Pneumatic tire

A technology of pneumatic tires and tires, which is applied to off-road vehicle tires, tire parts, tire treads/tread patterns, etc., which can solve the problems of easy decline in wear resistance and achieve the effect of maintaining wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

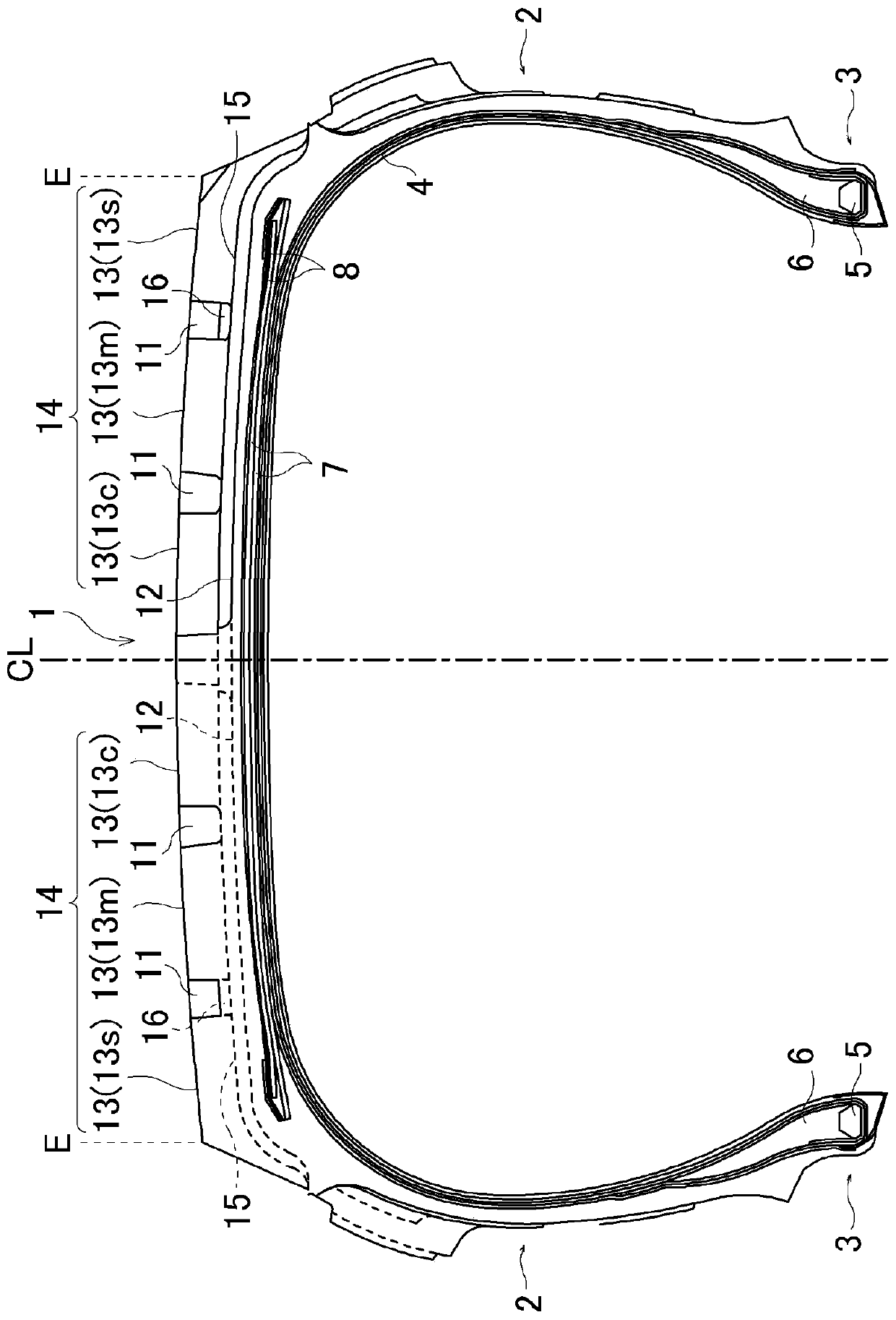

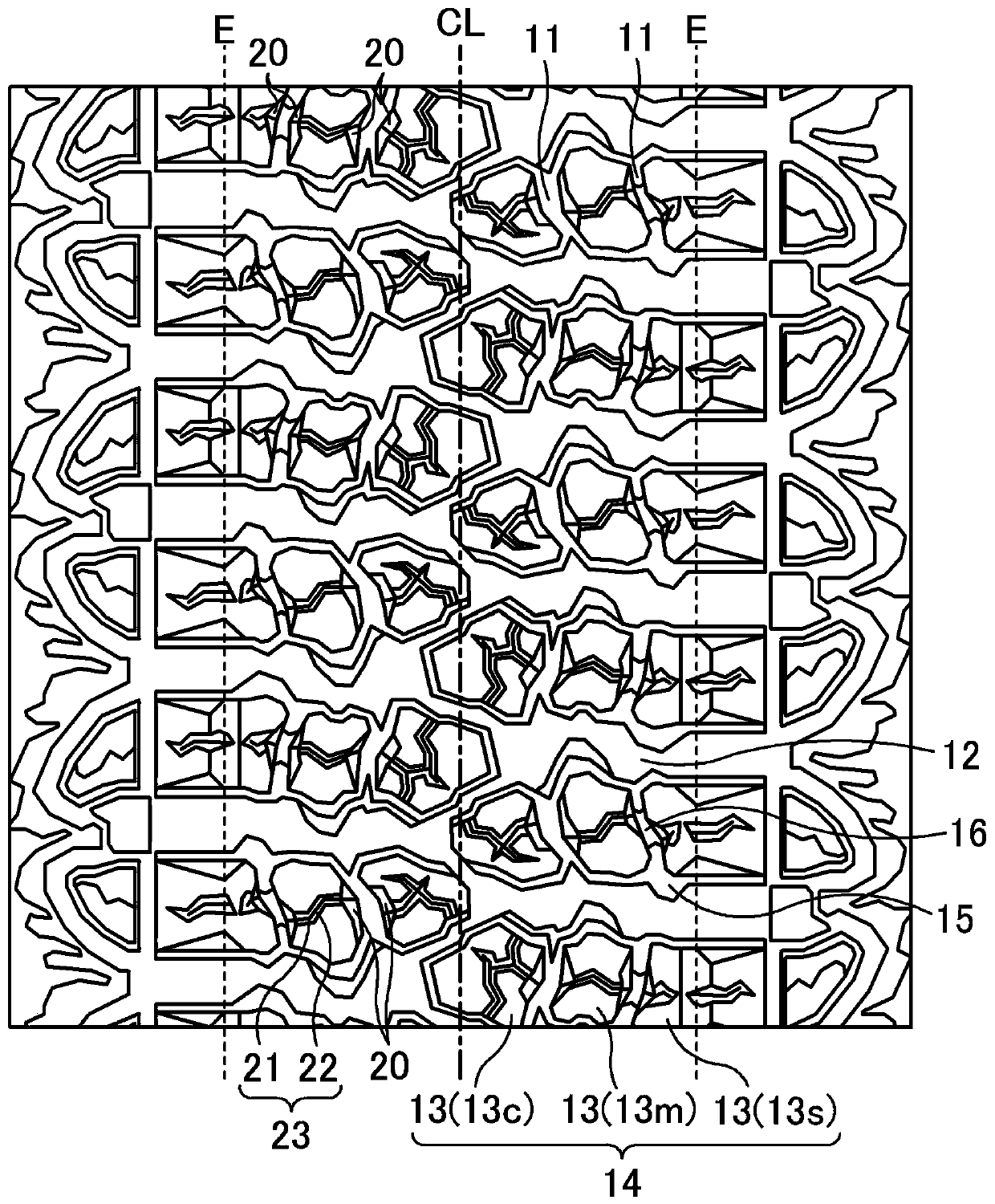

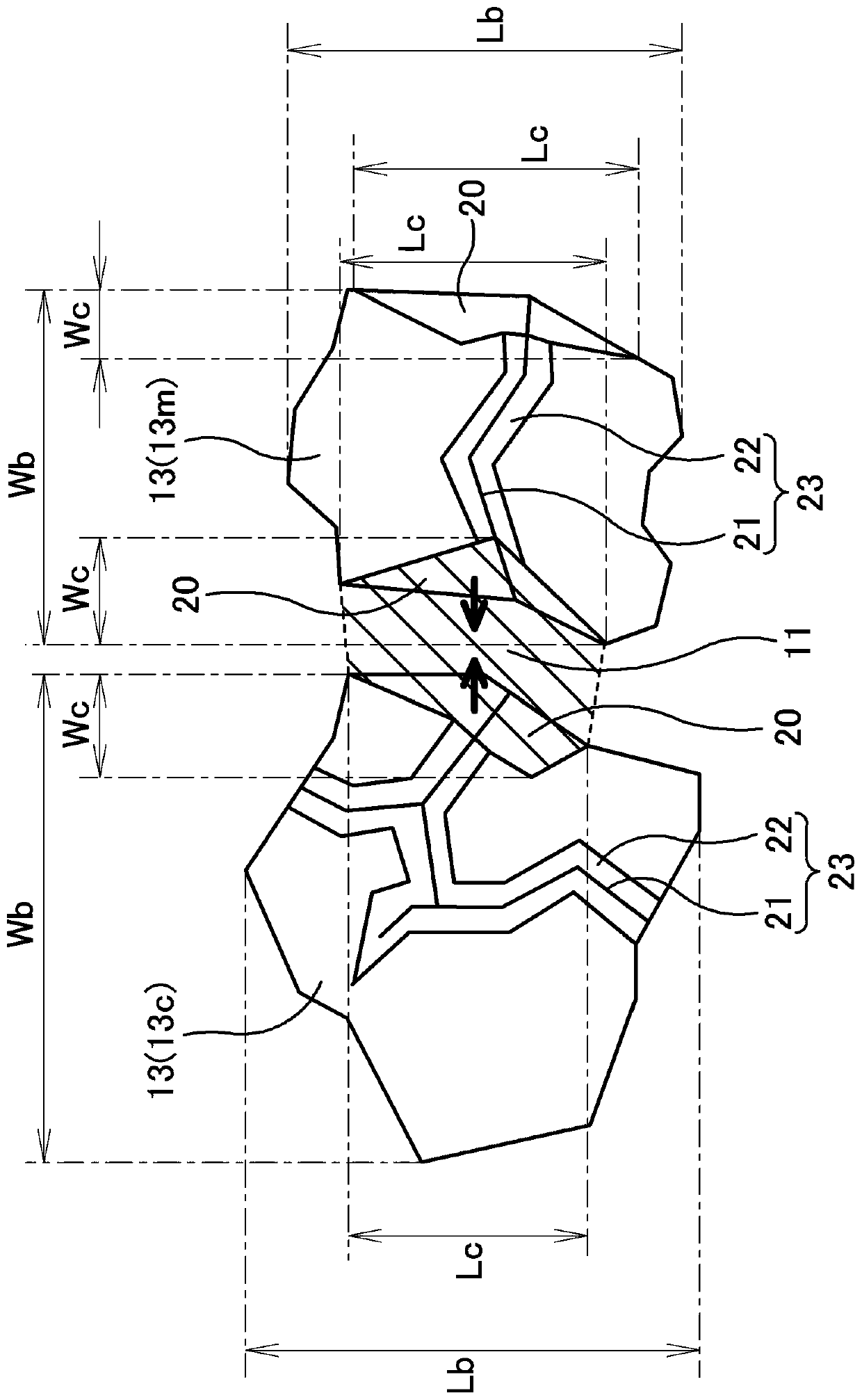

[0044] Made a tire size 35×12.50R17 and has figure 1 The basic structure illustrated and with figure 2 The tread pattern is based on the notch, and the presence or absence of the notch, the position of the notch, the shape of the notch, the type of elements other than the notch provided in each block, and the notch width Wc of the notch are relative to the tire width direction of the block. The ratio of the length Wb (Wc / Wb×100%), the ratio of the height H of the part with the largest notch depth from the groove bottom of the vertical groove to the maximum groove depth Dg of the vertical groove (H / Dg×100%), the tread surface of the block The ratio of the area of the notch to the projected area of the tread surface of the block, the ratio of the notch length Lc of the notch to the tire circumferential length Lb of the block (Lc / Lb×100), the amount of the bottom of the notch There were no 25 types of pneumatic tires of Conventional Example 1, Comparative Example 1, and Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com