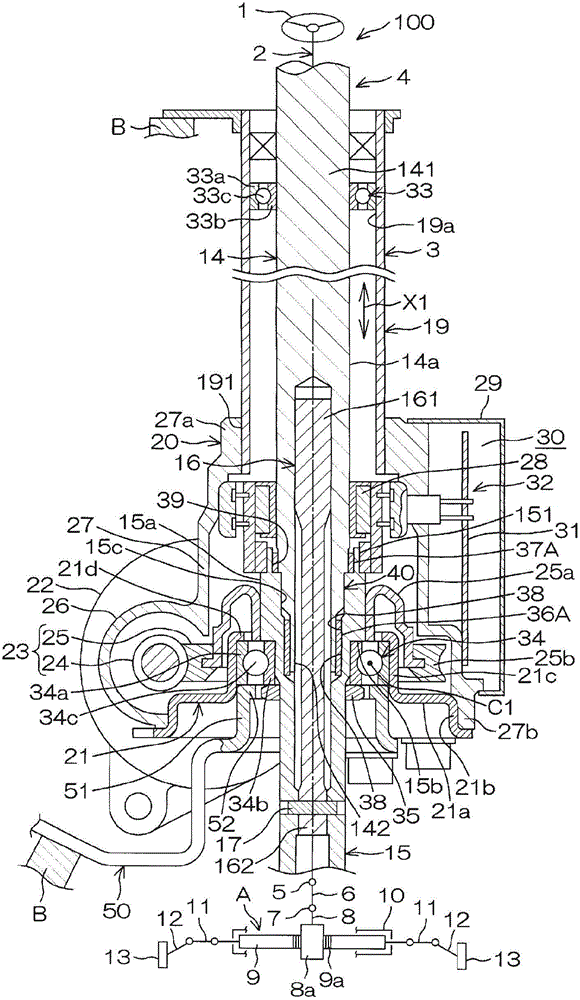

[0020] The preferred embodiments of the present invention will be described with reference to the drawings.

[0021] figure 1 It is a schematic cross-sectional view of an electric power steering system 100 as a vehicle steering system according to an embodiment of the present invention. Reference figure 1 The electric power steering device 100 includes a steering shaft 2 for transmitting the rotation of a steering wheel 1 as a steering member. The steering shaft 2 includes: a column shaft 4, which is rotatably supported by a steering column 3 as a support member fixed to the vehicle body B; an intermediate shaft 6, which is connected to the column shaft 4 via a universal joint 5; and a pinion gear The shaft 8 is connected to the intermediate shaft 6 via a universal joint 7.

[0022] In addition, the electric power steering device 100 includes a steering mechanism A constituted by a rack and pinion mechanism. The rack and pinion mechanism includes: the pinion shaft 8 described abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com