pneumatic tire

A pneumatic tire, tire circumferential technology, applied in tire parts, tire tread/tread pattern, vehicle parts, etc., can solve problems such as performance degradation, cleat shedding, and deterioration of the surrounding environment of the road, and prevent studs from falling off. , the effect of suppressing dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

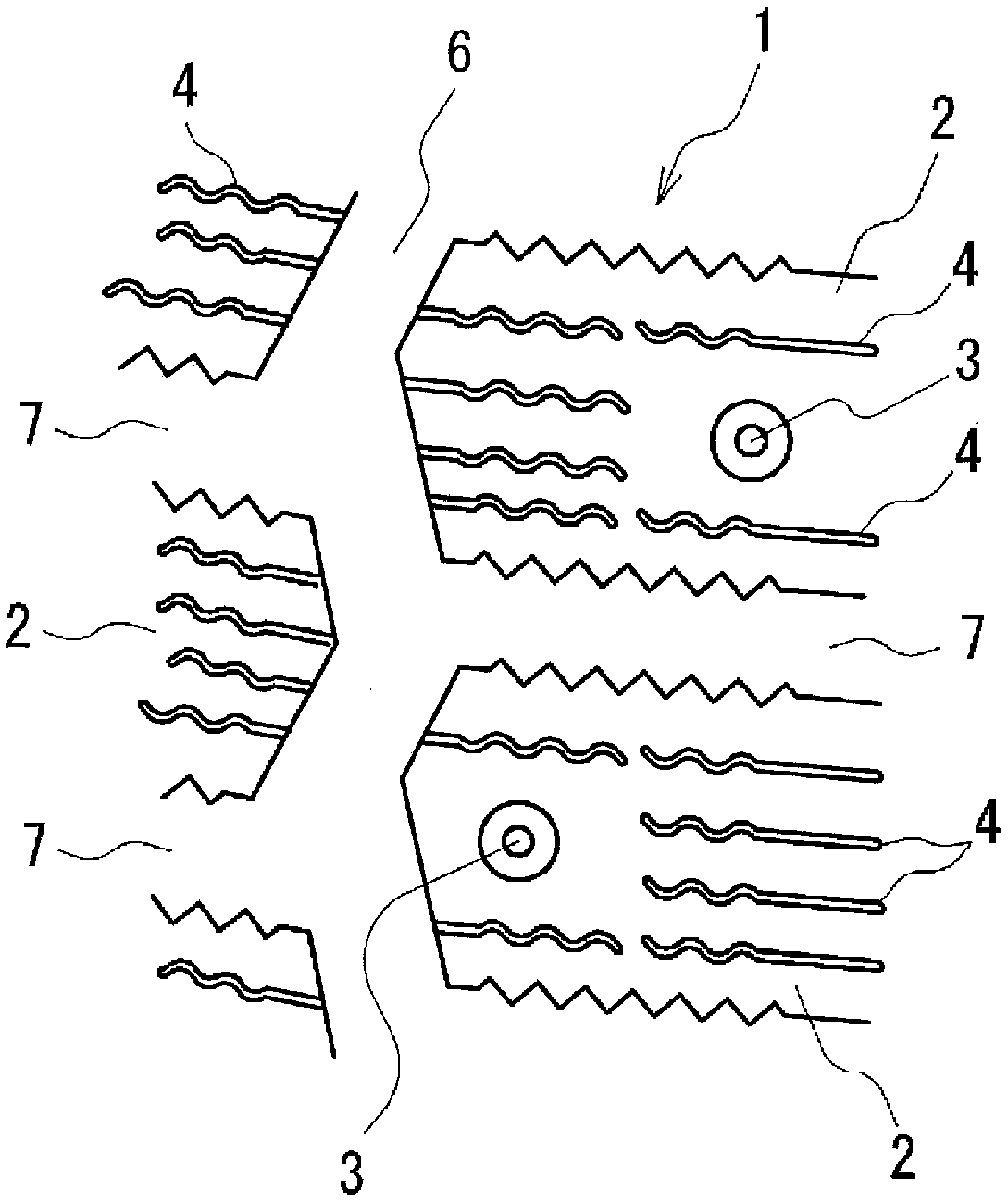

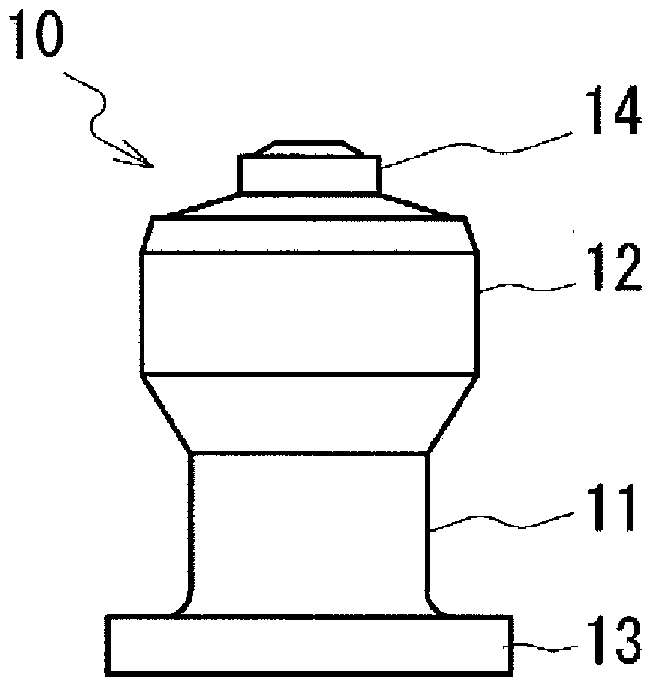

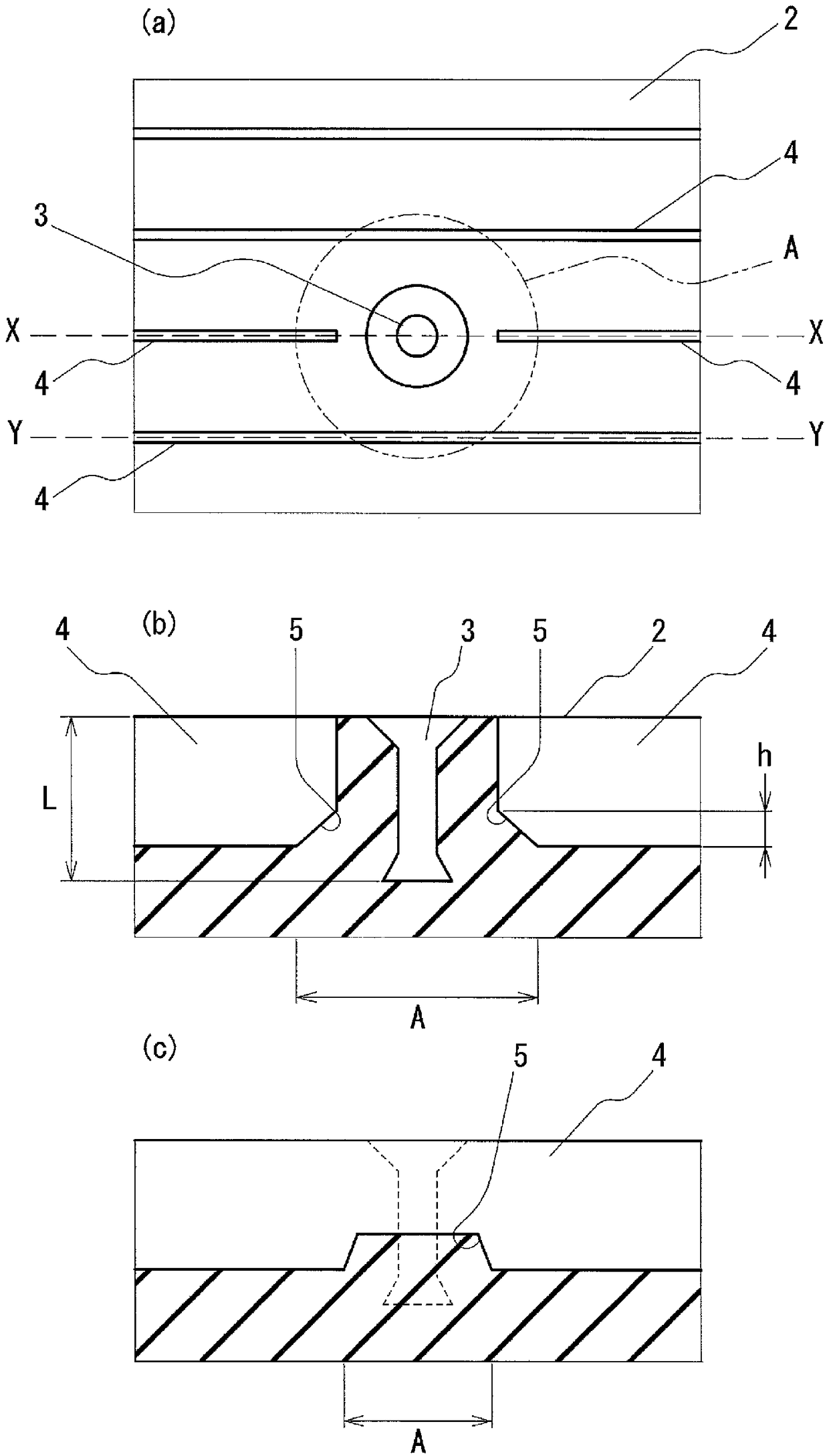

[0040] Seven types of pneumatic tires (tyre The size is 205 / 55R16; conventional examples, examples 1 to 6) were subjected to vulcanization molding. Such as Figure 7 As shown in (a) and (b), in the pneumatic tire of the conventional example, the sipe 4 in the peripheral region of the stud hole 3 does not have a bottom raised portion. The pneumatic tires of Examples 1 to 6 have in common image 3 (a), (b), and (c) shown in the form of the raised bottom portion, but the size of each raised bottom portion is different as described in Table 1. In the table, the "arrangement ratio of raised bottom portion" is the percentage of the total length of the raised sipe in the peripheral area to the total length of the sipe located in the peripheral area, and the "maximum raised height h ” is expressed as a ratio relative to the distance L from the surface of the block to the bottom of the stud hole.

[0041] Studs were driven into the stud holes of the obtained pneumatic tire to manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com