Car battery installation structure

A technology for mounting structures and automobile batteries, which is applied to superstructures, subassemblies of superstructures, vehicle components, etc., which can solve problems such as large input force and release of hooks, and achieve the effect of inhibiting fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

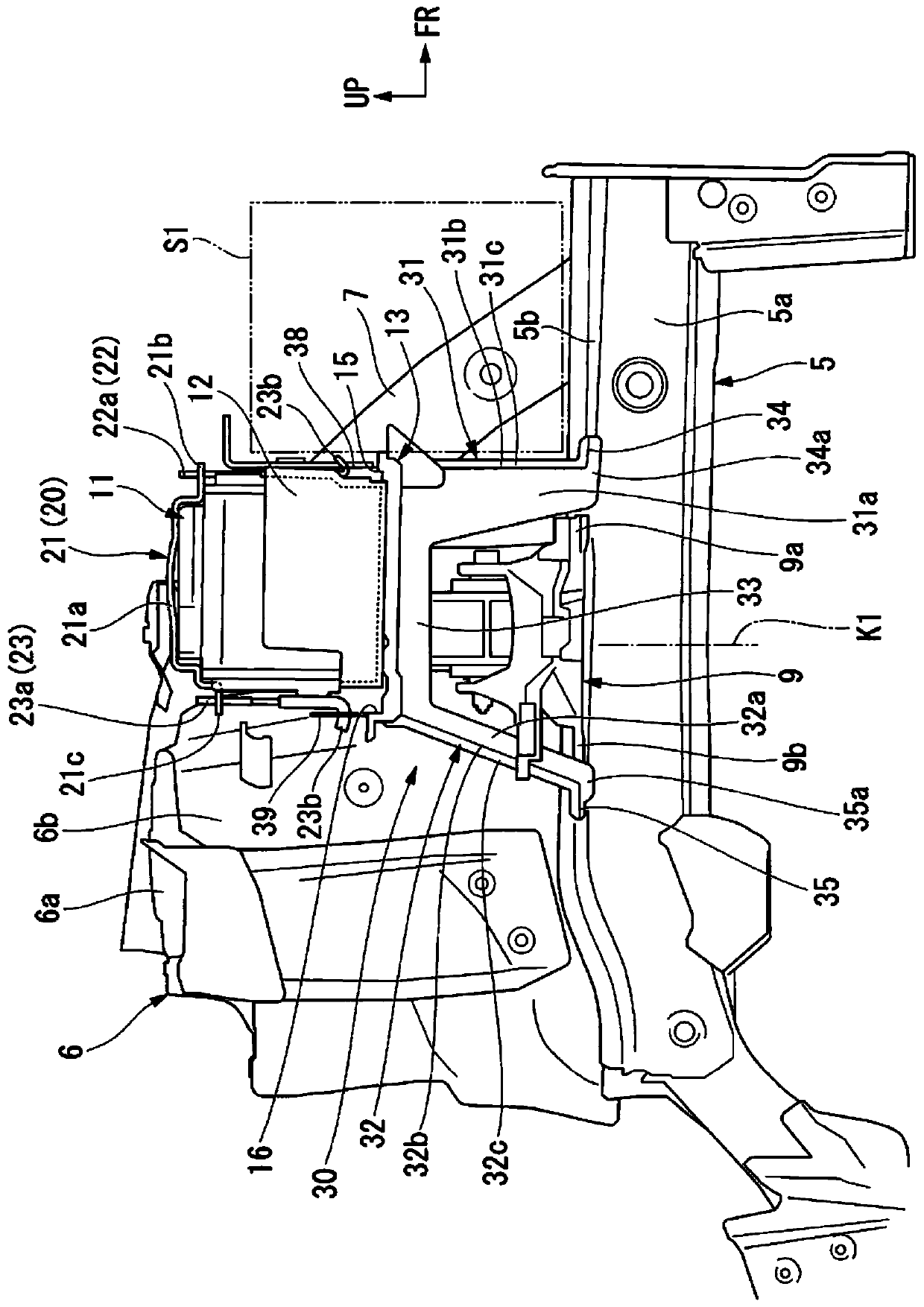

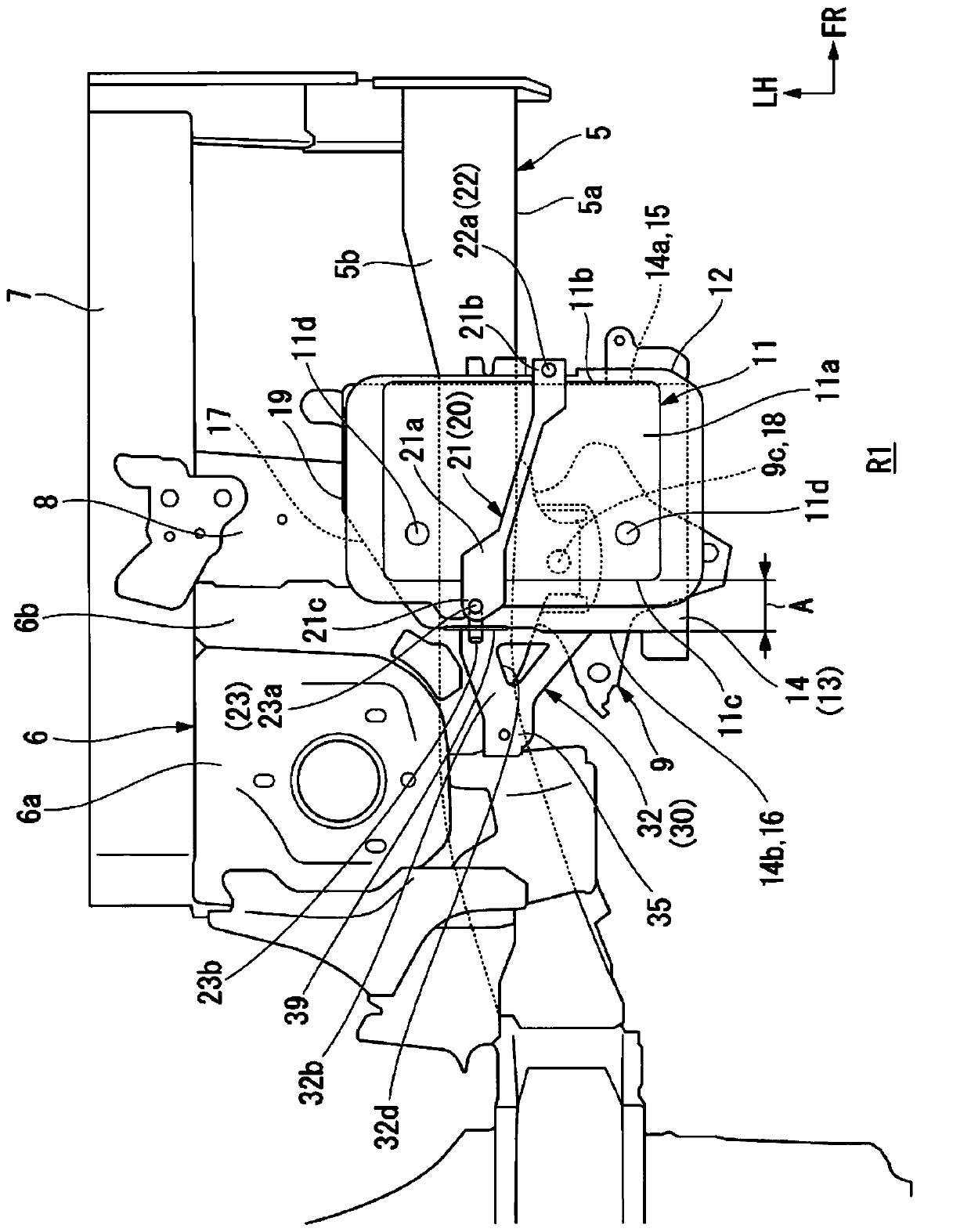

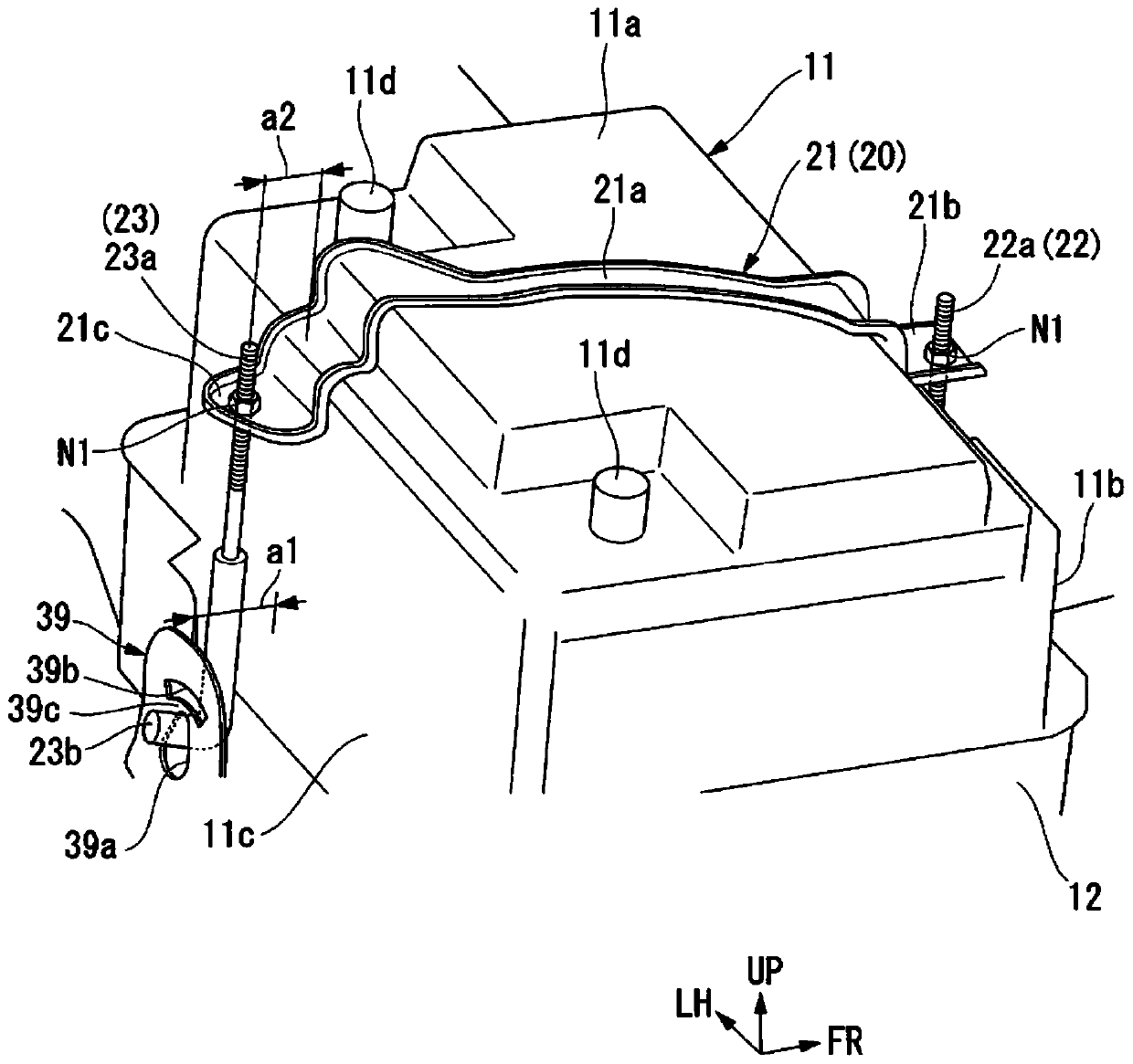

[0030] One embodiment of the present invention will be described below based on the drawings. In addition, directions such as front, rear, left, and right described below are the same as directions of a vehicle described below, unless otherwise specified. In addition, arrows FR indicating the front of the vehicle, arrows LH indicating the left of the vehicle, and arrows UP indicating the upward direction of the vehicle are shown at appropriate places in the drawings used in the following description.

[0031] Such as figure 1 , figure 2 As shown, at the front of the vehicle body of the automobile, on both sides of the vehicle width direction (left and right direction) of the engine room R1 in front of the compartment, there are provided with: a front side frame 5 extending along the front and rear directions of the vehicle; and a shock absorber housing 6 , which supports the upper end of a suspension damper (not shown) located above the front side frame 5 .

[0032] Upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com